Академический Документы

Профессиональный Документы

Культура Документы

PDI 1.05.1 Engineering Materials Corrosion Rates of NaOH

Загружено:

Saurabh Singh0 оценок0% нашли этот документ полезным (0 голосов)

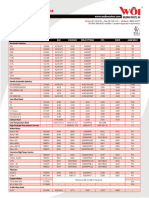

150 просмотров1 страницаThis document contains information about corrosion rates of various materials in sodium hydroxide solutions. It includes four graphs showing: 1) the relationship between temperature, sodium hydroxide concentration, and stress cracking of carbon steel; 2) corrosion rates of Alloys 200 and 201 with increasing sodium hydroxide concentration; 3) an isocorrosion chart for stainless steels 304 and 316 with a stress cracking boundary; and 4) comparative corrosion rates of various alloys in 50% sodium hydroxide solution with and without sodium chlorates.

Исходное описание:

Engineering Materials Corrosio

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document contains information about corrosion rates of various materials in sodium hydroxide solutions. It includes four graphs showing: 1) the relationship between temperature, sodium hydroxide concentration, and stress cracking of carbon steel; 2) corrosion rates of Alloys 200 and 201 with increasing sodium hydroxide concentration; 3) an isocorrosion chart for stainless steels 304 and 316 with a stress cracking boundary; and 4) comparative corrosion rates of various alloys in 50% sodium hydroxide solution with and without sodium chlorates.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

150 просмотров1 страницаPDI 1.05.1 Engineering Materials Corrosion Rates of NaOH

Загружено:

Saurabh SinghThis document contains information about corrosion rates of various materials in sodium hydroxide solutions. It includes four graphs showing: 1) the relationship between temperature, sodium hydroxide concentration, and stress cracking of carbon steel; 2) corrosion rates of Alloys 200 and 201 with increasing sodium hydroxide concentration; 3) an isocorrosion chart for stainless steels 304 and 316 with a stress cracking boundary; and 4) comparative corrosion rates of various alloys in 50% sodium hydroxide solution with and without sodium chlorates.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Charisma Global Networks Limited

CGNL : MTS 002

June 2003

Materials of Construction

125

100

Cracking

Area

150

50

Cracking Reported

Above Curve

100

25

50

0

20

10

30

40

50

Sodium Hydroxide, wt. %

F

600

500

300

Corrosion Rates for Alloy 200

& Alloy 201

250

5 mpy

400

200

Boiling Point Curve

1 mpy

300

150

0.1 mpy

200

0.1 mpy

100

Melting Point

Curve

< 0.1 mpy

20

40

60

80

Sodium Hydroxide, wt. %

100

50

0

100

Corrosion Rates for Nickel Alloy 200 & Low Carbon

Nickel Alloy 201 in Sodium Hydroxide

Date: 28.06.2003

1-50

mpy

200

100

< 1 mpy

250

>30 mpy

150

30 mpy

1-30 mpy

1 mpy

200

60

300

100

Relation of Temperature & Concentration of Sodium

Hydroxide to cause Stress Corrosion Cracking of Carbon Steel

Temperature

400

75

Danger Zone

Apparent Stress Corrosion

Cracking Boundary

Atmospheric boiling

point curve >30 mpy

Melting

Point Curve

50

0

20

40

60

80

Sodium Hydroxide, wt. %

Isocorrosion chart for AISI 304 & 316 S.S. Steels in Sodium

Hydroxide, with stress cracking boundary superimposed

100

mpy

No Chlorates

mm/yr

Sodium Chlorates

50

0.05

0.025

2

1

0.5

0.2

0.1

2.5

0.5

0.25

20

10

Corrosion Rate

Temperature

200

500

200

904L

825

600

Severe Cracking

250

300

200

904L

825

600

Boiling Point Curve

F

600

C

150

Temperature

F

300

0.005

0.0025

Sodium Hydroxide, 50 wt. %, 300 F (150 C)

Typical comparative corrosion rates for several alloys in

sodium hydroxide in the presence of sodium chlorates

Drawn by: Arun S.

Checked by: N.K.Roy

Вам также может понравиться

- An Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicДокумент12 страницAn Experimental Study To Corelate Water Jet Impingement Erosion Resistance and Properties of MetallicsaatehОценок пока нет

- Material P NumberДокумент1 страницаMaterial P Numberrameez khanОценок пока нет

- Fisher Type 667 Diaphragm ActuatorДокумент32 страницыFisher Type 667 Diaphragm Actuatorimran khanОценок пока нет

- Metal matrix composites: Processing and InterfacesОт EverandMetal matrix composites: Processing and InterfacesR EverettОценок пока нет

- QT 16Cr PDFДокумент1 страницаQT 16Cr PDFYaroslav RuizОценок пока нет

- Material 11373Документ1 страницаMaterial 11373Deepak MadnaikОценок пока нет

- Flame Spraying Gun Uni Spray JetДокумент5 страницFlame Spraying Gun Uni Spray JetCristobal MontalbaОценок пока нет

- Installation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HДокумент36 страницInstallation and Operating Manual FMTB 5000 Test Bench: 0.5 - 5000 m3 / HDaniel Oscar100% (1)

- RT Series: Project Name Model Qty HP TotalДокумент1 страницаRT Series: Project Name Model Qty HP TotalDon Ing Marcos LeónОценок пока нет

- Valve TrimДокумент1 страницаValve Trimjsrplc7952Оценок пока нет

- Common Steel StandardsДокумент3 страницыCommon Steel Standardsva3ttnОценок пока нет

- Thies - Safety Valves 356 - 357Документ4 страницыThies - Safety Valves 356 - 357Piero Graffigna Pruzzo100% (2)

- Size MI N (In) Size MA X (In) Abrev Short Word Details Component SДокумент16 страницSize MI N (In) Size MA X (In) Abrev Short Word Details Component SAnthony InostrozaОценок пока нет

- 17 Tubing FittingsДокумент30 страниц17 Tubing FittingsGILBERTO YOSHIDAОценок пока нет

- Douglas Chero Catalogue Valve 6-2003Документ89 страницDouglas Chero Catalogue Valve 6-2003Yurizki LhzОценок пока нет

- Of The Nuclear Safety Standards Commission (KTA)Документ123 страницыOf The Nuclear Safety Standards Commission (KTA)smallik3Оценок пока нет

- Understanding Article 2 ASME Sec V - Radiographic ExaminationДокумент46 страницUnderstanding Article 2 ASME Sec V - Radiographic Examinationrosli2503Оценок пока нет

- Watson Marlow Bredal SPX PumpsДокумент12 страницWatson Marlow Bredal SPX PumpsCesar Armando Hernandez ViteОценок пока нет

- Din en 1320-1996Документ18 страницDin en 1320-1996edcam13Оценок пока нет

- A4 NTN Freedom Paper Jig 2012Документ3 страницыA4 NTN Freedom Paper Jig 2012lingonОценок пока нет

- Deaerators BrochureДокумент4 страницыDeaerators BrochurefahimshkОценок пока нет

- Despiece de Reductor y NombresДокумент1 страницаDespiece de Reductor y NombresDaniel Alarcon RodriguezОценок пока нет

- Ecoline-Gtr 16P: PN 16 DN 40 - 600Документ4 страницыEcoline-Gtr 16P: PN 16 DN 40 - 600Siapa PunОценок пока нет

- Hodge JM Orehoski MA Trans AIME 1946 167 502 PDFДокумент11 страницHodge JM Orehoski MA Trans AIME 1946 167 502 PDFPablo CollantesОценок пока нет

- Hydrofluoric Acid Processing Valves: - PhillipsДокумент4 страницыHydrofluoric Acid Processing Valves: - Phillipsxaaabbb_550464353Оценок пока нет

- Listado Normas PFIДокумент2 страницыListado Normas PFIIsidoro LópezОценок пока нет

- Aws Publications Catalog: Summer 2010Документ20 страницAws Publications Catalog: Summer 2010saeedahmad901Оценок пока нет

- Annealed Pickled SS Tubing (MS 02 315 ER0)Документ2 страницыAnnealed Pickled SS Tubing (MS 02 315 ER0)herysyam1980Оценок пока нет

- Rovalve PDFДокумент4 страницыRovalve PDFWilliam ValenciaОценок пока нет

- Model For Microbiologically Influenced Corrosion PDFДокумент16 страницModel For Microbiologically Influenced Corrosion PDFGenis Andres Castillo VillamizarОценок пока нет

- DENAIR Oil-Free Air CompressorДокумент10 страницDENAIR Oil-Free Air CompressorSAUL OSPINOОценок пока нет

- PFI ES 2 2000 Method of Dimensioning Piping AssembliesДокумент4 страницыPFI ES 2 2000 Method of Dimensioning Piping AssembliesedwinОценок пока нет

- Oklahoma City Home Office: 9500 Series Pilot Operated Safety Relief Valve Sizing ProgramДокумент6 страницOklahoma City Home Office: 9500 Series Pilot Operated Safety Relief Valve Sizing Programdilema_pgОценок пока нет

- Spir Star Duralife Flex Hose Type 4/2 Data SheetДокумент1 страницаSpir Star Duralife Flex Hose Type 4/2 Data Sheetadlib13Оценок пока нет

- Failure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedДокумент6 страницFailure Analysis of Reformer Tubes: Technicalarticle-Peer-ReviewedOwais MalikОценок пока нет

- Datasheet BombaДокумент4 страницыDatasheet BombasaculОценок пока нет

- Pages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturerДокумент4 страницыPages Welding High Strength Bolts: Anchor Bolt and Construction Fastener ManufacturermauricioveracorreaОценок пока нет

- Cameron Fully Welded Ball Valves PDFДокумент36 страницCameron Fully Welded Ball Valves PDFCARLOSОценок пока нет

- Sulfuric Acid and Hydrochloric Acid Dew-Point Corrosion-Resistant SteelДокумент0 страницSulfuric Acid and Hydrochloric Acid Dew-Point Corrosion-Resistant SteelMatt AgonyaОценок пока нет

- Split Tee CatalogoДокумент3 страницыSplit Tee Catalogobotella berОценок пока нет

- Bomba Peristalticas ABAQUE PSGДокумент49 страницBomba Peristalticas ABAQUE PSGGabrielОценок пока нет

- Design of Sugar Mill Gears by P.w.jonesДокумент5 страницDesign of Sugar Mill Gears by P.w.jonesanwarmughal0% (1)

- Atom Arc 7018-B2L: Typical Tensile PropertiesДокумент1 страницаAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlОценок пока нет

- 1 Pipes Weights and Dimensions ASME ANSI B36.10-19Документ1 страница1 Pipes Weights and Dimensions ASME ANSI B36.10-19Leonardo Cusó ContrerasОценок пока нет

- Cat. Gral MercomarveДокумент43 страницыCat. Gral Mercomarvewillys8Оценок пока нет

- Service Bulletin 8-12-109hДокумент16 страницService Bulletin 8-12-109hexergicОценок пока нет

- Molykote® P-37 Datasheet Eng PDFДокумент2 страницыMolykote® P-37 Datasheet Eng PDFBib GmzОценок пока нет

- Astm B 32 - 00Документ9 страницAstm B 32 - 00kaminaljuyuОценок пока нет

- Corrosion Damage in Waste Heat Boilers Major Root Causes and RemediationДокумент10 страницCorrosion Damage in Waste Heat Boilers Major Root Causes and Remediationvaratharajan g rОценок пока нет

- Normas ISO Sobre Vibraciones Mecánicas en MaquinariaДокумент2 страницыNormas ISO Sobre Vibraciones Mecánicas en MaquinariaAdrian Rodrigo Jofre AlvarezОценок пока нет

- MANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016Документ10 страницMANUAL DE PARTES REBANADORA BERKEL 829-A MX January 2016ivan reyes TorresОценок пока нет

- Shell Omala 320 Data SheetДокумент4 страницыShell Omala 320 Data SheetAyus SyariffianaОценок пока нет

- Sodium Leak Through Pin HolesДокумент9 страницSodium Leak Through Pin HolesAvinash ChittellaОценок пока нет

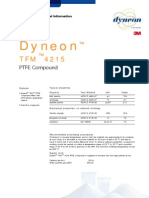

- TFM 4215Документ2 страницыTFM 4215Mohit SharmaОценок пока нет

- Astm A105Документ1 страницаAstm A105Isaac SamuelОценок пока нет

- ASME Section V - Art 1 - Subsection A Nondestructive Methods of ExaminationДокумент18 страницASME Section V - Art 1 - Subsection A Nondestructive Methods of ExaminationFavio Fernández LongОценок пока нет

- Welding Duplex Stainless SteelДокумент44 страницыWelding Duplex Stainless SteelTran Thanh HaoОценок пока нет

- Alloy 276 Spec SheetДокумент3 страницыAlloy 276 Spec SheetermusatОценок пока нет

- AVESTA How To Weld Duplex SteelДокумент20 страницAVESTA How To Weld Duplex SteelGMacella100% (1)

- 2005 Carbon SteelДокумент65 страниц2005 Carbon SteelmageshkumarОценок пока нет

- B253-Flushing For Marine Rev 1Документ2 страницыB253-Flushing For Marine Rev 1Saurabh SinghОценок пока нет

- EPCC 09 B224 137 TA2 ExtractДокумент2 страницыEPCC 09 B224 137 TA2 ExtractSaurabh SinghОценок пока нет

- JD GM Projects PDFДокумент1 страницаJD GM Projects PDFSaurabh SinghОценок пока нет

- Gantt ChartДокумент17 страницGantt ChartSaurabh SinghОценок пока нет

- PMP Question Bank PDFДокумент16 страницPMP Question Bank PDFRyan Li67% (15)

- Study PlanДокумент4 страницыStudy PlanSaurabh SinghОценок пока нет

- GMA Blast Grade Product Data SheetДокумент1 страницаGMA Blast Grade Product Data SheetSaurabh SinghОценок пока нет

- Abrasive Blast Cleaning & Field Painting of StructureДокумент15 страницAbrasive Blast Cleaning & Field Painting of StructureSaurabh SinghОценок пока нет

- B253-Flushing Table For MarineДокумент11 страницB253-Flushing Table For MarineSaurabh SinghОценок пока нет

- Definition & Abrevation On Paint ProductДокумент3 страницыDefinition & Abrevation On Paint ProductSaurabh SinghОценок пока нет

- Coating Work in The Fabrication ShopДокумент6 страницCoating Work in The Fabrication ShopSaurabh Singh100% (1)

- Galvanizing and Mechanical Preparation of Steel - 1Документ4 страницыGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghОценок пока нет

- B253-Flushing Procedure Cover Page R1.Документ1 страницаB253-Flushing Procedure Cover Page R1.Saurabh SinghОценок пока нет

- Paints Industry GlossaryДокумент11 страницPaints Industry GlossaryHany AminОценок пока нет

- P NumberДокумент6 страницP NumberSaurabh SinghОценок пока нет

- Overcoating of Aged & Zinc PrimersДокумент2 страницыOvercoating of Aged & Zinc PrimersSaurabh SinghОценок пока нет

- GMA Garnet Blasting ConditionsДокумент1 страницаGMA Garnet Blasting ConditionsSaurabh SinghОценок пока нет

- STDДокумент21 страницаSTDSaurabh SinghОценок пока нет

- Conversion TablesДокумент5 страницConversion TablesSaurabh SinghОценок пока нет

- Why FailДокумент5 страницWhy FailMohit AwasthiОценок пока нет

- Galvanizing and Mechanical Preparation of Steel - 1Документ4 страницыGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghОценок пока нет

- Hot Dip GalvanizingДокумент16 страницHot Dip Galvanizinglesonthach100% (1)

- Paint FundamentalsДокумент19 страницPaint FundamentalsSaurabh SinghОценок пока нет

- Paint Application: Protective CoatingsДокумент4 страницыPaint Application: Protective CoatingsSaurabh SinghОценок пока нет

- Inorganic Zinc Vs GalvanisingДокумент3 страницыInorganic Zinc Vs GalvanisingminhnnОценок пока нет

- 4.0 - Piping Construction Standard (PS)Документ58 страниц4.0 - Piping Construction Standard (PS)Saurabh SinghОценок пока нет

- Wind Load Over The VesselДокумент28 страницWind Load Over The VesselSaurabh SinghОценок пока нет

- Vessel Thickness CalculationДокумент60 страницVessel Thickness CalculationSaurabh SinghОценок пока нет

- Base Ring DesignДокумент2 страницыBase Ring DesignSaurabh SinghОценок пока нет

- Pgms or Pges: Platinum Group Metals or Platinum Group ElementsДокумент2 страницыPgms or Pges: Platinum Group Metals or Platinum Group Elementsrefpt007Оценок пока нет

- Minor09 QP DLP NEET2019 (Pmtcorner - In)Документ33 страницыMinor09 QP DLP NEET2019 (Pmtcorner - In)jay danenjeyanОценок пока нет

- Comparing Covalent and Ionic Lattices S4Документ3 страницыComparing Covalent and Ionic Lattices S4Fatima Ahmed-VeriterОценок пока нет

- Chemical ReactionsДокумент26 страницChemical ReactionsEvernim OmpacanОценок пока нет

- Introduction To Copper and Copper AlloysДокумент51 страницаIntroduction To Copper and Copper AlloysVidya VasudevanОценок пока нет

- Stacking Fault Energies of Seven Commercial Austenitic Stainless SteelsДокумент7 страницStacking Fault Energies of Seven Commercial Austenitic Stainless SteelsADRIANOОценок пока нет

- Purpose of Alloy Elements in A Galvanizing Kettle (Dr. Galv, 2006 Dec, Vol .88)Документ1 страницаPurpose of Alloy Elements in A Galvanizing Kettle (Dr. Galv, 2006 Dec, Vol .88)thaw kaung mawОценок пока нет

- Cytec Solutions 14 FinalДокумент24 страницыCytec Solutions 14 FinalAnonymous KDM8wArgОценок пока нет

- PhosphorousДокумент8 страницPhosphorousUJJWAL JHAОценок пока нет

- F3-ANCQ-2017 (Year 8)Документ10 страницF3-ANCQ-2017 (Year 8)2G (01) Cho Joshua Chi HoОценок пока нет

- 11th Chemistry Practical Notes Analysis of 15 Simple Salts Xi STDДокумент38 страниц11th Chemistry Practical Notes Analysis of 15 Simple Salts Xi STDPratheeksha shalbinОценок пока нет

- Ch4 WS1Документ1 страницаCh4 WS1FerminОценок пока нет

- Part IV Acids and Alkalis: LQ 01 (Answer) Properties of Acids and AlkalisДокумент12 страницPart IV Acids and Alkalis: LQ 01 (Answer) Properties of Acids and AlkalisCharmine HolmesОценок пока нет

- Tian Amalda Sabrina - Potassium BifluorideДокумент1 страницаTian Amalda Sabrina - Potassium BifluorideTian Amalda SabrinaОценок пока нет

- Lesson 1.2 Writing and Naming of Compounds-Group UploadДокумент60 страницLesson 1.2 Writing and Naming of Compounds-Group UploadMike MarquisОценок пока нет

- Solutions For Ch04Документ16 страницSolutions For Ch04wesleyaОценок пока нет

- Unit 13 Metals and Reactivity: Summary QuestionsДокумент2 страницыUnit 13 Metals and Reactivity: Summary QuestionsLei YinОценок пока нет

- Chemsampledraft e PDFДокумент36 страницChemsampledraft e PDFantonio latenОценок пока нет

- Chemistry Research Project On 5 Elements of The Periodic TableДокумент28 страницChemistry Research Project On 5 Elements of The Periodic TableRanjitha RaviproluОценок пока нет

- Manual de Partes Wirtgen W200Документ741 страницаManual de Partes Wirtgen W200Taller SamangaОценок пока нет

- 7.2.28 AOAC Official Surplus Method 920.30 Sodium and Potassium CyanidesДокумент1 страница7.2.28 AOAC Official Surplus Method 920.30 Sodium and Potassium CyanidesKhaled KayaliОценок пока нет

- 10th EXP 1-3Документ18 страниц10th EXP 1-3Siriki Chandra MouliОценок пока нет

- Orrego Uranium Resources ChileДокумент43 страницыOrrego Uranium Resources ChileJuanPerezRooneyОценок пока нет

- Steel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Документ15 страницSteel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Agustine SetiawanОценок пока нет

- Platinum Group Metals and Compounds: Article No: A21 - 075Документ72 страницыPlatinum Group Metals and Compounds: Article No: A21 - 075firda haqiqiОценок пока нет

- Stoichiometry Worksheet+AnswersДокумент2 страницыStoichiometry Worksheet+AnswersAnonymous 6MSekAxCnZ0% (3)

- 5: Chemical Trends - Topic Questions: Year Series Paper NumberДокумент10 страниц5: Chemical Trends - Topic Questions: Year Series Paper NumberSumaira AliОценок пока нет

- Analyze A Sample of Brass QualitativelyДокумент4 страницыAnalyze A Sample of Brass QualitativelyMEGHNA MATHURОценок пока нет

- RLJDMC Dav Public School, RaniganjДокумент5 страницRLJDMC Dav Public School, RaniganjVikrant SharmaОценок пока нет

- C067Документ49 страницC067Gato Sesa0% (1)