Академический Документы

Профессиональный Документы

Культура Документы

Notes: of Rodcl

Загружено:

reach_arindomОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Notes: of Rodcl

Загружено:

reach_arindomАвторское право:

Доступные форматы

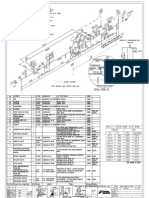

NOTES

3 RODS EQUALLY SPACED-WITH 120 LONG

SEE DETAIL " G " OR "D"

SEE NOTE 8

STEAM INLET

SEE NOTE 5

150

S.O. FLG.

SEE DET. "B"

(TYP.)

JACKETED PIPE TABLE

LINE SIZE

PROCESS

DN

JACKET SIZE

STEAM JACKET

NPS

DN

NPS

3/4"

50

2"

40

1 1/2"

80

3"

80

3"

15

1/2"

25

1"

20

50

50

50

NPS

NPS

NPS

20

3/4"

2"

2"

20

3/4"

3"

3"

4"

150

6"

20

8"

250

10"

350

14"

250

10"

350

14"

100

200

300

12"

400

4"

3/4"

3/4"

3/4"

20

8"

25

12"

25

16"

3/4"

20

20

20

6"

300

NPS

3"

150

200

2"

2"

DN

80

2"

100

STEAM, COND. & DRAIN

CONNECTION SIZE 90ELL.45ELL. CONC.

RED..

25

2"

2"

3"

3"

4"

4"

1"

12"

10"

12"x10"

1"

16"

14"

16"x14"

1"

8"

14"

18"

8"

12"

16"

100

PROCESS LINE

150

TO TRAP

PROCESS

JACKET LINE

"S"

LINE SIZE

SEE DET. "E"

150

(TYP.)

100

DN

15

20

25

(MIN.)

12000

"S"

(MAXIMUM)

BREAK FLANGE

LINE SIZE

ROD

DN

45 S.R. ELL.

SEE NOTE 2

15

20

25

40

STEAM JACKET

50

MIN. "L"

MIN. "L"

ROD

TYPICAL

LINE

LINE

45 L.R. ELL.

TYPICAL

C

L OF ROD

PROCESS LINE

TYP. DETAIL AT BENDS

FOR 3/4"(DN20) TO 6"(DN150) PIPE

C

L OF ROD

90 S.R. ELL.

90 L.R. ELL.

14"

16"

14

8

6

19

17

18

16

5

15

4000

5200

6400

7200

8300

9400

10500

10900

11100

80

100

1000

1 1/2"

1500

1"

11-IMPINGEMENT PLATE FOR PROTECTING PROCESS LINE

AGAINST CRROSION.

12-"X" SHALL BE AS FOLLOWS:

t < 6

X=t

t > 6

X=6

WHERE "t" IS THE PIPE WALL THICKNESS.

13-WELDING LOACTION OF PROCESS ELBOW WILL DIFFER

RESPECT TO THE JACKETED ELBOW BASED ON ELBOWS

DIMENSION.

14- IS BASED ON SCH.40 THICKNESS FOR JACKETING.

1800

8"

2500

250

10"

350

14"

200

300

1500

4"

OR

N

CH

TIO

AN

EC

BR

NN

G

CO

RIN

N

"

IO

"H

SIT

AN

AIL

T

TR

DE

E

SE

1500

3"

6"

PROCESS

TACK WELD

STEEL ROD SPACER

STEAM JACKET

2000

S.W HALF CPLG.

3000

3000

FOR 3/4"(DN20) TO 14"(DN350) PIPE

100 130 50

DETAIL "E"

DETAIL "D"

TYP. BRANCH CONN. DETAIL

TYP. DETAIL AT 45 ELBOW

150

DRAIN

PROCESS LINE STUB-IN

BRANCH CONNECTION

3000

12"

W.NECK FLG.

ST

IN

1000

2"

150

SEE NOTE 2

1000

3/4"

10-IN PROCESS AREA A NEW STEAM SHALL BE SUPPLIED

AT EVERY 12 METERS MAX. WHICH IS MAXIMUM LENGTH

OF JACKET PIPE AND OUTSIDE THE PROCESS AREA A

NEW STEAM SHALL BE SUPPLIED AT EVERY 24 METERS

MAX. WHICH IS MAXIMUM LENGTH OF JACKET PIPE,

ANY HOW EVERY 12 METERS JACKET PIPE SHALL BE

TRAPPED.

OF COUPLING SEE SPOOL DWG.

STEAM JACKET TEE

"L" DIM.

NPS

1/2"

S.W. HALF COUPLING

STEAM INLET

STEAM OUTLET

MIN.

SEE NOTE 2

37 30' 2 30'

TRANSITION RING TABLE

50x30x6mm.

SEE NOTE 11

STEAM JACKET

LINE SIZE

LINE

ROD

SEE DETAIL "C"

150

TYP. DETAIL AT BENDS

FOR 8"(DN200) TO 14"(DN350) PIPE

100

S.W. HALF COUPLING

DRAIN TO CONDENSATE

RECOVERY STATION

130

100

TRANSITION RING

SEE DETAIL "H"

130

DETAIL " G "

SEE NOTE 10

TYPICAL

JACKET LINE

MIN. "L"

D

SEE NOTE 14

PROCESS

PROCESS LINE

LINE

3"

3"

4"

6"

8"

10"

12"

2500

3000

3500

9- PROVIDE BREACK FLANGE IF IT IS NECESSARY.

SEE NOTE 9

SEE NOTE 13

PROCESS

80

80

100

150

200

250

300

350

400

13

7

7

8- STEAM PIPE SIZE TO BE SAME AS CONNECTION SIZE.

STEAM CONNECTION FOR ORIENTATION

ROD LOCATION

AT BENDS TABLE

SEE NOTE 2

90 L.R. ELL.

PROCESS

14"

2"

2"

2"

TRANSITION RING SEE DET. "H"

STEAM JACKET TEE

C

L OF ROD

SEE NOTE 13

2"

3"

4"

6"

8"

10"

12"

NPS

DN

50

50

50

MAX.

ROD

SPACING

18"x16"

DETAIL " A "

90 S.R. ELL.

NPS

1/2"

3/4"

1"

1

1/2"

ROD

DIA.

7- ALL WELDINGS SHALL CORRESPOND TO PROJECT WELDING

PROCEDURE.

DETAIL " C "

DETAIL " B "

14"x12"

40

50

80

100

150

200

250

300

350

ROD SPACING

150

STEAM

JACKET

PROCESS

TACK WELD

STEAM JACKET

W.N. FLG.

ROD

ROD TABLE

STEEL ROD SPACER

STEAM INLET

JACKETED VALVE

6"

SECTION "S"-"S"

SEE SPOOL DWG.

6"

1"

25

2"

3/4"

1"

25

2"

30

30

STEAM CONNECTION

FOR ORIENTATION OF COUPLING

SPACERS SEE DETAIL "C"

JACKETED VALVE

PROCESS

LINE

TACK WELD

(TYP.)

SLIP-ON RED. FLG.

1- ALL THICKNESS VALUES AND DIMENSIONS ARE IN mm.

2- JACKET FITTING TO BE SPLIT FOR ASSEMBLY OF PROCESS

LINE & JACKET.

3- LENGTH OF LINE BETWEEN FLANGES OR RINGS TO BE

DETERMINED BY STRESS ANALYSIS BUT SHALL NEVER

EXCEED 12000.

4- STEEL PIPE TO BE SAME SIZE AS STEAM INLET LINE AS

CALLED FOR ON P&ID.

5- JACKETS MAY BE CONNECTED IN SERIES UP TO MAXIMUM

LENGTH OF 20000.

6- ROD DIA. BASED ON JACKETING PIPE ASTM A53 Gr.B WITH

SCH. STD. UP TO 8"(DN200) & SCH.30 FOR 10"(DN250)

& LARGER.

(SEE TABLE)

STEAM JACKET

LINE

PROCESS LINE

50

X

SEE NOTE 12

JACKET LINE

TRANSITION RING

ASTM A515 Gr.70

DETAIL " H "

50

2"

60.3

55.7

80

3"

88.9

81.1

4"

150

6"

8"

250

10"

350

14"

3/4"

40

150

0 C

20

25

80

100

1/2"

1"

1

1/2"

2"

3"

150

6"

250

10"

350

14"

200

300

TRANSITION RING

NPS

NPS

15

STEAM JACKET

DN

DN

12"

100

200

300

400

0 D

4"

114.3

107.0

8"

219.1

207.5

168.3

158.9

273.1

259.3

355.6

338.1

12"

323.9

16"

406.4

308.0

385.8

0 E

23.3

28.7

35.4

50.3

10

62.0

15

116.1

20

221.5

20

90.7

170.7

276.4

327.2

359.2

15

C

B

A

REV.

DATE

NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

20

STEAM JACKET DETAILS

25

25

25

DESCRIPTION

IRANIAN PETROLEUM STANDARDS

DATE

DRAWING No.

IPS-D-PI-127

SHEET

1

REV.

Вам также может понравиться

- Home PlansДокумент5 страницHome PlansRoberto Herrera100% (1)

- Tool Kit For Fabricator Piping: S.No Size Unit QTY DecriptionДокумент7 страницTool Kit For Fabricator Piping: S.No Size Unit QTY DecriptionZain Ul Islam ButtОценок пока нет

- Harrison Superduct Dimensions 2009Документ18 страницHarrison Superduct Dimensions 2009prayoothОценок пока нет

- Sri Jayaram Engineering College Cuddalore - 3 Code / Name of The Lab: Ge 1101 /engineering Practices LabДокумент4 страницыSri Jayaram Engineering College Cuddalore - 3 Code / Name of The Lab: Ge 1101 /engineering Practices LabsedhuselvaОценок пока нет

- Existing House Side View With Porch Porch Area: RCC, Inc 1365 Broad ST Johnstown, Pa 15906Документ4 страницыExisting House Side View With Porch Porch Area: RCC, Inc 1365 Broad ST Johnstown, Pa 15906Ldriver104Оценок пока нет

- Partial Level 4 Framing Plan - South: Bohlin Cywinski JacksonДокумент1 страницаPartial Level 4 Framing Plan - South: Bohlin Cywinski JacksonAkshay ReddyОценок пока нет

- Noxon BSP Threaded FitiingsДокумент24 страницыNoxon BSP Threaded FitiingsZoran DanilovОценок пока нет

- Uwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesДокумент4 страницыUwp Model 2030 Os&y Gate Valve 2.5 In.-24 In. SizesHector Acaro RodriguezОценок пока нет

- Saudi AramcoДокумент1 страницаSaudi AramcoAbhilash P PaulОценок пока нет

- BrutusДокумент4 страницыBrutusgoloskokovicОценок пока нет

- Thermal Expansion DataДокумент4 страницыThermal Expansion DataMajid MoradiОценок пока нет

- Sample11 DrawingДокумент1 страницаSample11 DrawingSidra KhanОценок пока нет

- E X52eДокумент4 страницыE X52eTommy DavisОценок пока нет

- Final Contruction Document Set Kelsey-RoybalДокумент19 страницFinal Contruction Document Set Kelsey-Roybalapi-289643276Оценок пока нет

- Figure Numbers for 12” 3PC Body Forged Trunnion Mounted Ball ValveДокумент2 страницыFigure Numbers for 12” 3PC Body Forged Trunnion Mounted Ball Valveshashikanth79Оценок пока нет

- CPVC Duct Dimensions 2023Документ19 страницCPVC Duct Dimensions 2023savithree.wОценок пока нет

- Price ListsДокумент15 страницPrice ListsMarc Gregory Queral OlanioОценок пока нет

- SHEET No. 4 - 6 - 11 .01: FE-4502-2 FE-4502 FE-4504 FE-4505Документ1 страницаSHEET No. 4 - 6 - 11 .01: FE-4502-2 FE-4502 FE-4504 FE-4505alvimranОценок пока нет

- Dismantling JointsДокумент1 страницаDismantling JointsHaneefa ChОценок пока нет

- 134-05 EsДокумент2 страницы134-05 EsFreddy Ibañez PeñaОценок пока нет

- Nominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndДокумент3 страницыNominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndRani FelishaОценок пока нет

- Pipings and FittingsДокумент1 страницаPipings and FittingsengenheiroalencarОценок пока нет

- ASME VIII-1 pressure vessel design code and operating conditionsДокумент1 страницаASME VIII-1 pressure vessel design code and operating conditionsNomi KhanОценок пока нет

- Gas Well Status Diagram (1) (Version 1)Документ6 страницGas Well Status Diagram (1) (Version 1)Olaoluwa OlatonaОценок пока нет

- A Com Ecu PateДокумент5 страницA Com Ecu Pateheels1310Оценок пока нет

- Sella Flow Regulator 392 393Документ2 страницыSella Flow Regulator 392 393Veronica MendosaОценок пока нет

- PRD SystemДокумент1 страницаPRD SystemJitendra Kumar PanigrahiОценок пока нет

- Bridle and Soldering Supply ChecklistsДокумент4 страницыBridle and Soldering Supply ChecklistsAshishMahajanОценок пока нет

- OEM National 12-P-160 PDFДокумент12 страницOEM National 12-P-160 PDFHaridevОценок пока нет

- PVC Duct Dimensions PDFДокумент18 страницPVC Duct Dimensions PDFAswin Lovez Candy'sОценок пока нет

- Pressure Drop CalculationДокумент6 страницPressure Drop CalculationRaja JiОценок пока нет

- Bom Storage Tank (M.S.)Документ8 страницBom Storage Tank (M.S.)Varun MalhotraОценок пока нет

- Butterfly Valves: Internacional, S.LДокумент36 страницButterfly Valves: Internacional, S.LFabrizzio_ValerОценок пока нет

- Lvo 2010Документ10 страницLvo 2010Kevin SwotekОценок пока нет

- BN MLS 21 PTSC 307526Документ1 страницаBN MLS 21 PTSC 307526mailmaverick8167Оценок пока нет

- GASKETS CORRUGATED DOUBLE - JACKETEDДокумент3 страницыGASKETS CORRUGATED DOUBLE - JACKETEDCarlos RenerОценок пока нет

- Pilot Valves and AccessoriesДокумент12 страницPilot Valves and Accessoriesvhfdz1175Оценок пока нет

- Power SupplyДокумент1 страницаPower SupplySor MiОценок пока нет

- 12204-1000 MSU Bio Engineering Facility - Volume 2 - Bid Release - 2 - Bids (2014 - 01 - 08) PDFДокумент101 страница12204-1000 MSU Bio Engineering Facility - Volume 2 - Bid Release - 2 - Bids (2014 - 01 - 08) PDFJesus RobinsonОценок пока нет

- Pipe Reinforcing at SupportДокумент12 страницPipe Reinforcing at SupportSeungmin Paek100% (3)

- AGE Pipe ChartДокумент1 страницаAGE Pipe Chartminhaj_kccОценок пока нет

- Min allowable values small end pipe fittingsДокумент3 страницыMin allowable values small end pipe fittingsHomer SilvaОценок пока нет

- Pipings and FittingsДокумент3 страницыPipings and FittingsAnonymous YTyro2NG4HОценок пока нет

- Instantaneous Gas Water Heater Parts Exploded ViewДокумент10 страницInstantaneous Gas Water Heater Parts Exploded ViewAnonymous JV62GwcОценок пока нет

- Foundation Details for Steam BoilerДокумент1 страницаFoundation Details for Steam Boiler1449900% (1)

- Lifting Eye Blind: NotesДокумент1 страницаLifting Eye Blind: Notesnarutothunderjet216Оценок пока нет

- 8475-3A Gardner Denver PZ-7 5000PSIДокумент8 страниц8475-3A Gardner Denver PZ-7 5000PSIAmauri CortesОценок пока нет

- Bulletin B150-5 - Ball Valve For H2O2Документ0 страницBulletin B150-5 - Ball Valve For H2O2pdaga19691383Оценок пока нет

- Toyo - Heat Exchanger-1Документ70 страницToyo - Heat Exchanger-1alokbdas100% (1)

- Material ShortageДокумент24 страницыMaterial Shortageheri_prasetyadiОценок пока нет

- Product Data Sheet DetaiДокумент10 страницProduct Data Sheet DetaiQUALITY CONTROL FABHINDОценок пока нет

- Arch HardwareДокумент24 страницыArch HardwareBrigida RuriОценок пока нет

- Air Preparation Modular Filters and RegulatorsДокумент9 страницAir Preparation Modular Filters and RegulatorshadeОценок пока нет

- 1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsДокумент3 страницы1100 Series Standard Pressure Gauge MODEL:1100: ApplicationsfatherbyteОценок пока нет

- Pressure Drop Calc - STDДокумент25 страницPressure Drop Calc - STDhardik5818Оценок пока нет

- Nominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndДокумент3 страницыNominal Size Nominal Size: Conc. and Ecc. Reduct. Min. Allowable Value On Small EndleonardoportocОценок пока нет

- Inclened FFB Scrapper Conveyor No.2Документ1 страницаInclened FFB Scrapper Conveyor No.2Joey_Tirtawija_61850% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IОценок пока нет

- 13 Stress Strain 1Документ20 страниц13 Stress Strain 1Razell RuizОценок пока нет

- Understand The Harmonic Analysis and Ensure The Pressure Pulsation Comply With API 674 With PDFДокумент11 страницUnderstand The Harmonic Analysis and Ensure The Pressure Pulsation Comply With API 674 With PDFreach_arindomОценок пока нет

- Arindom Kundu Language ItalianДокумент1 страницаArindom Kundu Language Italianreach_arindomОценок пока нет

- New Microsoft Word DocumentДокумент1 страницаNew Microsoft Word Documentreach_arindomОценок пока нет

- British Steel European Ipe Sections DatasheetДокумент3 страницыBritish Steel European Ipe Sections Datasheetreach_arindomОценок пока нет

- IBR DetailsДокумент10 страницIBR Detailsreach_arindomОценок пока нет

- Film Review - Chak de IndiaДокумент2 страницыFilm Review - Chak de Indiareach_arindomОценок пока нет

- 1erection Drawing of DM Water Tank - T75.5AB - U-HWS - R2Документ1 страница1erection Drawing of DM Water Tank - T75.5AB - U-HWS - R2reach_arindomОценок пока нет

- Steel-Tables 2 PDFДокумент110 страницSteel-Tables 2 PDFMahmoud AllamОценок пока нет

- Arindom Kundu Language RussianДокумент1 страницаArindom Kundu Language Russianreach_arindomОценок пока нет

- Ibr Acceptable Weld JointДокумент10 страницIbr Acceptable Weld Jointreach_arindomОценок пока нет

- Emergency Ramps Reflect Pragmatism After Fatal Runway Overrun IncidentsДокумент8 страницEmergency Ramps Reflect Pragmatism After Fatal Runway Overrun Incidentsreach_arindomОценок пока нет

- IBR Thickness CalculationДокумент17 страницIBR Thickness Calculationreach_arindomОценок пока нет

- Project On Set Up of Day Care CentreДокумент1 страницаProject On Set Up of Day Care Centrereach_arindomОценок пока нет

- Area Reinforcement CalculatorДокумент5 страницArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Exp LoopДокумент37 страницExp Loopreach_arindomОценок пока нет

- Summary of anchor nozzle movementsДокумент18 страницSummary of anchor nozzle movementsreach_arindomОценок пока нет

- 02 - Heat ExchangersДокумент88 страниц02 - Heat ExchangersDana GuerreroОценок пока нет

- Dyke Sizing CalculationДокумент1 страницаDyke Sizing Calculationreach_arindomОценок пока нет

- Ows Piping Size2BLДокумент3 страницыOws Piping Size2BLreach_arindomОценок пока нет

- Exloop 3dimДокумент69 страницExloop 3dimreach_arindomОценок пока нет

- Revised Fire Water Calculation-Pol Depot, Asoj: LPM/M LPM/M LPM/M LPM/M LPM/MДокумент1 страницаRevised Fire Water Calculation-Pol Depot, Asoj: LPM/M LPM/M LPM/M LPM/M LPM/Mreach_arindomОценок пока нет

- Calculating beam deflection and stresses using Young's modulus, moment of inertia, and applied loadДокумент2 страницыCalculating beam deflection and stresses using Young's modulus, moment of inertia, and applied loadreach_arindomОценок пока нет

- DummyДокумент12 страницDummyrajkamal eshwarОценок пока нет

- Thermal Expansion Data PDFДокумент4 страницыThermal Expansion Data PDFFabio OkamotoОценок пока нет

- Failure theories-IITMДокумент5 страницFailure theories-IITMsunil_patil_38Оценок пока нет

- Summary of Anchor / Nozzle Movements For Vertical VesselДокумент17 страницSummary of Anchor / Nozzle Movements For Vertical Vesselreach_arindomОценок пока нет

- Expansion Loop Length FormulaДокумент1 страницаExpansion Loop Length Formulareach_arindomОценок пока нет

- Bechtel - Use of Startup StrainerДокумент17 страницBechtel - Use of Startup Strainerreach_arindomОценок пока нет

- ASTM material cross-reference chart for valves, fittings and flangesДокумент1 страницаASTM material cross-reference chart for valves, fittings and flangessgm6911Оценок пока нет

- SMACNA CAD StandardДокумент6 страницSMACNA CAD StandardDenan SaherОценок пока нет

- Catalogue RAC Mitsubishi ElectricДокумент10 страницCatalogue RAC Mitsubishi ElectricYizhar Bechamel MestokoОценок пока нет

- Mark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Документ6 страницMark Qty Size Description Length: Petrobras P-52 Total Piping BOM 2/1/05Marcos AndréОценок пока нет

- Seal Supply Systems - Thermosiphon Systems: Rely On ExcellenceДокумент5 страницSeal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDikaAnindyajatiОценок пока нет

- Anti Blowout Stem OVIKOДокумент2 страницыAnti Blowout Stem OVIKORicОценок пока нет

- Bootstrap Air Cooling System for AircraftДокумент7 страницBootstrap Air Cooling System for AircraftSubash DhakalОценок пока нет

- Condensador r410 Ycjd30-60btu TrifДокумент24 страницыCondensador r410 Ycjd30-60btu TrifmeganemesisОценок пока нет

- Valvulas de Exceso de Flujo ArgusДокумент3 страницыValvulas de Exceso de Flujo ArgusJoseОценок пока нет

- Pufferspeicher 500-5000 240 810-5 EnglДокумент6 страницPufferspeicher 500-5000 240 810-5 Englpatrutionel99Оценок пока нет

- Metec Design and Construction Engineers India (P) LTD: Itc LimitedДокумент21 страницаMetec Design and Construction Engineers India (P) LTD: Itc LimitedBalaОценок пока нет

- Heat Exchangers and TypesДокумент26 страницHeat Exchangers and Typesch umairОценок пока нет

- Four-way Reversing Valve GuideДокумент10 страницFour-way Reversing Valve Guideleopoldo larezОценок пока нет

- Rheem CONTEMPO SeriesДокумент1 страницаRheem CONTEMPO SeriesConrad GutierrezОценок пока нет

- Vapor Compression Refrigration PDFДокумент155 страницVapor Compression Refrigration PDFمحمد متوليОценок пока нет

- VKM-GM Series VKM-G Series: DX-coil and Humidifier DX-coilДокумент9 страницVKM-GM Series VKM-G Series: DX-coil and Humidifier DX-coilcodefinderОценок пока нет

- Valves - Hassan ElBanhawiДокумент3 страницыValves - Hassan ElBanhawijesus_manrique2753Оценок пока нет

- 4 AppendicesДокумент12 страниц4 AppendicesZainul Abedin SayedОценок пока нет

- Bathtub: What Are They?Документ5 страницBathtub: What Are They?John Paul DenajibaОценок пока нет

- Grundfosliterature 5439390Документ108 страницGrundfosliterature 5439390ptlОценок пока нет

- Youli SN-3Документ19 страницYouli SN-3Priyogo SutantiyoОценок пока нет

- Water Tank (Reservoir) DetailsДокумент1 страницаWater Tank (Reservoir) DetailsAlyanna Marie PalenciaОценок пока нет

- Manual Control Emerson PDFДокумент8 страницManual Control Emerson PDFFredy RodriguezОценок пока нет

- Panganiban ResumeДокумент3 страницыPanganiban Resumejerianne abrasaldoОценок пока нет

- Water-Cooled Refrigerant Recovery and Recycling Units: Operation & MaintenanceДокумент54 страницыWater-Cooled Refrigerant Recovery and Recycling Units: Operation & MaintenanceUmar MajeedОценок пока нет

- Hot and cold water faucet fixture with adjustable valvesДокумент6 страницHot and cold water faucet fixture with adjustable valvesmarlondijiОценок пока нет

- Cryogenics & LNG Application GuideДокумент16 страницCryogenics & LNG Application GuidesusantoОценок пока нет

- 2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Документ1 страница2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Hassan KhanОценок пока нет

- Product BrochureДокумент20 страницProduct Brochuremarijn coenenОценок пока нет

- Pressure. Pressure Loss in A Steam Pipe. Tyler ExampleДокумент70 страницPressure. Pressure Loss in A Steam Pipe. Tyler ExampleMinh Tran0% (1)

- EFD-015 - General Valve List - 200731Документ3 страницыEFD-015 - General Valve List - 200731cmc261185Оценок пока нет