Академический Документы

Профессиональный Документы

Культура Документы

A4 4303100037 PT 12 30 (Instrument Schedule PT Plant) - r1

Загружено:

AnujGargОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A4 4303100037 PT 12 30 (Instrument Schedule PT Plant) - r1

Загружено:

AnujGargАвторское право:

Доступные форматы

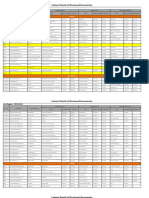

INSTRUMENT SCHEDULE (PT PLANT)

CONTRACT NO: 4303100037

SR.NO.

TAG. NO.

FLOW DIAGRAM NO: A1-4303100037-PT-01-01/02

DESCRIPTION

PROCESS

CONNECTION.

SET

POINT

SIGNAL FROM /

SIGNAL TO

REMARKS

0-8 KG/CM2

0-8 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

0-4 KG/CM2

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

20 NB FLANGED

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

150 MM DIAL, DIE CAST AL

0-2000 NTU

0-100 NTU

0-100 NTU

0-100 NTU

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

1/2" NPT (F)

NA

NA

NA

NA

FIELD - PLC

FIELD - PLC

FIELD - PLC

FIELD - PLC

MICROPROCESSOR BASED

MICROPROCESSOR BASED

MICROPROCESSOR BASED

MICROPROCESSOR BASED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

100 NB FLANGED

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

ADJ

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

FIELD - CP

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

2 POINT, TOP MOUNTED

QTY.

RANGE

PRESSURE GAUGE ( DIAPHRAGM SEAL TYPE )

1

PI 001

DISCHARGE OF SLUDGE DISPOSAL PUMP P1 A

2

PI 002

DISCHARGE OF SLUDGE DISPOSAL PUMP P1 B

3

PI 003

DISCH OF ALUM SOLN PREP PUMP DP1 A

4

PI 004

DISCH OF ALUM SOLN PREP PUMP DP1 B

5

PI 005

DISCH OF ALUM SOLN PREP PUMP DP1 C

6

PI 006

DISCH OF ALUM SOLN PREP PUMP DP1 D

7

PI 007

DISCH OF LIME SOLN SLAKING PUMP DP2 A

8

PI 008

DISCH OF LIME SOLN SLAKING PUMP DP2 B

9

PI 009

DISCH OF LIME RECIR CUM DOSING PUMP DP3 A

10

PI 010

DISCH OF LIME RECIR CUM DOSING PUMP DP3 B

11

PI 011

DISCH OF POLYELECTROLYTE DOSING PUMP DP4 A

12

PI 012

DISCH OF POLYELECTROLYTE DOSING PUMP DP4 B

13

PI 013

DISCH OF POLYELECTROLYTE DOSING PUMP DP4 C

14

PI 014

DISCH OF POLYELECTROLYTE DOSING PUMP DP4 D

1

1

1

1

1

1

1

1

1

1

1

1

1

1

TURBIDITY ANALYSER (4 WIRE TYPE)

1

AIT-001(TURB)

INLET OF STILLING CHAMBER

2

AIT-002 (TURB)

OUTLET OF HRSCC A

3

AIT-003 (TURB)

OUTLET OF HRSCC B

4

AIT-004 (TURB)

OUTLET OF HRSCC C

1

1

1

1

LEVEL SWITCH (TOP MOUNTED FLOAT OPERATED)

1

LS 001

IN SLUDGE SUMP 1

2

LS 002

IN SLUDGE SUMP 2

3

LS 003

IN OVERHEAD CLARIFIED WATER TANK

4

LS 004

IN ALUM SOLN PREPARATION TANK DT1 A

5

LS 005

IN ALUM SOLN PREPARATION TANK DT1 B

6

LS 006

IN ALUM SOLN PREPARATION TANK DT1 C

7

LS 007

IN LIME SOLN SLAKING TANK DT2 A

8

LS 008

IN LIME SOLN SLAKING TANK DT2 B

9

LS 009

IN LIME SOLN SLAKING TANK DT2 C

10

LS 010

IN LIME SOLN PREPARATION TANK DT3 A

11

LS 011

IN LIME SOLN PREPARATION TANK DT3 B

12

LS 012

IN LIME SOLN PREPARATION TANK DT3 C

13

LS 013

IN POLYELECTROLYTE DOSING TANK DT4 A

14

LS 014

IN POLYELECTROLYTE DOSING TANK DT4 B

1

1

1

1

1

1

1

1

1

1

1

1

1

1

MAKE

MODEL

NO.

ION EXCHANGE ( INDIA) LIMITED

DOCUMENT NO : A4-4303100037-PT-12-29

CLIENTS DOC NO :

INSTRUMENT SCHEDULE (PT PLANT)

CONTRACT NO: 4303100037

SR.NO.

TAG. NO.

FLOW DIAGRAM NO: A1-4303100037-PT-01-01/02

DESCRIPTION

QTY.

RANGE

MAKE

SHEET

MODEL

NO.

: 1 OF 2

PROCESS

CONNECTION.

SET

POINT

SIGNAL FROM /

SIGNAL TO

REMARKS

INSTRUMENT SCHEDULE (PT PLANT)

CONTRACT NO: 4303100037

SR.NO.

TAG. NO.

FLOW DIAGRAM NO: A1-4303100037-PT-01-01/02

DESCRIPTION

QTY.

RANGE

MAKE

MODEL

NO.

PROCESS

CONNECTION.

SET

POINT

SIGNAL FROM /

SIGNAL TO

REMARKS

FLOAT & BOARD TYPE LEVEL INDICATOR

1

LIFB 001

IN OVERHEAD CLARIFIED WATER TANK

2

LIFB 002

IN ALUM SOLN PREPARATION TANK DT1 A

3

LIFB 003

IN ALUM SOLN PREPARATION TANK DT1 B

4

LIFB 004

IN ALUM SOLN PREPARATION TANK DT1 C

5

LIFB 005

IN LIME SOLN SLAKING TANK DT2 A

6

LIFB 006

IN LIME SOLN SLAKING TANK DT2 B

7

LIFB 007

IN LIME SOLN SLAKING TANK DT2 C

8

LIFB 008

IN LIME SOLN PREPARATION TANK DT3 A

9

LIFB 009

IN LIME SOLN PREPARATION TANK DT3 B

10

LIFB 010

IN LIME SOLN PREPARATION TANK DT3 C

11

LIFB 011

IN POLYELECTROLYTE DOSING TANK DT4 A

12

LIFB 012

IN POLYELECTROLYTE DOSING TANK DT4 B

1

1

1

1

1

1

1

1

1

1

1

1

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

40 NB FLANGED

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LEVEL INDICATING TRANSMITTER (ULTRASONIC TYPE)

1

LT 001

IN CLARIFIED WATER RESERVOIR 1

2

LT 002

IN CLARIFIED WATER RESERVOIR 2

1

1

80 NB FLANGE

80 NB FLANGE

NA

NA

FIELD - CP

FIELD - CP

2 WIRE LOOP POWERED

2 WIRE LOOP POWERED

LEVEL GAUGE (REFLEX TYPE)

1

LI 001

2

LI 002

3

LI 003

4

LI 004

1

1

1

1

32 NB FLANGE

32 NB FLANGE

32 NB FLANGE

32 NB FLANGE

NA

NA

NA

NA

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

LOCAL INDICATION

REFLEX TYPE GAUGE

REFLEX TYPE GAUGE

REFLEX TYPE GAUGE

REFLEX TYPE GAUGE

FLANGED

FLANGED

FLANGED

NA

NA

NA

FIELD - CP

FIELD - CP

FIELD - CP

ULTRASONIC, 2 WIRE TYPE

ULTRASONIC, 2 WIRE TYPE

ULTRASONIC, 2 WIRE TYPE

IN POLYELECTROLYTE DOSING TANK DT4 A

IN POLYELECTROLYTE DOSING TANK DT4 A

IN POLYELECTROLYTE DOSING TANK DT4 B

IN POLYELECTROLYTE DOSING TANK DT4 B

OPEN CHANNEL FLOW METER (ULTRASONIC TYPE)

1

FT 001

FLOW METER IN PARSHALL FLUME PF A

2

FT 002

FLOW METER IN PARSHALL FLUME PF B

3

FT 003

FLOW METER IN PARSHALL FLUME PF C

1

1

1

0-2500 M3/HR

0-2500 M3/HR

0-2500 M3/HR

INSTRUMENT SCHEDULE (PT PLANT)

CONTRACT NO: 4303100037

SR.NO.

TAG. NO.

FLOW DIAGRAM NO: A1-4303100037-PT-01-01/02

DESCRIPTION

QTY.

RANGE

MAKE

MODEL

NO.

PROCESS

CONNECTION.

SET

POINT

ION EXCHANGE ( INDIA) LIMITED

DOCUMENT NO : A4-4303100037-PT-12-29

CLIENTS DOC NO :

SHEET

: 2 OF 2

SIGNAL FROM /

SIGNAL TO

REMARKS

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Starbucks Delivering Customer Service Case Solution PDFДокумент2 страницыStarbucks Delivering Customer Service Case Solution PDFRavia SharmaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 08.precommissioning Checklist GeneralДокумент19 страниц08.precommissioning Checklist GeneralAnujGarg100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- NEBOSH IGC IG1 Course NotesДокумент165 страницNEBOSH IGC IG1 Course NotesShagufta Mallick100% (13)

- Share Purchase Agreement Short FormДокумент7 страницShare Purchase Agreement Short FormGerald HansОценок пока нет

- Commissioning Report For RectifierДокумент29 страницCommissioning Report For RectifierAnujGarg100% (1)

- Contract of EmploymentДокумент5 страницContract of EmploymentFarisОценок пока нет

- Measuring Food Safety Culture in Food Manufacturing-59-173!50!115Документ66 страницMeasuring Food Safety Culture in Food Manufacturing-59-173!50!115ômąŕ ĕżžãőůįОценок пока нет

- 10.storage, Civil& Erection Checklist-GeneralДокумент14 страниц10.storage, Civil& Erection Checklist-GeneralAnujGargОценок пока нет

- Lighting Fixture DETAILED REPORTДокумент47 страницLighting Fixture DETAILED REPORTAnujGargОценок пока нет

- Rectifier O and M Manual - Nuberg - FluoderДокумент59 страницRectifier O and M Manual - Nuberg - FluoderAnujGargОценок пока нет

- Control Valves Basics - Sizing & SelectionДокумент64 страницыControl Valves Basics - Sizing & SelectionKajer quemar100% (1)

- Chlorine-Alkali ElectrolysisДокумент16 страницChlorine-Alkali ElectrolysisAnujGargОценок пока нет

- Bulk Application Form - Industrial CustomersДокумент7 страницBulk Application Form - Industrial CustomersAnujGargОценок пока нет

- or 00 Fat f21 020 Electrical Safety ProcedureДокумент10 страницor 00 Fat f21 020 Electrical Safety ProcedureAnujGargОценок пока нет

- Fire Alarm and Detection SystemsДокумент9 страницFire Alarm and Detection SystemsPeanut d. DestroyerОценок пока нет

- S.ST Assessment Portion For Grade 3Документ1 страницаS.ST Assessment Portion For Grade 3AnujGargОценок пока нет

- Urdu Power Point Presentation - Class 3 - (APRIL 2015)Документ25 страницUrdu Power Point Presentation - Class 3 - (APRIL 2015)AnujGargОценок пока нет

- 03 Specs For Electrical Works - 6B and 6CДокумент60 страниц03 Specs For Electrical Works - 6B and 6CsasikalaОценок пока нет

- Soft Starter in Industrial ApplicationsДокумент10 страницSoft Starter in Industrial ApplicationsAnujGargОценок пока нет

- Fire Alarm and Detection SystemsДокумент9 страницFire Alarm and Detection SystemsPeanut d. DestroyerОценок пока нет

- 00.micro Schedule GenaralДокумент11 страниц00.micro Schedule GenaralAnujGargОценок пока нет

- Installation, Operation & Maintenance Manual InstrumentationДокумент1 страницаInstallation, Operation & Maintenance Manual InstrumentationAnujGargОценок пока нет

- Minutes of Meeting Held Between M/s. Sigma Overseas and M/s. Nuberg Engineering PVT LTDДокумент2 страницыMinutes of Meeting Held Between M/s. Sigma Overseas and M/s. Nuberg Engineering PVT LTDAnujGargОценок пока нет

- 01 LTC CardДокумент14 страниц01 LTC CardAnujGargОценок пока нет

- Minutes of Meeting Held Between M/s. Sigma Overseas and M/s. Nuberg Engineering PVT LTDДокумент2 страницыMinutes of Meeting Held Between M/s. Sigma Overseas and M/s. Nuberg Engineering PVT LTDAnujGargОценок пока нет

- Drive Current List For Whole Plant at 8Документ1 страницаDrive Current List For Whole Plant at 8AnujGargОценок пока нет

- A4 4303100037 Powt 12 03 (PD Potable Feed Pumps) r1Документ1 страницаA4 4303100037 Powt 12 03 (PD Potable Feed Pumps) r1AnujGargОценок пока нет

- Letter Head NbelДокумент2 страницыLetter Head NbelAnujGargОценок пока нет

- Available Electrical Spares at SiteДокумент7 страницAvailable Electrical Spares at SiteAnujGargОценок пока нет

- Extg. SCH T3 DLH AirportДокумент9 страницExtg. SCH T3 DLH AirportAnujGargОценок пока нет

- Installation & Operational Manual IndeX-8710Документ3 страницыInstallation & Operational Manual IndeX-8710AnujGargОценок пока нет

- Weight Calculation For 200 NB, 150, 100nb PipeДокумент2 страницыWeight Calculation For 200 NB, 150, 100nb PipeAnujGargОценок пока нет

- 8.8 Pump Head Available (In Bar)Документ4 страницы8.8 Pump Head Available (In Bar)AnujGargОценок пока нет

- Area For Gas SuppressionДокумент3 страницыArea For Gas SuppressionAnujGargОценок пока нет

- A4 4303100037 WTP 12 01 (Thickness Calc Pressure Vessels) r5Документ6 страницA4 4303100037 WTP 12 01 (Thickness Calc Pressure Vessels) r5AnujGargОценок пока нет

- Yashu Internship Report 21Документ45 страницYashu Internship Report 21Lakshmi dayanand DayaОценок пока нет

- Difference Between Distinct and Group byДокумент1 страницаDifference Between Distinct and Group byPavelStrelkovОценок пока нет

- Micro Link Information Technology Business College: Department of Software EngineeringДокумент34 страницыMicro Link Information Technology Business College: Department of Software Engineeringbeki4Оценок пока нет

- Dissertation Sample CommerceДокумент4 страницыDissertation Sample CommerceBuyPapersOnlineForCollegeCanada100% (1)

- Science, Technology and SocietyДокумент2 страницыScience, Technology and SocietyHamieWave TVОценок пока нет

- 1LA7070-4AB10-Z A11 Datasheet en PDFДокумент1 страница1LA7070-4AB10-Z A11 Datasheet en PDFKraponis TylnessОценок пока нет

- Chats: Dini-Ay TriciaДокумент1 страницаChats: Dini-Ay Triciaaiyana sopiaudaundoОценок пока нет

- Talent Neuron NewsletterДокумент2 страницыTalent Neuron NewsletterTalent NeuronОценок пока нет

- ChromatographyДокумент24 страницыChromatographysolehah misniОценок пока нет

- Company Grasim ProfileДокумент48 страницCompany Grasim ProfileNitu Saini100% (1)

- Sop ECUДокумент5 страницSop ECUSumaira CheemaОценок пока нет

- RICS APC Candidate Guide-Aug 2015-WEB PDFДокумент24 страницыRICS APC Candidate Guide-Aug 2015-WEB PDFLahiru WijethungaОценок пока нет

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Документ183 страницыPsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatОценок пока нет

- Account Statement 060922 051222Документ51 страницаAccount Statement 060922 051222allison squad xXОценок пока нет

- Queen Elizabeth Olympic Park, Stratford City and Adjacent AreasДокумент48 страницQueen Elizabeth Olympic Park, Stratford City and Adjacent AreasRavi WoodsОценок пока нет

- Industrial Training HandbookДокумент26 страницIndustrial Training HandbookChung tong Betty wongОценок пока нет

- GM1. Intro To FunctionsДокумент5 страницGM1. Intro To FunctionsGabriel Benedict DacanayОценок пока нет

- Google Translate - Google SearchДокумент1 страницаGoogle Translate - Google SearchNicole Alex Bustamante CamposОценок пока нет

- International Journal On Cryptography and Information Security (IJCIS)Документ2 страницыInternational Journal On Cryptography and Information Security (IJCIS)ijcisjournalОценок пока нет

- Material Submission Form Register - STR (20210929)Документ1 страницаMaterial Submission Form Register - STR (20210929)HoWang LeeОценок пока нет

- Divisional Sec. Contact Details 2019-03-01-UpdateДокумент14 страницDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Оценок пока нет

- Valentine Carol Ann Duffy EssayДокумент8 страницValentine Carol Ann Duffy Essayafibybflnwowtr100% (1)

- Yosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasДокумент4 страницыYosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasFutsal AlcoletgeОценок пока нет

- Device Protocol - v2.2.4Документ81 страницаDevice Protocol - v2.2.4Aston MartinОценок пока нет

- Ba 133 Gbs For Week 02Документ13 страницBa 133 Gbs For Week 02Arnete Carla VitugОценок пока нет