Академический Документы

Профессиональный Документы

Культура Документы

Introduction To Piping Engineering

Загружено:

kysucoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Introduction To Piping Engineering

Загружено:

kysucoАвторское право:

Доступные форматы

Piping Guide www.pipingguide.

net

INTRODUCTION TO

PIPING ENGINEERING

Piping Guide www.pipingguide.net

FUNCTION OF PIPING ENGINEERING

PIPING ENGINEERING TEAM

PLANT LAYOUT

STRESS ANALYSIS

LAYOUT

PIPE FITTINGS CLASSIFICATION

VALVE CLASSIFICATION BASED ON FUNCTION

PIPE ROUTING

OBJECTIVE

REQUIREMENTS OF SUPPORTS IN PIPING SYSTEM

TYPE OF SUPPORTS

FAMILIARIZATION WITH STRESS SYMBOLS

MATERIAL ENGINEERING

BASIS FOR MATERIALS SELECTION

MATERIAL SELECTION DIAGRAM

MATERIAL SELECTION AS A FUNCTION OF TEMPERATURE

Piping Guide www.pipingguide.net

Piping

Project Execution Group

- Project Leading

- Equipment Layout &

Pipe Routing

- Material Take Off

Material Engineering Group

- Piping Material Spec

- Requisition

- Technical Bid Evaluation

Stress Analysis Group

- Static Analysis

- Dynamic Analysis

- Composite Analysis

Piping Guide www.pipingguide.net

FUNCTION OF PIPING ENGINEERING

THE FUNCTION OF THE PIPING ENGINEERING IS TO APPLY KNOWLEDGE OF

FLUID FLOW, STRESS ANALYSIS, MATERIAL PROPERTIES, ENGINEERING

JUDGEMENT AND CONVERT THE PROCESS ENGINEERS SPECIFICATION INTO

DRAWINGS AND DATA FROM WHICH MATERIALS CAN BE PURCHASED,

FABRICATED AND ASSEMBLED INTO PIPING SYSTEMS WHICH FULFIL THE

REQUIREMENT OF THE PROCESS.

THIS MUST BE FULFILLED AT THE MINIMUM DESIGN COST WITHOUT

SACRIFICING THE QUALITY AND DESIRED FUNCTION, THE PIPING SYSTEM

WILL OPERATE WITHOUT PHYSICAL FAILURE OR EXCESSIVE PRESSURE

LOSSES FOR THE ENTIRE SPAN OF DESIGNED PLANT LIFE.

Piping Guide www.pipingguide.net

Plant Layout

Piping Guide www.pipingguide.net

Plant Layout

A Process plant, which consist of the various different sections such as raw material

storage, intermediate and finished product storage, process units, control rooms,

Flare system, Raw material loading and uploading facilities, utilities generation and

distribution etc. should be arranged so as to follow the general route of the raw

material to process, to Intermediate/Finished product storage, to dispatch.

Generally block concept is prevalent for the plant layout where in the entire plot area

is divided into blocks. The size of the blocks depends upon the facilities to be

accommodated.

Following points are to be considered while locating the blocks .

Process unit block shall be centrally located with straight approach from the

main gate.

The blocks shall be so arranged considering the prevalent wind direction that

flammable gases should not be carried by the wind on to source of ignition.

Utility blocks shall be located adjacent to unit blocks.

Flare shall be located upwind of process units so that the inflammable gas from

plant is not carried towards flare.

Equipment requiring frequent maintenance shall have easy accessibility.

Piping Guide www.pipingguide.net

Pipe Fittings Classification

Socket

Weld

Screwed

Butt Weld

Bends

45 Degree

Elbow

Tees

90 Degree

Elbow

Short Radius

Elbow

Equal Tee

Long Radius

Elbow

Caps

Reducing

Tee

Reducers

Concentric

Reducer

Eccentric

Reducer

Coupling

Full

Coupling

Reducing

Coupling

Unions

Half

Coupling

Spl. Fittings

(Olets)

Weldolet

Sockolet

Elbolet

Nippolet

Piping Guide www.pipingguide.net

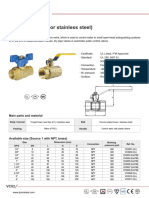

VALVE CLASSIFICATION BASED ON FUNCTION

VALVES

ON/OFF

REGULATION

NON-RETURN

MULTI-PORT

GATE

GLOBE

BALL

NEEDLE

FLUSH BOTTOM

PLUG

BUTTERFLY

FLOAT

PISTON

DIAPHRAGM

FOOT

DIAPHRAGM

PISTON

LINE BLIND

BUTTERFLY

PINCH

PINCH VALVE

CHECK

SPECIAL

Piping Guide www.pipingguide.net

In any plant various fluids flow through pipes

from one end to other.

Now let us start with a plant where we see

three tanks.

Tank-1, Tank-2 and Tank-3

We have to transfer the content of Tank no. 1

to the other two tanks.

We will need to connect pipes to transfer the

fluids from Tank-1 to Tank-2 and Tank-3

LET US BRING THE PIPES.

This is the plane white sheet we

start with

Let us start drawing a simple

piping system

Piping Guide www.pipingguide.net

To solve these

problems we need the

pipe components,

which are called

We have just brought the

pipes, now we need to solve

some more problems.

Pipes are all straight pieces.

PIPE FITTINGS

We need some

branch

We need some

connections

branch

connections

We need some

bend connections

Piping Guide www.pipingguide.net

These are the pipe fittings,

There are various types of fittings for various

purposes, some common types are Elbows/Bends, Tees/Branches,

Reducers/Expanders, Couplings, Olets, etc.

Anyway, the pipes and

fittings are in place, but the

ends are yet to be joined

with the Tank nozzles.

We now have to complete the

end connections. These, in

piping term, we call

TERMINAL CONNECTIONS.

Piping Guide www.pipingguide.net

So far this is a nice arrangement.

But there is no control over the flow from

Tank-1 to other tanks.

We need some arrangement to stop the

flow if needed

These are flanged

joints

This is a welded joint

To control the flow in a pipe

line we need to fit a special

component.

That is called - VALVE

Piping Guide www.pipingguide.net

There are many types of valves, categorized

based on their construction and functionality,

Those are - Gate, Globe, Check, Butterfly, etc.

Other than valves another

important line component of pipe

line is a filter, which cleans out

derbies from the flowing fluid.

This is called a STRAINER

Piping Guide www.pipingguide.net

Here we see a more or less functional piping

system, with valves and strainer installed.

Let us now investigate some aspects of pipe

flexibility.

If this tank

nozzle expands,

when the tank is

hot.

In such case we need to fit a

flexible pipe component at that

location, which is called an

EXPANSION JOINT

Piping Guide www.pipingguide.net

When some fluid is flowing in a pipe we

may also like know the parameters like,

pressure, temperature, flow rate etc. of the

fluid.

To know these information we

need to install INSTRUMENTS in

the pipeline.

Piping Guide www.pipingguide.net

Next we shall

look into how to

SUPPORT the

pipe/and its

components.

There are various types instruments to measure various

parameters. Also there are specific criteria for

installation of various pipe line instruments.

Piping Guide www.pipingguide.net

Here are some of the pipe supporting

arrangements. There can be numerous variants. All

depend on piping designers preference and

judgement.

Let us see some OTHER types of supports

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

Stress Analysis

Piping Guide www.pipingguide.net

Objective

Pipe stress analysis provides the necessary techniques for

engineers to design piping systems without overstressing and

overloading the piping components & connected equipment.

The objective of stress analysis can be listed as follows:

A) To limit the stresses in the piping system to the limiting value.

B) To limit the deflection in the piping system to the limiting

value.

C) To limit the loads on nozzles of connected equipment.

D) To limit the loads on supports.

E) To check for leakage at flange joints.

F) Unintentional disengagement of pipes from supports.

G) Excessive displacement .

Piping Guide www.pipingguide.net

Requirements of supports in piping system are:

To carry the weight of the pipe, fittings, valves with / without insulation,

with operating / test fluid.

To provide adequate stiffness to the piping against external loads such

as wind load, ice, snow, seismic load etc.

To avoid overstressing of the piping material.

To avoid of sagging of pipe which creates draining problem.

To control the thermal expansion / contraction in desired manner

To withstand and dampen vibration produced by connected equipment

such as pump, compressor etc.

Piping Guide www.pipingguide.net

LOADS ON PIPING

LOADING

STATIC

PRESSURE

TEMPERATURE

INTERNAL

RESTRAINT

EXTERNAL

DIFFERENTIAL

GROWTH

DYNAMIC

WEIGHT

FRICTION

DEAD

PIPE

INS-MAT

LIVE

OPERATING

SNOW

RANDOM

HARMONIC

IMPULSE

WIND

EQUIPMENT

VIBRATION

RELIEF

VALVE

EARTH

QUAKE

PULSATION

FLUID

HAMMER

ACCOUSTIC

SLUG

FLOW

Piping Guide www.pipingguide.net

STEPS IN STRESS ANALYSIS

Piping Guide www.pipingguide.net

Type of Supports

Supports

Hanger / Support

Restraint

Vibration Absorbers

To sustain the dead

weight of the piping

system.

To

restrict

the

movement

due

to

thermal

/

dynamic

loading

To restrict the movement

due to vibration caused by

wind, earthquake, fluid

flow.

Types

Anchor

Guide

Directional Anchor

U Clamps

Struts

Types

Snubbers

Sway Brace

Hold down

Types

Rigid Hanger

Spring Hanger

Variable

Constant

Shoes

Trunnions

Piping Guide www.pipingguide.net

Familiarization with Stress symbols

Rest

Axial stop/Directional Stop

Anchor

Spring Hanger

Rest

Resting and Guide

Z

X

Global Co-ordinate System

Piping Guide www.pipingguide.net

MATERIAL GROUP

Piping Guide www.pipingguide.net

Basis For Materials Selection

Materials of construction are selected and corrosion allowances are

determined on the basis of anticipated corrosion or material

degradation under the most severe combination of process variables

(e.g., stream composition, velocity, temperature and pressure) resulting

in sustained maximum normal operating conditions.

Appropriate temperature and pressure margins should be added to

the sustained maximum normal operating conditions to determine the

design conditions upon which the high temperature mechanical

design is based. Typically, these margins are up to +50F (28C) above

operating temperature and up to +10% of the operating pressure (up

to a maximum of 50 psi (0.35 MPa)).

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

Piping Guide www.pipingguide.net

- 22 / 22 -

Вам также может понравиться

- Piping Design Concepts: July 9 2016 BY CAE TeamДокумент14 страницPiping Design Concepts: July 9 2016 BY CAE TeamJaydeep RamaniОценок пока нет

- Form A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Документ2 страницыForm A-1P Manufacturer'S Data Report For Plate Heat Exchangers As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DОценок пока нет

- PVE Piping Layout Presentation - Part 2Документ117 страницPVE Piping Layout Presentation - Part 2Nguyen Quang NghiaОценок пока нет

- Stress QuizДокумент8 страницStress QuizNagarjuna SeellaОценок пока нет

- AutoPIPE Tutorial PDFДокумент204 страницыAutoPIPE Tutorial PDFDavid Luna MolinaОценок пока нет

- Thermoplastic Support Catalog 1st Edition PDFДокумент38 страницThermoplastic Support Catalog 1st Edition PDFlaguna028Оценок пока нет

- Heat Exchanger Reference TheoryДокумент23 страницыHeat Exchanger Reference TheoryMurugan VeluОценок пока нет

- Piping PDFДокумент29 страницPiping PDFEzekielОценок пока нет

- Vendor Drawing Review A Review of Valve DrawingsДокумент3 страницыVendor Drawing Review A Review of Valve Drawingsthuyenquyen_vt100% (1)

- Dynamic Load in Piping SystemДокумент3 страницыDynamic Load in Piping SystemAMITDEWANGAN1991100% (1)

- Remove Support: Issued For ConstructionДокумент1 страницаRemove Support: Issued For Construction86tejasОценок пока нет

- Cae Pipe Bourdon EffectДокумент2 страницыCae Pipe Bourdon Effectsabi_shiОценок пока нет

- 15 Difference Between Pipe and TubeДокумент6 страниц15 Difference Between Pipe and TubegetashishvaidОценок пока нет

- Expansion Loop IДокумент50 страницExpansion Loop IDar FallОценок пока нет

- Process Plant Layout and Piping Design: Fundamentals ofДокумент4 страницыProcess Plant Layout and Piping Design: Fundamentals ofSolakhudin Al Ayubi100% (1)

- Calgary 2011 Nozzle Loads PresentationДокумент10 страницCalgary 2011 Nozzle Loads PresentationpexyОценок пока нет

- Venturi Scrubber SpecДокумент15 страницVenturi Scrubber SpecKamal RajuОценок пока нет

- Ball Valve SpecДокумент35 страницBall Valve SpecsandystaysОценок пока нет

- New Why To Use A Spring SupportДокумент9 страницNew Why To Use A Spring SupportAmarKumarОценок пока нет

- Thumb RuleДокумент42 страницыThumb RuleShabeer KiblaalamОценок пока нет

- Zinq - AnalysisДокумент116 страницZinq - AnalysisAimiОценок пока нет

- Engineering Standard - Piping Material Specification - Table of Contents PDFДокумент3 страницыEngineering Standard - Piping Material Specification - Table of Contents PDFSoniОценок пока нет

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateДокумент1 страница01 E02STB007-W146693-03-0 - BC - Stress Update86tejasОценок пока нет

- Nozzle Loads - Part 1 - Piping-EngineeringДокумент5 страницNozzle Loads - Part 1 - Piping-EngineeringShaikh AftabОценок пока нет

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterДокумент4 страницыv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212Оценок пока нет

- Floating and Trunnion Ball Valves PDFДокумент15 страницFloating and Trunnion Ball Valves PDFAlienshowОценок пока нет

- A Recommended Approach To Piping Flexibility StudiesДокумент12 страницA Recommended Approach To Piping Flexibility StudiesbbmokshОценок пока нет

- StressISO TroubleshootingДокумент31 страницаStressISO TroubleshootingDarren Kam100% (1)

- Jacketed PipingДокумент4 страницыJacketed Pipingbinukumar100Оценок пока нет

- Air Pollution Control Technology Fact Sheet: EPA-452/F-03-017Документ0 страницAir Pollution Control Technology Fact Sheet: EPA-452/F-03-017widhisaputrawijayaОценок пока нет

- Pipe Fittings PDFДокумент164 страницыPipe Fittings PDFjlvega18Оценок пока нет

- Pressure DropДокумент4 страницыPressure Dropsrishanthi82Оценок пока нет

- Pressure Surges and Air Valve Specification PDFДокумент22 страницыPressure Surges and Air Valve Specification PDFTONОценок пока нет

- Pipe Thread SizeДокумент1 страницаPipe Thread SizeJeffrey WalkerОценок пока нет

- Design and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsДокумент7 страницDesign and Analysis of Industrial Ball Valve Using Computational Fluid DynamicsPradeep AdsareОценок пока нет

- Venturi Scrubbers: Lesson 3Документ14 страницVenturi Scrubbers: Lesson 3AdhitomoWirawan100% (1)

- Piping Engineering NotesДокумент46 страницPiping Engineering NoteslightsonsОценок пока нет

- Pipe Components PDFДокумент179 страницPipe Components PDFmatevzartacОценок пока нет

- Filter CalculationДокумент4 страницыFilter CalculationRashmi RanjanОценок пока нет

- SIF Calculation For Piping ConnectionsДокумент6 страницSIF Calculation For Piping ConnectionsManuelОценок пока нет

- Manual CAEPipeДокумент47 страницManual CAEPipeClaudio GimenezОценок пока нет

- Piping Design CriteriaДокумент20 страницPiping Design Criteriasuman_ghosh6798Оценок пока нет

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisДокумент8 страницGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22Оценок пока нет

- 11.plant Layout PumpsДокумент16 страниц11.plant Layout Pumpshalder_kalyan9216Оценок пока нет

- Piping Input and OutputДокумент7 страницPiping Input and OutputpraneshОценок пока нет

- Pipe Support DetailsДокумент8 страницPipe Support DetailsGodwinОценок пока нет

- Piping For Process Plants Part-1Документ6 страницPiping For Process Plants Part-1sriman1234Оценок пока нет

- Piping - Nozzle LoadingДокумент2 страницыPiping - Nozzle Loadingaap1100% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- Piping Layout UDLДокумент24 страницыPiping Layout UDLLegend Anbu100% (1)

- Piping PresentationДокумент113 страницPiping PresentationAsif KaliyadanОценок пока нет

- Fundamentals of PipingДокумент35 страницFundamentals of PipingMustafaMahmoudОценок пока нет

- DefnДокумент46 страницDefnsaranyabhuvanaОценок пока нет

- Piping FundamentalsДокумент12 страницPiping FundamentalsKurian JoseОценок пока нет

- Piping FundamentalsДокумент47 страницPiping FundamentalsNguyễn Thanh TùngОценок пока нет

- Piping Fundamentals:: M.N.RaghuДокумент26 страницPiping Fundamentals:: M.N.RaghuAlex Salvin100% (2)

- Tubing String and Installation: Assoc. Prof. Issham IsmailДокумент99 страницTubing String and Installation: Assoc. Prof. Issham IsmailHaziq Yussof100% (2)

- Piping - IntroductionДокумент39 страницPiping - Introductionsppatil100% (1)

- Vibration Control of Piping SystemsДокумент6 страницVibration Control of Piping SystemskysucoОценок пока нет

- Tyco Prv2size Quick Start GuideДокумент27 страницTyco Prv2size Quick Start GuidekysucoОценок пока нет

- Vibration MethodДокумент9 страницVibration MethodkysucoОценок пока нет

- Steel ManualДокумент114 страницSteel ManualkysucoОценок пока нет

- Explant-A User GuideДокумент14 страницExplant-A User GuideFaizal SattuОценок пока нет

- PSR SteelHandbookДокумент68 страницPSR SteelHandbookkysucoОценок пока нет

- Autocad: Secrets Every User Should KnowДокумент35 страницAutocad: Secrets Every User Should Knowkysuco100% (1)

- Drivers License Number Redaction SampleДокумент3 страницыDrivers License Number Redaction SamplekysucoОценок пока нет

- Drivers License Number Redaction SampleДокумент3 страницыDrivers License Number Redaction SamplekysucoОценок пока нет

- LICAD DrawingsДокумент21 страницаLICAD DrawingskysucoОценок пока нет

- Tonisco Service Eng 2019 MailДокумент12 страницTonisco Service Eng 2019 Mailchristian tortugoОценок пока нет

- Plumbing and Sanitary WorksДокумент6 страницPlumbing and Sanitary WorksZyrose Jardiolin GuevarraОценок пока нет

- VC02 Brass Ball Valve Full Port Full BoreДокумент2 страницыVC02 Brass Ball Valve Full Port Full Boremahadeva1Оценок пока нет

- L Mitter - Young & Franklin - RatchetSequencingValve PDFДокумент18 страницL Mitter - Young & Franklin - RatchetSequencingValve PDFlochtayОценок пока нет

- Simplify BOG Recondenser Design and OperationДокумент20 страницSimplify BOG Recondenser Design and OperationvalmaxjeonОценок пока нет

- DJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1Документ1 страницаDJ 302 O en SCO 00 0005 - Basement MEP Coordination Part 1info.infinitytechnicalОценок пока нет

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoДокумент4 страницыHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairОценок пока нет

- 3 Building Water System and Design Part 1Документ28 страниц3 Building Water System and Design Part 1Rayan Ahmad Barodi100% (2)

- DXR 145 Spare Part ListДокумент47 страницDXR 145 Spare Part ListColin LeeОценок пока нет

- US Chevron Spec. PSV - Sizing and Selection of Pressure Relief ValvesДокумент20 страницUS Chevron Spec. PSV - Sizing and Selection of Pressure Relief Valves울프Оценок пока нет

- Copia de ACCESORIOS BAUER EN FIERRO GALVANIZADO Bauer SpanishДокумент1 страницаCopia de ACCESORIOS BAUER EN FIERRO GALVANIZADO Bauer SpanishVentasVarias AntofaОценок пока нет

- Numerical Flow and Performance Analysis of Waterjet Propulsion SystemДокумент22 страницыNumerical Flow and Performance Analysis of Waterjet Propulsion SystemAlex BmxОценок пока нет

- 06 Final Drive & Tandem PDFДокумент4 страницы06 Final Drive & Tandem PDFManuales De Maquinaria JersoncatОценок пока нет

- QA&QC D2020.15060-Pipes & Pipe Fittings EDITEDДокумент4 страницыQA&QC D2020.15060-Pipes & Pipe Fittings EDITEDbryesanggalangОценок пока нет

- FWDS 0236 AДокумент2 страницыFWDS 0236 AAlanka PrasadОценок пока нет

- ASPE PSD - Fire Pump InstallationДокумент4 страницыASPE PSD - Fire Pump InstallationNiong DavidОценок пока нет

- Steel Flange DimensionsДокумент3 страницыSteel Flange DimensionssazidalamОценок пока нет

- Bid Evaluation TabulationДокумент1 страницаBid Evaluation Tabulationpeach5Оценок пока нет

- SRHДокумент2 страницыSRHTeree Sanches SaLazОценок пока нет

- 120K HydДокумент4 страницы120K HydMarco OlivettoОценок пока нет

- Henry Catalog Rev 2010Документ144 страницыHenry Catalog Rev 2010Tiago GoncalvesОценок пока нет

- 750L & 850L Crawler Dozer Electrical, Hydraulic SchematicДокумент2 страницы750L & 850L Crawler Dozer Electrical, Hydraulic Schematicmohanad abdullahОценок пока нет

- Wilo 252754Документ13 страницWilo 252754Elshad AslanliОценок пока нет

- Casing SpidersДокумент3 страницыCasing SpiderszlОценок пока нет

- Offshore Gas Pipeline Linepack To Improve The Flexibility of System FacilitiesДокумент7 страницOffshore Gas Pipeline Linepack To Improve The Flexibility of System Facilitiesreclatis14Оценок пока нет

- Ce6451 - FMM 2017-18Документ65 страницCe6451 - FMM 2017-18rajmehaОценок пока нет

- Buckling PinДокумент6 страницBuckling Pinwsjouri2510Оценок пока нет

- Technical Manual Index - March 1, 2022: or From BAE atДокумент95 страницTechnical Manual Index - March 1, 2022: or From BAE atMohand Said ArroudjОценок пока нет

- NegotiateДокумент5 страницNegotiateallovidОценок пока нет

- How To Prevent Pump Cavitation - EnggcyclopediaДокумент7 страницHow To Prevent Pump Cavitation - EnggcyclopediaSurya DharmaОценок пока нет