Академический Документы

Профессиональный Документы

Культура Документы

Calibration Training: References

Загружено:

houssИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calibration Training: References

Загружено:

houssАвторское право:

Доступные форматы

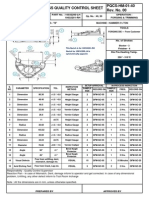

CALIBRATION TRAINING

REFERENCES:

1) REFERENCE FOR QSP-4.11.2 & QSP-4.11.1 IS ISO-10012-1

(QUALITY ASSURANCE REQUIREMENTS FOR MEASURING EQUIPMENT INTERNATIONAL STANDARD) CAN BE

FOUND IN THE RELIABILITY AND MAINTAINABILITY BOOK.

FORMS:

1)

2)

3)

4)

5)

6)

7)

FOR

FOR

FOR

FOR

FOR

FOR

FOR

CALIBRATION RECORDS DATA BASE USE QF-03

CALIBRATION REJECTION NOTICE USE QF-79

CALIBRATION REJECTION W/EXCEPTION USE QF-80

MICROMETER WORKSHEET USE QF-29

CALIPER WORKSHEET USE QF-30

HEIGHT GAGE WORKSHEET USE QF-31

REJECTIONS USE QF-25

JOB PREP:

1) OPEN COMPUTER TO CALIBRATION DATA BASE

2) OPEN GAGE LOG AND PRINT LIST OF TOOLS DUE FOR PRESENT MONTH (SPECIFY PLT-1 OR 2)

3) NOTIFY CMM OPERATORS OF HEIGHT GAGES BY INSPECTION REQUEST FORM

RETENTION:

ALL HARD COPY DATA SHEETS TO BE RETAINED ONE YEAR IN FILE DRAWER.

CMM INSTRUCTIONS (HEIGHT GAGES)

1)

2)

3)

4)

5)

6)

7)

8)

9)

RECEIVE INSPECTION REQUEST FORM

THE CMM OPERATOR CHECKS EACH GAGE LISTED ON THE I.R.F. PER GAGE I.D.#.

PERFORM THE FOLLOWING STEPS TO CHECK THE GAGE:

CLEAN TABLE AND BASE OF GAGE

PRESET CMM FOR HEIGHT GAGE

ZERO HEIGHT GAGE TO CMM PRESET

SET GAGE ACCORDING TO DATA SHEET

READ GAGE AS IS ( DO NOT CLEAN MORE THAN THE BASE )

IF GAGE READS BAD, CLEAN AND REREAD, IF IT READS GOOD: NOTIFY DEPARTMENT SUPERVISOR

THAT THERE MAY BE SUSPECT MATERIAL WHICH WAS MEASURED BY THIS GAGE.

10) RECORD RESULTS ( FOR HEIGHT GAGES CHECK THE GAGE AT 7 DIFFERENT INTERVALS AND ANGLES

BUMP ANGLE AT LEAST 3 TIMES ACROSS AND 3 TIMES UP)

11) COMPLETE WORKSHEET AND MARK OFF THE GAGE I.D. # ON I.R.F.

12) FILE WORKSHEET INTO CALIBRATION LOG

13) ATTACH NEW CERTIFICATION TAG TO GAGE

14) IF GAGE FAILS:

A REJECTION NOTIFICATION OR REJECTION WITH EXCEPTION MUST BE ISSUED. THE REJECTION

NOTIFICATION OR REJECTION WITH EXCEPTION MUST BE SIGNED BY OWNER OR IF COMPANY OWNED THE

MANAGER WILL SIGN. REFER TO QSP-4.11.2 FOR PROCESS CONCERNING PRODUCT MEASURE BY A FAIL

GAGE.

MANUAL INSTRUCTIONS (MICS, CALIPERS)

1) IDENTIFY TOOLS. IF NOT PREVIOUSLY ACCOMPLISHED, ASSIGN UNIQUE I.D. NUMBER AND LOG IN RECALL

SYSTEM.

2) VISUALLY INSPECT FOR DAMAGE. NICKS ON TIPS, BENT SPINDLE, ETC.

3) SELECT GAGE BLOCKS ACCORDING TO DATA SHEET.

4) READ GAGE AS IS ( DO NOT CLEAN MORE THAN THE BASE )

5) IF GAGE READS BAD, CLEAN AND REREAD, IF IT READS GOOD: NOTIFY DEPARTMENT SUPERVISOR THAT

THERE MAY BE SUSPECT MATERIAL WHICH WAS MEASURED BY THIS GAGE.

6) CHECK ZERO ON TOOL, ADJUST AS NECESSARY. USE O/D BLADES ON CALIPERS. FOR MICS BIGGER THAN

1 OR 25 MM; ZERO ON THE APPROPRIATE GAGE BLOCK ( I.E. 1-2 MICS USE 1 GAGE BLOCK).

7) USING GAGE BLOCKS VERIFY ACCURACY OF TOOL AT INTERVALS CALLED OUT ON THE DATA SHEET.

REPEAT STEPS 4&5 AS NEEDED.

8) PASS : AFFIX NEW CALIBRATION STICKER TO TOOL

9) FAIL: A REJECTION NOTIFICATION OR REJECTION WITH EXCEPTION MUST BE ISSUED. THE REJECTION

NOTIFICATION OR REJECTION WITH EXCEPTION MUST BE SIGNED BY OWNER OR IF COMPANY

OWNED THE MANAGER WILL SIGN. REFER TO QSP-4.11.2 FOR PROCESS CONCERNING PRODUCT

MEASURE BY A FAIL GAGE.

10) TOOLS THAT ARE ON COMPANY PROPERTY BUT ARE NOT USED, MUST BE CALIBRATED, LABELED AND

SEALED IN BAG.

AT NEXT CALIBRATION DUE DATE, IF BAG IS STILL SEALED, MAKE NEW LABEL AND

ATTACH TO GAGE

THEN RESEAL.

HAND TOOL R&R TRAINING(mic's, caliper's, hieght gage)

TOOL R&R REFERENCES:

1) REFERENCE TO QSP-4.11.2 & QSP-4.11.1 CAN BE FOUND IN THE Q.S. 9000 MANUAL TITLED (M.S.A.)

MEASURING SYSTEM ANALYSIS.

2) USE QSP-4.14.1 AS REFERENCE FOR FAILURE.

TOOL R&R FORMS:

4) QF-18 ( GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET) CAN BE FOUND IN THE CALIBRATION

FILE.

5) QF-18A (GAGE REPEATABILITY AND REPRODUCIBILITY REPORT) CAN BE FOUND IN THE CALIBRATION

FILE.

6) QF-25 (concern / matrix)

TOOL R&R INSTRUCTIONS

4) GATHER GAGES NEEDED:

A) 0-1 MIC

B) 0-6 DIGITAL CALIPER

C) 1 DIGITAL HEIGHT GAGE

5) MAKE SURE ALL GAGES ARE CLEAN AND IN GOOD WORKING ORDER.

6) CHECK GAGES ZEROING CAPABILITIES USING APPROPRIATE GAGE BLOCKS.

7) GATHER 10 DIFFERENT PARTS

8) TECHNICIAN #1 TAKES READINGS ON ALL 10 PARTS 3 TIMES. LOG READINGS ON WORK SHEET (QF-18).

THIS WILL TEST REPEATABILITY.

9) TECHNICIAN 2&3 WILL USE THE SAME GAGE, PARTS AND PROCESS AS TECHNICIAN 1. THIS WILL TEST

REPRODUCIBILITY.

10) THE CALIBRATION TECHNICIAN WILL LOG ALL READINGS INTO THE COMPUTER AND PRINT OUT REPORT

(QF-18A).

11) PASS: PLACE REPORT IN FILE LABELED GAGE R&R.

A) FAIL: IF FAILURE IS BY MORE THAN 20%, A CONCERN MATRIX (QF-25) MUST BE SUBMITTED TO THE

INSPECTION DEPARTMENT MANAGER.

REV 5

8-22-01

CMM R&R FOR CALIBRATION TRAINING

CMM R&R REFERENCE

1)

REFERENCE TO QSP-4.11.2 & QSP-4.11.2 CAN BE FOUND IN THE Q.S. 9000 MANUAL

TITLED (M.S.A.) MEASURING SYSTEM ANALYSIS.

GAGE R&R FORMS:

QF-18 (GAGE REPEATBILITY AND REPRODUCIBILTY DATA SHEET) CAN BE FOUND IN THE

CALIBRATION FILE.

2) QF-18A (GAGE REPEATABILITY AND REPRODUCIBILTY REPORT) CAN BE FOUND IN THE

CALIBRATION FILE.

3) QF-25 (concern / matrix)

1)

CMM R&R INSTRUCTIONS:

1) RETRIEVE CHECK AID.

2) GATHER 10 PARTS

3) FOLLOW LB506 OR GD&T FOR PINNING AND CLAMPING SEQUENCE

4) TECHNICIAN #1 TAKES READINGS ON 10 PARTS IN RANDOM ORDER 3 TIMES AND LOGS

READINGS ON FORM QF-18. (THIS WILL TEST REPEATABILITY)

5) TECHNICIAN #2 & #3 WILL USE THE SAME PROCESS AS TECHNICIAN #1. (THIS WILL TEST

REPRODUCIBILITY.)

6) THE CALIBRATION TECHNICIAN WILL LOG ALL READINGS INTO THE COMPUTER AND

PRINT OUT REPORT (QF-18A.)

7) PASS: PLACE REPORT IN FILE LABELED GAGE R&R.

8) FAIL: IF FAILURE IS BY MORE THAN 20% A CORRECTIVE ACTION REPORT (QF-25) MUST

BE SUBMITTED TO THE INSPECTION DEPARTMENT MANAGER.

REV 4

8-22-01

Вам также может понравиться

- Chapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Документ12 страницChapter 15. Monitoring and Measurement Resources Related: (Clause Description-Paraphrase)Vikram BillalОценок пока нет

- CNC HMC Acc CheckДокумент2 страницыCNC HMC Acc CheckKalees WaranОценок пока нет

- Iqc Chapter 01 PDFДокумент8 страницIqc Chapter 01 PDFNaveen Kumar GunisettyОценок пока нет

- Title: Process Validation Report of Stress Relieving: 1. AbstractДокумент3 страницыTitle: Process Validation Report of Stress Relieving: 1. AbstractCorrosion FactoryОценок пока нет

- F-05 Corrective Action FormДокумент1 страницаF-05 Corrective Action Formsuhara hussainОценок пока нет

- QA-R-12 Calibration History CardДокумент1 страницаQA-R-12 Calibration History CardRaja DuraiОценок пока нет

- BGL-FM-HR-38 Training Cum Effectiveness Record 01Документ2 страницыBGL-FM-HR-38 Training Cum Effectiveness Record 01Mohit SinghОценок пока нет

- Cutting Procedure WorkingДокумент3 страницыCutting Procedure Workingrial100% (1)

- Ensure Your Calibration Program Is Audit ReadyДокумент10 страницEnsure Your Calibration Program Is Audit ReadyThanasate SОценок пока нет

- Purpose:: Procedure Manual FifoДокумент3 страницыPurpose:: Procedure Manual FifoartiОценок пока нет

- QSP-010 Product Iden.&TraceabilityДокумент5 страницQSP-010 Product Iden.&TraceabilityJamal Mohamed Rahamathullah100% (1)

- 01.supplier Evaluation ProcedureДокумент1 страница01.supplier Evaluation ProcedureShaukatAliОценок пока нет

- AC 21-20B - Supplier Surveillance ProceduresДокумент10 страницAC 21-20B - Supplier Surveillance Procedurestwj84Оценок пока нет

- Centurion Power Cables (P) LTD.: 1.0 PurposeДокумент4 страницыCenturion Power Cables (P) LTD.: 1.0 PurposetriveshОценок пока нет

- Supplier Evaluation Checklist F-PU-05 - FILLEDДокумент2 страницыSupplier Evaluation Checklist F-PU-05 - FILLEDNav Talukdar100% (1)

- Master List of InstrumentsДокумент35 страницMaster List of Instrumentskrichenaraj6931100% (1)

- Centurion Power Cables (P) LTD.: Control of DocumentДокумент4 страницыCenturion Power Cables (P) LTD.: Control of DocumenttriveshОценок пока нет

- SOP of MachinesДокумент2 страницыSOP of MachinesSangram Kandekar100% (1)

- PQCS Tube Flange Rough - ForgingДокумент1 страницаPQCS Tube Flange Rough - ForgingBalram JiОценок пока нет

- Packaging Details: Vendor Name & AddressДокумент4 страницыPackaging Details: Vendor Name & AddressPk NimiwalОценок пока нет

- Audit Checklist (RM Store)Документ1 страницаAudit Checklist (RM Store)Mohamed ShabirОценок пока нет

- Internal Audit Observation ReportДокумент2 страницыInternal Audit Observation Reportsenk197100% (1)

- In-House Calibration SheetДокумент4 страницыIn-House Calibration SheetKannan MurugesanОценок пока нет

- PD-F 03 .Engineering Change Note - Internal & Sup. InitiationДокумент2 страницыPD-F 03 .Engineering Change Note - Internal & Sup. InitiationHarjeet SinghОценок пока нет

- JH SheetДокумент6 страницJH SheetAshish parmRОценок пока нет

- 23.sop - HRDДокумент4 страницы23.sop - HRDrishi gautamОценок пока нет

- Manufacturing Process of Piston IN Shriram Pistons & Rings LTDДокумент11 страницManufacturing Process of Piston IN Shriram Pistons & Rings LTDVipul SinghalОценок пока нет

- AE-QA-02 - First Piece Inspection ReportДокумент1 страницаAE-QA-02 - First Piece Inspection ReportKarthi ThiyagarajanОценок пока нет

- Control Plan PQCT TableII PDFДокумент1 страницаControl Plan PQCT TableII PDFRehman LatifОценок пока нет

- Manufacturing Process Audit: RatingДокумент3 страницыManufacturing Process Audit: Ratingrajesh.bОценок пока нет

- 07.01.05 Fabrication Galvanizing R1Документ11 страниц07.01.05 Fabrication Galvanizing R1Bhanu Pratap ChoudhuryОценок пока нет

- 10.2 Internal Audit ReportДокумент9 страниц10.2 Internal Audit ReportDhananjay Patil100% (1)

- In Process QC FormatДокумент9 страницIn Process QC FormatSunil ChaubeyОценок пока нет

- Samples Inspection ReportДокумент5 страницSamples Inspection ReportArun GuptaОценок пока нет

- In-House Verification or Calibration WI ExampleДокумент1 страницаIn-House Verification or Calibration WI ExampleSachin RamdurgОценок пока нет

- Caliper CalibrationДокумент3 страницыCaliper CalibrationBalamurugan BalahaisninОценок пока нет

- Root Cause Analysis - ToolДокумент11 страницRoot Cause Analysis - ToolmuneerppОценок пока нет

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Документ5 страницStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomОценок пока нет

- Anexo 06 - PA - Process Audit v1.1Документ19 страницAnexo 06 - PA - Process Audit v1.1BalajiОценок пока нет

- Contoh Form RMAДокумент1 страницаContoh Form RMAAgung NurfadillahОценок пока нет

- FINAL Inspection Report PO#KL-3448 PDFДокумент21 страницаFINAL Inspection Report PO#KL-3448 PDFArslan HaiderОценок пока нет

- 8.fixture Inspection ReportДокумент1 страница8.fixture Inspection ReportBASAVA ENGINEERINGОценок пока нет

- Department: Lab Auditor: AuditeeДокумент2 страницыDepartment: Lab Auditor: AuditeeAnkit SainiОценок пока нет

- In House PPM MonitoringДокумент2 страницыIn House PPM MonitoringSrinath NavadaОценок пока нет

- Melt Flow Work InstructionДокумент1 страницаMelt Flow Work Instructionsuresh kumarОценок пока нет

- Control of Monitoring and Measuring EquipmentДокумент3 страницыControl of Monitoring and Measuring EquipmentLinda Setya WatiОценок пока нет

- Mahabal Metals Pvt. LTD.: Induction TrainingДокумент3 страницыMahabal Metals Pvt. LTD.: Induction TrainingNitin KambleОценок пока нет

- Supplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingДокумент17 страницSupplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingRicky MarkОценок пока нет

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportДокумент2 страницыWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiОценок пока нет

- RMA and ReturnsДокумент19 страницRMA and Returnsविजय शर्माОценок пока нет

- Causes & Preventation of Defects (Burr) in Sheet Metal Component PDFДокумент5 страницCauses & Preventation of Defects (Burr) in Sheet Metal Component PDFMajad RazakОценок пока нет

- 4-04-1 Contract ReviewДокумент4 страницы4-04-1 Contract Reviewjeric bañaderaОценок пока нет

- FME-170011-DWRДокумент6 страницFME-170011-DWRKyОценок пока нет

- Car & Par ReportДокумент1 страницаCar & Par ReporthabibrgfОценок пока нет

- Quality Control: and Inspection SystemДокумент32 страницыQuality Control: and Inspection SystemAshley Kane P. DumayОценок пока нет

- Keerthi Engineering: Initial Production Part TagДокумент2 страницыKeerthi Engineering: Initial Production Part Tagkeerthi EngineeringОценок пока нет

- NcManagement - SA1 - 2021Документ13 страницNcManagement - SA1 - 2021Nagarajan100% (1)

- Al PSW FormatДокумент2 страницыAl PSW Formatabhayjha1988Оценок пока нет

- ExtinguisherДокумент1 страницаExtinguisherhoussОценок пока нет

- What Is Measurement RiskДокумент4 страницыWhat Is Measurement RiskhoussОценок пока нет

- Sample Thermohydrometer Y205188Документ5 страницSample Thermohydrometer Y205188houssОценок пока нет

- Attribute Gage R & R Effectiveness: InstructionsДокумент8 страницAttribute Gage R & R Effectiveness: InstructionshoussОценок пока нет

- Temperature Humidity Log SheetДокумент1 страницаTemperature Humidity Log SheethoussОценок пока нет

- Accuracy, Precision, and UncertaintyДокумент1 страницаAccuracy, Precision, and UncertaintyhoussОценок пока нет

- Uncertainty in ExcelДокумент6 страницUncertainty in ExcelhoussОценок пока нет

- AbsoluteДокумент3 страницыAbsolutehoussОценок пока нет

- Temperature Log (CCP) : Quality Systems RecordДокумент1 страницаTemperature Log (CCP) : Quality Systems RecordhoussОценок пока нет

- MIZ 22 User ManualДокумент192 страницыMIZ 22 User ManualMuhammad UmairОценок пока нет

- MFM Calibration CertificateДокумент16 страницMFM Calibration CertificatesanjayОценок пока нет

- 1175411I SNC Patient Software Reference Guide SДокумент564 страницы1175411I SNC Patient Software Reference Guide SZeka ValladolidОценок пока нет

- Brooks Instrument 3809G Datasheet CompressedДокумент20 страницBrooks Instrument 3809G Datasheet Compressedravichandran0506Оценок пока нет

- Calibration Certificate: Issued by An Accredited Calibration LaboratoryДокумент4 страницыCalibration Certificate: Issued by An Accredited Calibration LaboratoryAlireza GolpesarОценок пока нет

- Automated Clinical Chemistry Analyzer-2-2565Документ48 страницAutomated Clinical Chemistry Analyzer-2-2565อัมพกา ทองแท้Оценок пока нет

- Co2 LДокумент3 страницыCo2 LARIF AHAMMED P100% (1)

- 90012Документ273 страницы90012umsterfigoОценок пока нет

- The Physics of The AAPM's TG51 - RogersДокумент58 страницThe Physics of The AAPM's TG51 - Rogersphysics1947Оценок пока нет

- BR Shake The BoxДокумент16 страницBR Shake The BoxreflectorОценок пока нет

- Siwarex Cs Quick Guide v4 0Документ19 страницSiwarex Cs Quick Guide v4 0classic777Оценок пока нет

- GMP+ B2 (2010) - en 9236Документ48 страницGMP+ B2 (2010) - en 9236BartelloniОценок пока нет

- Iap Comp Digital Operational Manual v1.3Документ42 страницыIap Comp Digital Operational Manual v1.3byjurpОценок пока нет

- Nabl 130Документ11 страницNabl 130itisprasanthОценок пока нет

- 533 RMYoung Wind Monitor 05103Документ11 страниц533 RMYoung Wind Monitor 05103Brayan AlexisОценок пока нет

- 4 Gas RatiosДокумент56 страниц4 Gas Ratiosdrillinganaco95% (22)

- PTB Flouda EaP PTs 13528 NABs P - Day - 2Документ138 страницPTB Flouda EaP PTs 13528 NABs P - Day - 2shyne.galaponОценок пока нет

- DC Voltage/Current Generators/Calibrators: For Evaluating and Calibrating Precision Instruments and CircuitsДокумент2 страницыDC Voltage/Current Generators/Calibrators: For Evaluating and Calibrating Precision Instruments and CircuitsnameОценок пока нет

- CPP1000 M L ManualДокумент84 страницыCPP1000 M L ManualMohamed MusaОценок пока нет

- Hach HQ40-dДокумент3 страницыHach HQ40-dNizar AhmadОценок пока нет

- Six Sigma Template Worksheets NCSUДокумент35 страницSix Sigma Template Worksheets NCSUKioshiEvelynSakura50% (2)

- MEP Vol. 1.6 Automation and Alarm EquipmentДокумент47 страницMEP Vol. 1.6 Automation and Alarm EquipmentSaransh MotwaniОценок пока нет

- Étalonnage Des Capteurs de ForceДокумент13 страницÉtalonnage Des Capteurs de ForceWadie KhatiОценок пока нет

- PMT Hps Smartline Family Brochure 2021Документ12 страницPMT Hps Smartline Family Brochure 2021Comercial2 processОценок пока нет

- Water Depth Sensor MS5540C Arduino TutorialДокумент8 страницWater Depth Sensor MS5540C Arduino TutorialRohit JangidОценок пока нет

- UM-2D User ManualДокумент31 страницаUM-2D User Manualwahyu wibowoОценок пока нет

- Qav Basf Apr 2015Документ6 страницQav Basf Apr 2015Rika AnnelОценок пока нет

- Calibration and Calibration Verification: Clinical Laboratory Improvement Amendments (CLIA)Документ5 страницCalibration and Calibration Verification: Clinical Laboratory Improvement Amendments (CLIA)Ricky BatehОценок пока нет

- EMCEE 1152 InfoДокумент3 страницыEMCEE 1152 InfobnjaimahОценок пока нет

- Use of Remote Indicators Is ForДокумент11 страницUse of Remote Indicators Is Forcaat_06Оценок пока нет