Академический Документы

Профессиональный Документы

Культура Документы

High Conductivity in DM Water Action Plan

Загружено:

Rakesh MishraАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

High Conductivity in DM Water Action Plan

Загружено:

Rakesh MishraАвторское право:

Доступные форматы

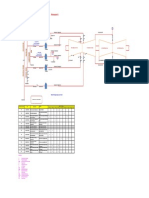

To know the perfect reason of high conductivity in DM water following in action plan:

1. Transfer of DM water from Tank-1 to Tank-2 through MB-2 Unit and made tank-1 empty. Parallely

measure the conductivity of the tanks by some other source.

2. Then Tank-2 DM water recirculation into same tank to decrease conductivity and water used for running

plant. We will observe cation conductivity during transfer and recirculation process.

3. To check DM water parameters from third party lab. Because mainly cation conductivity problem due to

negative ion such as chloride or salt such as NaCl. Or organic matter passing thought DM stream & it is

not controllable. So. TOC checking in specifically in DM water (if possible additionally in raw water,

clarified water so as to ascertain the real origin of TOC, if found in the DM tank outlet). There is very

less chance to passes chloride from MB outlet; but for confirmation purpose we have to go for that.

4. To arrange degassed conductivity meter from nearby industries (specifically Kribhco, if possible) or

third party on rent or need to be repaired our own conductivity meter. We cant decide without this

instrument that CO2 contamination in water or not. Thus, Measurement of Degassed conductivity for the

same needs to be done.

5. Checking of all instrument related to CC in SWAS. To determine the healthiness of the analyzers in

SWAS, along with the temperature sensors; solenoid operation based on temperature and the Analyzers.

6. Measurement of conductivity of DM water in (a) MB outlet (b) DM tank outlet / cycle makeup pump

suction (c) from cycle makeup pump discharge to SWAS panel.

7. Performance of CO2 Degasser unit. Very less chance, but can check for conformity.

8. Degasser Blowers capacity and inspection of discharge pipes healthiness.

9. KOH solution's technical performance to confirm for ability of CO2 removal from atmospheric breathed

air.

10. Reversing the DM tank # 1; top air release valves sealing sheet; as it has been replaced with rubber

sheet and previously used Teflon sheet. As this change in seat material has enhanced the sealing and thus

creates vacuum inside the DM Tanks. Air breathing is not done from any other sources except KOH

breather as observed while tank paralleling. There might be a possibility of KOH Solution fumes

settlement in DM tank before and after heavy breathing.

11. Other point

Вам также может понравиться

- Responsiblities of Technical CellДокумент3 страницыResponsiblities of Technical CellRakesh MishraОценок пока нет

- Optimisation Time For Startup and Shutdown Time of CCPPДокумент3 страницыOptimisation Time For Startup and Shutdown Time of CCPPRakesh MishraОценок пока нет

- SWAS Taking ActivityДокумент1 страницаSWAS Taking ActivityRakesh MishraОценок пока нет

- X Criteria InstrumentlocationДокумент1 страницаX Criteria InstrumentlocationRakesh MishraОценок пока нет

- Optimisation Time For Startup and Shutdown Time of CCPPДокумент3 страницыOptimisation Time For Startup and Shutdown Time of CCPPRakesh MishraОценок пока нет

- Major Start Up ActivityДокумент2 страницыMajor Start Up ActivityRakesh MishraОценок пока нет

- Equipment Changeover Practice ProposedДокумент2 страницыEquipment Changeover Practice ProposedRakesh MishraОценок пока нет

- Fuse CutoutДокумент2 страницыFuse CutoutRakesh MishraОценок пока нет

- CWДокумент2 страницыCWRakesh MishraОценок пока нет

- CAWTL - Monthly ReportДокумент5 страницCAWTL - Monthly ReportRakesh MishraОценок пока нет

- Reliability Test For The CCPPДокумент3 страницыReliability Test For The CCPPRakesh MishraОценок пока нет

- Near Miss Reporting FormatДокумент1 страницаNear Miss Reporting FormatRakesh MishraОценок пока нет

- LDP Micom Relays P441 & P442 For Distance ProtectionДокумент16 страницLDP Micom Relays P441 & P442 For Distance ProtectionRakesh MishraОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)