Академический Документы

Профессиональный Документы

Культура Документы

Calculation For Tempreture Rise

Загружено:

Sridhar Reddy Gandra0 оценок0% нашли этот документ полезным (0 голосов)

52 просмотров7 страниц33

Оригинальное название

Calculation for Tempreture Rise

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ33

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

52 просмотров7 страницCalculation For Tempreture Rise

Загружено:

Sridhar Reddy Gandra33

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

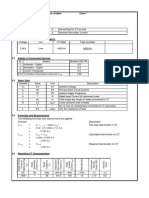

CALCULATIONS FOR TEMPERATURE RISE OF ALUMINIUM BUS BARS

Rating : [1508] Amps.

Wath Pare!

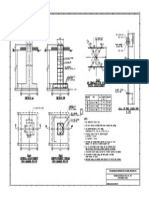

1 nsbar size selected : a 250° sq.m. /phase

Reting of Aluminium Bus Bar for@8” © ambit & 8S ©. operating Teasp.of conductor

‘Ab per KC. Ageawal hand Book sheet - 30/1050 B45 Jam

fs per KC. Agrawal ans Bool Sheet -90/1060, Note no. eursent fr E918 0370

8) erating factor for S0° C ambient é 85°C Operating temperature : ais

‘As pee H.C. Agrawal ancl Book Shiet - 28/1005

Ratingof Bus Bar after shove Derating SBT Jam.

1b) Derating factor for Proximity effect: oat

9) Uprating factor 100

44) erating due to Grade of busbar material (E-91E or DSOS-WP) Too

2) Derating dus to onctosure-

We hae wath | Heaghr

1) Cross Sectional Area of Busbar Chamber/Duct 30 [250] 200000 $4

St Ratio of C/S ares: - 100

aa Yi

Derating factor duc to enclonsre oy

cating of Selected size B97 amos

‘Therefore the c/s area of Busbar size selected is suitable for TS0K Amps.

|" *Dorating factor for lndoor, Woll ventilated enclosures as por Indal Data shoct:

<1 - os

DOCUMENT NO. : VCE -ABB-407-601, Rev.

4, CALCULATIONS FOR TEMPERATURE RISE OF ALUMINIUM BUS BARS

Rating: [2500] Amps.

Wath Pare!

1 char size selected: a 300, sq. mm-/phase

Reting of Aluminium Bus Bar for@8” © ambit & 8S ©. operating Teasp.of conductor

As per KC. Agrawal han! Bok Sheet - 30) 1050 660 Jam

As per KC. Agrawal hel Book Sheet - 20/1060, note no-t curren for E-9 0370

8) erating factor for S0° C ambient é 85°C Operating temperature : ais

‘As pee H.C. Agrawal ancl Book Shiet - 28/1005

Ratingof Bus Bar after shove Derating BREA

1b) Derating factor for Proximity effect: oat

©) Uprating factor 100

44) erating due to Grade of busbar material (E-91E or DSOS-WP) Too

2) Derating dus to onctosure-

We hae wath | Heaghr

1) Cross Sectional Area of Busbar Chamber/Duct Boo [ a0] 240000 54. mm

St Ratio of C/S ares: - 100

1050 aa Yi

Derating factor duc to enclonsre oy

cating of Selected size 359 amon

‘Therefore the c/s area of Busbar size selected is suitable for 250K Amps.

*Dorating factor for Indoor, Woll ventilated enclosures as por I

<1 - os

DOCUMENT NO. : VCE -ABB-407-602, Rev.1

CALCULATIONS FOR TEMPERATURE RISE OF ALUMINIUM BUS BARS

Rating: [400A] Amps.

wath | Heaht [Parael

DBosbar size selected : a oo 600 sq. mim. /phase

Reting of Aluminium Bus Bar for@8” © ambit & 8S ©. operating Teasp.of conductor

As per KC. Agrawal han! Bok Sheet - 30) 1050 TOES Jam

As per K.C. Agrawal ie! Book Sheet - 20 1050, note not curren for £918 3970

8) erating factor for S0° C ambient é 85°C Operating temperature : ais

‘As pee H.C. Agrawal ancl Book Shiet - 28/1005

Ratingof Bus Bar after shove Derating BOR Jam

1b) Derating factor for Proximity effect. 385

9) Uprating factor 100

44) erating due to Grade of busbar material (E-91E or DSOS-WP) 100

2) Derating dus to onctosure-

We hae wath | Heaghr

1) Cross Sectional Area of Busbar Chamber/Duct Boo [ a0] 240000 54. mm

St Ratio of C/S ares: - 100

a8}

Derating factor due to enclonsre 370

cating of Selected size FF Jamon

‘Therefore the c/s area of Busbar size selected is suitable for (earl) 700K Amps.

*Dorating factor for Indoor, Woll ventilated enclosures as por I

<1 - os

DOCUMENT NO. : VCE -ABB-407-603, Rev.-1

4, CALCULATIONS FOR TEMPERATURE RISE OF ALUMINIUM BUS BARS

Rating: [630A] Amps.

Wath Pare!

1 char size selected: a 1750 sq, mm./phase

Reting of Aluminium Bus Bar for@8” © ambit & 8S ©. operating Teasp.of conductor

As per KC. Agrawal han! Bok Sheet - 30) 1050 THE amp

As per KC. Agrawal hel Book Sheet - 20/1060, note no-t curren for E-9 0370

8) erating factor for S0° C ambient é 85°C Operating temperature : ais

‘As pee H.C. Agrawal ancl Book Shiet - 28/1005

Ratingof Bus Bar after shove Derating 927 Jam.

1b) Derating factor for Proximity effect. 385

©) Uprating factor 100

44) erating due to Grade of busbar material (E-91E or DSOS-WP) 100

2) Derating dus to onctosure-

We hae wath | Heaghr

1) Cross Sectional Area of Busbar Chamber/Duct Boo [ a0] 240000 54. mm

St Ratio of C/S ares: - 100

ao Yi

Derating factor due to enclonsre oy

cating of Selected size SEO asnon

‘Therefore the c/s area of Busbar size selected is suitable for (earl) 20K Amps.

*Dorating factor for Indoor, Woll vntilated

lomures a8 por I

<1 - os

DOCUMENT NO. : VCE -ABB-407-604, Rev.

CALCULATION FOR MINIMUM CROSS - SECTIONAL AREA OF CONDUCTORS WITH REGARDS

tO THERMAL STRESS DUE TO SHORT CIRCUIT CURRENT (10KA FOR 1 SEC)

las per 15C439/18-8623 :

Ve

Sp

Where +

Sp Cross-sectional area, in square millimeters

1 Value (r.m.s,) of a.c, fault current for a fault of negligible impedance which can flow

through the conductor in Amps.

t Operating time of the disconnecting device, in seconds

kk Factor dependent on the material of the protective conductor, the insulation and other

parts and the initial and the final temperature. Copy of IS 8623 attached.

IMinimum cross section area required for Short Circuit fault current is as under :

Fault Current 10000 Amps.

Duration T__ sec.

substituting value for Aluminium: — |“TOOO7 a [aes7]s0. mm,

———s

substituting value for Coppers =. / TOG 7 [Je mm,

143

which is less than the size selected for this case. Hence selection is safe

Factor k for Al. = 95 as per 1S:8623

Factor k for Cu. = 143 as per 1S:8623,

CALCULATION FOR MINIMUM CROSS - SECTIONAL AREA OF CONDUCTORS WITH REGARDS

ITO THERMAL STRESS DUE TO SHORT CIRCUIT CURRENT (25KA FOR 1 SEC)

las per 180439/18-8623

Ve

Sp

Where +

Sp Cross-sectional area, in square millimeters

1 Value (r.m.s,) of a.c, fault current for a fault of negligible impedance which can flow

through the conductor in Amps.

t Operating time of the disconnecting device, in seconds

kk Factor dependent on the material of the protective conductor, the insulation and other

parts and the initial and the final temperature. Copy of IS 8623 attached.

IMinimum cross section area required for Short Circuit fault current is as undex

Fault Current 25000 Amps.

Duration T__ sec.

substituting value for Aluminium: — <_/ZS0007 sq [[28J50. mm,

———s

substituting value for Copper: mm.

which is less than the size selected for this case. Hence selection is safe

Factor k for Al. = 95 as per 1S:8623

Factor k for Cu. = 143 as per 1S:8623,

CALCULATION FOR MINIMUM CROSS - SECTIONAL AREA OF CONDUCTORS WITH REGARDS

TO THERMAL STRESS DUE TO SHORT CIRCUIT CURRENT (50KA FOR 1 SEC)

las per 180439/18-8623

Ve

Sp

Where +

Sp Cross-sectional area, in square millimeters

1 Value (r.m.s,) of a.c, fault current for a fault of negligible impedance which can flow

through the conductor in Amps.

t Operating time of the disconnecting device, in seconds

kk Factor dependent on the material of the protective conductor, the insulation and other

parts and the initial and the final temperature. Copy of IS 8623 attached.

IMinimum cross section area required for Short Circuit fault current is as undex

Fault Current 50000 JAmps.

Duration T__ sec.

substituting value for Aluminium: — “500007 [[26J50. mm,

———s

substituting value for Copper: / SOOO aT [507]. am,

143

which is less than the size selected for this case. Hence selection is safe

Factor k for Al. = 95 as per 1S:8623

Factor k for Cu. = 143 as per 1S:8623,

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Survey No.328-1BДокумент1 страницаSurvey No.328-1BSridhar Reddy GandraОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 33KV IsolatorДокумент12 страниц33KV IsolatorSridhar Reddy Gandra0% (1)

- Process Flow Chart For The Solar1Документ1 страницаProcess Flow Chart For The Solar1Sridhar Reddy GandraОценок пока нет

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Документ1 страницаOne-Line Diagram - OLV1 (Short-Circuit Analysis)Sridhar Reddy GandraОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Документ1 страницаOne-Line Diagram - OLV1 (Short-Circuit Analysis)Sridhar Reddy GandraОценок пока нет

- Annexure III: S.No. ExclusionsДокумент1 страницаAnnexure III: S.No. ExclusionsSridhar Reddy GandraОценок пока нет

- Adopter Box Ultratech Sridhar 24-09-14Документ1 страницаAdopter Box Ultratech Sridhar 24-09-14Sridhar Reddy GandraОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 33kV CPL FoundationДокумент5 страниц33kV CPL FoundationSridhar Reddy GandraОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Annexure IV: S.No. AssumptionsДокумент1 страницаAnnexure IV: S.No. AssumptionsSridhar Reddy GandraОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Annexure II: S.No. Terminal PointsДокумент1 страницаAnnexure II: S.No. Terminal PointsSridhar Reddy GandraОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Specification For DCDBДокумент3 страницыSpecification For DCDBSridhar Reddy GandraОценок пока нет

- Transmission Corporation of Andra Pradesh Ltd. Foundation Details of 220 KV CVT (For Normal Soils)Документ1 страницаTransmission Corporation of Andra Pradesh Ltd. Foundation Details of 220 KV CVT (For Normal Soils)Sridhar Reddy GandraОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Cable NotationДокумент1 страницаCable NotationSridhar Reddy GandraОценок пока нет

- Lc-Tul L? - Hru: "' 8: I I: ,:::::,,: LL I' 1":ii,:.Документ1 страницаLc-Tul L? - Hru: "' 8: I I: ,:::::,,: LL I' 1":ii,:.Sridhar Reddy GandraОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Cover Page - HT SwitchgearДокумент1 страницаCover Page - HT SwitchgearSridhar Reddy GandraОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- 3.3kV Board Bus Coupler - CORE-1Документ1 страница3.3kV Board Bus Coupler - CORE-1Sridhar Reddy GandraОценок пока нет

- Voltag Regulation of Conductors: 3 Phase 60 Cyel - Ov - RH Ad Lin - Pow - Rf.etor of Gul - TlonДокумент1 страницаVoltag Regulation of Conductors: 3 Phase 60 Cyel - Ov - RH Ad Lin - Pow - Rf.etor of Gul - TlonSridhar Reddy GandraОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- RPCL - GMW - 3Документ1 страницаRPCL - GMW - 3Sridhar Reddy GandraОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)