Академический Документы

Профессиональный Документы

Культура Документы

1 - FW STD - Piping Material Specs

Загружено:

alikami100%(1)100% нашли этот документ полезным (1 голос)

2K просмотров3 страницыОригинальное название

1_FW Std_ Piping Material Specs

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

2K просмотров3 страницы1 - FW STD - Piping Material Specs

Загружено:

alikamiАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

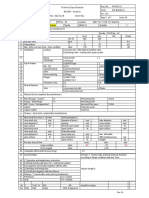

FOSTER WHEELER ENGINEERING STANDARDS

PIPING MATERIAL SPECIFICATION

SPEC FLUID MAX PIPE DESIGN DESIGN PIPE MATERIAL CORROSION FLANGE INSPECTION

CODE SIZE TEMP. PESSURE ALLOWANCE CLASS & CLASS

inch o

C barg mm FACE

1 A1B Cooling Water 48 75 7.0 CS API 5L Gr. B 1.5 150 RF II

2 A1B Instrument Air 4 65 10.0 CS API 5L Gr. B 1.5 150 RF II

3 A1B Process Air 28 195 1.0 CS API 5L Gr. B 1.5 150 RF II

4 A1B Compressed Air 6 200 9.7 CS API 5L Gr. B 1.5 150 RF II

5 A1B IP Nitrogen 10 65 8.6 CS API 5L Gr. B 1.5 150 RF II

6 A1B Conveying Gas 12 160 8.6 CS API 5L Gr. B 1.5 150 RF II

7 A1B Effluent 14 260 7.0 CS API 5L Gr. B 1.5 150 RF II

8 A1B Paraxylene 8 185 8.6 CS API 5L Gr. B 1.5 150 RF II

9 A1B Fuel Oil LP 6 135 3.5 CS API 5L Gr. B 1.5 150 RF II

10 A1B Relief Valve Discharge 8 325 9.3 CS API 5L Gr. B 1.5 150 RF II

11 A1B Vent 4 200 3.5 CS API 5L Gr. B 1.5 150 RF II

12 A1C 98 % Sulphuric Acid 4 60 4.0 CS API 5L Gr. B 3.0 150 RF II

13 A1D Raw Water 20 60 8.0 CS API 5L Gr. B 6.0 150 RF II

14 A1D Fresh Water 20 60 8.0 CS API 5L Gr. B 6.0 150 RF II

15 A1D Fire Water (above ground) 16 75 17.3 CS API 5L Gr. B 6.0 150 RF II

16 A1G HP Fire Water-Dry (above ground) 4 60 9.7 CS API 5L Gr. B Galv Nil 150 RF II

17 A1G Portable Water (above ground) 4 60 9.7 CS API 5L Gr. B Galv Nil 150 RF II

18 A1N LP Caustic 5 % 8 100 8.6 CS API 5L Gr. B 1.5 150 RF II

19 A1N LP Caustic 47 % 6 75 8.6 CS API 5L Gr. B 1.5 150 RF II

20 A1S Steam & Condensate 24 325 9.3/FV CS API 5L Gr. B 1.5 150 RF II

21 A1S Steam & Condensate 24 185 14.5/FV CS API 5L Gr. B 1.5 150 RF II

22 A1S Steam & Condensate 30 210 6.9/FV CS API 5L Gr. B 1.5 150 RF II

23 A1T Steam Tracing 1.5 185 6.9 CS API 5L Gr. B 1.5 150 RF II

24 A1U Cooling Water (under ground) 48 75 7.0 CS API 5L Gr. B 1.5 150 RF II

25 A1U Effluent 14 60 1.0 CS API 5L Gr. B Nil 150 RF II

26 A1V Portable Water (under ground) 4 40 7.2 CS API 5L Gr. B Galv 1.5 300 RF II

27 B1B Process Air 16 280 30.0 CS API 5L Gr. B 1.5 300 RF II

28 B1B HP Nitrogen 2 200 30.0 CS API 5L Gr. B 1.5 300 RF II

29 B1B Conveying Gas 8 160 24.0 CS API 5L Gr. B 1.5 300 RF II

30 B1B Fuel Oil 8 135 21.0 CS API 5L Gr. B 1.5 300 RF II

31 B1N IP Caustic 5 % 8 100 30.0 CS API 5L Gr. B 1.5 300 RF II

32 B1N HP Caustic 5 % 8 100 30.0 CS API 5L Gr. B 1.5 300 RF II

33 B1S Steam & Condensate 6 325 39/FV CS API 5L Gr. B 1.5 300 RF II

34 C1B Process & Utilities 6 220 86.0 CS API 5L Gr. B 1.5 600 RF I

35 C1B Seal System 6 220 86.0 CS API 5L Gr. B 1.5 600 RF I

36 C1B Nitrogen 6 220 86.0 CS API 5L Gr. B 1.5 600 RF I

37 D1H Hydrogen 1.5 200 100.0 CS API 5L Gr. B 1.5 900 RF I

38 D1S Steam & Condensate 16 325 109.0 CS API 5L Gr. B 1.5 900 RF I

39 E1B Nitrogen 8 185 160.0 CS API 5L Gr. B 1.5 1500 RF I

40 E1B Boiler Feed Water 8 354 109.0 CS API 5L Gr. B 1.5 1500 RF I

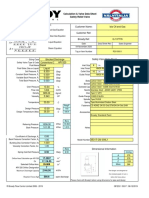

FOSTER WHEELER ENGINEERING STANDARDS

PIPING MATERIAL SPECIFICATION

SPEC FLUID MAX PIPE DESIGN DESIGN PIPE MATERIAL CORROSION FLANGE INSPECTION

CODE SIZE TEMP. PESSURE ALLOWANCE CLASS & CLASS

inch o

C barg mm FACE

41 B2B Process 18 260 26/FV Hastelloy C 276 1.5 300 RF II

42 E2B Process 8 320 99.0 Hastelloy C 276 Nil 1500 RF I

43 A3B Demin Water 8 75 14.0 SS Type 304 L Nil 150 RF II

44 A3B Demin Seal Water HP & LP 6 75 14.0 SS Type 304 L Nil 150 RF II

45 A3B Purification Effluent 3 75 3.0 SS Type 304 L Nil 150 RF II

46 A3C Process 54 150 3.5 SS Type 304 L 1.5 150 RF II

47 A3C Inert Gas 8 150 12.0 SS Type 304 L 1.5 150 RF II

48 A3C Hot Caustic 6 150 8.6 SS Type 304 L 1.5 150 RF II

49 A3C Methanol 4 185 6.9 SS Type 304 L 1.5 150 RF II

50 A3C Vent 12 185 6.9/FV SS Type 304 L 1.5 150 RF II

51 A3C Compressed Air 6 110 6.0 SS Type 304 L 1.5 150 RF II

52 A3D Process 22 165 4.5FV SS Type 316 L 2.5 150 RF II

53 A3D Process 20 225 10.6/FV SS Type 316 L 2.5 150 RF II

54 A3D Process 20 75 14/FV SS Type 316 L 2.5 150 RF II

55 A3F Acetic Acid 1 25 10.0 SS Type 316 L 1.5 150 RF II

56 A3P TA Powder Transfer 18 150 8.6 SS Type 304 L Nil 150 RF II

57 A3P Cooling Water 16/14 150 8.6 SS Type 304 L Nil 150 RF II

58 A3P Cooling Water (jacket) 12/10 150 8.6 SS Type 304 L Nil 150 RF II

59 A3X Process 20 170 5.2 Duplex SS 22 Cr S 31803 1.5 150 RF I

60 B3B Demin Seal Water (HHP) 3 75 36.0 SS Type 304 L Nil 300 RF II

61 B3B Demin Water 12 75 15.0 SS Type 304 L Nil 300 RF II

62 B3C Process 20 260 26/FV SS Type 304 L 1.5 300 RF I

63 B3C Methanol 4 75 16.5 SS Type 304 L 1.5 300 RF I

64 B3D Process 10 205 26.5/FV SS Type 316 L 2.5 300 RF I

65 B3D Process 10 164 30.1/FV SS Type 316 L 2.5 300 RF I

66 B3H Process 28 550 24.0 SS Type 316 H 1.5 300 RF I

67 B3X Process 18 250 24.0 Duplex SS 22 Cr S 31803 1.5 300 RF I

68 C3C Process & Demin Water 18 260 44.0 SS Type 304 L 1.5 600 RF I

69 C3C Glycerine 10 260 44.0 SS Type 304 L 1.5 600 RF I

70 C3D Process 8 280 35.0 SS Type 316 L 2.5 600 RF I

71 E3C Process 8 320 109.0 SS Type 304 L 1.5 1500 RF I

72 E3C Process 8 260 125.0 SS Type 304 L 1.5 1500 RF I

73 F4A HP Steam Upstream of D/S 2 530 109.0 Alloy 21/4 Cr 1.5 2500 RJ I

74 A5E Oxidation Catalyst 10 75 3.0 CPVC-FRP Nil 150 RF -

75 A5E Hydrochloric Acid 4 75 5.0 GRP Nil 150 RF -

76 A5E Chemical Dosing 3 60 6.0 Titanium Nil 150 RF -

77 A5Y Fire Water (under ground) 16 75 17.3 Titanium Nil 150 FF -

78 A7B Process 16 170 14.0 Titanium Nil 150 LTF/RF I

79 A7B Process 8 295 7.0 Titanium Nil 150 LTF/RF I

80 B7B Process 26 250 24/FV Titanium Nil 300 LTF/RF I

FOSTER WHEELER ENGINEERING STANDARDS

PIPING MATERIAL SPECIFICATION

SPEC FLUID MAX PIPE DESIGN DESIGN PIPE MATERIAL CORROSION FLANGE INSPECTION

CODE SIZE TEMP. PESSURE ALLOWANCE CLASS & CLASS

inch o

C barg mm FACE

81 B7B Process 26 256 30.0 Titanium Nil 300 LTF/RF I

82 B7B Process 26 130 37.0 Titanium Nil 300 LTF/RF I

Вам также может понравиться

- Piping Classes PDFДокумент429 страницPiping Classes PDFMichael Jordan100% (4)

- Common Materilas For CS PipingДокумент2 страницыCommon Materilas For CS PipingValiullah SarpanchОценок пока нет

- Barred TeesДокумент1 страницаBarred TeesAdvisОценок пока нет

- Y-Strainer Technical SpecificationДокумент7 страницY-Strainer Technical SpecificationKailas NimbalkarОценок пока нет

- Piping Specialty Item Design Guide ProcedureДокумент3 страницыPiping Specialty Item Design Guide ProcedureCivil Friend67% (3)

- Piping and Valve Specifications Rev. A PDFДокумент28 страницPiping and Valve Specifications Rev. A PDFYessine RebaiОценок пока нет

- Piping SpecificationsДокумент67 страницPiping SpecificationsVedran Kosanovic100% (3)

- Piping - Guideline For Line ListДокумент13 страницPiping - Guideline For Line Listcordobaluisf100% (1)

- Piping ClassДокумент881 страницаPiping ClassAvr Chandana100% (1)

- Aterial Specification & All Thickness CalculationДокумент35 страницAterial Specification & All Thickness CalculationPanjiUte100% (1)

- Floating Head Heat Exchanger MaintenanceДокумент15 страницFloating Head Heat Exchanger MaintenanceZaid Tariq AlabiryОценок пока нет

- Piping Design Requirements PDFДокумент6 страницPiping Design Requirements PDFkarunaОценок пока нет

- VDS (Valve Data Sheet)Документ1 страницаVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Fully and Partially Jacketed Piping SystemsДокумент15 страницFully and Partially Jacketed Piping SystemsSUKANTA DALAI100% (1)

- UT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Документ5 страницUT-CPF1-2016-V13220A-035 HP-COMP-PK13210A-SUCTION SCRUBBER (1st Stage) V-13220A 20170111Jinlong SuОценок пока нет

- Hyundai Pipe CatalogueДокумент36 страницHyundai Pipe Cataloguefelram100% (2)

- 6 44 0005 A1 PDFДокумент15 страниц6 44 0005 A1 PDFS.selvakumarОценок пока нет

- Piping 5.0 - Introduction to Piping EngineeringДокумент32 страницыPiping 5.0 - Introduction to Piping EngineeringSteve WanОценок пока нет

- Piping Class DatasheetДокумент5 страницPiping Class Datasheetcyno21100% (2)

- Piping Material Service Index ChartДокумент3 страницыPiping Material Service Index ChartOghenekevwe OrumahОценок пока нет

- Material Selection GuideДокумент12 страницMaterial Selection Guideaajmsae*Оценок пока нет

- Pig Launcher and Receiver TrapДокумент1 страницаPig Launcher and Receiver TrapJaroslaw KoniecznyОценок пока нет

- Code Ref.Документ155 страницCode Ref.Selvakpm06Оценок пока нет

- SP Item DatasheetsДокумент21 страницаSP Item DatasheetsSELVAMANIОценок пока нет

- KG-DWN-98/2 Piping Installation DrawingsДокумент51 страницаKG-DWN-98/2 Piping Installation DrawingsNguyen Anh Tung100% (3)

- LS 545-15 Anchor supports for horizontal pipingДокумент7 страницLS 545-15 Anchor supports for horizontal pipingtejasp8388Оценок пока нет

- Basket Type StrainerДокумент12 страницBasket Type Strainerprateek_bhoir100% (1)

- A1a PMSДокумент5 страницA1a PMSS.selvakumarОценок пока нет

- Checklist For Nozzle OrientationДокумент4 страницыChecklist For Nozzle OrientationPhilippe LAVOISIERОценок пока нет

- Corporate Piping SpecДокумент56 страницCorporate Piping Specamanojp100% (2)

- Branch Reinforcement Per Asme B31.4 PipelineДокумент1 страницаBranch Reinforcement Per Asme B31.4 PipelinegateauxboyОценок пока нет

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubДокумент1 страницаLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiОценок пока нет

- Thickness Calculations As Per ASME B 31.3, 31.4 and 31.8Документ9 страницThickness Calculations As Per ASME B 31.3, 31.4 and 31.8harsh_158250% (2)

- Iit MumbaiДокумент242 страницыIit Mumbaiapi-3828788100% (5)

- Thumb RuleДокумент42 страницыThumb RuleShabeer KiblaalamОценок пока нет

- PIP - Piping Material Specifications Collection - IHSДокумент3 страницыPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourdeОценок пока нет

- Check List For Piping GADДокумент3 страницыCheck List For Piping GADkaruna100% (2)

- Ac 036630 001Документ1 страницаAc 036630 001navaronefraОценок пока нет

- Blowdown of LPG PipelinesДокумент10 страницBlowdown of LPG PipelinesBehnam HosseinzadehОценок пока нет

- Pipe FittingsДокумент40 страницPipe FittingsLucky Jaswal100% (1)

- Norms Overview.: Pipeline ConstructionДокумент3 страницыNorms Overview.: Pipeline ConstructionRjeb mohamedОценок пока нет

- Piping Spec - Piping ClassДокумент53 страницыPiping Spec - Piping Classalin2005100% (1)

- ASME Flange & PN RatingДокумент7 страницASME Flange & PN Ratinggetz_meОценок пока нет

- Piping FabricationДокумент36 страницPiping FabricationMouchartStéphanieОценок пока нет

- UHDE-Specs Section-9 PaintingДокумент12 страницUHDE-Specs Section-9 PaintingDivyansh TripathiОценок пока нет

- New Pipeline Dia. (Inches) Pipeline Material/ Schedule New Pipeline Distance (Meters) No. of JointsДокумент4 страницыNew Pipeline Dia. (Inches) Pipeline Material/ Schedule New Pipeline Distance (Meters) No. of JointsAkhilОценок пока нет

- N 1693Документ27 страницN 1693Daniela Valdomiro PatrícioОценок пока нет

- Asme b31.3 Allowable StressДокумент23 страницыAsme b31.3 Allowable Stressjoaquin torrano veraОценок пока нет

- Sizing CalcДокумент1 страницаSizing CalcHilary AbaratuОценок пока нет

- U00034-PL-MTO-0001 - MTO For Export PipelinesДокумент7 страницU00034-PL-MTO-0001 - MTO For Export PipelinesThiên KhánhОценок пока нет

- Tdi 50000 Tpy, GNFCДокумент6 страницTdi 50000 Tpy, GNFCkrunal panchalОценок пока нет

- 2020B Rev 5 - FS - Seamless Pipes - Submarine Pipelines - Sour ServiceДокумент39 страниц2020B Rev 5 - FS - Seamless Pipes - Submarine Pipelines - Sour Serviceanshul agrawalОценок пока нет

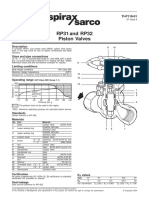

- Spirax Sarco Piston Valve RP31Документ2 страницыSpirax Sarco Piston Valve RP31PaulОценок пока нет

- f13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdДокумент5 страницf13 Rfs Ansi150 Cast Steel Flange End Ball Valves IdsimanjuntakagusboyОценок пока нет

- Bestract Amended PriceДокумент4 страницыBestract Amended PriceRescos KasarachiОценок пока нет

- Leading Latin American manufacturer of cryogenic valves and pumpsДокумент50 страницLeading Latin American manufacturer of cryogenic valves and pumpsAlvaro Antonio Cristobal AtencioОценок пока нет

- Piping Class Data Sheet for Gulf Indonesia ResourcesДокумент21 страницаPiping Class Data Sheet for Gulf Indonesia ResourcesMekar MeinaОценок пока нет

- Engine Test Cell Results: Shutdown SISДокумент2 страницыEngine Test Cell Results: Shutdown SISJesusОценок пока нет

- 11d Pms Rev00a Ongc 27jul15Документ3 страницы11d Pms Rev00a Ongc 27jul15abhiОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Investigations On Fouling Rate in Convective BundlesДокумент11 страницInvestigations On Fouling Rate in Convective BundlesAnitha Kumari SivathanuОценок пока нет

- XII Chemistry CH#11 Notes (Sir Nasim Zulfiqar)Документ9 страницXII Chemistry CH#11 Notes (Sir Nasim Zulfiqar)salmanОценок пока нет

- Satriana Et Al 2019 - European Journal of Lipid Science and TechnologyДокумент1 страницаSatriana Et Al 2019 - European Journal of Lipid Science and TechnologyMuhammad Dani SupardanОценок пока нет

- Small STNTechnical ManualДокумент8 страницSmall STNTechnical ManualMajid KhanОценок пока нет

- Manufacturing porcelain figures using binder jetting 3D printingДокумент8 страницManufacturing porcelain figures using binder jetting 3D printingcesarОценок пока нет

- Katalog Mikrofilter Facet AllДокумент12 страницKatalog Mikrofilter Facet Alltogentong100% (1)

- CT TPДокумент5 страницCT TPcesarchiletОценок пока нет

- 03 Trib OlogyДокумент24 страницы03 Trib Ologyluis martinezОценок пока нет

- Chemical Looping of CO2Документ23 страницыChemical Looping of CO2shyamОценок пока нет

- B42 - Midterm10w CH 15-16-17-1Документ7 страницB42 - Midterm10w CH 15-16-17-1Siao Ryan YangОценок пока нет

- Notice IchloreДокумент228 страницNotice IchloreHervé MunozОценок пока нет

- Uponor PEX Plumbing Solutions GuideДокумент73 страницыUponor PEX Plumbing Solutions GuideMaxmore Karumamupiyo100% (1)

- Genei: Latex Agglutination Teaching Kit ManualДокумент7 страницGenei: Latex Agglutination Teaching Kit ManualNidhi LashkariОценок пока нет

- Analyzing 1H NMR Spectra of PDMSДокумент5 страницAnalyzing 1H NMR Spectra of PDMSAsrina RoslanОценок пока нет

- Momentum Heat Mass Transfer For Chemical and Food EngineeringДокумент37 страницMomentum Heat Mass Transfer For Chemical and Food EngineeringTigrigna TenagariОценок пока нет

- Jackman 1996Документ66 страницJackman 199612545343Оценок пока нет

- AIATS Practise Paper-01 AnalysisДокумент111 страницAIATS Practise Paper-01 AnalysisC R Ramsakha100% (1)

- Flow Sensor Technical Guide BookДокумент20 страницFlow Sensor Technical Guide Books12originalОценок пока нет

- Streeter-Phelps equation for predicting dissolved oxygen levelsДокумент7 страницStreeter-Phelps equation for predicting dissolved oxygen levelsAditya SheoranОценок пока нет

- NRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureДокумент4 страницыNRAC Publication No. 170 An Introduction To Water Chemistry in Freshwater AquacultureSk RajОценок пока нет

- SIS 2.0 Refill Capacities (M0124697-02)Документ6 страницSIS 2.0 Refill Capacities (M0124697-02)Carlos U. CallirgosОценок пока нет

- Project Report On Activated Carbon (Granular and Powder)Документ9 страницProject Report On Activated Carbon (Granular and Powder)EIRI Board of Consultants and Publishers100% (1)

- One Dimensional Steady State Conduction: By: Taz 1Документ52 страницыOne Dimensional Steady State Conduction: By: Taz 1Adam AndualemОценок пока нет

- Analysis QBДокумент167 страницAnalysis QBChethan PrabhuОценок пока нет

- AkzoNobel - Colloidal Silica For Adhesives BrochureДокумент6 страницAkzoNobel - Colloidal Silica For Adhesives BrochureCarlos GuerreroОценок пока нет

- Ele541 Kje412 SJ 12Документ13 страницEle541 Kje412 SJ 12Mu'izz KaharОценок пока нет

- Chem 16 LE-1 AnswerKeyДокумент4 страницыChem 16 LE-1 AnswerKeyAntonette OngОценок пока нет

- Failure TheoryДокумент11 страницFailure TheoryGaurav MallaОценок пока нет

- Painting Technical RequirementsДокумент28 страницPainting Technical RequirementshazopmanОценок пока нет

- Gay Lussac (DLP)Документ8 страницGay Lussac (DLP)Marvin EusebioОценок пока нет