Академический Документы

Профессиональный Документы

Культура Документы

Methodology For Subsoil Improvement

Загружено:

Mehedi HasanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Methodology For Subsoil Improvement

Загружено:

Mehedi HasanАвторское право:

Доступные форматы

Methodology for subsoil improvement:

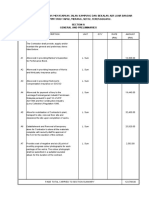

List of Equipment:

1)

2)

3)

4)

Crawler crane 30 ton.

Vibratory Hammer 60KW, 329Kn driving force.

12 Inch Casing pipe with shoe cap.

250KW Generator.

Materials:

1.2 FM Filling sand.

Procedure:

Survey will be done to find out the points where we have to do sand pilling. Every

location will be properly marked. Then the machines will be placed to the point. The

casing pipe which is capped by shoe will be driven to the desired length, hole of 12

inch will be constructed and the soil will be pressed vertically and horizontally and

then uplift of the casing pipe will be done by hammer & crane and up to 4 M length

of the prepared hole will be filled by sand and then again the shoe fitted casing will

be placed to the hole. After that we will apply vibration by the vibratory hammer

which will ensure the compaction of the filled soil. Again the casing pile will be

uplifted and refill of soil in the will be done and compaction will be done as same

procedure as before. In this way the total length will be filled by compacted soil.

This procedure is reliable to improve the subsoil and will ensure proper compaction

of the filled soil.

Safety:

All PPE will be strictly maintained. The working area will be blocked by caution tap.

All equipment will be rechecked before starting work.

Summary:

Less hazard for shifting equipment from point to point. Quick working procedure.

Less safety hazard.

Best performance ensured. Totally equipment oriented work so less manpower will

be deployed which ensure less accident.

Вам также может понравиться

- Maintenance Work Order Request Form: General InformationДокумент2 страницыMaintenance Work Order Request Form: General InformationProgress TherapyОценок пока нет

- PQC - Road ConcreteДокумент10 страницPQC - Road Concretemangeshshinde124100% (1)

- 04.1 ExcavatingEquipmentДокумент10 страниц04.1 ExcavatingEquipmentNur Azlin IdayuОценок пока нет

- Structural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringДокумент12 страницStructural Steel Design: DR - Mu'taz K.M Ass. Prof. in Civil EngineeringAhmed Non MeemОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Chapter 7 Soil ExplorationДокумент128 страницChapter 7 Soil ExplorationCrislie AlbateraОценок пока нет

- Method Statement For Bored PilingДокумент5 страницMethod Statement For Bored PilingAhmed KassemОценок пока нет

- Construction Method Statements - Method Statement For Bored PilingДокумент5 страницConstruction Method Statements - Method Statement For Bored PilingLin ChayОценок пока нет

- Strategic Open Pit Mine Planning Course PDFДокумент1 009 страницStrategic Open Pit Mine Planning Course PDFAnonymous IabqZQ1tk100% (1)

- Sand ColumnДокумент16 страницSand ColumnZulfadli MunfazОценок пока нет

- Portal Frame Structures1745,1735Документ25 страницPortal Frame Structures1745,1735Priya Chauhan100% (1)

- Vertical Crater RetreatДокумент30 страницVertical Crater Retreatyorka25100% (2)

- 4 Phases Involved in Bored Cast inДокумент3 страницы4 Phases Involved in Bored Cast inRajesh KhadkaОценок пока нет

- Embankment On Soft SoilДокумент5 страницEmbankment On Soft SoilMehedi HasanОценок пока нет

- Going Trenchless HistoryДокумент3 страницыGoing Trenchless HistoryJoyce Wm Wong100% (2)

- Applications of Vibro For Infra Structure Projects in IndiaДокумент8 страницApplications of Vibro For Infra Structure Projects in IndiasuvraОценок пока нет

- Underground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineДокумент6 страницUnderground Haulage Selection: Shaft or Ramp For A Small-Scale Underground MineluisparedesОценок пока нет

- Field Density Test by Sand Replacement MethodДокумент4 страницыField Density Test by Sand Replacement Methodibrih wazirОценок пока нет

- Microsoft Word - STP Method Statement by Ecobuilders - 30jan2013Документ14 страницMicrosoft Word - STP Method Statement by Ecobuilders - 30jan2013Mar Maslan80% (5)

- Dewatring Method StatementДокумент8 страницDewatring Method Statementreachpunnya5538Оценок пока нет

- Ground Improvement Techniques ME 3rd SemДокумент57 страницGround Improvement Techniques ME 3rd SemSojil Jain86% (7)

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AДокумент9 страницMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasОценок пока нет

- MP Mackintosh Probe - Appendix 2Документ4 страницыMP Mackintosh Probe - Appendix 2Deraman AbdullahОценок пока нет

- Base Grouting PaperДокумент5 страницBase Grouting PaperNajib AliОценок пока нет

- AVOCA Mining MethodДокумент9 страницAVOCA Mining MethodCarlos A. Espinoza M100% (2)

- 9) Sand Cone MethodДокумент6 страниц9) Sand Cone MethodPn Ekanayaka100% (1)

- The Architectural Theory of Viollet-le-DucДокумент14 страницThe Architectural Theory of Viollet-le-DucColor OctubreОценок пока нет

- Middle Semester TestДокумент13 страницMiddle Semester TestCahyani SeptyanaОценок пока нет

- KELOMPOK 1-Pages-DeletedДокумент12 страницKELOMPOK 1-Pages-DeletedCahyani SeptyanaОценок пока нет

- BP (Method Statement) - 2Документ5 страницBP (Method Statement) - 2khraieric16Оценок пока нет

- Bored PileДокумент4 страницыBored PileLarah PiencenavesОценок пока нет

- West Texas - Permian BasinДокумент8 страницWest Texas - Permian BasinPesireron RoberthОценок пока нет

- A Brief Discussion On The Construction and Design 16101101026Документ24 страницыA Brief Discussion On The Construction and Design 16101101026Souvik MitraОценок пока нет

- Soil Compaction Test: Insitu Density Test Using Sand Cone Replacement MethodДокумент3 страницыSoil Compaction Test: Insitu Density Test Using Sand Cone Replacement MethodHu DaОценок пока нет

- IAS Mains Civil Engineering 2014Документ28 страницIAS Mains Civil Engineering 2014rahulОценок пока нет

- Method Statement and Design Dewatring SharqДокумент17 страницMethod Statement and Design Dewatring SharqMohammed RajapОценок пока нет

- Annex - Ground Improvement Works at Changi EastДокумент4 страницыAnnex - Ground Improvement Works at Changi EastlittlestepjОценок пока нет

- Method Statement For Grout ColumnДокумент1 страницаMethod Statement For Grout ColumnAlsonChin100% (1)

- Earth Filling Procedure - NroДокумент3 страницыEarth Filling Procedure - NronkdnksndОценок пока нет

- Module 2: Solid Fossil Fuel (Coal) Lecture 8: Coal MiningДокумент6 страницModule 2: Solid Fossil Fuel (Coal) Lecture 8: Coal MiningBrijesh BhartiОценок пока нет

- Effectiveness of Sand Column As A Ground Improvement TechniqueДокумент5 страницEffectiveness of Sand Column As A Ground Improvement TechniqueMuhammad IrfanОценок пока нет

- GeoTech 1 - Short QuizДокумент2 страницыGeoTech 1 - Short QuizJosel BayogОценок пока нет

- Draft PPT Pile FoundatationДокумент14 страницDraft PPT Pile FoundatationDwijendra ChanumoluОценок пока нет

- Transportation PresentationДокумент11 страницTransportation Presentationfurqanseller12Оценок пока нет

- Group 5 - Field CompactionДокумент29 страницGroup 5 - Field CompactionAllan VillaverdeОценок пока нет

- Benefit of ManagementДокумент3 страницыBenefit of ManagementMohammad SyeduzzamanОценок пока нет

- DCC1023 Civil Engiineering Materials: Name: Muhd Izzat Syahmi Akmal BinДокумент8 страницDCC1023 Civil Engiineering Materials: Name: Muhd Izzat Syahmi Akmal BinMiko ChanОценок пока нет

- Field Dry Density Test Using Sand Replacement MethodДокумент29 страницField Dry Density Test Using Sand Replacement MethodJassel Jalandoni100% (1)

- CPT PDFДокумент6 страницCPT PDFkhemankarОценок пока нет

- Pipe Jacking: Technique - Factors - Applications - AdvantagesДокумент18 страницPipe Jacking: Technique - Factors - Applications - AdvantagesGakwaya Jules CesarОценок пока нет

- EarthworkДокумент3 страницыEarthworkSaibatul As-syahidahОценок пока нет

- FIELD DENSITY TEST CommentaryДокумент3 страницыFIELD DENSITY TEST CommentaryAstray NoirОценок пока нет

- What Is Ground ImprovementДокумент5 страницWhat Is Ground ImprovementDipankar HazarikaОценок пока нет

- Sand Filling Earth Filling and Road Bed Preparation ProcedureДокумент4 страницыSand Filling Earth Filling and Road Bed Preparation ProcedureHasan ShahriarОценок пока нет

- Well 6507/7-6Документ19 страницWell 6507/7-6wasim78622Оценок пока нет

- 2mark and 16markДокумент8 страниц2mark and 16markGowri ShankarОценок пока нет

- Irc 049-1973Документ11 страницIrc 049-1973harivennelaОценок пока нет

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159От EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159Оценок пока нет

- Electronic Transfer SI Data PDFДокумент111 страницElectronic Transfer SI Data PDFMehedi HasanОценок пока нет

- Influence LinesДокумент6 страницInfluence LinesClorinda Astete ChuquichaicoОценок пока нет

- Settlement Analysis Via PlaxisДокумент5 страницSettlement Analysis Via PlaxisMehedi Hasan100% (1)

- Proposed 2 Storey BLDG ElevationДокумент6 страницProposed 2 Storey BLDG ElevationKarl HelbiroОценок пока нет

- Seismic Checks Asce7 10Документ9 страницSeismic Checks Asce7 10طه حلمىОценок пока нет

- EN 12275 enДокумент2 страницыEN 12275 enMauricio GaviriaОценок пока нет

- Pavement Components Lec-1Документ32 страницыPavement Components Lec-1Sumon ChowdhuryОценок пока нет

- E-Brochure DaisanДокумент66 страницE-Brochure DaisanWinerNainggolanОценок пока нет

- Thesis On Low Cost HousingДокумент8 страницThesis On Low Cost Housingrachelquintanaalbuquerque100% (1)

- Submerged Floating TunnelДокумент12 страницSubmerged Floating TunnelHarsha Vardhan MeduriОценок пока нет

- BiaxialДокумент13 страницBiaxialM. Fikra NaufaldyОценок пока нет

- ISC Geometry, Building DrawingДокумент1 страницаISC Geometry, Building DrawingMohitОценок пока нет

- TD Part 2 Section VI Requirements Technical SpecificationДокумент190 страницTD Part 2 Section VI Requirements Technical SpecificationAyhan AgeliyevОценок пока нет

- HST Hydraulic Setting Tool: ApplicationsДокумент2 страницыHST Hydraulic Setting Tool: ApplicationsMostafa HashemiОценок пока нет

- Building Permit (Complete Bundle)Документ17 страницBuilding Permit (Complete Bundle)Jean TroncoОценок пока нет

- Floor Truss Span TablesДокумент2 страницыFloor Truss Span TablesTucker KellyОценок пока нет

- 1x1.2x1.2 BOX CULVERT GAD-2-LANEДокумент1 страница1x1.2x1.2 BOX CULVERT GAD-2-LANEbakhteyar shaikhОценок пока нет

- 1 Incinerator SchedulesДокумент16 страниц1 Incinerator SchedulesLenny ErastoОценок пока нет

- Jubilee Greenway Section 6Документ13 страницJubilee Greenway Section 6ilaria zaccagniniОценок пока нет

- NORMAN MYANMAR - CATWALK FACTORY No 02 & 07 - APD - 02 Jul 2021Документ9 страницNORMAN MYANMAR - CATWALK FACTORY No 02 & 07 - APD - 02 Jul 2021thang TranОценок пока нет

- Curriculum Vitae: K.D.A.B. KumarasingheДокумент4 страницыCurriculum Vitae: K.D.A.B. Kumarasingheshamen AmarasekaraОценок пока нет

- BMCT - V: Truss Less Roof StructuresДокумент25 страницBMCT - V: Truss Less Roof StructuresDevine MerakiОценок пока нет

- ) Manufacturing PlantДокумент3 страницы) Manufacturing PlantAnna Jane TanОценок пока нет

- BQ Preliminaries Projek Paip Air Dan Jalan Di Besut2Документ11 страницBQ Preliminaries Projek Paip Air Dan Jalan Di Besut2Anonymous 94TBTBRksОценок пока нет

- UGC Company Profile For Accreditation 11.15.21Документ54 страницыUGC Company Profile For Accreditation 11.15.21AJ PAJEОценок пока нет

- Adler Catalogue Charnieres GBДокумент68 страницAdler Catalogue Charnieres GBSolakhudin EngineeringОценок пока нет

- QSE Lecture 1Документ17 страницQSE Lecture 1Muhammad Hassan Syed BSCVE2021Оценок пока нет

- Affordable Group Housing ProjectДокумент35 страницAffordable Group Housing ProjectAarooni ThakurОценок пока нет