Академический Документы

Профессиональный Документы

Культура Документы

GSD WWTP Dedication June 22, 1933 Brochure

Загружено:

Tom Bates0 оценок0% нашли этот документ полезным (0 голосов)

5 просмотров11 страниц1933 Brochure about a old wwtp

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1933 Brochure about a old wwtp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

5 просмотров11 страницGSD WWTP Dedication June 22, 1933 Brochure

Загружено:

Tom Bates1933 Brochure about a old wwtp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 11

PROGRAM

Dedication of the

Galesburg Sanitary District

Treatment Plant

Thursday, June 22, 1933

A. ©, Lindsteum, President of the Board, presiding,

Tnvocatio

a—Rev. Father J. A Phelan.

An A

sciation—Fred R Jelliff, Editor Daily Reg:

ster-Mail

Public Attitude for Better Health—judge Riley E.

Address—Dr. John L. Conger, Depart.

nt of History

College.

ined Political Science, Knox

Rev. P, A, Johnson

Inspection of Plant

— ae

THE GALESBURG

SANITARY DISTRICT,

GALESBURG, ILLINOIS

Description of Sewage

Treatment Plant, Intercepting

Sewers, and Channel

Improvement for Flood Relief

Trustees

ANDREW 0. LINDSTRUM-~-.-- PRESIDENT

VERN E. CARTER-

D. B. SWANSON--..

ALDEN M, ROSE

WOOLSEY, STICKNEY & LUCAS.__ATT'YS

ALVORD, BURDICK & HOWSON ENGINEERS:

History

The Galesburg Sanitary District was authorized at an

election held November 4, 1924, Included within the boun-

daries of the District is the City of Galesburg and about six

square miles of adjacent territory, the total area being ap-

proximately 18 square miles. (Boundaries shown in Fig-

ure 1). Tt is interesting to note here that the problem con

fronting the Board was of long standing. On April 30,

1858, the first complaint was registered against the foul

condition of Cedar Fork Creek which even at that early

date, was used as an outlet for raw sewage from the City

of Galesburg.

On November 22, 1924, the first Board members were

appointed by the County Judge. The Board organized on

December 8, 1924, with the following officers: L. Wein-

berg, President, J. E. Potter, Vice President, D. B. Swan-

son, Clerk. Andrew O. Lindstrum was appointed Novem-

ber 25, 1927 in place of L. Weinberg and elected President

Decemper 6, 1927. The other members of the Board were

re-elected to their offices on the same date. Vern E. Carter

wes appointed on January 6, 1928 Vice J. E. Potter re-

signed, and elected Vice President January 10, 1928.

Since 1928, the personnel of the Board has been con-

tinued unchanged to the present date with Andrew O.

Lindsirum, President, Vern E, Carter, Vice President, and

D.B. Swanson, Clerk. Alden M. Rose was appointed Treas-

urer on May 7, 1925 and has continued to fill this offic:

Woolsey & Lucas were Attorneys for the Board from its

ception to December 6, 1927 and since this date, Woolsey,

Stickney & Lucas have been Attorneys for the Board

Alvord, Burdick & Howson were appointed Engineers

for the Sanitary Distriet on April 4, 1928 and in July, 1928,

submitted a report recommending the construction of @

sewage treatment plant, channel improvement consisting of

enlargements, straightening and paving certain portions of

the channel of Cedar Fork and the construction of inter-

cepting sewers to deliver all sewage to the treatment plant,

‘The recommendations embodied in the report were ac-

cepted by the Board and the Engineers were authorized on

July 8, 1928 to prepare plans and specifications.

On July 2, 1928, a special election was held and a bond

issue of $650,000 was authorized. In addition to the money

obtained trom the sale of bonds and tax collections, the A

T. & 8. F. RR. contributed $200,000 and such railroad

rights-of-way as were required for channel improvement

and the C. B. & Q.R.R. built the culvert under its Rio

branch, which was estimated to cost $51,000. In addition,

these railroads are large tax payers in the Sanitary Distriet.

Without the contributions from the railroad companies, the

extensive improvements completed to date would have been

materially curtailed, A description of the work completed

to date is given in the following pages and these with future

improvements contemplated, are shown on Figure 1

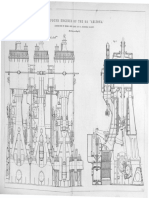

TREATMENT PLANT BUILDING

Sewage Treatment Plant.

‘The sewage treatment plant is located two miles

downstream from the center of the city and consists of

mechanically raked sereens, grit chamber, mechanically

cleaned settling tanks, sludge digestion tanks, sprinkling

filters and sludge beds. (Fig. 2)

It is designed for 1940 conditions when the estimated

population will be 35,000 and the dry weather flow will

average 2,800,000 gallons per day. For about three or four

months of Use year, the flow will be 5,500,000 gallons per

day. ‘This is during the wet season when the infiltration

approximately equals the dry weather flow.

Sewage flowing to the plant first passes through the

sereen house where the mechanically raked screen is locat-

ed. Here all floating material of any appreciable size is

removed by the coarse screens, which have clear openings

of one inch, The screens serve two purposes in that any

material that might damage the pumps is removed and also

other material is retained on the sereens that might clog

jipes and interfere with the operation of the plant. All or

part of the flow can be bypassed at the screen house. After

passing the sereen, the sewage flows to 2 conerete conduit

underneath the floor of the pump room. Here the sewage

is pumpd to the grit chamber by one of three sewage

pumps and then flows by gravity through the rest of the

plant.

‘The grit chamber consists of a Dorr traction type de-

tritor, grit remover and classifier. The period is one min-

ute alter which the sewage flows to the two primary set

thing tanks,

‘The settling tanks are 55 fect in diameter by 12 feet

six inches in depth. The settling period will average ap-

proximately three hours. These tanks are equipped with

Clarifier mechanisms of the Dorr traction type. From the

settling tanks, the sewage flows by gravity to the dosing

tanks and sprinkling filter. ‘The effluent from the sprink-

ling filter is discharged into Cedar Fork Creek below the

plant.

The sprinkling filter contains six feet of stone. The

lower five feet of stone is of such a size that it will pass a

2 inch screen and be retained on a 11g inch sereen, the top

foot passing a LY inch sereen and retained on a 1 inch

screen. ‘The distribution system is of cast iron, both later-

als and risers, Nozzles are spaced 15 feet 91% inches on

centers, Design is based upon 3,000 persons per acre per

foot of stone or 18,000 persons per acre. ‘The underdrain

system is of vitrified tile blocks designed by the Wm. B. Dee

Company and is known as the Dee bottom. Tt consists of

vitrified blocks containing two cylindrical flow passages

abou: four inches in diameter. The sewage enters these

blocks through concinuous slots in the top %%4 ineh in width.

"The blocks are grouted in place on the conerete floor of the

filter, The plant design provides for two 1 acre stone beds

of which but one has been constructed, the other being de-

ferred on account of insufficient funds, A secondary set-

tling tank will also he built at a later date.

Adiacent to the two primary settling tanks on the south,

are three sludge digestion tanks. The tanks are 35 feot

square and 17 feet deep, Sludge storage is provided in the

amount of one and three fourths eubie feet per capita. Hach

sure Work

Completed and ut

‘The Galesburg Sanilary Distlet Showing

tank is provided with a sludge stirring device and equipped

with a dome for gas collection, Gas meters are attached

to each tank to measure the gas production so that an ac-

curate record is kept of the Performance of each tank,

After passing tho gas meters, the gas is piped through a

main ges header to the boilers where it is used as fuel for

heating the plant and also in keeping the sludge digestion

tanks at a uniform temperature. Pipe coil radiation is pro-

jed in each of the sludge digestion tanks. Sludge piping

is so arranged that sludge can be pumped from either pri-

mary settling tank to any sludge tank or sludge may be

pumped from any sludge digestion tank to either of the oth-

er tyro tanks.

After the sludge is digested or ripened sufficiently, it

is drained from the tanks by gravity to the sludge drying

beds. There are six beds each 40 by 100 feet, the equiva-

ont of 2-3 sq. ft. per capita in 1940, A narrow gage rail-

way with stecl dump cars is used for removing the dried

sludge. ‘The beds are partitioned off by creosoted wood

planks set in conerete posts.

‘Three sewage pumps are installed at the present time

and space is provided for a fourth unit when needed. The

pumps are Yeomans Company nonclogging type of sewage

pump with capacities of four million gallons for one unit

and six million gallons each for the other two. Total oper-

ating head is B5 feet,

The pumps are operated by automatic controls. Sep-

arate float pipes cut each pump into service when the water

in the cuction conduit reaches a certain level. Protection

devices prevent pumps from operating unless fully primed

The priming pump operates automatically through switches

connected to the float pipes. Protection against overload

and low voltage is also provided. Operation may be mun-

ual through push bution control if desired

In addition to the treatment, part of the plant, there is

an offiee, laboratory, switchboard room, boiler room, tool

room, employees shower bath room and garage. (Fig. 2).

‘The substructure is of concrete and the superstructure of

brick with some cut stone trim and quoins of. slag-brix.

Simplicity has been adhered to in the design and the build-

ing as completed presents an attractive appearance.

Provision has been made in the design so that ad

tions may be made to the existing plant without interfering

with the operation or losing any of the first investment.

Intercepting Sewers.

The intercepting sewers now built extend from the

‘

northeast part of Galesburg to the treatment plant, south-

west of the city, a distance of approximately 4.3 miles, With

the exception of the upper 5,280 feet, which is some dis-

tance from the channel, the intercepting sewer parallels

the channel on the north bank and in the paved sections is,

laid in the north bank 10 feet from the center line of the

channel. Size varies from 15 inches at the upper end to

48 inches in diameter at the treatment plant.

‘Three types of construction were used for the inter-

cepting sewers. From the treatment plant to the central

portion of the city, brick was used, the diameters being 48

and 42 inches respectively. Where the concrete channel

section is built, the sewer is carried under the floor of the

channel in the form of a rectangular conerete box with the

invert paved with brick. ‘The remaining sewers, varying in

size from 30 inches down to 16 inches in diameter, are dou-

ble strength vitrified tile. Asphaltie filler was used in Iny-

ing the vitrified tile to keep the infiltration as low as pos:

sible. ‘The brick sewers are plastered on the top half of the

exterior with one inch of mortar and extra care taken in

the invert to see that all joints were filled with mortar to

make these sewers as water tight as possible.

Unit prices and lengths of the various sized sewers are

tabulated below:

Length cost

Sin Description feet per foot

Bin, Three ring brick 490 $18.00

48 in. ‘Two ring brick 9750 975

42 in ‘wo ring brick 720 70

30 in, D. 8. Vitrified Tile 1965 3.80

2Tin. D. S. Vitrified Tile 1630 3.30

24 in, D. 8. Vitrified Tile 1400 2.80

20 D. S. Vitrified Tite 1626 2.30

18 in. D. S$. Vitrified Tile 1267 2122

15 in. D. S. Vitrified Tile 2387 1.69

Four foot diameter manholes $75.00 each,

Studies were made to determine the capacities of the

present combined sewers. In the past few vears, there has

been a large increase in impervious surfaces, resulting most

ly from paving so that most of the sewers have became

adequate. Storm water intercepting sewers are required in

most portions of the city. The financial condition of the

Sanitary District did not permit carrying out the entire con-

struction program under the original lettings and the work

now completed is accordingly so laid out that the greatest

benefit will result from the first expenditures. Tt is esti-

mated that several years will be required to carry out all the

recommendations outlined in the report of the Consulting

Enginoers,

‘The intercepting sewers are designed for 1970 cond

tions when through the construction of the storm wate

sewers mentioned above, the present combined sewers will

have been changed to separate sewers, with the exception

of a small area in the business distriet_ and which will

amount to about 15% of the population at that time.

Channel Improvements

Codar Fork Creek channel had a eapacicy of approxi

mately 500 cubic feet per second before being improved.

‘This was exceeded frequently and in 1924 and 1926, floods

occurred in which the discharge just wesi of Galesburg was

CONCRETE CHANNEL,

estimated to be 4500 cubic feet per second. At the upper

end of the city, the discharge was 1500 cubie feet per

ond. ‘The old creek channel was not adapted to carr

flood discharges. The banks were uneven with numerous

bends and obstructions. Debris had accumulated at var-

ious points so that the creek was virtually blocked.

‘The improved channel is designed for flows of 5500

and 2500 cubic fect per second at the lower and upper ends

respectively. Three types of construction were used in the

channel improvement. In the lower reaches west of the

city, the channel is an earth ditch with bottom widths of 15,

20, 80 and 40 feet and side slopes of one and one-half to one.

10

‘There is also a short section at the upper end with a bot

tom ten feet. in width

One section is paved with conerete with vertical side

walls having a height of 12 feet. (See Fig. 3). The net

width of this section is thirty-five feel. The total width in

this section varies somewhat for a portion of the channel is

a twin barrel section with a 24 inch center wall while an-

other section has an 18 inch center wall. Where a center

wall is provided, the channel has a roof for carrying indus-

trial buildings or railroad switeh tracks.

‘The third type of chamnel is paved with vitrified tile

blocks 12 inches by 12 inches by two and one-half inches

thick. (See Fig. 4). These blocks are tongue and grooved

and are perferated with two holes on six inches centers.

One-half inch reinforeing rods pass through the holes to

anchor the blocks in place. These rods extend parallel to

ihe axis of the channel. The blocks were designed for thi

VILE BLOCK CHANNEL

particular job and have been manufactured locally, | En-

gineers for two railroads have visited the work and have

been so favorably impressed with them that they are con-

sidering adopting them for similar work. Where this type

of channel section is built, the bottom width varies from

10 to 15 feet with side slopes of one and one-half to one.

The specifications call for the bottom blocks only to be

grouted in place.

It has been necessary to replace all existing bridges

with new structures. While this would have been necessary

in some instances on account of changes in street grades, the

main reason was on account of the inadequate waterways

wien the eld bridges. Sixteen new bridges were bullt with

treShannel improvement. ‘These are either two span or

EMlale span structures built of reinforced eonerete with the

qinale spa" jab type of floor system. Balustrades are of

concrete with rectangular panels for ornamentation,

‘Total length of improved channel is 20,750 feet, or

approximately four mil

Costs.

‘The cost of the work completed to date is in round fig-

ures as follows: Treatment plant—$324,000; channel ime

provements including bridges, intercepting sewers, ¢tte

$750,000; making a total cost of $1,046,000 not including

the culvert built by the 0. B, & Q.R.R.

Construction,

Bids were received in May, 1930 on the treatment plant

and sutiliary equipment and on the channel improvements,

and guxiliareepting sewers and connections, |The, treet,

bridger it was completed in March 1931 and the channel

iment Piegoptember, 1952. This latter date is 74 years and

wore onthe after the first complaint was made regarding

the condition of Cedar Fork.

Operation.

Operation of the sewage treatment plant started Supe

1, 1981 om a limited scale, only part of the sewage reaghing

Ao ee ac due to construction operations on the channel. On

September 1, 1982, completion of intercepting sewer Hol

Septem Pccatment of all sewage and this has continued to

Tater As a result of the operation, the stream below the

oie; has been clear and odorless at all times and a satistor-

peat patent of distoived oxygen has been maintained in the

creek.

Invitation to the Public.

esburg Sanitary District ex

ints to the public to visit the works at all

sister-ail Print

Вам также может понравиться

- General Arrangement Engines'J-End THE: OF Boilers OF Normandie."Документ5 страницGeneral Arrangement Engines'J-End THE: OF Boilers OF Normandie."Tom BatesОценок пока нет

- 1895 - Molesey Sewage WorksДокумент4 страницы1895 - Molesey Sewage WorksTom BatesОценок пока нет

- 1894 - Marie HenrietteДокумент10 страниц1894 - Marie HenrietteTom BatesОценок пока нет

- 1902 - Floating DrydockДокумент9 страниц1902 - Floating DrydockTom BatesОценок пока нет

- The Richmond Precipitation WorksДокумент9 страницThe Richmond Precipitation WorksTom BatesОценок пока нет

- 1880 - ArizonaДокумент8 страниц1880 - ArizonaTom BatesОценок пока нет

- 1890 - HMS BarhamДокумент7 страниц1890 - HMS BarhamTom BatesОценок пока нет

- 1891 - Doune CastleДокумент4 страницы1891 - Doune CastleTom BatesОценок пока нет

- Lli.! Llil (: Q I - M@-!!!!!!!Q!! !!!!!! EДокумент10 страницLli.! Llil (: Q I - M@-!!!!!!!Q!! !!!!!! ETom BatesОценок пока нет

- 1914 - MargaretДокумент9 страниц1914 - MargaretTom BatesОценок пока нет

- 1914 - BritannicДокумент28 страниц1914 - BritannicTom Bates100% (2)

- 1921 - MendozaДокумент16 страниц1921 - MendozaTom BatesОценок пока нет

- 1921 - Giulio CesareДокумент9 страниц1921 - Giulio CesareTom BatesОценок пока нет

- 1916 - City of CantonДокумент6 страниц1916 - City of CantonTom BatesОценок пока нет

- The French South American Quadruple-Screw "Lutetia.": IN LinerДокумент9 страницThe French South American Quadruple-Screw "Lutetia.": IN LinerTom BatesОценок пока нет

- 1914 - Buenos AiresДокумент10 страниц1914 - Buenos AiresTom BatesОценок пока нет

- 1915 - Scotia 2Документ9 страниц1915 - Scotia 2Tom BatesОценок пока нет

- Driftmaster GAДокумент1 страницаDriftmaster GATom BatesОценок пока нет

- 1914 - ImperatorДокумент11 страниц1914 - ImperatorTom BatesОценок пока нет

- Driftmaster GAДокумент1 страницаDriftmaster GATom BatesОценок пока нет

- 2 Deck ArrangementДокумент1 страница2 Deck ArrangementTom BatesОценок пока нет

- M1 Machinery ArrangementДокумент1 страницаM1 Machinery ArrangementTom BatesОценок пока нет

- DD 793Документ1 страницаDD 793Tom BatesОценок пока нет

- BB-64 USS WisconsinДокумент15 страницBB-64 USS WisconsinTom BatesОценок пока нет

- MontmagnyДокумент2 страницыMontmagnyTom BatesОценок пока нет

- Leopard 1924Документ6 страницLeopard 1924Tom BatesОценок пока нет

- BBC AsiaДокумент1 страницаBBC AsiaTom BatesОценок пока нет

- 1908 - June 23Документ9 страниц1908 - June 23Tom BatesОценок пока нет

- 1908 - June 9Документ8 страниц1908 - June 9Tom BatesОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)