Академический Документы

Профессиональный Документы

Культура Документы

BS 6004 - 2000

Загружено:

sangitaghaisas100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров42 страницыBritish Standard - Electric cables - PVC insulated, non armoured cables for voltages up to and including 450/750 V, for electric power, lighting and internal wiring

Оригинальное название

BS 6004 - 2000

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBritish Standard - Electric cables - PVC insulated, non armoured cables for voltages up to and including 450/750 V, for electric power, lighting and internal wiring

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

1K просмотров42 страницыBS 6004 - 2000

Загружено:

sangitaghaisasBritish Standard - Electric cables - PVC insulated, non armoured cables for voltages up to and including 450/750 V, for electric power, lighting and internal wiring

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 42

BRITISH STANDARD

a

Electric cables —

PVC insulated, non-armoured

cables for voltages up to and

including 450/750 V, for

electric power, lighting and

internal wiring

[NO COPEING WITHOUT NS! PERMISSION EXCEPT AS PERMITTED BY COPYRIGET LAW

EEE

BS 6004:2000

a

mee

BS 6004:2000

——————

Committees responsible for this

British Standard.

‘The preparation of this British Standard was encrusted by Technical Commitee

GEL2), Electric cables, co Subcamumittee GEL/20/1, Wirnng cables, below 1 k, upon

which the folowing borkes were represented

Association of Consulting Engincers

Association of Mamvatacarers Aled tothe Eleciuieal and Electric Indasiry

(BEAMA Lid.)

Bitch Approvals Service for Cables

British Cables Association

British Plastics Fodoration

Pritish Retail Consortium

(Chartered Institution of Building Services Engineers

Departnet of Thade and Indseay (Consuener Safety Unit, CA Divison)

‘lecitical Installation Equipment Manufacturers Association,

Blecriity Association

‘Bnengy Industries Cour

[Engincering Industries Association

[ERA Technology Lu

Institution of Incorporatod Engincers

Lift and Hecalatoe Industry Assoclation

London Underground Lad.

‘Transmission and Distribution Association (BEAMA Ltd.)

‘een prepared under he

cin fhe eaten

‘eee shanty ore

Sundards Commies and comes

Ins eft on 15 Deceber 2000

‘ops s2200 Amendments issued since publication

Piotinblshed Angst o69 Amdo. | Date ‘Comments

Second etton January 1076

‘Tir edu Nay 13

oumh wcton Ober 1280

Tih edten Nove 1981

Ath eon December 200

“Te toning BSH ese

ene be weaken fos

‘Commie reference GEL2M.

Dra tor commere 09242739 DC

{SN 06600041 1

BS 6004:2000

— eee

enst vom

Contents

g

Conunittees responsible

Foreword

Beope

[Norzative references

Definitions

Volizge designation

General

‘Construction details

Bhectrieal ests

| _Noneleetrcal tosis

‘Annex A (informative) Guide to We use of PVC insulated cables

‘Annex B (informa) Guidance on procedure for routine tests on PVC insulated

cables of rated voltages Uo/U up to 450/750 V

Annex C (normative) Electrical tests

‘Annex D (normaiive) Measurement of thicknesses

‘Annex E (normative) Procedure for choclang the efficacy of the spark testing

‘method and equipment

Annex F Spare

‘Annes 6 (normative) Cornpanity tas

Big —

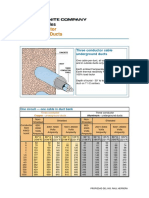

Figure C.1 — Tex apparatus for measarement of transfer impedance due to

resistive and magnetic coupling

‘ure C2 — Correction faccor F”

Figure C3.— Correction facior F*

gure D 1 — Measurement of sheath thickness

‘Figure E.1 — Preparation of core for spark test equipment checkc removal of

inealation

Figure B2— Preparation of core for spatk test equipment clieck: covers, with

tape,

‘Tape 1 — List OF GSES applcablo wo CADIS spocihed in Tables ¥to Ee

‘Table 2 —Scheciule of tests

‘Table 3 — Compatibitcy requirements

‘Table 4 — PVC irsulatod, non sheathed gonoral purpose cable, 450/750 V, single

core 0

‘Table 5 —PYC insulated, norsheathed cable for internal wiring, C0000 V, single

core and twisced Gna

‘Table 6 — PVC insulated, PVC sheathed, ight cable, 300/500 V, circular twin,

E

&

i

i

et

2

27

uM

ss

6

6

RBRS

cod &

3.core, core and Scare 8

‘Table? — PVC insulated, PVC sheathed cable, 300600 V, single core, at twin

and Score ub

‘Table 5 — PYG sulated, PYG sheathed cable with etrext protective conductor,

300600 V, single core, lar rein and 3.ccro 6

Table 9 — PVC insulated, PVC sheathed cable with or without cicuit protective

conductor, 900600 ¥, single core and flat twin (alerative conductor versions) 17

Table 10 —PYC insulated, nor-sheathed cable, 4507750 V, single core for

snetallaton at leur termperatires 18

Table 1] — PVC insulated nom sheathod, heat resisting cable for internal wiring,

150/750, singe core 2

‘Table 12 PYG insulated, nor-sheathed, heat resisting cable for internal wiring,

300f00¥, single core and ivisted torn a

‘Table 13 — Of resisting PVC sheathed, sereened cables, 300700 V, having

Iberwren 2 and 60 cores 2

‘Table A'1 — Guide to the use of PVC insulated cablos a

‘Table B1 — Spark test voltage 5

‘Table B2 — Insulation test volage 5

‘Table 3 — Temperature correction factors Ey

‘Table C1 — Summary of electrical tests zi

BS 6004:2000

———————

Foreword

‘This British Standard has boon prepared by Subcomunittee GEL/20/1 1 supersedes,

BS C04 1996 which is withdrawn.

“Tn revision of BS 6004 specifes requirements for PVG insulated nom armoured cables

for elocne power, ighang an inverted wiring. I. bicorpotates cables from TID 21.9,

HD 2U7 and HD21.9-and sereened cables from HD 21.15

‘The following harmonized cables have been introduced:

OSV. types;

HOTVZR and HOTV2-K types (conductor sizes above 25 man)

HOBV2R pes:

HOSWCAVE-K txpes

‘The following harmonized types have been transferred from BS 6500:

HOSV-K types;

HOBV2K types

thas been assumed in the preparation ofthis standard thatthe execution ofits

provisions willbe enirusted to appropriately qualified and experienced people for

‘Whose use it has boon produced.

‘Annexes ©, D,E and G are normative, Annexes And 8 aro informative. Annex F is

pare.

WARNING. This Batish Standard calls for the use of substances andor procedures

that may be injurious to health i adequate precantions are not taken. Ie refers only 10

technical suitability and does not absolvo the use from legal obligations relating 10

Tals and anfty at any stage.

Certification, Aversion is drawn to the certification services (see page 37) ofthe

[ntish Approvals Service for Cables (BASEC)". These services include heensing

‘manulactirers to use BASEC ceruiieation marks as independent assurance that cables

for cords have beon dedigned and manufactured to appropriate Ertsh Standards,

ASEC ia subooribor to an agreement in CENELEC whereby cables or cards coming.

within harmorized code designations and manufacoured under s BASEC licence, can

Cary marks aoceptable to other sigatory countries (CENELEC “Common Masling")

‘A British Standard docs not purport to include all the necessary provisions of

Contract, Users of British Standards are responsible for their correc: application.

Compliance with a British Standard does not of ltsel€ confer imnunity

‘from leyal obligations.

‘Summary of pages

"This document compris a front cover, an inside front cove, pages i andi, pages L

to37 and aback cover

‘The BSI copyright notice dispayed in this document indicates when the document was

tat issie|

2 ag aro Set Cae 25 reser War, Comb iti eye, chan

© os 122000

BS 6004:2000

1 Scope

‘This British Standard epeeifies requirements for the construction, dimensions and moctanical and electrical

properties of nonarmoured polyvins] chloride (PVC) insulated cables for operation at voltages up to and

Treliing 450 Vac. 1 earth and 750 V ae. between conductors, inended for electric power, lighting ard

‘ternal wiring,

‘The types of cable included in the standard are:

‘Table 4a) andb) PVC insulated, non-sheathed general purpase cable, single core, CHOTV:

HOTW-R and HOV-K) 450/750;

Tables [PVC insulated, non-sheathed cable for internal wiring, single core and

‘pwisted twin. (HDSV-U, HOBV-R and HOSV-K) 3007500 ¥;

Tables PVC insulated, PVC sheathed, light cable, cieular twin, Soom, core

and 5-core. (No code) 300/500 V5

Tale? PVC insulated, PVC sheathed cable, single core, Hat twin and 9 coro.

(National type) 300/500 V5

Tables PVC insulated, PVC sheathed cable with cireut protective conductor,

single core, flat twin and Score. (National type) 300/500 V5,

‘Tanleo PVC insulated, PVC sheathed cable with or without circuit protective

‘conductor, single core and fat brin (aktemotive conductor versions).

(National type) 00/500 ¥;

Table 10a) and) PVC insulated, non-heathed cable, single core for insiallation at low

temperatures, (HOTV3U, HOIV3.R and HOTV3-K) $5070 V;,

‘Table 11a) andb) PVC insulated, non-sheathod, heat resisting cable, for internal witing,

sige core, (U07V2U, HOTV2R and HUTV2-K) 450750 V;

Table 12 PVC insulated, non sheathed, heat resisting cable, for intemal wiring,

single core and twisted twin. (HOSV-U, HOSV2.R and KOSV2-K) 300/800 V;

Table 13 (0 resisting PVC sheathed, scroonod eables, having between 2

‘and 60 cores. (HOSWWCAVS-X) 300/600 V.

[A guide to the use of the cables specifiod in this standard is given in annex A. Guidance to manufactarers on

procedures for routine testing is given in annex B, Test methods are given in annexes C, D, E and G.

2 Normative references

‘The following normetive documonts contain provisions which, through reference in this taxt, constiite

provisions of this British Standard For dated roferences, subsequent amencments to, o revisions of, any of

these publications do not apply. For undated references, the latest edition of the publication referred to

applies,

BS 4727.2:Group 08, Glossary of lectrotecknical, power, telecommunication, electronics, lighting and colour

terms — Part2: Terms particular to power engineering — Group 08: Electric cables.

[BS 6360, Specification Jor conductors in insulated cables and cords.

[BS6745C, Colour chart for insulation and shoath of elciric cables.

BS 7665-81, Specification Jor insulating and sheathing materials for ecbles— Part: PVC insulating

compounds — Section 8.1: Harmonized types.

[BS 7655-41, Speclfwation for insulating end sheathing materials for cables — Part-4: PVC sheathing

‘compounds = Section 4.1: Farimunized types.

BS 7655-42, Specification for insulating and sheothing materials for enbles — Part 4: PVC shewthing

‘compounds — Section 4.2: General application.

BSEN 50265-2-1:1999, Common test methods for eables under fire conditions — Test for resistance to

vertical flame propagation for a single insulated conductor or cabla— Part 2-1: Procedures —

TTIW pre-minel lm

BSEN 60334, Marking by inscription for the identification of cores of electric cables having more

‘than 5 cores

in preparation

ens 200 i

BS 6004:2000

BSEN 60811-1-:1995, Insulating and sheathing materials of eloctris cables — Common test methods —

Pari I: General application — Section 1-1: Measurement of Uuickwess and overall dimensions — Tests for

determining the mechantoal properties.

BEEN 60811-12:1006, Inculating and choathing materials of el2ctric cables — Common test metheds—

Pars I: General ayphication — Section 12: Thermal ogeing mediods.

TEC 605C2-1:1007, Power eablas with extruded insulation ard their accessories for rated voltages from

TAY (Um = 1.2 BY) up to 50 kV (Um = 36 AV) — Port I: Cables for rated voliages of 1 kV (Um = 1,2 EV)

and 3 kV Uim= 3,0 KV).

PN 2979, Rapister of colours af manufacturers’ identification threads for electric eables and cords.

3 Definitions

Forte purposes ofthis Dinh Sand he defo gen n BEATE Gro OB and he folowing

app

aA

rated voltage Up

rnontinal power frequency voltage between conductor(s) and earth, for which the cable is suitable

32

rated voltage I

‘nominal power frequency vollage between phase conductors for which the cable is suitable

33

nominal value

value by which a quantity is designated and which is often used in tables

Novena rea es use 0 ast be ee semen ang so et

34

approximate value

value which is only indicative

[NOTE dhe standard eaor deere st “approxnats" donot corstinte reqaroments tote chest Oy measurement

35

type tests (symbol T)

tests requized to be made before supplying a type of cable covered by this standard on a gonoral commercial

‘basis n order to demorstrate satisfactory performance characteristics to meet the intended application

NOTH. Thess tote are os ante tt, tor ey Pave Doe made thy ee Not Re repeated ules changes ae me the

"able item sgh or pe of wunutacing pucens wich mi charg the performance characterises

36

sample tests (symbol)

tests made on samples of completed cable, or components taken from a completed cable adequate to verify

that the Finished produc: meets the design specifications

a7

routine tests (eymbol R)

tests made on all production lengths of cable to demonstrate their integrity

4 Voltage designation

Cables shall be designated by the rated voltages Up and U, expressed in the form Uo.

Im an ac, system, the mated vollage of a cable shall be atleast equal to the nominal voltage of the system for

‘which its intended and this applies both to the value Up and to the value.

Ina de, systen, the nominal voltage Detweon the conductors shall be not higher chan 1.5 times the raied

‘voltage U of the cable and the nominal voltage between arg condetor and earth shall be not higher

than 1.5 times the rated voltage Uo of the eable

“The rated voltages recognized for the purposes ofthis standard shall be 900/500 V and 450/750 V.

NOTE The opemting votage of» setam mey pormanertiy exceed the nna wtinge of ch tem by 10% A eae cam beset

Mosstigher voltage than te rated voltage ft ter sat ast eqn tote tanta valkape ef he em

© pst 2200

BS 6004:2000

5 General

5.1 Construction

"Tho construction of the cables shall bo as epecified in the appropriate construction table (Table 4 to 12)

Conformity shall be checked by examination,

5.2 Core identifieation

52.1 General

Bach core shall bo identified by its colour or numbor as indicated in the appropriate construction tab.

5.2.2 Core colours

‘The colour shall be cither throughout the whole of the insulation or on its surface.

‘The colours of the cores according to tte mumber of cores inthe cable and also the sequence of the colours

shall be as given in the appropriate construction table.

(On the core with the bi-colour combination green/ycllow, the distribution of these colours shall be such that

for every 15mm length of eore, one of these colours shall cover atleast 30% and not more than 709% af the

surface of the core, while the other colour covers the remainder of the surface.

‘Conformity shall be checked by measurement

NOTEL incase o aspue rear the gew/elow conbnaton ang where appypnate tothe method of cour marin of

uston a satale est reco fur cheung coneraty gien BOWS FE clases

[NOTE2 tis unerstod thatthe clous green and yellow when they ee cominned as pected ave reoprized as eating

‘cust decor need for ise a a ear contr o seta peteeten Tae coe te for he ieripeazen oe core

Sended to be connected oneal bn I Ue sn tetra, ve may be use to Healy any cove excep forte ang

rowers condor

[NOTES Aeron is dn othe tc ha aor thease to With cables afew Ue putty CoA he sie to the one

{tour roqerertaapeifedt DT, bree Diss Olanards or ois Sales ota replaro or teary equi

[NOTES nackte wo te combaeion eerie a he mono-conr Ne, the felomtng other mone-clos are engine 2

aoniz ack, beown ey, oranges Pe, rus Ye al Whe

5.2.8 Core numbering

Where cables with more than 5 cores are identified by marking by inscription this shall be in accordance

with BS EN GOO.

5.2.4 Clarity and durability of colour

‘The colours shall be clearly identifiable and durable.

Conformity shall be checked by trying to remove the colour of the cores by rubbing the core lightly 10 times

‘ith a piece of cotion wool or cloth soaked in water.

5.3 Cable markings

5.3.1 General

Designated harmonized codes for cables are given in the appropriate construction tables and, except where

explicitly shown as national types, these cables shall be permitted to bear tho CENELEC Common Marking

in accordance with 6.3.3

5.3.2 Indication of origin

All eables shall be provided with an indication of origin consisting of cther an identification thread or

threads or the continuous marking of the manufacturer's name or tradematk.

If coloured threads are wed, the colours shall conform to those registered in PD 279, where applicable. The

colours shall be easy to recognize or shall become recognizable by cleaning with petrol or other suitable

solvent, if necessary.

‘The marking of the manufacturer's name or trademark, if used, shall be by one of the following alternative

methods

«) printed tape within the eable;

>) printing, indenting or embossing on the insulation of zt leas tho blue core;

© printing, indenting or embossing on the sheath, i any.

ont 200

Bach specified mark shall be legible and shall be regarded as continuous if the distance between the end of

the mark and the beginning of the next identical mark does not exceed:

1) 580 mm if the marking is on the cuter sheath of the cable;

2) 27 mum ifthe marking

on the insulation of an unsheathed cable;

i) on the insulation of a sheathed cable;

ii) on a tape within a sheathod cable.

Conformity shall be checked by measurement.

NOTE. A ‘epecied mar’ i¢ mandatory mack covered by ths stander

hea,

5.3.3 CENELEC “Common Marking”

It shall be permitted for a cable for which a harmonized code designation is given in the appropriate

construcricn table, to carry an indication that it has been manufactarod under a licence issued by one of the

approvals organizations subscribing to the CENELEC agreement on the use of a commonly agreed marking

{or cables. It does camry such an indication this stall be one of the following.

1) The mark of the approvals organization, followed by the Common Marking HAR > applied by one of

the three metheds specified in 5.3.2

1b) An identification thread extending throughout the length of the cable indicating the approvals

‘organization, ‘The base colour shall be yellow and this shall be serially dyed or printed red and black. The

Tengshs of the coloured sections shall conform to the dimensions laid down by CENELEC for that

approvals organization (see PD 2379),

Neither of these indications shall be used for a cable shown in the construction tables as a national type or

national sie,

‘he name CENLEC, in full or abbreviated, stall not be marked on, oF in, he cable.

53.4 Identification mark

Where particular cables are to be distinguished from other cables by additional marking, the marking shall

‘be as given in the applicable construction tab.

‘The marking shall be continuous as specified in 5.9.2

‘Conformity shall be checked ky measurement.

53.5 Durabitity of marking

‘Any marking by printing shall be durable.

‘Conformity shall be checked by rubbing the mariing lightly 10 times with a picce of cotton wool or cloth

soaked 1n water.

5A Cable testing

BALL Schedule of tests

‘Tests to be performed on cables specified in this standard shall he 2s specified in Table 2, which refers to

the relevant elaine of the standard specifying the roquirementz and teat msthoda aa well aa the eategory Of

‘each tost which applies, Le. T, $ oF R (as defined im clause 3),

[NOTE Table? abo indicates which tests re wo th completed cables, an which relate to comme.

5.4.2 Test conditions

5A.2.1 Ambiont temporature

‘Tosts shall be performed at an amblent temperature of (20 ¢ 15) °C unloss otherwise specified in the details

for a particular tet,

542.2 Frequency and waveform of power frequenoy test vallages

Unless athorwise epectiod for a particular tot the frequency ofthe allomating tst voltages shall bo in he

range of 49 Hz to 61 Hz The waveform shail he substantially sinusoidal ne

te oponal CENELEC Carmen Maing specifi

4 const zm

BS 6004:2000

6 Constructional details

6.1 Conduetor

"The condactors shall a annealed copper conforming to BS 6950. The class of conductor shall be as given in

the appropriate construction table. It shall be permissible for the wires to be tinned except for the types

specified in Tables 7, Sand 9,

The de. resistance of the conductors shall be as specified in 7.2.

6.2 Insulation,

6.2.1 Type of tnsutation

‘The insulation shall be PYC of type TL1, TL2, TI3 or TI conforming to BS 7655.1, as specified in the

appropriate construction table.

6.22 Application

‘The ineulation ehall be apphed closely hy exmision to the ennductor

1 shall be possible Lo remove the insulation easily without damage to the insulation itself tothe conductor

fr to the tin coating, if any.

Conformity shall be checked by examination and by & manual test.

62.3 Thickness

‘The radial thickness of the insulation, when determined by taking the average of a number of measurements

‘im sccordance with D.1, shall be not Tess than the value given in the appropriate construction table and the

‘smallest of the measured values shall not fal below the value by more than 10%-+ 0.1 mm,

6. Core identification

Each core shall be identified by its colour or number in accordance with 5.2 and the specific requirements

saven in the approprialo eonstruction table.

6.4 Fillers, inner sheath and extruded inner covering

64.1 Fillers

‘When separate filles are used they shall be composed of one of the following, oF a combination of the two:

4) an extraded compound based on unvulcanizod rubber or plastics;

») natural or synthetic textile fibres.

‘A centre filler shall not be used in multicore cables unless specifically permitted in the appropriate

‘construction table

6.4.2 Inner sheath

"The inner sheath of cables specified in Table 18 shall he PVC of type TM 2 conforming to BS 7056-41,

‘applied around the care assembly.

‘The radial thickness of the inner sheath, when determined by taking the average of a number of

‘measurements in aecordanee with D.2, shal be not loss than the value given in Table 13 or, for cables with a

rnon-peeferred naraber of cores, not loss than the value fs, in milimetres, calculated from the following

featation, and the smallest of the measured values shall not fall below the value by more than 15 % + 0:1 mm.

t= D0Dp +08

whare

Dy ia the fictitious dhameter over the core assembly calculated in accordance with IEC 60502-1:1997,

annex A, excluding IEC 60502-11007, 8.2.4, in Fulumetres (mm)

For conductors not given in TEC 60502.1:1007, annex A, the following values of the fictitious conductor

diameter, De, shall be used according to the crose-sectional area of the conductor:

—crosesectional area 05 man? De = 08

—crosssectional area 0.76 mm: De = 1.05

— cross-sectional area LOmm? Do = 1.

It shall be permissible forthe inner sheath to fil the spaces between the cores, thas forming a filling, but it

shall not adhere to the cores,

ons weme 5

BS 6004:2000

64.3 Extruded inner covering

‘The inner covering of the cables specified in Table shall consist of an extruded compound based on

‘unvuleanized rubber or plastics

‘The inner covering shall be compatible with the PVC cores. Conformity shall be checked by the compatibility

test specified in 84,

[NOTE ‘The thickness ofthe ier covering enn Table 6 fr guidance ly ad eeasrenens Hue kes a rege

65 Screen

‘The seroen of the cables specified in Table 13 shall be applied over the inner sheath, in the form of a braid

of plain or tinned copper wires

Fora cable with a preferred number of cores, the diameter of the copper wires shall not exceed the

smasiamum value given in Table 13.

For other cables the diameter of the copper wires shall not exceed the following maximum values, 2s

applicable:

= 0.10sun for Dp = 10.0 ma,

= 021 mum for: 10am < Dy = 20.0 mam;

= 026 mam for: 20am < Dy = 90.0 mon;

= 051 mum for: Dp > 300 mun,

‘where Dp i the Setitious diameter under the braid, which is calculated hy adding together the fstious

diameter over the core assembly, Dp (calculated as specified in 6.4.2), and twice the inner shoath

thickness, fs (calculated fom the equation given in 6.4.2).

"The diameter of the wires shall be measured using 2 micrometer.

‘The screening efficiency shall be determined ly measuring the transfer impedance in accordance with 7.8,

‘The wala obsinad shall not exeonad 250 mim a 30 ME

6.6 Sheath

6001 Type of sheath

‘The sheath shall be PVC of one of the folowing types, as specified in the appropriate construction table:

4) type TM 1, TM 2.0r TMS conforming to BS 7655-4.15

») types contorming to Hs 1e55-4.2

66.2 Application

‘The sheath shall be extruded as an homogeneous layer, and shall be capable of being removed without

damage to the cores

[NOTE A separstor consisting tape o fem maybe placed under the sheath,

646.3 Thickness

6.63.1 The radial thickness of the sheath, when determined by taking the average of a number of

measurements in accordance wih D2 or D3 as applicable, shall be not less dan the value given in the

appropriate construction table or, for cables with a non-preterred number of cores, the value tsp calculated

in accordance with 6.6.3.2, and the smallest of the measured values chall net fall below the value by more

‘han 1595+ Oo ma

6.6.32 For cables spocified in Table 13, but with a non-preferred number of cores, the radial thickness, Igo,

in mullimetree (mam) of the outer sheath shall he as ealeulated by the following equation:

gq = 0.08Ds + 0.4

‘with a maximum value of 2.4mm,

where

Ds, is the fictitious diameter over the screen, calculated by adding together the fictitious diameter under

the braid Dp (calculated as specified in 6,5) and four times the relevant value for the maxianur

‘diameter of the copper wires (as specified in 6.3).

6.64 Colour

‘The colour of the sheath shall he 2 speeified In the appropriate construction table. The colour shall be

throughout the whole of the sheath or on its surface.

Where surface colouring is applied, the surface colour shall be of essentially the samme material as the

‘underlying material ard shall be applied as pact of the extrusion process The surface colour shall not be

separable from the underlying material and shall be durable

6 ons am

BS 6004:2000

7 Blectrical tests

7.1 General

‘The electrical tests to be peeformed on cables specified in this standard shail be as specified in Table 1

‘These tests shall be performed in accordance with the test schedule given in Table 2

7.2 Conduetor resistance

When the dc. resistance of each conductor is measured in accordance with BS 6360 on a sample of cable at

least 1 m in length it shall confor to BS 6360.

7.3 Voltage test on completed cable

When the cable is tested in accordance with C.2 no breakdown of the insulation shall occur.

7A Voltage test on cores

‘When the cores are tested in accordance with © no breakdown ofthe insulation shall oceur.

7.5 Absence of faults in the insulation

When the cable is teated in accordance with C.6 no breakdown of the insulation shall occur

7.6 Insulation resistance

When the cable is tested in accordance with C4, the insulation resistance of each core shall be not less than

‘the minimam value specified in ihe appropriate construction table,

7.7 Long term resistance of insulation to dc.

‘The insulation shall not break down nor shall the exterior ofthe insulation show damage when the cable is

tested in accordance with C.5, Discoloration of the insulation shall be ignored,

7.8 Screening efficiency

For the cables specified in Table 13, te transfer impedance of the sereen shall not exceed 250 mim

‘at 30 MHz, when tested in accordance with C7,

8 Non-electrieal tests

8.1 General

“The nor-lectrical tests to be performed on cables specified in this stardard shall be as specified in Table L

‘The tests shall be performed in accordance with the test schedule given in Table 2.

[NOTE some tea the prpuzacon and preston of th et empl can have a teal effect onthe el Fhe st, $0 115

‘Sosnlthat at carlo Sve slepeprepated cael

‘Test saunples shall be examined for damage before testing. Teat samples which have been damaged during

‘preparation shall not be tested

8.2 Mean overall dimensions

‘The mean overall diameter of circular cables and the mean overall dimensions of flat cables shall be within

‘te lants specified in the appropriate construction table, with the exception of national types and sizes for

‘which the lower lint given inthe construction cables stall be taken as an indicative value and not a

roquirement for conformity to this standard.

Conformity shall be checked by the method described in BS EN 60611-1-1:1995, 8.3.

‘One sample of eable shall be taken from each of three places, separated by at least 1 m. For circular cables

‘the mean of the six valties obtained stall be talen as the mean overall diameter. For fla cables, the mean of

feaeh Set of Utes Values, or the major and minor axis, respocavely, shall De wakes the relevant Overall

dimension.

8.3 Ovality of circular cables

‘The difference between any to values of the ovorall diameter of circular sheathed cables at the same

‘cross-section shall not excced 15% of the upper init for the mean overall diameter given in the appropriate

‘constraction table.

‘Conformity shall be checked using the method! doseribed in BS EN 6811-1-1:1985, 8.3,

‘One sample of eable shall be taken from each of Uiree places, separated by at least 1 m.

‘Two measurements shall be taken at the same cross section of the cable, covering the maximum and

minimum values.

ons emo 7

BS 6004:2000

84 Compatibility

For cables specified in Tables 6 to and Table 13, aftar 2 samplo of completed cable has been aged in

‘accordance with G.2, the insulation and outer sheath stall conform to the requirements given in Table 3.19

fualtion, us the end o£ the Lest period in the oven, the blotting paper shall be free of stains

85 Flame propagation of a single cable

Cables shall be tested in accordance with BS EN 6026521. The test shall be carried out on a sample of the

‘completed cable. After the tes, the cable shall conform to the performance requirements recommended in

[BSEN 50265.2-:1000, annex A.

‘Table 1— List of tosts applicable to eabl

specified in Tables 4 to 13

Gawe] Tet T Cae specie ube

number #7 se] e[ 7] s] ol ol ul a]

Bera tests

12 Conductor resistance x {x [x |x |x [xX |x [x [x [x |

7a |Votage test on complesed cable at2000v — |—|x Jx [x |x |x |—|—|x |x

73 |Volige test on completed able at 2500V fx |—|—]—|—|— |x Jx J— |-

7A | Votage test on cores a: 1600 V™ =e |x |x jx fx J- fe |e |x

7 | Votiage test on cores a 2060 = ax |x jx fx [== [-)x

75 | Absence of fats in the insulation x [x |x fx jx [x |x fx fx |x

76 | Inoulaton resitanco at 70°C x fx fa fx [x fx [x fo fe |x

76 | Ingulaton rsstanco at 80°C —|-|=|-|-|-|- |x |x

1 Long term resistance to d.c. x |x fx [x x |x |x |x

78 __|Sorooingefcieney jel IE Ele lee Ie lx

Conctructicnel and dimensional tess 1

6 | Cheek on construction x fx |x x ix [x jx fx fx |x

62.9 | stearremont of auton thickness x fx fx fx x |x fx |x [x |x

64.2 | Measurement of ner sheath thickness —|-\-|-/-|-|-|-!-|x

Measurement ofsreering wire ameter = |— |— |— |— |—)— |—|— |— |x

Measurement of sheath thickness |= |x fx x fx J— |= ]ae

2 | seasuremen of overall dimensions x jx fx jx ix fx |x fx |x |x

83 __|Mesurement of ovaty ~ |= |x |= |---| |e |x

84 | Company os SEE ei

85 | Fane promagation ofa single cable x fe xe [xe x [x Ie [x

Dx Ran nee fo wa een

8 © as 12290

BS 6004:2000

‘Table2— Schedule of tests

= wae ae me

=a =

memoaeae

ore, [te

oo

as as sean

eas

ae co freateumasnn ;

a = fees i

Tiresammyace [ae (eae :

an

a mz fasueas I

wa 4 i

= “ois :

o

=

iin 2 fete :

sora t

oe 12 maateanmnnataamrint {a

hen aan 3

coe |e |e :

Sone ug :

ee Tectmaan [i (es t

meetin a ie :

aoe ules :

Sem (ad (isaromsumenas :

= fees :

a Ho ese I:

Flame propagation of a single cable _| 8.5 [BS EN 50255-2-1 |r

NOTE Tests essed as sump) and on (8)

‘De med spat of «Ge approval Shee

‘Table $— Compatibility requirements

Compan Parner TEegurenent for wateial pe

\o" ar [ne [et | tH | Tee

Tnsilation | Minimum versie strerqah (ina? Bs fio 7— J— |- |

Minimum percentage elongation at break ws liso | [— je

Maximum percentage varahon® of ersitesuengh — [20 x20 |— |= |=

Masirmam percontage varisiont of elongation at break 220 [329 |— || —

Sheath Minimum tense srenath (ina =— [= [as fies feo]

Minismum poceentage elongation at brea [|Z fs jiso fies

Maximam percentage varation*of tensile strength |— |= 820/90 | 420

Maximum percentage variation of elongation at break |— |_| 320 | 20 | #20

fe fun

[ite varaonsthe france bern the repre waives Obtined Dur Wo ard aie Fea alias, resed a «PEARS

a

const en

‘Table 4— PVC ingulated, non-sheathed general purpose cable, 450/750, single core

[Ta eonpreonncor

NOTET Theiler mayb uaa or age op oT UVa orapw OW wah ae Ge me)

Nore? Canes nang mb es salle dun na? we pes Ta

Harmonized code designations: Sold conductor 1X07

Stranded condicor: HOT

Construction:

Conductor — cass I copper, soli, or class copper, stranded, a indicated below.

Insulation —PYC type TL.

Colours for cone idenincaos

Groowyello, blue or other colours (sce 6:3)

nial hick innma

Stlomladon |—T3seriimit | Upper tnit | Iam

itn * rn Main

15 T oF % 7B Voit

15 2 o7 ar 23 aie

25 1 08 a a9 ano

25 2 03 33 40 ce 9

4 1 08 ae aa ee 7

4 2 08 as 45 ows 2

6 1 08 4 59 oor s

6 2 os a3 52 oor

0 1 10 aa sa 10072

10 2 10 56 “7 (00067

16 2 10 8 0.005 6

B 2 12 oz 0063

=» 2 12 108 coos

0 2 14 18 oot

0 2 14 jue 6.004 0

95 2 \16 jira 0.003 9

20 2 16 8 0036

160 2 209 0.0036

185 2 22 ones

240 2 256 oma

200 2 ae ons

0 2 32 Joona j

008 2 a9 oons0

ea0e 2 uo au oom

10 pst econ

BS 6004:2000

‘Table 4 — PVC insulated, non-sheathed general purpose cable, 450/760 V, single core (continued)

1) Flenbie copper concuetor

NOTE The cates may be sulle for vohagee wp 101 WOW. or wp wo TOV to enh (ee anox A

[NOTE Fie rates hse cous szs sealer thn Sree? ae specie in Tale.

Harmonized code designation: HOW-K

Construction:

Conductor — class 5 copper, flexible

Insulation — PVC type 111.

Colours for core identification:

Green/yellow, blue or other colours (see 6:3),

‘Nominal ‘Radin aie ‘Mean overall diameter

crommaccciona aren | “of tnaulation Toot aes

Sieonductor

16 oz 28 34

258 os 34 41

4 08 30 48

6 08 44 53

10 10 57 68

16 10 87 an (0.005 3

B 12 84 12 0.0050

96 12 97 a 0.0043

50 14 115 138 0.0042

7 14 132 150 6.0036

6 16 151 182 0.0086

320 16 167 ena 0.0082

160 18 136 25 6.0032

185 20 206 249 0.0032,

240 22 235 284 6.0091

ens an uw

sulated, non-sheathed cable for Internal wiring, 900/500 V,

single core and twisted twin®

[Harmonized code designations: Solid conductor HOSV-U

Stranded conductor: HOEV-R

| Flexible conductor: HOSV-K

Construction

Conductor — cass 1 copper, sold, class2 copper, stranded or clas 5 copper, Nexible, as shown below

Insulation — PVC gre 7.

Colours for core identification:

Greenellow, blue or other colours (see 6.3 for harmonized tyres)

Gaswof | Badal aicaaees |___ Mew overall danct=r |

contactor a

nm x wn Maen

T on i 33 oo

\ i) 21 25 aos

1 1 06 a2 27 aon

05 2 06 20 oo

ors 2 96 22 aoe

1 2 06 28 ou

as 5 06 21 25 oor

076 5 06 pry 2a om

1 5 06 2a 28 010

ea a Ee te Opa crs oo WV ana ite a

2 ‘onst 200

BS 6004:2000

‘Table 6 — PVC insulated, PVC sheathed, light cable, 300/500 V, circular twin,

B.core, ¢core and 5-core

Harmonized code designation: None allocaied (see note 1).

ROTEL Taste of cable is incned in CENELDC Honiton Deciser Ub 2.58%, tor co no of agreement on col

ride dgd akc cetle, th cable pe cant be crlcere ae harmonod at Ro Raroried coe desiation Mas Wee

cto

Construetion:

Conductor — class 1 copper, solid, or lass 2 copper, stranded, as indicated below.

Inculaion — PVC type TM 1

Sheath — PVC type TM1.

‘The cores shall be twisted together. A centre filler may be used

‘The twisted cores shall be covered by an extruded inner covering, It shall be possible to separate the cores

easy.

‘The sheath shall ft closely but not adhere to the inner covering.

NOTE2 The eelneas of th inne eming is gen for ince only snd measurement sno ee,

Colours for core identitication (see note 1

twin — red and black,

Beore — red, yellow and blue.

‘core — red, yellow, bive and black.

Score — red, yellow, blue, black and greenvyellow.

Colour of sheath:

Torweti

a

Se] ot] ae’ | atv [Covert | nner] san

es

ws | we | ice ses

a a i aco oir

>for les fief its fein

axos ft leases, sft? ft its oon

2 fo fos fia as pana

axe fr fea’ fos fia fs pues |

2 feo fee juz fics fas ours

axe ft fea fas fit fits fins oanre

2 es les tz its [ia ots

exo ft ta fas fie fies fies Joao

ax fe fotos, faa fins fon fom

xis [+ for low fiz fatto Joo

axes ft [owas tz— fut iz0 ooo |

2 [os oa tz moo [ize joao

east wan 18

‘Table 6 — PVC insulated, PVC sheathed, Lixht cable, 300500 V, circular twin,

‘B-core, 4-core and S-core (coniruued)

Tae Saree | iat ete ast | eso amar ain

coetitea [S| gk] CERRY | CEE [Taverne Uer tie) un

=r see

= Pe ee

ei oes

> foo fos fiz fine fase foo

axe ft law fow fie fiz tts ovo

2 fos fon fa ras fans foo

sx L LO 06 4 158 175 0.0070

afte fos [tetas fia fo

acu 2 to fos, fa fame fats fos

ges 2 az fos, ftw 2x0 fone ots

gee fp fae fio tw aus foo Joa

was ft for fo ae oo Jus aon

2 fer few faa oo (wo ane

wes ft fee Jaa tz faze fas0 aoe

a les fee fue fate ins Yana

wat few foe ta Jtzo Jus oom

2 fas fos fa fxs fase oor

ace ft fas fos ta Ste tco oar

le fea festa go fafa

aot fia fos, faa fies fino favor

2 fro fos fia fimo fats aos

ace a fun fos fe fotos Jes

aces fe fia fafa fos fans ooo

gee fata ans dato feo oa

seis [afer fon ae fist fine foot

2 for oa fiz fio Jizz oma

sees fi fas foe tz fits fief

2 fos loa xa zo fra Jt

exe fos fon aa fins fico foonns

2 fos fos faa Ste fit ooo

oxo ft tom fon, fia icons oar

2 fon fos. fia fass. figs fous

oxo |r fio stos, Ss fie fit fax facor0

2 to oes figs at Joes

exw = fp te fossa foto fas focc

5x2 2 12 10 16 270 a5 ooo |

tee fp lio lta is fan aso ——focana |

“ eran

BS 6004:2000

‘Table 7— PVG insulated, PVC sheathed cable, 300/500, single core, flat twin and 3-core

ational type

Construction

CCondhictar — clas 1 plain cupper, solid, or lass 2 plain copper, stranded, as shown below.

Insulation — PVC type TL.

Sneath —PYC ype

In tin and z-core cables, the cores shall be 12 parle

‘The sheath shall lossy but not adhere to the corets).

Colours for core identification:

single core —red or black.

twin red and blac, of, for 2% 1 and2 x 15 cables, ved and red

Beare yellow (centre core) and blue

(Colour of sheath

single core — black, brown, grey, red oF white

fla twin and Score _— grey oF white confoming to BS CT40C (see 6.04

Numbered] —_Clamar | Raat sal Mean overall diners —| aime

imag | cette | ahs or | astm ot [Taner tinit | Uopertimie | Selon |

teeat wns

mat om ma mn om sini

Txi0 |r fas 08 38 rd oon

1X15 1 07 os 42 49 Joo

ixas | os og 43 38 010

1x4 2 oa oo ea 68 ‘ocr

1x6 2 oa og eo 14 0.006 5

1x10 2 10 ve i as |p0003

1x16 2 10 10 84 105 0.0085 2

1x2 2 12 u 109 25 005 0

1s 2 2 u 9 135 oust

xi jk os os 4oxez [arxad joan

xis |i or 09 saxo | axed | nn

2x25 08 10 s2xsa | o2xas |n010

2x4 2 08 10 soxas | 72x115 | 0077

2x6 2 08 ui exis | gox130 | 00065

2x10 2 19 2 rx ino | 96x 160/006

2x18 2 19 rey soxiss |uoxiss |o052

axso [a oo os soxes 47x00 [oon

axis it or oo 44xos | s4xis [oot

x25 |i 08 10 s2xus | 6ax135 |ao0

3x4 2 os 1 ssxiss | 714x165 |0.0077

9x6 2 os 1 saxiso | 8oxiso |n0065

x10 2 10 rey isxivo | 96x25 aos

axis 2 10 13 goxz0 [110x265 |ams2

TNOTR_Whar ud ya pau, aa cor wave Oca a ay aUaBe we Son Ben

onst em

6

‘Table § — PVC insulated, PVC sheathed cable with circult protective conductor, 300500 V,

‘single core, flat twin and 3-core

[Nationat type ]

| Construetion:

Conductor — clase | plain copper, sod, or clase 2 plain copper, stranded, as chown below.

Insulation — PVC type TL.

Sheath — — PVC pes.

| The core or cores shall be laid parallel with the uninsulated circuit protective conductor.

‘The cheath shall ft closely but not adhere to the cores

Colours for core identification

single core — rel or black.

twin, red and black, or, for 2 x 1 and 2 % L5 cables, red and red,

Bore — — red, yellow (centre core) and blue,

Position of circuit protective conductor

twin — centrally placed between cores in same plane.

Bore — centrally placed between yellow and blue cores in same plane

Colour of sheath:

Grey or white conforming to DS 67400 (see 6.6.4).

eT ae man eae | meoaiainaaac

occas) Tee | tea’ | he Tipe

ae

pest fos Jao. faaxos | ogc [ts ono

axa |e fos Jao Leexans. | ravine [us ors

pes fe fos fit. feasazs | aovease [as anes

px | [to jaz [eaxass. | comune Je omnes

pets tar fas faaoeans | eaves fie oon

[NOTE When reanired by the purchaser, alternative Conductor versions of cera sites way be avalabe ln de fem gm in Tales

ie condeies on

16 ons em

‘Table 9 — PVC insulated, PVC sheathed cable with or without circuit protective

conductor, 300/500, single core and flat twin (alternative conductor versions)

"Tis ble ves aerate cendavtr verte (Chis conductor) of erin ses of fo lon Gv in Tables and

‘tho eable construction, PVC sheath, colours for core identification, position of circult protective conductor

Gf relevant) and colour of sheath shall bo a8 given in Table 7 or Table 8, as applicable,

Tal ‘Gireait proteeive] Minami

teks of Tcndctery | isulation|

‘sheath inimusn nominal | resiacance

‘roonacctional | ae70°C

on rn Pores

Flat twin wihihou circuit protective conductor

(09 45x72 = Ooi

10 52x86 — 10

Flat twin with cirewit protective conductor

09 ax Be 10 oor

09 45x84 Lo" oon

10 52x08 1st 00

7 he csal prottve conductor sal be cna Joo vena TBR

‘Table 10— PVC insulated, non-sheathed cable, 450750 V, single core for

Installation at low temperatures

a) Rid copper conductor -

TROT Tw cabs ray be abe Tor WaIRGES UD TOTOWA OF TRV eer Ae Gow XA

Harmonized code designations: Solid conductor HU/V3.U

Stranded conductor. HOTV3.R

Construction:

Conductor — class | copper, sold, or class 2 copper, stranded, as indicated below.

Insulation — PYC type TL

Colours for coro identification:

Greon/yellow, blue or other colours (see 6.3).

‘Nominal ‘inse of | Mamie tezness Mean overal Gameter ‘naa

coaeeianataren | conehcte | “ottiaiston” —Toreriinis | Uppertinie | 0unon

iB T ~~ jor 26 32 rary

15 2 jor an 3a 010

25 1 os | 32 39 010

25 2 os 33. 40 e089

4 1 os 36 44 0.0087

‘ 2 os a8 46 0.082

6 1 os 4 50 0.0074

6 2 08 43 52 070

0 1 10 53 ot 007 2

0 2 10 56 er 0.0067

16 2 10 64 78 0.005 6

% 2 12 au ar | 0006 3

35 2 2 90 109 0.0046

50 2 us 196 128 0.0046

0 2 ut 124 M6 0.4040

95 2 1B Md 1 | 0.089

120 2 18 156 188, 0.008 5

150 2 1s. 173 209 000 5

185 2 20 ws 238 008 5

240 2 2a 220 209) 0a +

300 2 24 24s 206 Docs 3

$00 2 28. ars. 38.2, 0.005 1

8 8s eam

BS 6004:2000

‘Table 10 — PVC insulated, non-sheathed cable, 450/750 V, single core for

{installation at low temperatures (continue!)

1 Fess copper conor

OTE Te ee ay be He FTG Wp OUGUIYA oF ap DV tah CERRO

Harmonized code designation: HOTVS:X

Conserveion:

Conductor — clase 6 copper, flexible.

Inula — PVC insulation (pe ThA,

Colours for cone identification

Greewyellow, blue or other colours (see 6.3).

‘minal ead Tena aver dae Mian Fevalaton

crosnesetlonal aren | sickness of | Lower mit oe Ma resistance a 10

at ne = am Maen

oF ae a aor

03 ad 4 000 5

os a9 an gor 8

6 os ut 53 0.0068

0 10 87 68 02.006 5

6 10 67 81 0.0053

25 12 a woz 0.0050

% 12 27 ut 0083

0 ut us 139 anos

| ory 2 16.0 0.0036

95 1s mt 182 0.0036

0 18 167 02 0.0032

150 18 225 0.0002

185, 20 249 0.0032 |

240 22 2a4 0.0031 |

vst 22000 19

BS 6004:2000

‘Table 11 — PYC insulated, non-sheathed, heat resisting cable for

‘internal wiring, 450/150 V, single core

OTE Cabs Yavrg conus sans Shaler Wan SHY espe

Harmonized code designations: Solid conductor, —-HO7V2-U

Stranded conductor: HOTV2.R

Construction:

Conductor — class copper, solid, oF class 2 copper, stranded, as indicated below.

Insulation — PVC type T13.

Colours for coro identification:

Greeniyellow, blue or other colours (see 6.3).

Nominal Tas of —| Waal tno ean oer ao Tina

comer ren | cnttcor | “atinston” —Toperinie Upper aie malo

reat on ne min

15 T far 26 a ou

1B a or a a lemo

25 1 0.8 32 39 0.010

25 2 os 33 40 009

a 2 os 38 46 0082

6 2 os 43 sz 0070

0 2 10 56 6T 00067

6 2 10 64 18 1.0056

25 2 12 a1 or 0053

6 2 12 20 109 0016

a) Piet copper conductor

NOTE eile ales faving conc sea all han Sn ae peed Tale

Hiarmontzed code designation: HOTV2-K

Constrvetion

Condhictor — cass 8 copper, fexble

Insulation — PVC type T13

Colours for core identification:

Greenyellow, blue or other colours (se 6.3)

Nominal 1 Meas eral acter iain iwleton

rompacetinal even Tomer mi ‘Unper tine] tdetanee 00°C

sa? an an i ten

5 7 ry 3a

25 08 a4 4

4 os 39 \as

6 os “4 53

0 Lo 81 68

10 Lo or a1

2 2 sa 02,

35 12 97. juz |

20

ast sem

BS 6004:2000

‘Table 12 — PYC insulated, non-sheathed, heat resisting cable for internal wiring

200/500 V, single core and twisted twin*

[Harmonized code designations: Solid conductor HOSV215

Stranded conductor: HOSV2-R

Flexible conductor: HOSV2-K

Construction:

Conductor — class 1 copper, slid, class? copper, siranded, or class 5 copper, flexible, as indicated

below.

Insulation — PYC pe T13.

| Colours for core identification:

Groonlyeliow, blue or other colours (s2e 6.3).

romana area | contac | “Sthuacee” [Taser] imi) ilo

ot nm mm wn Navan

los 7 fas 13 2 v0

070 1 as ea 25 oars

1 1 06 22 2r oon

05 2 as 20 24 ars

07 2 03 22 26 oor

L 2 os 23 28 oon

jo: 5 5 0.6 a1 25 | 0.013

ons 5 03 22 27 acu

L 5 03 24 28 2010

7 td noel pe compe vo HOOD cates wid gab

est ten a

BS 6004:2000

‘Table 19 — OU resisting PVC sheathed, screened cables, 300500,

having between 2 and 60 cores

Harmonized code designation: HOSWWCAYS-K

Gonstrvction:

Conductor — class 5 copper.

Insulation — PVC type T12,

Inner sheath — PVC type T™M2.

Braided sereen. — plain or tinned copper wires.

Sheath = PVC ype TMS.

"The cores shall be twisted together, necessary, in soveral concentric layers.

A centre core is not permitted but a centre filer of suitable material may be applied.

Assemblies with three or more cores chall have one core coloured groen'yellow.

Around each layer a tape may be applied which may cover the cores fully or parly. The tape shall not

Jadhere to the cores.

For two core cables, the space between the cores shall be filed either by separate filers or by the sheath.

filing the interstices.

‘Cove identification:

xcept for the green/yellow cor, if ary, all cores shall be identified by number in accordance with

BS EN 50924, using black as the base and white for the inscription.

Numberand | Redial | — lal | Maziwem | — Redial ean ovata damatar —| Minimom

‘hieknors of | ‘hicknose Of Foyer] Upper nme) insulation

c otter sheath resistane|

70°C

2x05 os ar 016 oo 77 36

axa jos 07 |oa6 foo 80 100 oon

2x1 08 or p16 09 82 10a 0.010

2x 15 07 07 6 10 903 16 010

2x25, 08 or 016 ub 107 133 0.008

sxo5 08 lor xe 09 50 100 ors

axo7 — |06 07 016 09 83 jos oo

3x1 05 7 016 10 BB 10 010

3x15 07 or 016 10 97 11 oo10

9x25 08 07 016 1 us 140 0.008

4x05 06 07 016 09 85 107 oars

4xa7s os. lor 016 10 a 43. oot

ba 06 07 016 10 94 7 0.010

4x15 oz o7 016 ua 107 132 ocx

4x25 08 os 016 12 126 155 ce

5x05 06 07 0.16 10 93 jie joors.

5xa7 [06 07 016 10 or oon

5x1 06 or 016 ua 103 128 010

5x15 o7 08 06 2 us. 447 oto

5x25 08. 08 021 13 139 172. Doce

2 est 22000

BS 6004:2000

‘Table 13 — Oil resisting PVC sheathed, screened cables, 300/500 V,

having between 2-and 60 cores (contirad)

Ta | EE | eer — ag

——. geting] flokiay aes aerermer 7 eamre| are

a oma mae

wr | me | me | me | me | om | me | nom

x08 a a a ee a

sxom foe ler law = [urate tafe

ox loser fae fits Jno Jtgs ete

sxis or fea, fasta tarts ane

cxzs fos fes, fos fia figs funy cn

rxos fos far foe uns fuao,—S sane foun

Troms fos for fost fins, [ton

a” ee fea. oue fia fuze itso

Ris ier les fon 13 RRR th

reas ta fess fost figs Sans fo

axes fos fos fon fas sons

teas os fea fonts 2 foam

ber lee fee foe a ea

axis jor les fon ms ona

gece fea fee aS as ome

wxes fos foe fon faa 0 fom

wren fos fos fea lis te (oan

ta ies fas fat iS as onto

wei, |e (RE Rs me sie

was oa fas fasta ms omma

nxos fos fos fon as a1 — ons

zoos oo (os oat ar oa

fou” fos fea ot ie er

tous or fas oa fae mo om

goss fos ta ome as ieow

woxes fos foo ar fir fans

sexurs fos foo fot ists aga

sat fos, fos fot iS RR

sas for to ows ss Sete

36X25, 0.8 AL 0.26 a4 [sis 385 |0.009

waves lug «Slee slam tues, sda

48x07 [06 10 020 et |249 304 Joon

48x1 0.6. 10 026 2.1 BL 319 | 0.010,

foxus fer [trom fae fans, fate oma

gous fos tz ot ft RS to

wxes fos ao ows farses fata oan

coxa os tows ass ito talon

wor os (ts fos fas asta oto

axis for fit fos fk BR dS

axes los [tz on assassin tum

oust zane 2

BS 60042000

Annex A (informative)

Guide to the use of PVC insulated cables

Detail givon in this annex are intended only a gencral technical guidance ard not as an interpretation of any

UK etatutory requirements, where these anol.

[NOTE None othe cep sec this Maker send to be ld verre

‘The cables specified in this standard are suitable for use where the combination of ambient teraperature and

temperature rise duc o lood results in a conductor temperature not exceeding 70°C (90°C for heat resisting

‘pes specified in Tables 11 and 12) and, in dhe case of a shorecircut (maximum allowable time 5), the

‘maximum conductor temperature does ot exceed 150°C for conducior sizes up to iid nh 00 ran

and 140°C for eonduetcr sizes above 300 mn?

[NOTE 2 The shartccu erpeatre shes onthe sins proprtis of the isting mae. i exon that dhe sezesoes

‘ach are sed inthe cable stem with chars andor eeldeod eonnacone ate rier the Kenpertane taped for tne cle

[NOTE teataation requirerents ad cuent ratings er deed it 83757, or sii epenc> epson

NOTE. Anexpanded gle tn sete spore nti stan dad ie BS TED.

‘Tyical uses of te different types of cable specified in this Sandard are given in Table A.

‘Tuble A.1 — Gulde to the use of PVC insulated cables

cn Tae type ee ‘Compentr

7 ‘Siagla core, mem shoathed goal puarpoe

| and4b) | Installation m surface mourtod or Stitable for use in channels with cover, Suitable For

embedded conduits, or similar closed _| fined protected installation in or on light fitings and

systems, insie appliances, switchgear and contraigear, for

voltages up to 1.000 Vac. oF up to 750 to earth, de.

5 ‘Single Cove wail RSID Rpm,

‘won sheathed, for internal wiring

Fised protected inatallation inde Suitable for inatllaticn it suxface mounted oF

appliances and in or on light fitings | embedded conduits, cnly for signalling or control

L ‘conduits.

6 Tight PVC Sioned

‘hxed incallason in dry or i Unsuitable for outdoor use or embodding in concrete

7 Bandy |Shige cove flat hom ond Seore- PVC]

shecihert, with and without protecting

conductor

‘xed installation in dry or damp presises| Suitable for instalation in walls, on bors nd in

Cchannls oF embadded tn plaster

tay | Single core, non-sheathed for Toa

and 100) | iemporarure installation

‘As for Tables da) and 40), but suitable for | Suitable for uae in channels with cover Suitable for

installation at low tomperatures fixed protected installation in or on light fittings and

inside appliances, switchgear and controlgear, for

voltages up to 1 000 V ae oF up 10 7 V tp exrth, de

Tia) LID) | Single cove anu vised tin, Rea

and 12 | resisting non-cheothod |

For intemal wiring only. Maximum conductor temperature in normal use 90°C.

Not to be used in contact with objects at emperatures

higher than 85 °C,

Not sulable for fed installations in distribution

i gstome

ci Oil resist, PYC shanna, Soro 1

‘The interconnection of parts of machines |The cables are resistant to general purpose mineral oils

‘used for manufacturing purposes including) but are not designed for continuous immersion in

machine tools where some degree of | They are intended for use inside buildings. |

protection against electromagnetic Canauninaiion by tydrocarbons, acids and alkalis

interference is required. After installation | should be avoided and the cables should be protected

the cables may be move for the | agains: mechanical Gamage. Installation in eonduts,

reposiidoning, maintenance, adjustment | marking ete. advised. Where contact with special oils

‘and inspection of machines provided that | is likly, advice should be sought fram the

the cable isnot mechanically stressed | manufacturer.

during movement, but screened cables are

not designed for Continnal flexi

m const 2am0

Annex B (informative)

Guidance on procedure for routine tests on PVC insulated cables of rated

voltages Ui/U up to 450/750 V

NOTE The fllomingsonation i intended reovde glance othe abloke on slahe proces fr te rosie esting of

ores an conplctedcatlen They say he raane byte tarictrer at hs dread sb not be tesa ws queers

‘his stm

B.L Teste on cores

B.1.1 Spark test

CCanry out the spark test in accordance with BS 6000 using tho test voltages given in Table BL

‘Table B.1— Spark test voltage

Tibaisted radial Giciness of Inalation Test voleage

‘Abos Up cand incoaing ae may ae

mn co Ww W

= 10 é o

0 15 10 B

15 20 5 B

20 25 20 x

25, = 25, 8

See Tle conan Se 1

B2 Tests on completed cables

B21 General

‘Subject completed cables to the tosis described inB2.2 toB24.

1.22 Conductor restscance

B22. Prone

Leave the cable in the vest area, which is at a reasonably constant temperature, for sufficient time to ensure that

the cable temperature is equal to the ambient teruperatare

Messure the dc resistance of the eondactor at ambient temperaeure.

B.22.2 Recommended test criteria

Calculate the resistance per unt longi from the production longih of the completed cable and not from the

Jength of the individual cores.

The dc resistance of the conductor corrected to 20°C by the appropriate Factor given in IS 6360 should conform

to BS 6360.

B23 Voltage test

B2B1 Procedure

For single core shoathed and non-choathed cables, immerse the cable cample in water for not les than 12h and

then apply the test voltage between the conductor and the water, which should be earthed,

For tvin and multicore cables, apply the test voltage, without immersion in wacer, between each conductor and

{groups of other conductors in such a Way that tho insulation on each core i tasted agranst all adjacent cont and

‘any protective conductor or metalke screen, which should be earthed, The condctors of mukicore cables,

speeifiod in Table 13 may be suitably connected for sucocesive applications of the test voltage to limit the total

{esting time, provided that the sequence of connections ensures thatthe test voltage Is applied for the time given,

between each conductor and every other conducior

oko the test at ambiont tompersture with an aitamating voltage of approximately sine-wave form, having 0

Sroquoncy in the range 40 Hs to 61 Hz Inerease the voltage gradually and maintain it at she fall ems, value given

in Table B2 for 5 mi.

‘Table B.2— Insulation tost voltage

“Taulnea? radial ickness of imalation Tetvoiage ne Gand

o7 10 j20

Seo slevantcemmrtion i

BS 6004:2000

B.2.3.2 Recommended test criteria

No breaksiown of the insulation should ovcus

B24 Insulation resistance

B24. Procature

[Immediately ater completion of the voltage tes: described in B2.3, apply a dc. voliage of 300 V to 600 V to each

‘ore for mit and measure dhe insulation resistance.

For singe core sheathed ard non sheathed cables, leave the cable inmersed in the water and apply the test

voltage between the conductor and the wacer, which should be earthed. Malniain the temperature of te water at

or near 20°C,

For twrin and mukicore eabes, apply the test vakage between each conductor ane all adjacent consluctors,

including any protective condhicior or metallic screen, which should be earthed.

B24.2 Recommended test riteria

‘he insulation resistance of each core should be not Jess than tht derived from the following equation:

n-)

is the insulation resistance of each core at 29°C in megohim Kilomerzes (M-4an};

is the insulation resistance constant at 20°C in megohrn klemetes (equal to 35 Nika)

{is the diameter over the insulation in millimetres (ram);

Is tho diameter over the conductor in mlimetres (mu)

where

Rome

IW the test s carried out at a water temperature cthor than 20°C, the measured insulation resistance should be

‘mubipied by the appropriate correction factor from Table B.3 to give the insulation resistance at 20°C.

‘Table B.8 — Temperature correction factors

Tennecitare Carvetion asta

e

w oaT

nu oso.

2 on

1B ars

“ arr

16 080

16 jose

7 oss

18 89

19 ast

2 100

21 1.06

2 us.

3 120

24 at

25 135,

26 ae

27 154

28 165,

20 Lt

30 190

6 const 22m

BS 6004:2000

Annex C (normative)

Electrical tests

CA Test conditions

Unless otherwise specified for a particular tast, make tasts at ambiont tomperatare with allemaiings voltage of

approximately sino-wave form, having a frequency in the rango of 40 Ha to 61 Ha, and of the value given in

‘Table C1. The ratio peak valuefcms. value shall be equal to (2 wilh a tolerance of #795

‘Table C1 — Summary of electrical tacts

“Tet Unies | 900600 abies | aS07S0V cables

Coneuctor resistor (327.2)

Leng of sample (minim) ™ ou 1

Voltage test on completed cable (36073)

Length of ssanple (minim) ma 2»

Pesiod of immersion (rina) n 1 1

Temperature of water co ions +5

Applied acc voltage (rms) v 2500

‘Time of application in 15 15

Volta test on cores (see 7A)

Length of sample (rnin) ms —

Period of immersion (minum) h 1 7

‘Temperauure of water vc laos =

Applied ac. voltage (mss) according to the speified

‘thickness of lnsulztion:

for insulation thickness up to and inctudingd6mnm |v [1500 -

for insulation thickness exceeding 0.5 mm yy |2000 — |

‘Time of application min (5 —

Absence of faults tn the insulation (27)

Spark test

Result he obtained No breakdown of | No breakciown of

the insulation the msulation

Voltage test |

Applied ac. voltage (ems) fy | 2000 2.500

Applied de. voltage 5000 5000 |

aration of test nin [5 5

Result to be obtained No breakdown of _|No breakdown of

the insulaion | te insulation

[Preudation resistance (see 7.8)

Length of ounple (previously tested to G8 or 2) |m [5 °

Period of immersion (rinimurn) ne 2

‘Temperature of water (types TIL, T12, T14) so |ox2 7M:

‘Temperature of water (type TLS) so soe 22

Tong torn resistance of insulation to da emo) |

Length of sample im [5 5 |

Period of renersion (miniraury) hn 10x28 xa

Temparature of solution so feos x5 |

Duration of applied voltage h 10x24 woxm |

ona nemo a

BS 6004:2000

C2 Voltage test on completed eable

C21 Test sample

‘Take a sample of cable, as manufactured, of the lensth given in Table C21

C22 Procedure

[immerse the sample in water at the temperature, and forthe period, given in Table C1. Ensure tha the ends of

ue cores protrude above ihe water by a distance sufficient to prevent excessive Surface leakage when the test

voltage is applied

Apply a voliage of the magrutade given in Table C. in tun beeween each conductor ard all the others connertet

together and to the water, and between all conduetors and the water, for the ime given in Table C1. Connect

‘ny uninsulated circuit protective conductor or metalic sereen to the water at all mes.

‘The conductors of multicore cables may be suitably connected for successive application of the test voltage to

lint the total testing time, provided thatthe sequence of connections ensures thatthe voltage is applied, {or the

‘Specifed time, between each conductor and each other conductor.

C38 Voltage test on cores

C31 Test sample

Propare a sample of cable of the length given in Table C.1 by carefully removing the sheath and any other

covering or filing from a length of complete cable.

03.2 Procedure

Immerse the sample in water al the teruperatare, and forthe period, given in Table C.1. Ensure that the ends of

the cores protrude above the water by a distance suficient to prevent excessive surface leakage when the test

voltage is applied, Apply a voltage of the magrutude gven in Table C.L, betwoen the conducters and tho waver for

the tame givon in Tablo C.

Gal Insulation resistance test

CALI Test sample

‘Make the test on a sample of cable ofthe lengch given in Table C.1, previousty submitted to the tes specified

| C.3 or, this isnot applicable, on 2 sample previously submited to the test specified in C2.

C42 Procedure

Immerse the sumple in water previously beated tothe temperature given in Table Cl, with a length of

out 250mm at cach end of the sample projecting above the water, for the peciod of tine given in Table 21

Aprly a de. voliage of betaveen 80 V and £00 V between each conductor and the water.

Measure the inaation rewstance of each core 1 min after appllcaion ofthe voltage. Use this value to ealeulate

‘the insulation resistance of a1 kin lenglh of each core.

C5 Long term resistance of insulation to de.

C5. Test sample

Carry out the test on a sample of cable ofthe length given in Table C., from which all coverings have been

removed, Tako eare to avoid damage to the cores during removal of the coverings.

(C52 Procedure

Immerse the sample, for the period and at the temperature given in Table C1 in an aquecus solution af sodiam

chloride having a concentration of 10g, with a length of about260 mun at each end of the sample projecting

above the solution. Connect the negative pole of a220-V die Supply to the eandctorts) of tha ample nev the

positive pole to a copper electrode immersed in the solutcn, for the tne given in Table C1

C6 Absence of faults in the Insulation

C61 Tost Length

‘Test all cable that isin the final stago of manufactare, whother itis in delivery lengths or in manufacturing

lengths por to being cut inca delivery lenges,

©62 Procedure

62.1 Generat

‘Tet single core cables by the spark test in accordance with ©.62.2 and multicore cables and sheathed fat cables

diy the woltage test i accordance with 6.23.

Ey onst aM

BS 6004:2000

€.6.22 Spare test

©6.22.1 Apparatus

‘The spark test equipment shall provide a magnieude and presence of the voltage tha, together with the electrede

ssysiemn employed ana ine Speed oF passage erapioyed, is Capanle of detecting & puncture in the islation of the

cable having a diameter equal to or greats than haif of the speciied insulabon, thickness

‘The voltage applied by the spark tester shall beac. or de.

‘When the spark test equipment is testod as daseribod in annex E all the fate shall be registered by the

‘equipment. The recovery time ofthe spark tester shall be not greater than 1's

6.0222 Precemere

‘The cable shall be passed through the spark test equipment using the electrode system, voltage levels and

‘operating speed of passago established under C.4.22.1

6.6.2.3 Voliage test

With the cable in the dry stale and at anibient temperature apply a volage of the magnitude given in Table C.1

supplied elther from an zc. source br from a d.c. soiree, between each conductor and all the cer conductors

connected 19 earth,

Increase the voltage gradually and smantain it atthe ful value for the duration given in Table C1.

‘The conductors of multicore cables may be suitably connected for sucosssive application of the tect volage to

limit the total teting timo, provided that the sequence of cornections enmures that the voltage is applied, for the

‘spocdied time, borween each conductor and each other conckictn

C7 Serevning efficiency

NOTH: See IRE SUL ION, A.

(©7.1 Principle

‘The screening efficiency of a cable screen depends both on the screvning adainst cunrents and the screening

aguinst voliages

The sereoning ficiency against currents is specitied in tors of the transfer impedance due to resistive and

‘magnetic coupling per nit length, that against voliages in terms of the transfer admitance due to electric

‘coupling (sce note) per unit length. Transfer impedance is defined in an elenventary length of cable as Ue ratio of

Lhe voltage measured along the screen in the disturbed system to the curren: lowing in the iverferin system.

This may be of imerest at any frequency up to 10 000 MHz. In geceral, there ts to problem where hemingenens

Cylindrical shields are used since the screening effect in such cases ean be readily caleulaced, but where

braided or taped corstruction is employed it becomes necessary to measure the ecrecting efficiency. The present

Stato of experience chows that the eurface transfer impedance remains constant a frequencies from 0 Hz

to 0.1 Miz or | Miz, depending on the type of cable ard is equal tothe direct current resistance of the screen. At

frequencies over 0.1 MHz or 1 Mil the transfer impedance increases, Depending on the construction of the

seveen, tus increase starts direcly oF afer having passed through 2 minh,

(Over 10 Hz to 15 MH, the increase is proportional to the frequency.

‘Transfer admitince is defined in an elementary Iengh of cable asthe ratio of the current flowing tnto the

disturbed system to the voliage origatng it inthe specified interfering system. Measurements show that the

transfer admuttance may be represented by a capacitance whichis independent of Frequency from audio

fraquoncies up to 000 MHz atleast

NOTE Atertin s drown othe fact hatin seme courses he term “rarfer tance” take tobe the recto of acter

Inpedance” Misch sth coin he ander

C.72 Transfer impedance due to resistive and magnetic coupling

C72. Test apparatus

‘The apparotus io of the “tiple cou” form (see Figure C.1), A short length of the eylmical seen. under

investigation forms both the inner condacior of an energized ccaxtal system arc at the sane time, the outer

conductor of another coaxial line. The signal in the inner coaxal syste is caused by the surface transfer

Iinpedance of the sereen.

‘The cable with the screen to be measurod is termined at one end by a resistance, the value of whict is

‘numerically equal to the characteristic impedance of the screen. The lerninal resitance is stele] by a metal

lesve the edge of which, atthe open end, is soldered to the screen. The terminal resistance and dhe cable are

‘coaxially mounted inside'a metal ube. This ube Is venninated at the side oppasite the resisance by &

shorteireuling disc, which is soldered to the sereen (see Figure C.1).

‘The length of the cable in the meal tube shall ot excced 0.12 to 0.952 according to the measuzing ecuiorment

eed, wheres che wavelenh coresponding wo the frequency Of Ue test asa. THe length of te

projecting cable is of nn enasequence

8s 12200 a

BS 60042000

x

Vv

e

1, Terminating rsetor (of vexsionce 8)

2 Our oun apt

A Screen ener tet

‘fer coal ene |

& aes

8 Store dretng dive

R= Z,whero 2b the character impedance ofthe ner coal eter

[NOTH For tho measurements of sete coupling the abeath shed be removed rm the cae as the Hel seg

th outer cence sereuly ec by het,

Figure C.1— Test apparatus for measurement of transfer impedance due to

‘resistive and magnetic coupling

122 Tt prennie

‘he outer coax sem, fone by the seen under investgcn andthe metal re, shal be fc fom a

generator trough an inercorected resiance(Mta0dT) oF By way of direct connection (tethod 2)

‘The measurement. shal be eared outa. Mz

NOTE Perth method ce engh of Im or eqae. To consent sappy

Method I: Feng tough aresisanee

‘he generator feeds the outer coma vst through a pute resistance () which, to bet avant, sould be

etal fo about ties te value ofthe characte Inpeiace ofthe omer coal sys The mp vokage

to'te resstanee is measured by means oft sah volmecer The oop sltage ofthe ier owl seta

‘which s formed by’ the eable proper, is mearued by micns of a matched voltmeter

‘Tre wanster impedance, ots per mee (A) tal be allt tom the Towing equation

Be

Pal Bx Te x

where:

Bin the fooding recitance, in oluns (1,

42 istho length ofthe sereen under test, in metres (in) (62e Figure C1)

U;,_ fs the input voliago of the outer eystom measured before tho resistance R, in volts (V};

Uz_ is the output voltage of the inner systom measured atthe ond of the screen, in volts (V);

Fis. factor, which allows for the froauoncy response (sve Figize C2). The exact value ia caleulated fram

‘the equation:

(=r nleost ae eae

20 ows emo

ere

nM kee i of be damseingodes fe oe ano este

te drat gee of oer yen a ins

4, $6 the electrical wavelength in the outer systems

Jaq, isthe electrical wavelongth in the inner eystem;

Mesbot 2: Direct eating

‘The tans feeds the ower stem dec Te input volage of is system is measured athe begining of

the aeen Te ou vohage of the ner gern cared fs hated tt edd 1

‘This method is preferable if ii necessary to operate at seater input vokage, as for itstance with scree of a

‘ory Heh secon ciiclcy ot ih low sense oupasvoaters Fortis co, ger etc a

be wed ban foe metod 1

The uafer impedance, Zn obs per neue (i) ul be act an heaton:

Us

Pat 2a x BE Bc

Were 2, UU andy ae gen i et

FP” (gee Figure C.3) is caleulated from the equation:

F (Q - 2)sin x

Wrr(cos x — cos ney? + (sin — nsin nz?

tier wane are gen re

For either method, instead of measuring U; and Us separately the ratio Uy/U, may be determined direcay by

smears of a calbrated aitenuaicr

ons 2m

BS 60042000

18

ELLE eal

tL e-em

1

08.

06

04

02 I

20 05 19 ' 20 a

me oust wam0

, TTI

1

16 mye

he

he

“

n-ho

nbs

12 ee

LEE

. Bee

a

os

|

| os

os

é

HHH

0305 10 6 2 25

igure C3 — Correction factor |

|

en ws

BS 60042000

Annex D (normative)

Measurement of thicknesses

D.l Meaourement of insulation thickness

D.l.A Procedure

‘The thiciness of insulation shall be measured in accordance with BSEN 6(611-1-:1906, 8.1, Throe samples shall

be taken from the cable; each sample sal be separated from the next by a distance of at least Im.

Conformity shall be checked on each core

[i whdrawal of the conductor is diftcalt, it shal be stretched ina tensile testing machine or the picce of eore

shall be loosened by stretching or some cther suitable means that docs not damage the insulation.

‘The cores of fat non-shoathed cables shall not be separated.

D..2 Evaluation of results

"The aueas of Une 18 values (expressed in millimetres) obtalned from the three pleces of insulation from each core

‘hall be calculated to two decimal places and rounded off as follows, and this shall be taken as the mean value

ofthe thickness of insulation.

fm the calculation the second decimal igure is 6 or more, the firs: decimal figure shall be raised to the next

number, thus for example, 174 shall be rounded to L7 and 17510 18