Академический Документы

Профессиональный Документы

Культура Документы

Distance Between Weld To Weld

Загружено:

Sampath Kumar0 оценок0% нашли этот документ полезным (0 голосов)

487 просмотров1 страницаweld-weld

Оригинальное название

Distance Between Weld to Weld

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документweld-weld

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

487 просмотров1 страницаDistance Between Weld To Weld

Загружено:

Sampath Kumarweld-weld

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

TECHNICAL SPECIFICATION

SHOP AND FIELD FABRICATION OF PIPING

DEP 31.38,01.31-Gen.

2.2.2 Assembly of piping components

For butt-welding of ail piping components (e.g. pipe ends, fitings and welding neck

flanges), a uniform root gep shall be proviced as specified in the relevant Welding

Procedure Spectfcation

Refer to DEP 31.38.01.11-Gen, for flange misalignment acceptance criteria of misalignment

of flanges.

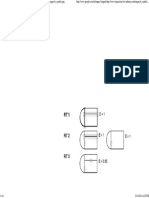

The minimum distance between the edges of two pressure-containing welds shall be twice

the wall thickness of the thicker pressure part. The same requirement applies to the

distance between non-pressure attachment welds and a pressure-containing weld in order

to allow non-destructive inspection of the pressure-containing weld. Longitudinal welds in

two adjacent pipes should be 180° apart, but in any case shall be separated by at least

twice the wall thickness of the thicker pipe.

BSP-12-STANDARD-601

TH E WELDING OF ME T ALS

Clause 328.4.3 Alignment

Add the following:

When two piping components of same nominal outer diameter having different wall

thickness are welded, the internal diameter of the thicker member shall be tapered to

4:4. Wherever, possible such rectification shall be carried out by machining in shop

rather than by grinding In the field.

Add new subsection (e) Weld separation The toes of adjacent circumferential welds

shall be separated by a minimum distance equal to the nominal outside diameter of

the pipe. Where the above

requirement cannot be met, the minimum distance between the toes of adjacent

circumferential welds shall not bé less than five times the nominal weld thickness of

50mm which ever is greater.

DEP SPECIFICATION

WELDING OF METALS (AMENDMENTS/SUPPLEMENTS TO

API RP 582)

DEP 30.10.60.18-Gen.

4.7.4.2 Spacing

Pipe or vessel containing longitudinal seams shall be separated by at least 45 ° of

rotation or

450 mm (6 in), whichever is the less. Additionally, any longitudinal welds in horizontal

pipes

shall also be so positioned that the weld Is at the upper segment of 120 ° of the

pipeline.

Circumferential welds shall be separated by at least 4 times the nominal wall thickness

(toe

to toe).

Attachments shall be at least 2 times the nominal thickness or 40 mm (1.5 in) (toe to

toe)

from any weld, whichever is the smaller.

Вам также может понравиться

- Tank TypeДокумент1 страницаTank TypeSampath KumarОценок пока нет

- API 510 PC 05mar05 Summmary of NDT Asme Viii 1Документ1 страницаAPI 510 PC 05mar05 Summmary of NDT Asme Viii 1Sampath KumarОценок пока нет

- Pressure Vessel Head Shapes - Piping DesignerДокумент3 страницыPressure Vessel Head Shapes - Piping DesignerSampath KumarОценок пока нет

- API 653 Study PlanДокумент7 страницAPI 653 Study PlanJeganeswaranОценок пока нет

- Andhra Jyothi CalendarДокумент8 страницAndhra Jyothi CalendarMunirajulu McОценок пока нет

- RT SymbolДокумент1 страницаRT SymbolSampath KumarОценок пока нет

- Vessel FigДокумент1 страницаVessel FigSampath KumarОценок пока нет

- Andhra Jyothi CalendarДокумент8 страницAndhra Jyothi CalendarMunirajulu McОценок пока нет

- Distance Between Weld To WeldДокумент1 страницаDistance Between Weld To WeldSampath KumarОценок пока нет

- Sampath Kumar: From: Sent: To: CC: SubjectДокумент12 страницSampath Kumar: From: Sent: To: CC: SubjectSampath KumarОценок пока нет

- Base PlateДокумент1 страницаBase PlateSampath KumarОценок пока нет

- Heat Treatment Cracking)Документ132 страницыHeat Treatment Cracking)Usman LiaqatОценок пока нет

- Cswip3.1 Part2Документ140 страницCswip3.1 Part2Sampath KumarОценок пока нет

- Cswip Part 1Документ140 страницCswip Part 1Sampath KumarОценок пока нет

- Cswip Part 1Документ140 страницCswip Part 1Sampath KumarОценок пока нет

- Grating STD DesignДокумент3 страницыGrating STD DesignSampath KumarОценок пока нет

- Structural Steel W Flange Section Properties Moment of Inertia, Steel Beam Size, Cross Section Area - Engineers EdgeДокумент2 страницыStructural Steel W Flange Section Properties Moment of Inertia, Steel Beam Size, Cross Section Area - Engineers EdgeSampath Kumar50% (2)

- Equalozation Tower AFC IssueДокумент1 страницаEqualozation Tower AFC IssueSampath KumarОценок пока нет

- A999Документ11 страницA999Sampath Kumar100% (1)

- SYLLABUSДокумент2 страницыSYLLABUSSampath KumarОценок пока нет

- Icp Fee Structure Effective January 2014: Initial Certification API Member Price Non Member PriceДокумент2 страницыIcp Fee Structure Effective January 2014: Initial Certification API Member Price Non Member PriceSampath KumarОценок пока нет

- DIN Material Equivalent PDFДокумент13 страницDIN Material Equivalent PDFMuralitclОценок пока нет

- Wide Flange Beam SpecificationДокумент3 страницыWide Flange Beam SpecificationSampath KumarОценок пока нет

- Wide Flange Beam SpecificationДокумент3 страницыWide Flange Beam SpecificationSampath KumarОценок пока нет

- Steel W-Shape Section DataДокумент7 страницSteel W-Shape Section DataSampath KumarОценок пока нет

- Typical Material Specifications For Major Component PartsДокумент9 страницTypical Material Specifications For Major Component PartsSampath KumarОценок пока нет

- Heat Treatment Cracking)Документ132 страницыHeat Treatment Cracking)Usman LiaqatОценок пока нет

- Cswip3.1 Part2Документ140 страницCswip3.1 Part2Sampath KumarОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)