Академический Документы

Профессиональный Документы

Культура Документы

Amine Thermal Degradation

Загружено:

saadashfaq0 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров1 страницаok

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документok

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров1 страницаAmine Thermal Degradation

Загружено:

saadashfaqok

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Amine Thermal Degradation (by Lili Lyddon)

In DEA degradation mechanism, Hydrocarbon Processing, October 1982, A. Meisen and M. L.

Kennard discuss the fact that DEA and MDEA thermal degradation is minimal up to 400F.

Although the degradation of DEA is caused by reaction with CO2 and not temperature alone,

temperature does affect the rate of degradation caused by reaction with CO2. This reference

states: Degradation increases strongly with temperature. This is not due to thermal breakdown

of DEA, but it requires the presence of carbon dioxide. Design and operation of DEA units must

avoid creation of elevated temperature throughout the plants. Heat transfer surfaces of DEA

stripper-reboilers (especially when gas fired) are particularly prone to formation of localized hot

spots. To prevent such hot spots in operating plants, DEA circulation through the stripperreboiler should be kept high and steam (or gas) temperature kept low. In many DEA units only

the bulk solution temperatures are measured. It must be remembered that the skin

temperatures of heat transfer surfaces can be very much higher, particularly during process

upsets. Reliance upon bulk temperatures is therefore inadequate.

In the paper Reduce amine plant solvent losses, Part 2 from Hydrocarbon Processing, June

1994, E. J. Stewart and R. A. Lanning mention that the thermal degradation of amines

accelerates above 350F, so the skin temperature of direct fired reboilers should be kept below

350F. They recommend a reboiler operation with an amine bulk temperature below

260F(126.67C) . This reference goes on to say: With hot oil and steam heating systems,

risk of thermal degradation is low since the heat media is usually not operated at high

temperature. However, in fired-reboiler operation, the temperature of amine on the tubes

surface can easily exceed 350F. In fired reboilers, forced circulation is often used to maintain

low skin temperatures. The rule of thumb is to maintain amine skin temperatures between

300F and 325F, and not exceed 350F. for these temperatures a conservative design heat flux

of less than 8000 Btu/ft2 of tube area is recommended.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Annu BarДокумент136 страницAnnu BarsaadashfaqОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Section 04 - FractionationДокумент112 страницSection 04 - FractionationsaadashfaqОценок пока нет

- Section 06 - PumpsДокумент28 страницSection 06 - Pumpssaadashfaq100% (1)

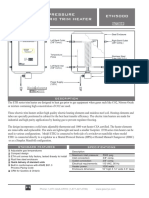

- Trim Heater PDFДокумент2 страницыTrim Heater PDFsaadashfaq100% (1)

- Options For Economical Supply of Hydrogen: Special EquipmentДокумент4 страницыOptions For Economical Supply of Hydrogen: Special EquipmentsaadashfaqОценок пока нет

- Check List - IfAДокумент1 страницаCheck List - IfAsaadashfaqОценок пока нет

- Mellapak 250Документ5 страницMellapak 250saadashfaqОценок пока нет

- Design Relief Vent FinalДокумент15 страницDesign Relief Vent FinalshamoojeeОценок пока нет

- Bell CurveДокумент3 страницыBell CurvesaadashfaqОценок пока нет

- Income Tax New Payment Sections TemplateДокумент2 страницыIncome Tax New Payment Sections TemplatesaadashfaqОценок пока нет

- Hbulletin Flat Type Glass Level GaugesДокумент3 страницыHbulletin Flat Type Glass Level GaugessaadashfaqОценок пока нет

- Accounting For Merchandising ActivitiesДокумент45 страницAccounting For Merchandising ActivitiessaadashfaqОценок пока нет

- Final Research Report - AamДокумент3 страницыFinal Research Report - AamsaadashfaqОценок пока нет

- Research Experiments: Adnan ZafarДокумент4 страницыResearch Experiments: Adnan ZafarsaadashfaqОценок пока нет