Академический Документы

Профессиональный Документы

Культура Документы

Leather Industry of Bangladesh

Загружено:

Samin Yeaser KhanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Leather Industry of Bangladesh

Загружено:

Samin Yeaser KhanАвторское право:

Доступные форматы

Strategy and Structure of the Leather industry

NORTH SOUTH UNIVERSITY

MGT. 489

A Report on Strategy and Structure of Leather Industry

Prepared By

Nazmus Sakib Plabon

1120281030

Md. Mahmudul Haque

1120375030

Tamanna Binte Bashir

1120155030

Samir Yeasir Khan

1120420030

A.S.M. Asif Iqbal

1120089030

Tunazzina Rahman Elan

1120756030

Prepared For

Md. Shahed Alam

Lecturer

Department of Management

School of Business

North South University

Date of Submission 10th July, 2015

Strategy and Structure of the Leather industry

Executive Summary

This Report mainly deals with the Leather Industry of the whole world. We have first found out

the Global industry structure and found out that the womens wear is the biggest percentage and

also USA is the biggest in terms of industry value then comes China and Russia. Also the Global

financial condition of the leather industry is increasing but the revenue growth is decreasing, still

the industry is evolving in many countries. Then we found out some of the global issues

including the environmental issues for the leather industry.

Then in the next part we wrote about Bangladeshi leather industry in the global context and

found out that around 95% of the leather products produced in Bangladesh are exported in

foreign countries. Some export issues and also some problems the industry is facing in this

country is also mentioned. Finally we have done the industry analysis- Porters Five Forces

along with SWOT analysis and then the industry life cycle and ended with some

recommendation for improving the sector.

Strategy and Structure of the Leather industry

Table of Contents

Executive Summary

Introduction

Global industry structure

5-7

Global industry issues

8-10

Bangladesh in global context

11-13

Analysis

14-17

Conclusion

18

Strategy and Structure of the Leather industry

Introduction

The Government of Bangladesh has identified the leather sector as one with considerable growth

and investment potential ranked fifth in the export earning sector. Currently Bangladesh produces and

exports quality bovine and ovine, caprine (buffalo and cow; sheep and goat) leathers that have a good

international reputation for fine textured skins. However, the entire leather sector meets only 0.5% of the

worlds leather trade worth US$75 billion. There are about 113 tanneries in Bangladesh that produce 180

million square feet of hides and skins per year. In addition there are about 30 modern shoe manufacturing

plants engaged in the production of high-quality footwear, with over 2500 smaller footwear

manufacturers also present in the sector. There are around 100 small-to-medium leather goods

manufacturers, and a small number of niche larger manufacturers. The sector directly employs

approximately 558, 000 people. Most of the tanneries do not have proper effluent plants and generate 20,

000m3 tannery effluent and 232 tones solid waste per day. Tannery liquid and solid wastes are a potential

pollutant but also have a potential value. Specific technologies to convert wastes are required. These vary

from crude and simple to highly sophisticated and complex.

A proposed new leather park is expected to bring a clear transformation to the leather industry with

marked increase in production, product diversification and new product lines with increased sustainability

of the sector. Sustainable and cleaner production will be a key issue for the development without placing

burdens on the environment.

The leather industry in Bangladesh is well established and is an important foreign exchange earner.

Leather production is based on the use of indigenous cowhides and goatskins. Two opportunities for

increasing export value of the leather industry are: A) Increasing value addition of the exported products

through exporting only finished leather and leather products; and B) importing raw hides or skins if

necessary, and converting these to leather and leather products to utilize the production capacity as much

as possible.

Strategy and Structure of the Leather industry

Global Industry Structure

The global footwear and leather industry is facing a stable growth rate which is due to changing

fashion trends. The industry has experienced a sustainable development because of driving factors

such as active lifestyle, increasing demand for new innovative and comfortable designs, growing

awareness about healthy products, rising population, increasing disposable income levels, and rise

in retail culture. So the footwear and leather industry has an expanding market.

Total global sales

Total global Sales of footwear and leather industry hit 190 billion in the year 2014. Industry growth

rate is 4.1%. Global economic recession reduced demand for footwear in the last five years. But

still, the industry revenue grew over the time period as demand from newly emerging nations hold

up the industry even when spending in the United States and Europe reduced.

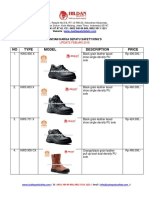

Global Sales Breakdown by category:

Category

Womens wear

Mans wear

Foot wear

Childrens wear

Accessories

Hosiery

Percentage of sales

39%

25%

20%

9%

4%

3%

Accessories

Hosiery

4%

3%

Childrenswear

9%

Foot wear

20%

Global Sales by Category

Womenswear

39%

Menswear

25%

The top three market account for 40% of total global sales. These three markets are USA, China

and Russia. The total value of market size and per capita spending:

Strategy and Structure of the Leather industry

Country

Total value of market

size

Per capita spending

USA

China

Russia

$67 billion

$52 billion

$21 billion

$212

$38

$145

Financial performance trends

The global footwear and leather industry was worth USD 185.2 billion in 2010. The industry is

expected to reach USD 211.5 billion in 2018. In the global foot wear and leather industry, Asia

Pacific is expected to gain lead position in terms of sales till 2018. It is forecasted that Asia Pacific

will enjoy 30.1% of the global footwear and leather industry revenue share in 2018 followed by

Europe.

Industry Revenue: in last five years industry revenue is showing an increasing trend. Revenue

increased from $118.5 billion in 2011 to $126.9 billion in 2015.

Industry Revenue ($)

2010

2011

2012

2013

2014

118.5

122.1

125.3

125.9

126.9

Revenue

Revenue in Dollar

$128.00

$126.00

$124.00

$122.00

$120.00

$118.00

$116.00

$114.00

2010

2011

2012

2013

2014

Revenue growth trend: Though the total value of the industry and revenue increased over the

last five years, the revenue growth rate slowed down than before.

Revenue Growth rate

2010

2011

2012

2013

2014

4.1%

3%

2.6%

0.5%

0.8%

Industry Concentration:

The industry is considered to have a low concentration level. The top five players in the industry

is account for around 12% of total industry revenue. But in future the level of industry

concentration is expected to increase. In the next five years as companies will merge or

consolidate operations the industry concentration level will increase.

Strategy and Structure of the Leather industry

Revenue growth rate

5.00%

4.00%

3.00%

2.00%

1.00%

0.00%

2010

2011

2012

2013

2014

Major geographic markets Relative sizes:

Major geographic markets in terms of consumption:

Region

China

Asia (excluding China)

Europe

North & Central America

Africa, Middle East, Oceania

South America

Total

Units (Million)

2,768

2,706

2,544

2,381

1,172

898

12,469

Percentage of total

22.2%

21.7%

20.4%

19.1%

9.4%

7.2%

100

In terms of global per capita consumption the top three markets are America (3.9), Europe (3.5),

and Asia (1.5).

Top ten Companies with their sales (2014):

Company

Nike (USA)

Adidas (Germany)

Reebok (UK)

Puma (Germany)

Converse (USA)

New Balance (USA)

Fila (Italy)

K-Swiss (Switzerland)

Asics (Japan)

Li-Ning (china)

Sales (million)

27.79

14.53

11.79

9.97

6.75

4.37

4.09

3.67

2.46

2.33

Strategy and Structure of the Leather industry

The Industrys Global Issues

The leather and its related downstream industries can claim to be the world's largest industrial sector

based upon a by-product. In the case of leather, the raw material is a by-product of the meat industry.

Hides and skins and their downstream products are vital earners of foreign exchange and they

compare very well with the other agricultural commodities and, in fact, with any internationally

traded commodities. This industry helps convertible a putrescible material into a stable and

marketable product. There are a few key issues this industry faces they are described below:

Environmental Impact of Leather Industry

The leather sector is well known for its effluent problems. The polluting nature of tanneries is evident

from the notorious odor that characterizes tanneries and tannery zones. While local populations are

daily aware of the air pollution, local authorities are equally, if not more concerned about tanneries'

liquid effluents which tend to be high in organic and inorganic suspended solids content

accompanied by propensities for high oxygen demand and containing potentially toxic metal salt

residues. Treatment technologies in effect reduce pollutants in the liquid form and convert them into

semi-solid or solid forms. Threat is being transferred from receiving waters to receiving land.

Because sludge can affect the quality of soil and groundwater, it is understandable that local

authorities and governments should be concerned that the disposal of sludge to soils and dry wastes

to landfill should not adversely affect the fertility of soil, nor that metal salt residues, such as

chromium, should inhibit crop growth in any way.

Technology Developments

The quality of finished leather depends on a combination of the original properties in the natural hide, and

the chemical and physical components added during the manufacturing process. New technologies are

being invented every year that make leather more versatile, more colorful and more appealing as an

alternative to woven fabrics and plastic.

Trending new: Special chemical treatments can enhance the fireproof qualities of leather to

supplement its natural heat resistance properties. This increases the safety of using leather in

applications where fire resistance is important like movie theatres, salons, cars, aero planes and

upholstery. Fireproof leather can even be used for common products like potholders that adhere

to any surface for a better grip.

A rainbow of choices: Purple leather? Advancements in the finishing processes make it possible

to produce leather in any color you can imagine in addition to traditional shades of brown and

black. Many internationally recognized designers are choosing leather to replace synthetic and

Strategy and Structure of the Leather industry

dyed fabrics in stunning new designs. From futuristic chic to natural glamour, leather is fast

becoming the first choice for apparel thats soft, stunning and sexy. Even protective clothing

made from leather has become stylish, with a fit and finish thats as appropriate on a Parisian

fashion runway as an airport runway.

Designers are also using leather for their latest products, working closely with tanneries to

develop leather with unique new properties like water resistance, not to mention a rainbow of

colors, textures and finishes that look and feel right in any room.

A new kick: When it comes to sports equipment, nothing can match the strength, abrasion

resistance, durability and flexibility of leather for footballs, equestrian harnesses, sport gloves,

baseball mitts and the safety equipment worn by athletes everywhere from the jogging track to

the ski slopes. Its no accident that motorcycle enthusiasts rely on leather for their

outerwearits the ultimate in protection from the elements, not to mention the asphalt.

Just like mom: When babies are born, the infants are often laid on a blanket made

ofleather! The soft, warm qualities of leather are far superior to other materials for the critical

moment when the child is first separated from its mother. This particular kind of leather must be

baby-proof through careful selection and processing to make it soft, safe and comfortable.

New Markets

The African leather sector is bursting with potential, but there is a wide gap between resources and

production. ITC's development program has galvanized the sector. The numbers tell the story: African

countries have 15% of the world's cattle and 25% of its sheep and goats, but produce only 14.9% of

global output of hides and skins - 8% of bovine hides and 14% of sheep and goat skins. Exports of hides

and skins have fallen in recent years to below 4%, yet leather is ranked very high as an export commodity

in several African countries. The countries' tanning capacity has fallen from 9.2% to 6.8%. At the same

time, the livestock population has jumped about 25% over the last decade, faster than the world trend.

The numbers tell the story: African countries have 15% of the world's cattle and 25% of its sheep and

goats, but produce only 14.9% of global output of hides and skins - 8% of bovine hides and 14% of sheep

and goat skins. Exports of hides and skins have fallen in recent years to below 4%, yet leather is ranked

very high as an export commodity in several African countries. The countries' tanning capacity has fallen

from 9.2% to 6.8%. At the same time, the livestock population has jumped about 25% over the last

decade, faster than the world trend.

Strategy and Structure of the Leather industry

Regulatory Issues

The personal leather goods and footwear manufacturing industries are regarded as environmentally

friendly ones. Very little problem waste is generated in the manufacture of products. Many thermoplastic

materials are recycled including the newer developments in toe puff and counter materials. Solvents are

used in sprays and cement attaching. However these are being replaced by water based finishes and

adhesives. The result of this clean technology is that there are few extra regulations imposed on the

industry.

The tanning industry produces large amount of chemical and waste which is very bad for environment

and in some countrys regulations do not allow this. Regulation from government are very strict under

this circumstances.

PETA (people for the ethical treatment of animals) have lobbied hard in the leather goods industry to the

extent that some buyers refuse to order shoes made with Indian leather particularly in Germany. For some

years the EU has been pushing for an eco-label to be used on all footwear signifying its ethical and nonpolluting origins. This is a voluntary code at present.

Don't buy leather goods from Bangladesh. Save River Buriganga from Hazaribagh Tannerieswas the

core of the slogans by Human Right Watch (HRW)--the international right organization--which organized

the campaign alleged that leather tanneries in Dhaka city have been releasing toxic effluent into a densely

populated neighborhood for decades. It urged foreign buyers at the fair not to buy products from

companies that don't abide by labor and environmental laws meant to protect people. The

environmentalists still hold the same position on Bangladesh leader products.

10

Strategy and Structure of the Leather industry

Bangladesh Leather Industry in global context

Leather Industry grew in Bangladesh on an extensive scale premise from the 1970s. Around 95%

of leather and leather products of Bangladesh are promoted abroad, for the most part as smashed

leather, completed leather, leather articles of clothing, and footwear. Most leather and leather

merchandise go to Germany, Italy, France, Netherlands, Spain, Russia, Brazil, Japan, China,

Singapore and Taiwan. Esteem expansion in these fares midpoints 85% nearby and 15% outside.

Around 100 current tannery units are presently in operation in the business. These are found for

the most part in the Hazaribagh territory of Dhaka city. In 1998, the segment sent out 178 million

sqft of leather and earned $160 million. The countrys share in leather business sector is 2%. The

fare of completed items, for example, shoes, slippers, leather coats, hand gloves, packs, handbags,

wallets, and belts likewise gain a sizeable measure of remote trade. Bangladesh expects to expand

its scope of leather items to infiltrate new market sections.

Amid the 1990s, the export market for Bangladeshi leather developed at a normal of 10 - 15% for

every annum. The normal yearly fares represented $225 million. Fine grain leather of Bangladesh

appreciates particular request in Western Europe and Japan. Low wage level and the boycott on

trading wet blue leather helped the business get another push in the nation. Natural concerns

emerging out of the high convergence of creation units in a little range of the more seasoned piece

of Dhaka city are being tended to with arrangements for their movement outside the city.

Around 40% of the supply of hide and leather originates from animals butchered during the yearly

Muslim celebration of eid-ul-Azha. Notwithstanding every day utilization of meat, celebrations,

Muslim weddings, and different festivals yield a significant supply of hide and leather. The tanning

business got a major support taking after the administration choice to advance more esteem

expansion in fares. The introduced limit for hull leather creation expanded. At present, it is twofold

the local supply of crude shroud and leather. Speculations are additionally made in putting in new

completing limit. The patterns urge more tanneries to deliver completed leather on a business

premise.

The producers accept Bangladesh's yearly $550-million footwear industry may develop to a $15billion division inside of a couple of years, if the open door is seized. Leather sector representatives

say outside business visionaries are occupied with Bangladesh's footwear, because of the

accessibility of crude conceal, handling foundation, low work expense, and a large number of

government motivators including obligation free machinery imports. At least 51 foreign

organizations had effectively communicated enthusiasm for building up joint-venture footwear

units in Bangladesh.

11

Strategy and Structure of the Leather industry

As indicated by the Export Promotion Bureau (EPB), Bangladesh earned $ 1.29 billion from fares

of leather, leather products and footwear in the 2013-14 fiscal. The sum represents 4.2 percent of

the nation's aggregate exports. Footwear alone gotten $550 million in outside trade of the leather

part's aggregate fare earnings. In the 2012-13 FY, the footwear division's fare income remained at

$419.3 million. Bangladesh has kept up the development in the fare of leather and leather

merchandise in the current 2014-15 FY, too. In the initial eight months of the FY, the nation posted

a 7 percent development in leather products sends out and 22.16 percent in footwear trades.

As indicated by the Leather Goods and Footwear Manufacturers and Exporters

Association (LGFMEA) 110 fare arranged production lines fabricate footwear in the nation. Of

them, Apex, FB, Picard Bangladesh, Jenny's, Akij, RMM Bengal and Bay have their own tanneries

and leather preparing units.

Problems of Bangladesh Leather and Footwear Export Sector

1) Absence of a coordinated far reaching approach with legitimate inputs by every one of the

stakeholders, for example, exporters, government, suppliers and purchasers.

2) A little number of manufacturing plants that have been set-up by for the most part

unpracticed business people and ever anxious hardware suppliers, who have utilized the

myth of the purchase back understandings to push their machine deals. These processing

plants all things considered have been not able to get off the ground in spite of extensive

interest in machineries and infrastructure.

3) An aggregate absence of enough prepared and talented Human Resource for production

and in addition for administrative work force in the leather footwear industry.

4) Absence of training institute for proper skill and technological development.

5) No supporting industry as far as linkage processing plants, for example, endures, cutting

kicks the bucket and so on, so there is a high import reliance in this way decreasing cost

intensity and additionally expanding lead times.

6) Low awareness in the foreign buyers as amount of factory working in industry is very low.

7) Deficient co-operation & co-appointment between different controllers, strategy creators

and stakeholders of the business. At times duplication of endeavors by different

organizations particularly benefactors is happening.

8) No simple access to the nearby market for exporters, making them very powerless against

the dangers of stock parts and retractions. In China and additionally India up to half of the

aggregate yield can be sold onto the local market, whilst as yet getting a charge out of

12

Strategy and Structure of the Leather industry

exporter status. In difference, in Bangladesh nearby deals are saddled at such high rates of

obligation which makes the cost too high for the mass market.

9) Disparity in the import strategy where the import obligation on completed shoes and on

shoe parts and embellishments is just about the same, in this way there is no point of

preference for producers. Today the nearby shoe industry is in effect extremely undermined

by shabby imports that are being carried and dumped from neighboring nations, for

example, Myanmar and India. For this many of the manufacturers are losing interest in the

leather industry.

10) No familiarity with global quality benchmarks, for example, Eco- labeling and packaging,

occupational standards and environmental management requirements and their growing

importance to foreign buyers.

Recommendations for improving this sector and to make it more profitable

Supporting an advertising battle particularly in Canada, USA, EU, and Japan to advance

the picture "MADE IN BANGLADESH".

Ensuring consumer safety and international standard of packaging to improve marketing

of leather and leather goods

Guaranteeing labour safety and work consistence issues to enhance international reputation

and image.

Acquainting successful measures with secure environment and enhance worldwide image

and reputation.

Rationalized tariffs and access to the local market for exporters should be allowed so that

this sector does not suffer from stock lots and cancellations.

Taking the activity to make makers and exporters mindful of global quality gauges, Ecolabelling and packaging, occupational standards and environmental management

requirements and their growing importance to international market.

Making value addition for high esteem things adaptable with the goal that high esteemed

leather and leather goods get to be competitive on international business market.

Setting up world class training and research offices, for example, a Leather Research

Institute, Footwear Development and Design Institute and keeping an eye on these with

profoundly experienced and prepared educators and experts to guarantee advancement of

this sector.

Making training centers for potential employees and laborers of this division, and provide

them proper education facilities to understand this sector properly.

Managing shipment charges so it doesn't impact the competitiveness of this sector.

Creating and presenting new and imaginative installment terms for purchasers to gain

competitive advantage.

Giving financial support to the regressive linkage commercial ventures of this segment.

13

Strategy and Structure of the Leather industry

Five forces analysis

The Industry of leather products

Porter five forces

Intensity

Competitive rivalry

High

Bargaining power of buyers

Medium

Bargaining power of suppliers

Medium

Entry barriers

High

Threat of substitute products

High

Competitive rivalry within the industry

The structure of the industry is oligopoly, which means there are numerous and equally

balanced competitors in producing luxury leather goods .Especially some famous big

companies which have their brand equity.

There have already exist many good brands which have long history and impressive brand

stories behind it, such like Louis Vuitton,Chanel,Gucci,Dior.etc. Which have already

occupied a large amount of market share and have good brand effect among customers. So it

can be very hard to get the market share for the participants of the industry.

Leather products of differentiation counts a lot. The target customers of the industry is the

wealthiest people who purchase higher buying experience so the goods need to be

distinguished enough which influence their view towards the brand.

High exit barriers. Emotional barriers some brands may not break even but continue operating

due to a small number of loyal customers. Also the specialized supply chain components to

produce leather goods are hard to sell or cant be easy to put it into other usage

Bargaining power of buyers

The bargaining power can be week, when the target customers have high brand loyalty and

they tend to have high emotional switching costs, which decide their consuming behaviors

towards one brand.

The buyers of the industry has low concentration, and the bargaining power of the buyers is

week.

Because of the products of the luxury industry are unique designed and most of them are done

in-house. So, the buyer has poor information about demand, actual market prices and even

supplier cost so that the bargaining power is week.

But the bargaining power also can be strong when the target customers focus on the

14

Strategy and Structure of the Leather industry

luxury itself, which means they just care about whether the products are luxury or not .And

there are a lot of other alternatives like cars, watches etc. for them to choose from besides

luxury leather products ,which also show the public their wealth and fame.

-Bargaining power of suppliers

The bargaining power of suppliers is strong when the resources are special and only from

some specific areas. The leather of LV is resourced from the cattle from the northern Europe

area.

The bargaining power of suppliers is week when the resources are general and there are a lot

of supplies to provide the material.

-Entrance barriers

The barriers of the entrances are strong, there already exist top brands in the industry.

Hard to get the market share for new entrants, because of many competitors.

Also the large amount of capital is needed enter the industry to make up with the brand equity.

More and more exclusive access to suppliers and hard to get a market share.

-Treat of substitute products

The target customers have many other choices to pursue the luxury products, the treat can be

very strong.

High

High

Medium

High

Medium

15

Strategy and Structure of the Leather industry

16

SWOT Analysis of leather industry

Strengths

High Growth

Ready availability of highly skilled and

cheap manpower

Large raw material base

Policy

initiatives

taken

by

the

Threats

Government

Capability to assimilate new technologies

and handle large projects

Continuous

emphasis

unorganised

on

product

development and design upgradation

Opportunities

Major part of the industry is

Limited scope for mobilising funds

through private placements and

public issues (many businesses

Rising potential in the domestic market

Growing fashion consciousness globally

Use of information technology and decision

are family-owned)

resulting in high cost of private

support software to help eliminate the

Difficulty in obtaining bank loans

borrowing

length of the production cycle for different

Stricter international standards

products

High

Use of e-commerce in direct marketing

competition

from

East

European countries and other

Asian countries

Weaknesses

Lack of communication facilities

and skills

Lack of warehousing support from the

government

International price fluctuation

Lack of strong presence in the global

fashion market

Strategy and Structure of the Leather industry

Unawareness of international standards

by many players

The Stage in Industry life cycle:

From the above analysis and the information provided, it is clear that the industry is in growth

stage. Form the SWOT analysis, we saw that there is still a threat of new entrants and only a

growth market has the most capability to get threats of new entrants. We see every now and then

that new companies are coming to the markets with their leather goods and footwears. Not only

the big brands but also some small and medium size non-brand companies are also coming to the

markets, especially the tanneries are opening their own leather goods outlets just to enter into the

leather goods and footwear market directly from the raw tanned leather market.

17

Strategy and Structure of the Leather industry

Conclusion

Developed countries are treating Bangladeshs leather sector as a secure for investment.

However, the sector has a rather constrained demand structure in the domestic market due to the limited

national purchasing power. Nevertheless, industry insiders are expecting a growth in the domestic market

in consideration of the fact that approximately 10% of Bangladeshs total population (around 15 million)

is estimated to have an income level comparable to that of the developed countries. Hence, there appears

to be a large unexplored domestic market for footwear and other leather products for Bangladesh with an

estimated demand for 30 million pairs per year. The footwear sub-sector of Bangladesh earned revenues

in excess of US$250 million in 2010-2011. The European Union (EU) is the biggest destination for

footwear exports with a 60% share, followed by Japan with 30%, and the rest of the world accounting for

10%. Bangladesh has only a 1% share of the world footwear market.

There are about 49, 300 tons of solid waste generated every year from tanneries in Bangladesh. The

government should try to facilitate growth in industries which can use these wastes to make other value

added products. A by-product manufacturing unit (chrome and protein recovery) and energy generation

could be useful options.

Bangladeshi leather products will have no access to developed countries, including those of European

Union if the government fails to set up the CETP by June 2014. The industry in Bangladesh as a whole

faces considerable concerns with regard to end-of-life, recycling and re-use of leather and leather products.

To make progress, the Government is keen to relocate tanneries from Hazaribagh to Savar, this gives the

unique opportunity to adopt sustainable practice in a suitable environment.

18

Вам также может понравиться

- Bangladeshi Leather IndustryДокумент8 страницBangladeshi Leather IndustrySyed Nayem100% (1)

- Leather Industry PresentationДокумент18 страницLeather Industry PresentationSara Pervez100% (1)

- Leather FinalДокумент58 страницLeather FinaletayhailuОценок пока нет

- Leather Goods FinalДокумент15 страницLeather Goods FinalImran1978Оценок пока нет

- Leather ExportsДокумент24 страницыLeather ExportsMehwishAbidОценок пока нет

- Dry FinishingДокумент3 страницыDry FinishingRonik JОценок пока нет

- Introduction To Bangladesh Leather IndustryДокумент28 страницIntroduction To Bangladesh Leather IndustryMostafa Noman DeepОценок пока нет

- Leather Industry of BangladeshДокумент7 страницLeather Industry of BangladeshAheen ImtiazОценок пока нет

- Contribution of The RMG Sector To The Bangladesh EconomyДокумент31 страницаContribution of The RMG Sector To The Bangladesh Economyfjaman31367% (3)

- Organization Study On LeatherДокумент32 страницыOrganization Study On LeatherMohammed ShaiqОценок пока нет

- Different Shoes Materials and Their FeaturesДокумент20 страницDifferent Shoes Materials and Their FeaturesAnamikaОценок пока нет

- Quality Control-Notes Presentation - Chongeri Azaria Mikas Leather Dit MwanzaДокумент81 страницаQuality Control-Notes Presentation - Chongeri Azaria Mikas Leather Dit MwanzaAzaria MikasОценок пока нет

- A Blueprint of African Leather IndustryДокумент86 страницA Blueprint of African Leather IndustryZaib KhanОценок пока нет

- Unit-4 Leather GradingДокумент19 страницUnit-4 Leather GradingumidgrtОценок пока нет

- 2 ( (Pec 1Документ132 страницы2 ( (Pec 1Advendro ChandraОценок пока нет

- A Report On Leather Leather Goods Industry of BangladeshДокумент13 страницA Report On Leather Leather Goods Industry of BangladeshProdip DasОценок пока нет

- B.Tech. Leather Technology: CurriculumДокумент45 страницB.Tech. Leather Technology: Curriculumdebjit senОценок пока нет

- Leather Industry of BDДокумент30 страницLeather Industry of BDsams zeesha100% (1)

- Leather: Classification of Animal SkinДокумент12 страницLeather: Classification of Animal Skinprottoy8787Оценок пока нет

- Disha Gopal: Vegan Leather or Pleather or LeaderetteДокумент26 страницDisha Gopal: Vegan Leather or Pleather or LeaderetteUday DokrasОценок пока нет

- Nonwoven IndustryДокумент6 страницNonwoven IndustryGaurav SachanОценок пока нет

- Leather-Goods Survey 70556Документ51 страницаLeather-Goods Survey 70556navnaОценок пока нет

- Since 1989 Da Milano Is An Integral Leather Brand That Manufactures and Retails High End Leather Bags and Accessories For Both Men and WomenДокумент21 страницаSince 1989 Da Milano Is An Integral Leather Brand That Manufactures and Retails High End Leather Bags and Accessories For Both Men and WomenPrerna Aggarwal100% (1)

- Studies On The Production of Football Leather From Cow HideДокумент40 страницStudies On The Production of Football Leather From Cow Hiderubelbclet100% (1)

- Various Type of Fabric Cutting Machines: Anirban Sikder Yogesh KadianДокумент19 страницVarious Type of Fabric Cutting Machines: Anirban Sikder Yogesh KadianYogesh KadianОценок пока нет

- Leather-Tanning DD 1982 PDFДокумент478 страницLeather-Tanning DD 1982 PDFwahaj afridiОценок пока нет

- Disha Gopal: Vegan Leather or Pleather or LeaderetteДокумент25 страницDisha Gopal: Vegan Leather or Pleather or LeaderetteUday DokrasОценок пока нет

- Materials For Athletic and Sports Shoes Upper, Midsoles and OutsolesДокумент4 страницыMaterials For Athletic and Sports Shoes Upper, Midsoles and OutsolesH S EngineersОценок пока нет

- Glossary of Leather Terms - ALCAДокумент33 страницыGlossary of Leather Terms - ALCAAnik AlamОценок пока нет

- Leather Alternatives and Where To Buy ThemДокумент8 страницLeather Alternatives and Where To Buy ThemVegan FutureОценок пока нет

- A Quick Review of Emerging Leather Sector of BangladeshДокумент10 страницA Quick Review of Emerging Leather Sector of BangladeshAtabur RahmanОценок пока нет

- Learning Material: 103 Footwear Materials TechnologyДокумент5 страницLearning Material: 103 Footwear Materials TechnologySbl IrvОценок пока нет

- Export-Import Procedure and Documentation: Topic: Exporting Leather Products To Germany Hussain Chunawala Roll No. 07Документ29 страницExport-Import Procedure and Documentation: Topic: Exporting Leather Products To Germany Hussain Chunawala Roll No. 07Thomas KevinОценок пока нет

- Patent LeatherДокумент10 страницPatent LeathervinothjohnnashОценок пока нет

- Adhersives & BondingДокумент19 страницAdhersives & BondingSavindra SilvaОценок пока нет

- Hotel Management System Correct Final SRSДокумент12 страницHotel Management System Correct Final SRSಶ್ವೇತ ಸುರೇಶ್Оценок пока нет

- Leather Burnishing & Polishing: Existing ProcedureДокумент6 страницLeather Burnishing & Polishing: Existing ProcedurevinothjohnnashОценок пока нет

- Processing of Leather by Microbial EnzymeДокумент13 страницProcessing of Leather by Microbial EnzymeSajjad Hossain Shuvo100% (1)

- Environmental Impact of Leather IndustryДокумент35 страницEnvironmental Impact of Leather IndustryMisganaw MekonnenОценок пока нет

- 4 Day Practical Leather TechnologyДокумент4 страницы4 Day Practical Leather Technologyemmanuel byoОценок пока нет

- Leather Processing PDFДокумент13 страницLeather Processing PDFsd100% (3)

- PC AdmixДокумент8 страницPC AdmixosamaОценок пока нет

- Footwear Testing at LASRA BOOKLETДокумент12 страницFootwear Testing at LASRA BOOKLETAqidah MutaharahОценок пока нет

- Pak Leather Crafts Limited PakistanДокумент24 страницыPak Leather Crafts Limited Pakistansherazhasan22Оценок пока нет

- Role of Phthalic and Glycolic Acids To Increase Chromium Uptake in Leather Tanning ProcessДокумент7 страницRole of Phthalic and Glycolic Acids To Increase Chromium Uptake in Leather Tanning ProcessAdvanced Research PublicationsОценок пока нет

- Tayyaba ReportДокумент19 страницTayyaba Reportsidra abdal100% (2)

- Pollution of Leather IndustryДокумент70 страницPollution of Leather IndustryBalaji GajendranОценок пока нет

- Niir Leather Processing Tanning Technology HandbookДокумент7 страницNiir Leather Processing Tanning Technology HandbookThahseen AfzalОценок пока нет

- Leather and FootwearДокумент10 страницLeather and FootwearArun SudarshanОценок пока нет

- AДокумент80 страницAhowardalistairroarkОценок пока нет

- Polyester Partially Oriented Yarn (POY)Документ7 страницPolyester Partially Oriented Yarn (POY)Dalia MokhmaljeОценок пока нет

- What Is Fluid?: Deforms Shear Stress Phases of Matter Liquids Gases Newtonian Fluids Non-Newtonian FluidsДокумент13 страницWhat Is Fluid?: Deforms Shear Stress Phases of Matter Liquids Gases Newtonian Fluids Non-Newtonian FluidsTan Wei TingОценок пока нет

- Leather Compendium2013Документ193 страницыLeather Compendium2013Satyadev RajuОценок пока нет

- Pollution Reduction in An Eco-Friendly Chrome-Free Tanning andДокумент8 страницPollution Reduction in An Eco-Friendly Chrome-Free Tanning andDavid Jacobo Ramirez ViedmaОценок пока нет

- Case Study Part of Lijjat PapadДокумент6 страницCase Study Part of Lijjat PapadaddityasurveОценок пока нет

- World Livestock PopulationДокумент5 страницWorld Livestock PopulationAnil PalliОценок пока нет

- Leather Companies BangladeshДокумент10 страницLeather Companies Bangladeshgzelle444Оценок пока нет

- Literature Review On Leather IndustryДокумент8 страницLiterature Review On Leather Industryafdttjcns100% (1)

- LeatherДокумент15 страницLeatherSingh Nitin80% (5)

- Arcteryx 2011Документ36 страницArcteryx 2011Marcelo Laranga100% (2)

- Leather Dye - Leather ColorДокумент15 страницLeather Dye - Leather ColorUday DokrasОценок пока нет

- Eco-Friendly Leather: Durable and Crack-Resistant Shoe UppersДокумент4 страницыEco-Friendly Leather: Durable and Crack-Resistant Shoe UppersInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Leather Industries of BangladeshДокумент28 страницLeather Industries of BangladeshMamun BappyОценок пока нет

- Thesis LeatherДокумент2 страницыThesis LeatherbablubhokalОценок пока нет

- Bag Tanning IndiaДокумент8 страницBag Tanning IndiaBurhoneySonОценок пока нет

- LE 3101, Finishing OperationsДокумент17 страницLE 3101, Finishing OperationsRupokОценок пока нет

- BASF Products Leather Industry-Binders PDFДокумент72 страницыBASF Products Leather Industry-Binders PDFMuhammad Hassan83% (6)

- Business Project 2014Документ120 страницBusiness Project 2014Ali BasraОценок пока нет

- Progrip 2011 CatalogДокумент96 страницProgrip 2011 CatalognobodyInOrbitОценок пока нет

- Italy ExportДокумент5 страницItaly ExportAjit PatelОценок пока нет

- Case Facts - HidesignДокумент11 страницCase Facts - HidesignVarunОценок пока нет

- Leather and Leather Products SectorДокумент2 страницыLeather and Leather Products Sectornehad898989Оценок пока нет

- Calligaris 2010 CatalogДокумент223 страницыCalligaris 2010 Catalogwww.everything4less.comОценок пока нет

- HS Code For Annex C PDFДокумент28 страницHS Code For Annex C PDFMohammad AsharОценок пока нет

- Catálogo Protech-8Документ13 страницCatálogo Protech-8Harry Orlando AlvarezОценок пока нет

- Saira Review PaperДокумент11 страницSaira Review Paperamala josephОценок пока нет

- Craftool Conversion ChartДокумент8 страницCraftool Conversion ChartAndré SilvaОценок пока нет

- Katalog King's Baru LengkapДокумент8 страницKatalog King's Baru LengkapurzaОценок пока нет

- Sample CV of A Leather TechnologistДокумент3 страницыSample CV of A Leather TechnologistTarik Aziz Khan0% (1)

- Tannery ReportДокумент6 страницTannery ReportdevajithОценок пока нет

- Strictly Confidential: TeaserДокумент18 страницStrictly Confidential: TeaserKhasar GanbaatarОценок пока нет

- YogeshДокумент5 страницYogeshYogesh SharmaОценок пока нет

- Unit 8 Documentation in Cutting Room: StructureДокумент11 страницUnit 8 Documentation in Cutting Room: StructureHarry AryanОценок пока нет

- Case Study ENT600Документ22 страницыCase Study ENT600auni75% (8)

- Uganda Project ProfilesДокумент42 страницыUganda Project ProfilesRahulKumbhareОценок пока нет

- Cricket Ball Manufacturing: Submitted To, Prof. Mr. Michael BeckerДокумент9 страницCricket Ball Manufacturing: Submitted To, Prof. Mr. Michael BeckerSurbhi SharmaОценок пока нет

- RevenueДокумент181 страницаRevenueKrishna Chaitanya V S0% (2)

- 2017 Russia Clothing Textile Sector 1Документ15 страниц2017 Russia Clothing Textile Sector 1FIERY TrackОценок пока нет