Академический Документы

Профессиональный Документы

Культура Документы

Design of Phenol Plant

Загружено:

api-292667997Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Phenol Plant

Загружено:

api-292667997Авторское право:

Доступные форматы

ABC Corporations Phenol Production Plant:

Design and Economic Evaluation for 300,000 tons/yr

Group 21: Laura Bertrand, Brandon Burns, Amiel Kirtikar, Brandon Lorentz

Economics

Design Objective

ABC Corporation is looking for a cost-effective method of attaining 300,000 tons of phenol

per year as a raw material for their downstream resin production. Currently, phenol is

purchased at $0.64 per pound. Cumene, a raw material in phenol production, can be

obtainable internally for $0.60 per pound. Our technical assignment included designing a

phenol plant, estimating the production cost of phenol per pound, and making an

economically feasible decision for ABC Corporation

Process Overview

Capital Costs

Continuous Process Emissions:

Total Capital Investment (TCI): $271 MM

Total Installed Equipment Cost, MM $

Unit

Coolers, $7.6

Misc, $15.1

Oxidation Reactor

Vent

Reactors, $13.4

Waste

Phase

Waste Flow and Composition

Treatment

(lbmol/hr) (mole %)

Treatment Emission Disposal

Total: 4080

Gas

4%_Oxygen, 96%_Nitrogen

Trace Amounts:

Burning as fuel

Acetone, Cumene,

credit

Carbon Dioxide

Vent to

Atmosphere

Hydrogen

Exchangers, $36.6

Columns, $25.9

Streams of compressed air and pure cumene are fed into oxidation reactors where the

cumene is oxidized to cumene hydro peroxide (CHP) and a by-product di-methyl benzyl

alcohol (DMBA). Cumene in the vent from the reactors is recovered and recycled back into

the process.

Unreacted cumene, CHP and DMBA are then sent to a distillation column where cumene in

the distillate stream is recycled back to the oxidation reactors. In the bottoms, CHP, DMBA,

and any remaining cumene is then sent to a cleavage reactor. CHP is cleaved to form Phenol

and Acetone and DMBA reacts with the sulfuric acid catalyst in the cleavage reactor to form

alpha-methyl styrene (AMS) and water.

Acetone, water, cumene, AMS, and phenol are then sent through a separation train of

distillation columns to isolate each component. Isolated cumene is recycled back into the

oxidation reactors. AMS is hydrogenated back into cumene, which is also recycled back to

the oxidation reactor. The water stream is sent to a wastewater treatment facility. The byproduct acetone is cooled and stored for sale, and the final phenol product is cooled and

sent to the resins plant.

Column T-100

Partial Condenser

Vent

Hydrogenation

Reactor Vent

Cleavage Reactor

Catalyst and

Organic Waste

Column T-104

Bottoms Waste

Compressor, $16.9

Operating Costs

Total: 23

Gas

Trace Amounts:

Nitrogen

86%_Nitrogen, 12%_Cumene, Phenol, Acetone

Vent to

Atmosphere

2%_Oxygen

Total: 5

Gas

98%_Hydrogen, 2%_Cumene

Trace Amounts:

Burning as fuel

Water, Carbon

Vent to

AMS

credit

Dioxide

Atmosphere

Not Simulated

Solid

Aqueous Sulfuric and Organic

Water-Treatment Salts

Bacterial

process

Digestion

Acid Salts with Sodium Phenolate

Total: 44

Liquid

98%_Water, 2%_Cumene

Trace Amounts:

Water-Treatment Cooling Water

Acetone

process

Total Annual Operating Costs: $483 MM/year

Production Costs, MM$/year

Misc

,$38.6

BTCF,

$91.4

Major Safety Considerations

Utility Costs, MM$/year

Cooling Water,$3.7

Reactions

Misc, $2.3

Cleavage Reactor:

-Rapid CHP decomposition causing a

Runaway Exothermic Reaction

Refrigerant,$0.4

Hydrogenation Reactor:

-Flammability of Hydrogen resulting in explosion

Electricity,$3.5

Oxidation Reactor

Cleavage Reactor

(Main Reaction)

(Main Reaction)

(Side Reaction)

Health & Environment

(Side Reaction)

Utilities,

$46.7

Raw

Materials

(Cumene &

Hydrogen,

$306

Minor Safety Considerations

Steam,$36.9

Oxidation Air Compressor:

-Compressed Air Temperature below 600 F to prevent auto ignition of cumene

Economic Decision

Final Production Cost of Phenol: $0.73 per pound

CHEAPER to BUY Phenol

High Pressure Steam Reboiler:

-600 psi steam used in AMS/Phenol Distillation Column Reboiler

Oxidation Reactor Vent Composition:

-Oxidation reactor vent LOC with cumene is less than 6 mol %

Commercial Uses and Supply Chain of Phenol

Hydrogenation Reactor

Phenol is used in various products:

Simulation:

Epoxy Resins paint coatings

Polycarbonate plastics CDs and domestic electrical appliances

Nylon and Polyamide plastics carpets, nets, and clothing

Antioxidant in rubber manufacture

Intermediate to herbicides and insecticides

Manufacture of surfactants, detergents, and emulsifiers

Precursor to pharmaceuticals aspirin and chloraseptic

Yield of Phenol: 99 %

Benzene

Specifications:

Pressure of oxidation reactor = 80 psia

Temperature of oxidation reactor = 212F

Pressure of cleavage reactor = 14.7 psia

Temperature of oxidation reactor = 176F

Pressure of hydrogenation reactor = 110 psia

Temperature of oxidation reactor = 194F

99.9 % Purity of Acetone

99.99% Purity of Phenol

Various pressures for distillation columns

Phenolic Resins

Naphtha

Cumene

Propylene

Air

Propane

Natural gas

Naphtha

Crude Oil

Phenol

Hydrogen

Air

Water

Crude Oil

Вам также может понравиться

- Phenol ProductionДокумент9 страницPhenol ProductionPlant Design100% (1)

- Phenol Plant CostДокумент3 страницыPhenol Plant CostIntratec SolutionsОценок пока нет

- Production of Aniline From Ammonolysis of Phenol - 2010-CH-09,61,65,87Документ17 страницProduction of Aniline From Ammonolysis of Phenol - 2010-CH-09,61,65,87Shiraz Daud100% (3)

- CEMS Operating & Maintenance ManualДокумент71 страницаCEMS Operating & Maintenance ManualFahmi Ali100% (4)

- Phenol From CumeneДокумент2 страницыPhenol From Cumeneali100% (2)

- KBR PhenolДокумент2 страницыKBR Phenolstavros7100% (2)

- Phenol From Cuemen and TolueneДокумент9 страницPhenol From Cuemen and TolueneAnonymous RJkpep7D0rОценок пока нет

- AnilineДокумент1 страницаAnilineCherry Pearl MiparanumОценок пока нет

- AnilineДокумент2 страницыAnilineKPAC333100% (2)

- PET Production Technical ReportДокумент78 страницPET Production Technical ReportMiguel Eduardo Sanchez Ramos100% (1)

- Production of PhenolДокумент22 страницыProduction of PhenolShubhranshu Kathuria71% (7)

- Production of PhenolДокумент120 страницProduction of PhenolAlyxОценок пока нет

- Engineers Guide - Cumene Peroxidation Process For Phenol ProductionДокумент2 страницыEngineers Guide - Cumene Peroxidation Process For Phenol ProductionEdrian A. Mañalong100% (1)

- Fundamentals of MasstransferandkineticshydrogenationДокумент14 страницFundamentals of MasstransferandkineticshydrogenationRamandhaPrasetyaAdibrataОценок пока нет

- Polyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976От EverandPolyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976A. GuyotОценок пока нет

- Yellowing Behavior of TextilesДокумент8 страницYellowing Behavior of TextilesMohammed Atiqul Hoque ChowdhuryОценок пока нет

- General Chemistry 1 2ND QuarterДокумент50 страницGeneral Chemistry 1 2ND QuarterJulienne Bigornia80% (5)

- Phenol PlantДокумент33 страницыPhenol PlantrakeshОценок пока нет

- Cumene To PhenolДокумент73 страницыCumene To Phenolvpsrpuch67% (3)

- Report BTPДокумент47 страницReport BTPvpsrpuchОценок пока нет

- Cumene To Phenol 2Документ73 страницыCumene To Phenol 2vpsrpuch0% (1)

- Side ReactionsДокумент22 страницыSide ReactionsAna Mariel VenturaОценок пока нет

- Production of Aniline by Reduction of Nitrobenzene: Group#2Документ26 страницProduction of Aniline by Reduction of Nitrobenzene: Group#2Arsal MaqboolОценок пока нет

- Presentation CumeneДокумент39 страницPresentation CumeneBis ChemОценок пока нет

- Presentation CumeneДокумент39 страницPresentation Cumeneممدوح الرويليОценок пока нет

- Market SurveyДокумент4 страницыMarket SurveyGenesis LowОценок пока нет

- Project: Design of A Reactor For The Aniline ProductionДокумент19 страницProject: Design of A Reactor For The Aniline ProductionLUIS ESTEBAN VÁSQUEZ CASTANEDAОценок пока нет

- Product Capsule Cumene/Phenol/Acetone: MarketworksДокумент7 страницProduct Capsule Cumene/Phenol/Acetone: MarketworksKevin L. BoyleОценок пока нет

- Methyl Methacrylate Plant CostДокумент3 страницыMethyl Methacrylate Plant CostIntratec Solutions50% (2)

- Project ReportДокумент12 страницProject ReportRabia SabirОценок пока нет

- Phenols in FuelДокумент12 страницPhenols in Fuelvzimak2355Оценок пока нет

- MEK in School SecondДокумент13 страницMEK in School Secondifiok100% (1)

- Cumene A PDFДокумент4 страницыCumene A PDFdanena88Оценок пока нет

- Phosgene-Free Route To Toluene DiisocyanateДокумент399 страницPhosgene-Free Route To Toluene DiisocyanateAhmed AliОценок пока нет

- Manufacture of Phenol From CumeneДокумент8 страницManufacture of Phenol From CumeneFabi OneОценок пока нет

- Direct Route To Phenol From Benzene PDFДокумент316 страницDirect Route To Phenol From Benzene PDFM Arslan AshrafОценок пока нет

- PresentationДокумент47 страницPresentationAsim FarooqОценок пока нет

- Types of Phenol Manufacturing ProcessДокумент4 страницыTypes of Phenol Manufacturing ProcessIsma AzraОценок пока нет

- CUMENEДокумент24 страницыCUMENEhiteshОценок пока нет

- C4 DerivativesДокумент2 страницыC4 DerivativesdaabgchiОценок пока нет

- Cumene ProductionДокумент26 страницCumene ProductionAMOGH JHANWARОценок пока нет

- CumeneДокумент5 страницCumeneNasmiyeth Rodriguez VittaОценок пока нет

- Production of Isopropyl Palmitate-Experimental StudiesДокумент12 страницProduction of Isopropyl Palmitate-Experimental Studiesikaw_3Оценок пока нет

- Economics of Aniline Production ProcessesДокумент4 страницыEconomics of Aniline Production ProcessesfdfОценок пока нет

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIДокумент12 страницPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshОценок пока нет

- Benzene: Chemical Economics HandbookДокумент3 страницыBenzene: Chemical Economics HandbookMaría VásquezОценок пока нет

- Acrylic Acid - MohitДокумент42 страницыAcrylic Acid - MohitvickuОценок пока нет

- Chemical Kinetics On Thermal Decompositions of CumeneДокумент8 страницChemical Kinetics On Thermal Decompositions of CumeneMario Alonso Velasquez FlorezОценок пока нет

- Cumene DatasheetДокумент12 страницCumene DatasheetDiana BanuОценок пока нет

- 0910 4 AbsДокумент9 страниц0910 4 AbsEngr Muhammad AqibОценок пока нет

- Wasteless Economic Method of Production of Phenol and AcetoneДокумент14 страницWasteless Economic Method of Production of Phenol and AcetoneSiswand BIn Mohd AliОценок пока нет

- Maleic AnhydrideДокумент6 страницMaleic AnhydrideTechnologist ChemicalОценок пока нет

- Linear Alkylbenzene Detal ProcessДокумент1 страницаLinear Alkylbenzene Detal Processramirali100% (1)

- 1,3 ButadieneДокумент7 страниц1,3 ButadieneAbdalmoedAlaiashyОценок пока нет

- Production of IsopropanolДокумент9 страницProduction of IsopropanolJohanОценок пока нет

- 64788Документ35 страниц64788ghatak2100% (1)

- Carboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsОт EverandCarboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsОценок пока нет

- Acetone Reactor Design Complete ProjectДокумент29 страницAcetone Reactor Design Complete ProjectSabeeh Ahmed91% (11)

- Phenol 12Документ2 страницыPhenol 12binaywatchОценок пока нет

- Proceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andДокумент5 страницProceso: Lummus Application: Improved Technology To Produce Highest Quality Phenol andAdrian Copa JОценок пока нет

- Chapter 1Документ4 страницыChapter 1miza adlinОценок пока нет

- Methanol From Natural Gas by ICI's FIMДокумент9 страницMethanol From Natural Gas by ICI's FIMFer MugrabiОценок пока нет

- Catalyst Catastrophes II: John Brightling and DR Mike RobertsДокумент12 страницCatalyst Catastrophes II: John Brightling and DR Mike Robertsvaratharajan g rОценок пока нет

- Schirmann 2001Документ18 страницSchirmann 2001Mencyn Michelle Kellie EbreoОценок пока нет

- Industrial ChemistryДокумент194 страницыIndustrial ChemistrySiti Mastura Abdul Rahman50% (2)

- The Environment Conservation Rules, 1997Документ49 страницThe Environment Conservation Rules, 1997Kawser Ahmed RaihanОценок пока нет

- Kidde Fire Systems Nitrogen Fire Protection System System DescriptionДокумент6 страницKidde Fire Systems Nitrogen Fire Protection System System DescriptionAbdel KoddousОценок пока нет

- Text Maam MarwiyahДокумент16 страницText Maam Marwiyahkhairunnisa P.O.V.PОценок пока нет

- Claude 3Документ139 страницClaude 3ndayizeyeyavan19Оценок пока нет

- Exemplar - Questions With Answer.Документ12 страницExemplar - Questions With Answer.Liveen .S100% (1)

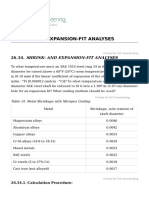

- Shrink - and Expansion-Fit AnalysesДокумент3 страницыShrink - and Expansion-Fit AnalysesScribdUser11235Оценок пока нет

- How A Century of Ammonia Synthesis Changed The World: FeatureДокумент8 страницHow A Century of Ammonia Synthesis Changed The World: FeatureYuthish KhannaОценок пока нет

- Soil FertilityДокумент75 страницSoil FertilitymarkovitОценок пока нет

- Bronkhorst Manual EL FLOW SelectДокумент51 страницаBronkhorst Manual EL FLOW SelectcccirmusОценок пока нет

- Drying of TransformerДокумент9 страницDrying of TransformerL P KUSHWAHA100% (7)

- Atomic Structure and Amount of Substance QДокумент30 страницAtomic Structure and Amount of Substance Qlucylovesbooks6770Оценок пока нет

- Cross Ref 1Документ7 страницCross Ref 1Devendra KhadeОценок пока нет

- Chapter 05Документ39 страницChapter 05pdaga19691383Оценок пока нет

- Silicon Based Fuels For Space Flight: David Padanyi-Gulyas and Andras D. BodoДокумент6 страницSilicon Based Fuels For Space Flight: David Padanyi-Gulyas and Andras D. BodoBill M. SpragueОценок пока нет

- ChemEngineering 02 00019 v2Документ14 страницChemEngineering 02 00019 v2Amine HamaouiОценок пока нет

- Group2 and 7 RevisedДокумент46 страницGroup2 and 7 Revised123456Оценок пока нет

- Air PollutionДокумент7 страницAir PollutionAsif NawazОценок пока нет

- Doc316 53 01086 PDFДокумент8 страницDoc316 53 01086 PDFMarian AlviОценок пока нет

- Science 7 Module 2Документ32 страницыScience 7 Module 2Lilah BlairОценок пока нет

- AR700-68 - Compressed Gas StorageДокумент103 страницыAR700-68 - Compressed Gas StoragetorolsoОценок пока нет

- A Level Environmental Management NotesДокумент26 страницA Level Environmental Management Notescharumbirakimtontapiwa751Оценок пока нет

- Nitrogen CycleДокумент10 страницNitrogen CyclebellaОценок пока нет

- 6 P Block Elements PDFДокумент91 страница6 P Block Elements PDFShanmugapriya RaguramanОценок пока нет

- Chemical Reaction and EquationДокумент8 страницChemical Reaction and EquationTr Mazhar Punjabi100% (1)