Академический Документы

Профессиональный Документы

Культура Документы

LDCBD5 Utility Consumption (Rev. 20141105) (KL Approved 20141119)

Загружено:

ponimin83Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LDCBD5 Utility Consumption (Rev. 20141105) (KL Approved 20141119)

Загружено:

ponimin83Авторское право:

Доступные форматы

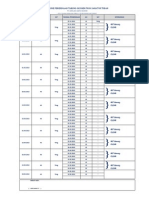

BATTERY LIMIT TABLE

FROM

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

B13

B14

B15

B16

B17

B18

B19

A20

A21

B22

B23

B24

A25

A26

SOURCE

RBDPO/ RBD OILS STORAGE

BIODIESEL STORAGE (REWORK)

SODIUM METHYLATE STORAGE

METHANOL STORAGE

NITROGEN 7 BARG MAIN SUPPLY

MP STEAM 12 BARG MAIN SUPPLY

HCL STORAGE

NAOH STORAGE

CRUDE GLYCERINE STORAGE (REWORK)

HOT WATER

SOFTENED WATER

PROCESS WATER

UNIT 166E3 CRUDE GLYCERINE BYPRODUCT

UNIT 166S1 FATTY MATTER BYPRODUCT

UNIT 163 CATALYST HEADER (RECIRC LOOP)

UNIT 160V2 (EMPTY SYSTEM)

MP STEAM CONDENSATE

LP STEAM CONDENSATE

ISBL CTW RETURN HEADER

OSBL CTW PUMP

INSTRUMENT AIR MAIN SUPPLY

UNIT 163E3B/C FINAL BIODIESEL

LIQUID EFFLUENT

UNIT 163S2/ 163S20 COOLING JACKET

UNIT 166P6 (RECIRC LOOP)

UNIT 166P7 (RECIRC LOOP)

TO

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

A13

A14

A15

A16

A17

A18

A19

B20

B21

A22

A23

A24

B25

B26

DESTINATION

UNIT 180E1

UNIT 180E1

UNIT 163 CATALYST HEADER (RECIRC LOOP)

UNIT 160V2

ISBL NITROGEN PRV HEADER

ISBL MP/ LP STEAM PRV HEADER

UNIT 166P6 (RECIRC LOOP)

UNIT 166P7 (RECIRC LOOP)

UNIT 166V3

SEPARATOR STARTUP & CLEANING

SEPARATOR STARTUP & CLEANING

SEPARATOR & OTHER USERS

CRUDE GLYCERINE STORAGE

FATTY MATTER/ CPO STORAGE

SODIUM METHYLATE STORAGE

METHANOL STORAGE

BOILER/ TO BE SPECIFIED BY CLIENT

BOILER/ TO BE SPECIFIED BY CLIENT

OSBL CTW RETURN HEADER

ISBL CTW SUPPLY HEADER

ISBL PNEUMATIC DISTRIBUTION HEADER

BIODIESEL STORAGE TANK

SEWER/ FAT TRAP

COOLING TOWER BASIN

HCL STORAGE

NAOH STORAGE

Notes Remark

1

REPORTED TO THE GROUND FLOOR

2

TO BE CONFIRMED DURING DETAIL ENGINEERING

3

OSBL CENTRIFUGAL PUMP IS FORESEEN

4

MINIMUM FLOW AT START-UP

6

7

8

9

10

11

DISCONTINUOUS FOR CENTRIFUGE WASHING

FOR BLANKETING

CONSIDER INSULATION FOR HEAT CONSERVATION

CONSIDER STEAM TRACING AND INSULATION FOR HEAT CONSERVATION

FROM DEDICATED EMERGENCY PUMP OR ESSENTIAL POWER SUPPLY

PEAK CONSUMPTION

:

:

:

LDCBD5 (LOUIS DREYFUS COMMODITIES LAMPUNG)

2

5/11/2014

SIZE

(DN)

TIE IN TIE IN

PIPING

SIDE LEVEL FLUID

CLASS

(VIEW) (m)

100

100

50

50

50

250

25

25

50

25

25

65

50

50

50

50

100

100

500

500

50

100

150

50

25

25

5

5

5

5

4

4

5

5

5

4

4

4

5

5

5

5

4

4

4

4

4

5

0

4

5

5

OL

MH

SM

ME

NN

MS

HC

NA

GR

WH

WS

PW

GR

HG

SM

ME

MC

LC

CW

CW

IA

MH

WW

CW

HC

NA

C101

F101

F101

F101

C101

C312

PV01

F101

F101

C121

C121

C121

S101

S101

F101

F101

C312

C111

C121

C121

G131

F101

C121

C121

PV01

F101

INSULATION

Project

Revision

Date

I1

I1

I2

I1

I7

-

I1

I1

I2

I1

I7

-

MIN FLOW

(kg/Hr)

20833

20833

3500

5000

40 Nm3/Hr

6250

1000

1000

2604

0

0

100

521

104

344

6320

3000

5000

1500000

1500000

30 Nm3/Hr

20833

50

50

1000

1000

OPE FLOW

(kg/Hr)

MIN

OPERATE

MAX

MAX FLOW

MIN TEMP OPERATE

MAX

PRESSURE PRESSURE PRESSURE

(kg/Hr)

(C)

TEMP (C) TEMP (C)

(BarG)

(BarG)

(BarG)

41667

50000

41667

50000

688

9000

4021

15000

40 Nm3/Hr 300 Nm3/Hr

12500

23750

2000

3000

2000

3000

5208

6250

2500

5000

2500

5000

14000

20000

5208

6250

208

1042

688

2064

12640

15800

6000

10000

10000

15000

1600000

1800000

1600000

1800000

67 Nm3/Hr 150 Nm3/Hr

41667

50000

334

3336

400

2000

2000

3000

2000

3000

3

3

4

3

7

12

1

3

3

2

2

3

3

1

3

3

10

2

2

4

6

3

GRAVITY

0.5

1

3

3

3

4

3

7

12

2

3

3

2

2

4

3

2

3

3

12

3

3

5

7

3

GRAVITY

0.5

2

3

6

6

6

6

9

15

3

6

6

6

6

6

11

3

6

6

12

4

6

6

9

6

GRAVITY

1

3

6

50

50

40

AMBIENT

AMBIENT

191

AMBIENT

40

50

70

AMBIENT

AMBIENT

50

40

40

AMBIENT

191

139

AMBIENT

AMBIENT

AMBIENT

50

50

25

AMBIENT

40

60

60

50

AMBIENT

AMBIENT

191

AMBIENT

50

60

80

AMBIENT

AMBIENT

60

50

50

AMBIENT

191

139

38

32

35

60

60

32

AMBIENT

50

100

100

80

60

50

205

60

90

100

90

50

60

100

80

60

60

205

152

60

38

50

60

90

38

60

90

OPE

DENSITY

(kg/m3)

940

860

960

790

9

6

1100

1510

1240

1000

1000

1000

1240

900

960

790

900

940

1000

1000

10

860

900

1000

1100

1510

OPE

Viscosity

(cP)

50

4

40

0.6

0.018

0.015

10

16

20

1

1

1

20

10

40

0.6

0.13

0.2

1

1

0.018

4

10

1

10

16

Notes

(3) (9)

(3) (9)

(3)

(3)

(8)

(3)

(3)

(3) (9)

(6)

(9)

(8)

(8)

(10)

(3)

(3)

Вам также может понравиться

- HR Deviation U#2 06.03.2016 (Day Avg)Документ32 страницыHR Deviation U#2 06.03.2016 (Day Avg)golden430Оценок пока нет

- PTC 4 1 Boiler Test EficiencyДокумент16 страницPTC 4 1 Boiler Test EficiencySirawet CharaspredalapОценок пока нет

- Sulphur Recovery UnitДокумент30 страницSulphur Recovery UnitDevendra Sharma100% (3)

- Pressures & Temperatures Fuel DataДокумент1 страницаPressures & Temperatures Fuel DataDaniel AlvarezОценок пока нет

- Nitric Acid Plant DetailsДокумент21 страницаNitric Acid Plant DetailsBon BonОценок пока нет

- Pareto Excel by SandroДокумент12 страницPareto Excel by SandrosandrositohangОценок пока нет

- DHDS Block OperationsДокумент77 страницDHDS Block Operationsmujeebmehar100% (2)

- Deisel Hydrotreating UnitДокумент9 страницDeisel Hydrotreating UnitRittu Paul100% (1)

- Aspen Reformer (Reparado)Документ138 страницAspen Reformer (Reparado)Vale Aracena100% (1)

- Ammonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGHДокумент22 страницыAmmonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGHR Kibik Sht100% (1)

- OverviewДокумент41 страницаOverviewSumitAggarwalОценок пока нет

- NaturalRefrigerantNH3CO2 PDFДокумент24 страницыNaturalRefrigerantNH3CO2 PDFPierreОценок пока нет

- Refinery ProcessДокумент45 страницRefinery ProcessAnubhav Tiwari100% (2)

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultДокумент87 страницAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalОценок пока нет

- Stripper InfoДокумент30 страницStripper Infonedian_2006Оценок пока нет

- ERC Refinery ProjectДокумент16 страницERC Refinery ProjectTarek Fawzy100% (1)

- Parameters - Stage-Ii (4X600 MW), Sliding Pressure: Parameter UOM Unit#1 Unit#2Документ4 страницыParameters - Stage-Ii (4X600 MW), Sliding Pressure: Parameter UOM Unit#1 Unit#2lp mishraОценок пока нет

- Gasoline MeroxДокумент66 страницGasoline MeroxkishoreprithikaОценок пока нет

- Miele G527 Dishwasher Wiring DiagramДокумент6 страницMiele G527 Dishwasher Wiring Diagramjules197350% (2)

- Refinery Overview FinalДокумент65 страницRefinery Overview FinalasifОценок пока нет

- Ammonia PlantДокумент28 страницAmmonia PlantHumayun Rashid Khan100% (1)

- Legend Sheet ModelДокумент1 страницаLegend Sheet ModelĐỗ Thiện100% (1)

- Ammonia Plant: Kribhco Shyam Fertilisers LTDДокумент51 страницаAmmonia Plant: Kribhco Shyam Fertilisers LTDSabeeh Faruqui100% (1)

- Mahek PresentationДокумент13 страницMahek PresentationAmit GangulyОценок пока нет

- Ammonia Process DescriptionДокумент51 страницаAmmonia Process DescriptionSaad Khan89% (9)

- ERC Refinery ProjectДокумент16 страницERC Refinery ProjectSameh El-Sabbagh100% (3)

- Turbine & AuxilariesДокумент64 страницыTurbine & Auxilariesulhatolkargmailcom100% (1)

- Combustion HandoutДокумент16 страницCombustion HandoutAbdallah Irfaan Ramjan100% (1)

- Process Design ConditionsДокумент8 страницProcess Design ConditionsGerald RahanraОценок пока нет

- 427-Landfill Gas Collection and RecoveryДокумент37 страниц427-Landfill Gas Collection and RecoveryJocelyn MasonОценок пока нет

- Project 2 Maleic AnhydrideДокумент11 страницProject 2 Maleic AnhydrideAhmed Ali50% (2)

- Biomass To Liquid Fuels Via Gas To Liquids Technology: Biomass Energy Opportunities in Indian CountryДокумент20 страницBiomass To Liquid Fuels Via Gas To Liquids Technology: Biomass Energy Opportunities in Indian CountryganesanpatelОценок пока нет

- Aspen Report FileДокумент30 страницAspen Report FileJoshua PetersonОценок пока нет

- 64788Документ35 страниц64788ghatak2100% (1)

- Ammonia Plant Design For 1 MtpaДокумент43 страницыAmmonia Plant Design For 1 MtpaPrateek Mall67% (3)

- HPCL IT DHDS Block OverviewДокумент37 страницHPCL IT DHDS Block OverviewSrija Mummidi100% (1)

- Experimental Results of HFO/HCFO Refrigerants in A Laboratory Scale HTHP With Up To 150 °C Supply TemperatureДокумент10 страницExperimental Results of HFO/HCFO Refrigerants in A Laboratory Scale HTHP With Up To 150 °C Supply TemperatureFocuОценок пока нет

- T Basak AromaticsДокумент41 страницаT Basak AromaticsDP PurwadiОценок пока нет

- Budgetary Project Cost Section Wise Equipment & Boughtout Items Cost Civil & Structural Section Project Cost (Machinery + Construction)Документ6 страницBudgetary Project Cost Section Wise Equipment & Boughtout Items Cost Civil & Structural Section Project Cost (Machinery + Construction)BhoomiSagarОценок пока нет

- Project 5 Maleic AnhydrideДокумент11 страницProject 5 Maleic Anhydrideandm9Оценок пока нет

- Depa Mine Unit AppendixДокумент256 страницDepa Mine Unit AppendixWalid Ben Husein100% (1)

- 7Документ81 страница7Alberto Fonseca UribeОценок пока нет

- AVU Critical EquipmentsДокумент55 страницAVU Critical EquipmentsmujeebtalibОценок пока нет

- FAAM ARA Cylinders 20110816Документ1 страницаFAAM ARA Cylinders 20110816Mirlo EspasticoОценок пока нет

- Facility Inspection Report: Tail Gas Treatment UnitДокумент7 страницFacility Inspection Report: Tail Gas Treatment Unitabdelkader benabdallahОценок пока нет

- PTC 4.1 Boiler Test EficiencyДокумент11 страницPTC 4.1 Boiler Test EficiencyPra Tiwi100% (2)

- Hydro Cracking TechnologyДокумент69 страницHydro Cracking TechnologySameh El-SabbaghОценок пока нет

- Refinery OverviewДокумент79 страницRefinery Overviewchikukotwal100% (1)

- Ebsm PDFДокумент16 страницEbsm PDFAhmed Ibrahim Ahmed EissaОценок пока нет

- Thermal Relief Therm - VTДокумент6 страницThermal Relief Therm - VTRafael ReyesОценок пока нет

- Fundamental of Ammonia Plants PDFДокумент28 страницFundamental of Ammonia Plants PDFali AbbasОценок пока нет

- Celanese PFD of MethanolДокумент1 страницаCelanese PFD of MethanolJessica CehОценок пока нет

- Cameron Abney and Associates Blog Review Formulas and Conversion ChartsДокумент2 страницыCameron Abney and Associates Blog Review Formulas and Conversion ChartsCameron Abney and Associates Blog ReviewОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsОт EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerОценок пока нет

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentОт EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentОценок пока нет

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОт EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualОценок пока нет

- 2.2 Curriculum Vitae Personnel GKMДокумент17 страниц2.2 Curriculum Vitae Personnel GKMponimin83Оценок пока нет

- Cert 1082 5693783Документ1 страницаCert 1082 5693783ponimin83Оценок пока нет

- Pipe & Fittings List (Preliminary) : Customer Plant Contract No Project No. Date Revision No. 1.0) PIPEДокумент22 страницыPipe & Fittings List (Preliminary) : Customer Plant Contract No Project No. Date Revision No. 1.0) PIPEponimin83Оценок пока нет

- Cert 1023 5693783Документ1 страницаCert 1023 5693783ponimin83Оценок пока нет

- Cert 1080 5693783Документ1 страницаCert 1080 5693783ponimin83Оценок пока нет

- Transmittal Letter: PT Ttlta Enarcon EngineeringДокумент1 страницаTransmittal Letter: PT Ttlta Enarcon Engineeringponimin83Оценок пока нет

- Fire Hydrant & Equipment (Brochure) PDFДокумент5 страницFire Hydrant & Equipment (Brochure) PDFponimin83Оценок пока нет

- Rigging PlanДокумент12 страницRigging Planponimin83Оценок пока нет

- Technical - AHU 1 - DM2-2033 GresikДокумент8 страницTechnical - AHU 1 - DM2-2033 Gresikponimin83Оценок пока нет

- Drawing BangkoДокумент11 страницDrawing Bangkoponimin83Оценок пока нет

- Hari TGL No. Payment/ Advance Transaksi Arus Kas Debet KreditДокумент5 страницHari TGL No. Payment/ Advance Transaksi Arus Kas Debet Kreditponimin83Оценок пока нет

- BQ of Hdpe Piping R - 2 (04!09!2014)Документ1 страницаBQ of Hdpe Piping R - 2 (04!09!2014)ponimin83Оценок пока нет

- Supplier PT. GKMДокумент7 страницSupplier PT. GKMponimin83Оценок пока нет

- LDCBD5 Preliminary Load List (Rev. 20141021) (KL Approved 20141119)Документ1 страницаLDCBD5 Preliminary Load List (Rev. 20141021) (KL Approved 20141119)ponimin83Оценок пока нет

- Bil of Quantity: PT - XXX Material Labour Jumlah A PreleminariesДокумент2 страницыBil of Quantity: PT - XXX Material Labour Jumlah A Preleminariesponimin83Оценок пока нет

- Rekap Penerimaan OksigenДокумент1 страницаRekap Penerimaan Oksigenponimin83Оценок пока нет

- Lurgi MTP ArticleДокумент10 страницLurgi MTP Articlerkhandelwal9604100% (1)

- Internal Tender EME-603Документ67 страницInternal Tender EME-603SheikhaAreebОценок пока нет

- DS410 83100fДокумент4 страницыDS410 83100fzliang100% (1)

- 77tsm312 Viking g432 Kentex Bomba BunkerДокумент10 страниц77tsm312 Viking g432 Kentex Bomba BunkerJohn Alexander WilliamsОценок пока нет

- Lit Ag OsДокумент2 страницыLit Ag OsRobert CoxОценок пока нет

- Aluminum Metal Matrix CompositesДокумент3 страницыAluminum Metal Matrix CompositesazeemdcetОценок пока нет

- FSAE Design Spec Sheet: Car No. SchoolДокумент4 страницыFSAE Design Spec Sheet: Car No. SchoolMohammad Parvez RazaОценок пока нет

- Piese CamionДокумент367 страницPiese Camionaiulica20Оценок пока нет

- Steam and Gas TurbinesДокумент2 страницыSteam and Gas TurbinesPunit ShindeОценок пока нет

- 1617 Level M Chemistry Brush-Up Make-Up Material PDFДокумент5 страниц1617 Level M Chemistry Brush-Up Make-Up Material PDFAndrewОценок пока нет

- Pantera Brochure EnglishДокумент6 страницPantera Brochure EnglishBerat HasolliОценок пока нет

- Cumminsonan Service ManualДокумент84 страницыCumminsonan Service ManualAhmad Khan100% (1)

- Atmospheric Crude Distillation UnitДокумент2 страницыAtmospheric Crude Distillation UnitFahmi Ramadhan PutraОценок пока нет

- Workshop Manual: 438 202 01 - Printed in GermanyДокумент193 страницыWorkshop Manual: 438 202 01 - Printed in GermanyWere Wolf100% (9)

- HalliburtonДокумент4 страницыHalliburtonwjawichОценок пока нет

- BORL HCU-DHT APC Scoping Study Report (Final)Документ45 страницBORL HCU-DHT APC Scoping Study Report (Final)AnilKumarОценок пока нет

- Animal Waste Incinerator Mini AB DatasheetДокумент5 страницAnimal Waste Incinerator Mini AB Datasheetaddfield100% (1)

- TD Lab ManualsДокумент40 страницTD Lab ManualsAjay Kumar AgarwalОценок пока нет

- Electrical PDFДокумент90 страницElectrical PDFriqtorresОценок пока нет

- Mechanical Troubleshooting: Testing & AdjustingДокумент102 страницыMechanical Troubleshooting: Testing & AdjustingDavidОценок пока нет

- Wartsila O E W 50DF PG Product GuideДокумент180 страницWartsila O E W 50DF PG Product GuideFábio Almeida100% (1)

- MTU 4000 12v 16v+Service+Manual PDFДокумент2 706 страницMTU 4000 12v 16v+Service+Manual PDFJorge Enrique Fuentes Marin87% (62)

- Mobil Lubricants Product GuideДокумент23 страницыMobil Lubricants Product Guidejizu67% (3)

- ZULF 29 ProgramДокумент60 страницZULF 29 ProgramJan Nico TorresОценок пока нет

- MPE 371 CH 1 - Air Standard Cycles-1Документ27 страницMPE 371 CH 1 - Air Standard Cycles-1Abraham MugambiОценок пока нет

- Production of Ethanol by Fermentation Process by Using YeastДокумент9 страницProduction of Ethanol by Fermentation Process by Using Yeastdeepu kumarОценок пока нет

- Work Diary FinalДокумент190 страницWork Diary FinalMasoodAnjumОценок пока нет

- Manual Fallas SPN Fault CodesДокумент4 страницыManual Fallas SPN Fault CodesOrhan TuncelОценок пока нет

- Article - Evaluation of Evaporative Emissions of Gasoline From Storage Sites and Service StationsДокумент17 страницArticle - Evaluation of Evaporative Emissions of Gasoline From Storage Sites and Service StationsKhalida MuddasserОценок пока нет