Академический Документы

Профессиональный Документы

Культура Документы

Class T ('Joffre Olefins')

Загружено:

Zvonko Bešlić0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров7 страницpiping class

Оригинальное название

Class t ['Joffre Olefins']

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документpiping class

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

9 просмотров7 страницClass T ('Joffre Olefins')

Загружено:

Zvonko Bešlićpiping class

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

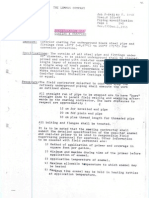

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION PAGE: tof 7

—

CONDENSATE

rating: dV 1000 PSIG (6895 kPag) MAX PRESS AT 250°F (121°C).

800 PSIG (5516 KPAG) MAX PRESS AT 275°F (135°C).

NOTES; 1 REDUCER SCHEDULE NUMBER OR WEIGHT CLASS.

SHALL BE THE LARGER OF THE TWO PIPES WHICH ARE

TO BE CONNECTED.

a \)\p ITEMS MARKED ** ARE SPECIAL ITEMS TO BE USED

ONLY AS SPECIFIED.

3. \\NO THREADED FITTINGS PERMITTED UNLESS

ISOLATED FROM PROCESS OR SOURCE BY WELDED OR

FLANGED VALVE)

AX 45) nyprostatic TESTPRESSURE 500 PSIG (10340 kPag)

BASED ON 1.5 X 1000 PSIG OPERATING MAXIMUM.

BRANCH CONNECTIONS:

90 DEG BRANCHES SHALL BE/DESIGNED AND INSTALLED.IN

ACCORDANCE WITH THE FOLLOWING TABULATION:

~ HEADER SIZE BRANCH SIZE CONNECTION

AAA

1/2 THRU 1-1/2 SAME AS HEADER TEE

1/2 THRU 1-1/2 SMALLER THANHDR TEE & SWAGE OR

RED.TEE

2ANDLARGER 1/2 THRU 1-1/2 SOCKOLET

2ANDLARGER SAME AS HEADER TEE

2ANDLARGER SMALLER THANHDR REDUCING TEE

OR WELDOLET

PIPE:

P-28B 1/2 THRU 1-1/2 ASTM A106 GR B, EX STRONG SEAMLESS,

STEEL PIPE.

P-27B 2 THRU 10 ASTM A106 GR B, STD WEIGHT SEAMLESS

STEEL PIPE,

P-28BX 12 THRU 16 ASTM A106 GR B, EX STRONG SEAMLESS

STEEL PIPE.

~~ specs\oiolefine\classt

June 13, 1950/wa

~-

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD

ENGINEERING

SPECIFICATION

LINE CLASS: T

REVISION: 1

PAGE: 2of7

EITTINGS:

E-90 DEG ELL, Lad5 DEG ELL, T=TEE, X=CROSS, R-REDUCER, C=COUPLING,

S=STUB END, U=UNION, PC=PIPE CAP, PB=PIPE BEND, PN=PIPE NIPPLE

ELT-64 1/2 THRU 1-1/2

Ragas) (OaTHRU 1-1/2

Cole 4/2 THRU M1/2

C-1dS 1/2, THRU 1-1/2

PC-27 1/2 THRU\-I72)

PC-26 1/2 THRU 1-1/2

PN-28BSW 1/2 THRU 1-1/2

PN-28 1/2 THRU 1-1/2

BSWXL

PN-106BTO 1/2 THRU 1-1/2

ELTR-ISB 2 THRU 10

C41 2 THRU 10

PC-51B 2 THRU 10

ELTR-I6B 12 THRU 16

sptes\o4\oleting\ cla t :

une 12, 1990/0

3000-LB SOCKET WELDING FORGED STEEL

FITTINGS, ASTM A105, ANSI B16.11.

EX STRONG STEEL SWAGED NIPPLE, ASTM

A106 GR B, PBE.

3000-LB SOCKET WELDING FORGED STEEL

COUPLING, ASTM A105, ANST B16.11.

3000-LB FORGED STEEL SOCKOLET, ASTM

1087

3000-LB SOCKETWELD-FORGED STEEL

CAP, ASTM A105, ANSI‘BI6.11

3000-L.B THREADED FORGED STEEL. CAP,

ASTMALOS, ANSHBI6(F(NOTE -

FOR VENTS.& DRAINS ONLY.)

ASTM A106 GR B, EX STRONG SEAMLESS

STEEL PIPE NIPPLE, PLAIN-ENDS, 3%

LONG.

ASTM A106 GR B, EX STRONG SEAMLESS

STEEL PIPE NIPPLE, PLAIN ENDS, 6"

LONG.

ASTM A106 GR B, EX STRONG SEAMLESS

STEEL PIPE NIPPLE, THREADED ONE.

END, 3" LONG. (NOTE - FOR VENTS &

DRAINS ONLY.)

STD WEIGHT SEAMLESS STEEL BW

FITTINGS, ASTM A234 GR WPB, ANSI B16,

STD WEIGHT STEEL WELDOLET, ASTM A105.

STD WEIGHT SEAMLESS STEEL BW

CAP, ASTM A234 GR WPB, ANSI B169.

EX STRONG SEAMLESS STEEL BW

FITTINGS, ASTM A234 GR WPB, ANSI

8169,

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION PAGE: 30f7

~~

PC-52B 12 THRU 16 EX STRONG SEAMLESS STEEL BW

CAP, ASTM A234 GR WPB, ANSI B169.

PC-42 12 THRU 16 EX STRONG WELDOLET ASTM A105

ELANGES:

F26-RES\ (Gy2 THRU 1-1/2 600-LB RAISED FACE SOCKET WELDING

FLANGE, ASTM A105, ANSI B16.5. XS BORE

F-8-RF DTHRUIG 600-LB RAISED FACE WELDING NECK

FLANGE, ASTM A105, ANSI B16.5,

BORE TO MATCH PIPE,

FAGRF \\))1/2 THRU YS 600-LB RAISED FACE BLIND FLANGE,

ASTM AT05, ANSI BI65,

ORIFICE FLANGE:

F-6SL 1 THRU 1-1/2 ORIFICE)FLANGES TO BE 600-LB RAISED

FACE SOCKET WELD TYPE, ASTM A105; ANSI

B16.36. XS BORE,

- F-6WN 2 THRU 16 ORIFICE FLANGES TOBE 600-1)B RAISED

FACE WELDING NECK TYPE.ASTM A {05

ANSI B16.36, BORE TO MATCH PIPE.

GASKETS:

304 STAINLESS STEEL SPIRAL WOUND, MICA

GRAPHITE FILLER - 1/8" THICK.

FLANGE BOLTS:

B-A193B7Q ASTM A193 GR B7 LIQUID QUENCHED AND

TEMPERED ALLOY STEEL STUD BOLTS

WITH ASTM A194 GR 2H HEAVY HEX NUTS.

BOLT LUBRICANT;

BL-2 FEL PRO C5-A.

VALVES:

GATE VALVES;

Ne sowss\ 04 otetinn tase

Fone 18, 1990/0n

Novacor/AGEC

OLEFINS LINE CLASSES

JOFFRE SITE STANDARD

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION PAGE: 4of7

~~

v-474 1/2 THRU 1-1/2 800-LB SOCKET WELDING OS&Y SOLID

WEDGE GATE VALVE.

V-619 1/2 THRU 1-1/2 600-LB FLANGED OS&Y SOLID WEDGE

Vigs2BA"" 1/2 THRU 1-1/2

V-110XGK <2

V-SP3 3 THRUY6

Vel2IKGK })9

Vespa 3 THRU

GLOBE VALVES:

V-595 1/2 THRU 1-1/2

~~

V-226XGK 2

V-SPS 3 THRU 8

CHECK VALVES:

V-594 1/2 THRU 1-1/2

V-112XGK 2

V-SP6 3 THRU 16

V-I20XGK 2

‘V-SP7 3 THRU 10

— spece\04\efinsclaa.¢

June 18, 1990/Wa

GATE VALVE,

800-LB FEMALE SOCKET WELDING BY

SCREWED OS&Y GATE VALVE. (INSTR.

CONNECTIONS ONLY,)**

600-LB WELD END OS&Y GATE VALVE,

600-LB WELD ENDS OS&Y GATE VALVE.

(PRESSURE SEAL BONNET.)

600:LB FLANGED OS&Y GATE VALVE.

600-LB FLANGED OS&Y GATE VALVE.

(PRESSURE SEAL BONNET.)

600-LB'SOCKET WELDING \OS&Y GLOBE

VALVE.

600-LB WELD END OS&¥-GLOBE YALVE.

600-LB WELD END OS&Y GLOBE VALVE.

(PRESSURE SEAL BONNET.)

600-LB SOCKET WELDING HORIZONTAL

LIFT CHECK VALVE.

600-LB WELD END HORIZ. SWING CHECK

VALVE.

600-LB WELD END PRESSURE SEAL,

HORIZ, SWING CHECK VALVE,

600-LB FLANGED HORIZ. SWING CHECK,

VALVE.

600-LB FLANGED PRESSURE SEAL HORIZ.

SWING CHECK VALVE.

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION, PAGE: Sof7

-

‘V-SP2 4 600-LB FLANGED AUTOMATIC

RECIRCULATION CONTROL CHECK VALVE.

V-SP11 4 600-LB FLANGED AUTOMATIC,

RECIRCULATION CONTROL CHECK VALVE

FOR E] P-904C.

‘V-SPI2) 4 600-LB FLANGED AUTOMATIC

RECIRCULATION CONTROL CHECK VALVE

FOR E2 P-924A/S.

BARSTOCK VALVE:

‘V-6025 1/2M X [72E t/2\MALE SOCKETWELD BY 1/2" FEMALE

NPT. (NOTE - USE FOR ORIFICE FLANGE

TAPS & 1/2" LINES ONLY )& FOR PIPE

INSULATION EQUAL’TO) OR LESS-THAN 2"

THICK.)

‘V-6026 1/2M X 1/2F 1/2..MALE/SOCKETWELD BY 1/2" FEMALE

NPT. (NOTE - USE FOR ORIFICE FLANGE

TAPS & 1/2" LINES ONLY & FOR PIPE

-— INSULATION GREATER THAN)2" & UP TO 4"

THICK.)

‘V-6027 3/4M X 1/2F 1/2" MALE SOCKETWELD BY 1/2" FEMALE

NPT. (NOTE - USE FOR PIPE INSULATION

EQUAL TO OR LESS THAN 2" THICK.)

‘V-6028 3/4M X 1/2F 3/4" MALE SOCKETWELD BY 1/2" FEMALE

NPT. (NOTE - USE FOR PIPE INSULATION

GREATER THAN 2" & UP TO 4" THICK.)

Ne eer atta ct

June 13, 1980/wn

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION PAGE: 607

~

INSTRUMENTATION

1 THE FOLLOWING SPECIFICATIONS ARE TO BE USED FOR

INSTRUMENTATION. FOR ITEMS NOT LISTED, THE PRECEDING PIPING

SPECIFICATION IS TO BE USE WHERE APPLICABLE.

2. PIPE REDUCTIONS SHALL BE MADE WITH SWAGE NIPPLES OR REDUCING

GQUPLINGS. NO BUSHINGS PERMITTED.

PIPE

P-108) ASTM A269 GR TP316 ANNEALED STAINLESS

STBEL SEAMLESS OR WELDED TUBING, 1/4"

OD AND 3/8" OM BY 0.035" WALL OR 1/2" 0D

BY 0.949" WALES,

ELCIINGS:

E=90 DEG ELL, L=45 DEG ELL, TeTEE, X6CROSS, R-REDUCER, C=COUPLING;

S«STUB END, UsUNION, PC=PIPE CAP, PB=PIFE\BEND, PN=PIPE NIPPLE

ELTR-103A 1/4 THRU 1/2 316 STAINLESS STEEL ’SWAGELOK? TUBING

FITTINGS. (TO SUIT TUBING SIZE).

ELTR-S 1/4 THRU 1 3000-LB THREADED FORGED STEEL,

FITTINGS, ASTM A105, ANSI B16.11,

c3 1/4 THRU 1 3000-LB THREADED FORGED STEEL

COUPLING, ANSI B16.11, OR 3000-LB

THREDOLET, ASTM A105,

u-2 1/4 THRU 1 3000-LB THREADED FORGED STEEL

UNION, ASTM A105, AAR DIMENSIONS,

STEEL TO STEEL SEAT.

PC-2 1/4 THRU 1 THREADED SOLID STEEL HEX HEAD PLUG,

ASTM A105, ANSI B16.11.

UND:

Jo-3 CRANE HIGH TEMP ANTISIEZE THREAD

COMPOUND OR JOHN CRANE THRED-

GARD.

FLANGES:

specs\04\olefine\elas.t

une 13, 1980/3

Novacor/AGEC OLEFINS LINE CLASSES JOFFRE SITE STANDARD.

LINE CLASS: T

ENGINEERING REVISION: 1

SPECIFICATION PAGE: Tof7

~

F26R-RF 1/2 THRU2 600-LB RAISED FACE THREADED

REDUCING FLANGE, ASTM A105, ANSI

BI6S.

VALVES:

VALVE:

v. ee ovat X12 SCREWED MALE & FEMALE HAND VALVE

(BLEED)

vee SCREWED MALE & FEMALE HAND VALVE

v6 3/4M X ;CREWED MALE & FEMALE HAND VALVE

Tory, Ci FEMALE PRESS GAUGE

von ae sonsyss sy ass oxv08

PG; 0

NEEDLE VALVES: Ter QO n

v-78 1/4 THRU 3/4 3000-1

~ v-650 1/4M X.1/4E 3000-LB SCREWED, MA\

Ne ees\ on ctein clan

une 13, 1900/0

Вам также может понравиться

- Technical Specification Index of Piping Material ClassДокумент3 страницыTechnical Specification Index of Piping Material ClassZvonko Bešlić100% (1)

- Class Vb1 ('Joffre Polyolefins')Документ5 страницClass Vb1 ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Useful Conversions ('MPB Industries')Документ1 страницаUseful Conversions ('MPB Industries')Zvonko BešlićОценок пока нет

- Klasa D1 ('Petrolinvest')Документ1 страницаKlasa D1 ('Petrolinvest')Zvonko BešlićОценок пока нет

- Class VB ('Joffre Polyolefins')Документ5 страницClass VB ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Class 1c1 ('Mooretown')Документ2 страницыClass 1c1 ('Mooretown')Zvonko BešlićОценок пока нет

- Class Vb1 ('Joffre Polyolefins')Документ5 страницClass Vb1 ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Foster Wheeler ClassesДокумент243 страницыFoster Wheeler ClassesZvonko Bešlić100% (1)

- Class Vc1 ('Joffre Polyolefins')Документ2 страницыClass Vc1 ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Class 1B3 - 1B4 ('MOORETOWN')Документ2 страницыClass 1B3 - 1B4 ('MOORETOWN')Zvonko BešlićОценок пока нет

- Class 1c5 ('Mooretown')Документ2 страницыClass 1c5 ('Mooretown')Zvonko BešlićОценок пока нет

- Class U ('Crawford & Russell')Документ5 страницClass U ('Crawford & Russell')Zvonko BešlićОценок пока нет

- Class 1c9 ('Mooretown')Документ4 страницыClass 1c9 ('Mooretown')Zvonko BešlićОценок пока нет

- Class 1c2 ('Mooretown')Документ4 страницыClass 1c2 ('Mooretown')Zvonko BešlićОценок пока нет

- Class 1b2 ('Mooretown')Документ2 страницыClass 1b2 ('Mooretown')Zvonko BešlićОценок пока нет

- Class Vc1 ('Joffre Polyolefins')Документ2 страницыClass Vc1 ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Class t2p ('Corunna Lummus')Документ1 страницаClass t2p ('Corunna Lummus')Zvonko BešlićОценок пока нет

- Class U ('Crawford & Russell')Документ5 страницClass U ('Crawford & Russell')Zvonko BešlićОценок пока нет

- Class t2p ('Petrostar Corunna')Документ1 страницаClass t2p ('Petrostar Corunna')Zvonko BešlićОценок пока нет

- Class t2n ('Corunna Lummus')Документ1 страницаClass t2n ('Corunna Lummus')Zvonko BešlićОценок пока нет

- Class Vb1 ('Joffre Polyolefins')Документ5 страницClass Vb1 ('Joffre Polyolefins')Zvonko BešlićОценок пока нет

- Class t3p ('Corunna Lummus')Документ2 страницыClass t3p ('Corunna Lummus')Zvonko BešlićОценок пока нет

- Class t2 ('Foster Wheeler')Документ1 страницаClass t2 ('Foster Wheeler')Zvonko BešlićОценок пока нет

- Class t1 ('Foster Wheeler')Документ1 страницаClass t1 ('Foster Wheeler')Zvonko BešlićОценок пока нет

- Class s12z ('Lummus')Документ1 страницаClass s12z ('Lummus')Zvonko BešlićОценок пока нет

- Class s11z ('Lummus')Документ1 страницаClass s11z ('Lummus')Zvonko BešlićОценок пока нет

- Class s10z ('Lummus')Документ1 страницаClass s10z ('Lummus')Zvonko BešlićОценок пока нет

- Class s4z ('Lummus')Документ1 страницаClass s4z ('Lummus')Zvonko BešlićОценок пока нет

- Class s9z ('Lummus')Документ1 страницаClass s9z ('Lummus')Zvonko BešlićОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)