Академический Документы

Профессиональный Документы

Культура Документы

L 03 Analysis and Design of One Way Slab System Part II Dec 2014

Загружено:

Hidayat UllahАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

L 03 Analysis and Design of One Way Slab System Part II Dec 2014

Загружено:

Hidayat UllahАвторское право:

Доступные форматы

Department of Civil Engineering, University of Engineering and Technology Peshawar

Lecture - 03

Analysis and Design of Oneway Slab System

(Part II)

By: Prof Dr. Qaisar Ali

Civil Engineering Department

UET Peshawar

www.drqaisarali.com

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

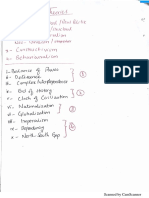

Topics

Design Problem: Option 2 for Design of Hall

References

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Design slab, beams, girder, columns and footings of a 90 60

Hall. Minimum obstruction to mobility inside the Hall requires

that only two columns can be allowed inside the Hall. Height of

the hall is 20.

Concrete compressive strength (fc) = 3 ksi.

Steel yield strength (fy) = 40 ksi.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Structural Arrangement

18 18

(assumed)

(18 wall

because hall

is 20 high).

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Structural Arrangement

A

Section A-A

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 01: Sizes

l = ln = 9.5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

l = ln = 9

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 01: Sizes

h = l/24 (0.4+fy/100000) = 3.8 (Minimum by ACI for end span) [l = 9.5]

h = l/28 (0.4+fy/100000) = 3 (Minimum by ACI for interior span) [l = 9]

End span governs. Finally take assumed h = 6.

Effective depth (d) = hf 0.75 (3/8)/2 = 5 (for #3 main bar)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 02: Loads

Table: Dead Loads.

Material

Thickness (in)

(kcf)

Load = thickness (ksf)

Slab

0.15

(6/12) 0.15 = 0.075

Mud

0.12

(3/12) 0.12 = 0.03

Tile

0.12

(2/12) 0.12= 0.02

Total

0.125 ksf

Factored Load (wu) = 1.2D.L + 1.6L = 1.2 0.125 + 1.6 0.04 = 0.214 ksf

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 03: Analysis

Bending moment diagram for slab

M = coefficient wu ln2

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 04: Design

Prof. Dr. Qaisar Ali

Calculate moment capacity provided by minimum reinforcement in slab:

Asmin = 0.002bhf = 0.002 12 6 = 0.144 in2/ft

Mn = Asminfy (d-a/2) = 0.9 0.144 40 (5-0.188/2) = 25.4 in-k/ft

Mn calculated from Asmin is > all moments calculated in Step No 3.

Therefore As = Asmin = 0.144 in2/ft (#3 @ 9.166 c/c)

This will work for both positive and negative steel as Asmin governs.

Reinforced Concrete Design II

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 04: Design

Main reinforcement spacing:

Maximum spacing for main steel reinforcement in one way slab according to

ACI 7.6.5 is minimum of:

3hf = 3 6 =18

18

Finally use, #3 @ 9 c/c.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 04: Design

Shrinkage steel or temperature steel (Ast):

Ast = 0.002bhf Ast = 0.002 12 6 =0.144 in2/ft

Shrinkage reinforcement is same as main reinforcement, because:

Ast = Asmin = 0.144 in2

Maximum spacing for temperature steel reinforcement in one way

slab according to ACI 7.12.2.2 is minimum of:

Prof. Dr. Qaisar Ali

5hf =5 6 =30 OR 18

Therefore 9 spacing is O.K.

Reinforced Concrete Design II

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Step No. 05: Drafting

Main reinforcement = #3 @ 9 c/c (positive & negative)

Shrinkage reinforcement = #3 @ 9 c/c

Supporting bars = #3 @ 18 c/c

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 01: Sizes

Minimum thickness of beam (simply supported) = hmin = l/18.5

l = clear span (ln) + depth of member (beam) c/c distance between supports

Let depth of beam = 2

ln + depth of beam = 29.25 + 2 = 31.25

c/c distance between beam supports = 30 + (9/12) = 30.75

Therefore l = 30.75

Depth (h) = (30.75/18.5)(0.4+fy/100000)12= 15.95 (Minimum by ACI 9.5.2.2).

Take h = 2 = 24

d = h 3 = 21

bw = 12 (assumed)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No 02: Loads

Load on beam will be equal to

Factored load on beam from slab +

factored self weight of beam web

Factored load on slab = 0. 214 ksf

Load on beam from slab = 0. 214 ksf x 10

= 2.14 k/ft

10

10

Factored Self load of beam web =

= 1.2 x (18 12/144) 0.15 = 0.27 k/ft

Total load on beam = 2.14 + 0.27 = 2.41

18

12 (assumed)

k/ft

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

15

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Prof. Dr. Qaisar Ali

Step No. 03: Analysis

Reinforced Concrete Design II

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for flexure (for positive moment)

Step (a): According to ACI 8.12, beff for T-beam is minimum of:

16hf + bw = 16 6 + 12 =108

(c/c span of beam)/4 =(30.75/4) 12 =92.25

c/c spacing between beams =10 12 =120

So beff = 92.25

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

17

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for flexure (for positive moment)

Step (b): Check if beam is to be designed as rectangular beam or T-beam.

Assume a = hf = 6 and calculate As:

As =Mu/ {fy (da/2)} =2249/ {0.9 40 (216/2)} = 3.47 in2

Re-calculate a:

a =Asfy/ (0.85fcbeff) =3.47 40/ (0.85 3 92.25) = 0.6 < hf

Therefore design beam as rectangular beam.

Prof. Dr. Qaisar Ali

After trials As = 3.01 in2 {Asmax = 5.11 in2 ;Asmin = 1.26 in2}

Therefore As = 3.01 in2 {4 #8 bars}

Reinforced Concrete Design II

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for flexure (for interior negative moment)

bw = 12 instead of beff for calculation of a because of flange in tension.

Mu = 2749 in-kip; h = 24; d = 21

Let a = 0.2d = 0.2 21 = 4.2

As =Mu/ {fy (da/2)} =2749/ {0.9 40 (214.2/2)} = 3.65 in2

Re-calculate a:

a =Asfy/ (0.85fcbeff) =3.65 40/ (0.85 3 12) = 4.77

After trials As = 4.17 in2 {Asmax = 5.11 in2 ;Asmin = 1.26 in2}

Therefore As = 4.17 in2 {6 #8 bars}

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

19

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Location

Vu

Reinforcement

sd =

smax,

Governing

(kips)

required?

Avfyd/(Vu Vc)

ACI

31.03

20.7

Yes

13

10.5

10.5

35.68

20.7

Yes

10.5

(kip)

Exterior

Interior

Prof. Dr. Qaisar Ali

Design for shear

Vc = 2

bwd

Smax, ACI is least of Avfy/(50bw), d/2 , 24, Avfy/ 0.75 f bw

Reinforced Concrete Design II

20

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for shear

Other checks

Check for depth of beam:

bwd (ACI 11.4.7.9)

Vs 8

Vs = (Avfyd)/sd

f bwd = 0.75 8 3000 12 21/1000 = 82.4 kips

= (0.75 0.22 40 21)/9 = 15.4 kip < 82.4 kip, O.K.

So depth is O.K. If not, increase depth of beam.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for shear

Other checks

Check if Vs 4

If Vs 4

bwd {ACI 11.4.5.3}:

f bwd, the maximum spacing (smax) is O.K.

Otherwise reduce spacing by one half.

f bwd = 0.75 4 3000 12 21/1000= 41.4 kips

Vs = (Avfyd)/sd

= (0.75 0.22 40 21)/9 = 15.4 kip < 41.4 kip, O.K.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

22

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Step No. 04: Design

Design for shear

Reinforcement provision

It will be practically more feasible to provide # 3, 2 legged @ 9 c/c

throughout, starting at sd/2 = 9/2 = 4.5 from the face of the support at

both ends.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

23

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 01: Sizes

l = ln + h lc/c

Assume h = 3 = 36

l = 29.25 + 3 = 32.25 > lc/c

Therefore, l = lc/c = 30.75

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

l = ln + h lc/c

Assume h = 3 = 36

l = 28.5 + 3 = 31.5 > lc/c

Therefore, l = lc/c = 30

24

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 01: Sizes

Minimum thickness of beam (simply supported) = hmin = l/18.5

l = 30.75

Depth (h) = (30.75/18.5)(0.4+fy/100000)12= 15.95 (Minimum by ACI 9.5.2.2).

Take h = 3 = 36

d = h 3 = 33

bw = 18 (assumed)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Behavior

of

Column-Supported

Beam"

and

Girder-Supported Beam"

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

26

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 02: Loads

Beams load can be approximated as point loads on girder. The

uniformly distributed load on girder is coming from self weight of girder

rib plus weight of slab directly resting on girder.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

27

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 02: Loads

P is the point load on girder and is the reaction coming from the interior

support of beam due to factored load.

Prof. Dr. Qaisar Ali

P = 2 40.5 = 81 kips

Reinforced Concrete Design II

28

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 02: Loads

(U.D.L)self wt = Factored self weight of girder rib

=1.2hwgbwgc

=1.2 (30 18 0.15)/144 =0.675 k/ft

Part of slab on girder {(U.D.L) sg}:

(U.D.L) sg = wu (on slab) x bwg = 0.214 18/12 =0.321 k/ft

Prof. Dr. Qaisar Ali

Therefore wg = (U.D.L) self wt + (U.D.L) sg = 0.675 + 0.321 = 1.0 k/ft

Reinforced Concrete Design II

29

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Applicability of ACI Approximate Analysis

According to ACI 8.3.3, ACI approximate analysis (coefficient

method) is subjected to following limitations

The structure has two or more spans

The spans are approximately equal, with the larger of the two adjacent

spans not greater than the shorter by more than 20 percent

Loads are uniformly distributed, and the unfactored live load does not

exceed 3 times the unfactored dead load

Prof. Dr. Qaisar Ali

Members are prismatic

Reinforced Concrete Design II

30

15

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Applicability of ACI Approximate Analysis

The ACI coefficient method cannot be applied to the girder as it is

subjected to uniform loading as well as pointed loads.

Any method of elastic analysis e.g., slope deflection method,

moment distribution method, flexibility method, stiffness method

etc. may be used for the analysis of such cases.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

31

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Prof. Dr. Qaisar Ali

Step No. 02: Analysis

Reinforced Concrete Design II

32

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Flexure

According to ACI 8.12, beff is minimum of:

16hf + bwg =16 6 + 18 = 114

(c/c span of girder)/4 = (30.75/4) 12 = 92.25

c/c spacing between girder = not applicable

beff = 92.25

Mu

(kip-ft)

d

(in.)

b

(in.)

As

(in2)

Asmin

(in2)

Asmax

(in2)

Bar

used

Exterior +

668.5

33

92.25

6.87

2.97

11.88

#8

9 (5 +4)

Interior

731.95

33

18

8.30

2.97

11.88

#8

12 (6 +6)

Interior +

190.55

33

92.25

1.93

2.97

11.88

#8

Section

Prof. Dr. Qaisar Ali

# of

bars

Reinforced Concrete Design II

33

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Shear: Shear design of girder is done by another approach

dg = 33 = 2.75

Vc = 2

Maximum spacing and minimum reinforcement requirement as permitted by ACI

f bwgdg = {0.752 3000 1833}/1000 = 48.8 kip

11.4.5 and 11.4.6 shall be minimum of:

Prof. Dr. Qaisar Ali

Avfy/(50bw) =0.22 40000/(50 18) = 9.77 9.5

dg /2 =33/2 =16.5

24

Avfy/ 0.75

f bw = 0.22 40000/ {(0.75 3000 18} = 11.90

Reinforced Concrete Design II

34

17

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Shear:

Shear design of girder is done by another approach

Since maximum spacing allowed by ACI is 9.5,

Vn = Vc + Vs

Vs = (Avfydg)/smax = (0.75 0.22 40 33/9.5) = 22.92 kip

Vn = 48.808 + 22.92 = 71.72 k > Max. Shear at A and B but < Max. Shear

at C, D and E

It means that maximum spacing of 9.5 as permitted by ACI governs

between point A and C.

We will calculate spacing for shear reinforcement between point C and E.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

35

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Shear:

Vmax

(kip)

Vu (@ d)

(kip)

Vc = 2 bwd

(kips)

CD

120.5

117.5

DE

96

94

Location

Prof. Dr. Qaisar Ali

sd =Avfyd/(Vu Vc)

smax,

48.8

9.5

48.8

4.5

9.5

S taken

ACI

Final Spacing: Providing 3 from C to E and F to H, and 9 elsewhere.

Reinforced Concrete Design II

36

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Shear:

Other checks

Check for depth of girder:

bwd (ACI 11.4.7.9)

Vs 8

Vs = (Avfyd)/sd

f bwd = 0.75 8 3000 18 33/1000 = 195.20 kips

= (0.75 0.22 40 33)/3 = 72.60 kip < 195.20 kip, O.K.

So depth is O.K. If not, increase depth of beam.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

37

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Step No. 04: Design

Design for Shear:

Other checks

Check if Vs 4

If Vs 4

bwd {ACI 11.4.5.3}:

f bwd, the maximum spacing (smax) is O.K.

Otherwise reduce spacing by one half.

f bwd = 0.75 4 3000 18 33/1000= 97.6 kips

Vs = (Avfyd)/sd

= (0.75 0.22 40 33)/3 = 72.6 kip < 97.6 kip, O.K.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

38

19

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design

Gross area of column cross-section (Ag) = 18 18 =324 in2

fc =3 ksi; fy =40 ksi

Load on column:

Pu = 297.8 k (Reaction at interior support of girder due to factored load)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

39

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design

Main Reinforcement Design:

Nominal strength (Pn) of axially loaded column is:

Pn = 0.80{0.85fc(AgAst) + Astfy} {for tied column, ACI 10.3.6}

Let Ast = 1% of Ag (Ast is the main steel reinforcement area)

Pn = 0.80 0.65 {0.85 3 (324 0.01 324) + 0.01 324 40}

= 492k > (Pu = 297.775 k), O.K.

Prof. Dr. Qaisar Ali

Ast = 0.01 324 =3.24 in2

Using 3/4 (#6) , with bar area Ab =0.44 in2

No. of bars = As/Ab = 3.24/0.44 = 7.36 8 bars

Use 8 #6 bars

Reinforced Concrete Design II

40

20

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design

Tie Bars:

Using 3/8 (#3) tie bars for 3/4 (#6) main bars (ACI 7.10.5),

Spacing for Tie bars according to ACI 7.10.5.2 is minimum of:

16 dia of main bar =16 3/4 =12 c/c

48 dia of tie bar = 48 (3/8) =18 c/c

Least column dimension =18 c/c

Finally use #3, tie bars @ 9 c/c

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

41

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Data Given:

Column size = 18 18

fc =3 ksi

fy = 40 ksi

qa = 2.204 k/ft2

Factored load on column = 297.775 kips (Reaction at the support)

Service load on column = 234 kips (Reaction at the support due to

service load)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

42

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Sizes:

Assume h = 18 in.

davg = h clear cover one bar dia

= 18 3 1(for #8 bar) = 14 in.

Assume depth of the base of footing from ground level (z) = 5

Weight of fill and concrete footing, W= fill(z - h) + ch

=100 (5 1.5) +150 (1.5) = 575 psf = 0.575 ksf

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

43

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Sizes:

Effective bearing capacity, qe = qa W

= 2.204 0.575 = 1.629 ksf

Bearing area, Areq = Service Load/ qe

= 234/1.629 = 143.95 ft2

Areq = B x B = 143.65 ft2 => B = 12 ft.

davg + c

B = 12

davg / 2 =

14/2 = 7

Critical Perimeter, bo = 4 x (c + davg)

= 4 (18 + 14) =128 in

c = 18

davg + c

B = 12

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

44

22

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Loads:

qu (bearing pressure for strength design of footing):

qu = factored load on column / Areq

= 297.775/ (12 12) =

2.068 ksf

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

45

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Analysis:

Punching shear:

Vup = quB2 qu(c + davg) 2

Vup = 2.068 122 2.068 {(18+14)/12)} 2

= 283.09 kip

B

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

46

23

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Critical Section

Analysis:

Flexural Analysis:

Mu = quBk2/2

k = (B c)/2 = (12 x 12 18)/2

qu

qu

= 63 in = 5.25

Mu = 2.068 12 5.25 5.25/2

= 342 ft-k

= 4104 in-kip

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

47

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Design:

bo

Design for Punching Shear:

davg

Vup = 283.09 kip

Punching shear capacity (Vcp)

= 4

f bodavg

= 0.75 4 3000 128 14/1000

= 294.45 k > Vup, O.K

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

48

24

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Design:

Design for Flexure:

Mu = 4104 in-kip

a = 0.2davg = 0.2 14 = 2.8

As = Mu/ {fy(davg a/2)} = 4104/ {0.9 40 (14 2.8/2)} = 9.05 in2

a = Asfy/ (0.85fcB) = 9.05 40/ (0.85 3 12 12) = 0.99

After trials, As = 8.42 in2 (Asmin = 0.005Bdavg = 10.08 in2 so Asmin governs)

Spacing = B Ab/Asmin = 12 12 0.79/10.08 = 11.28 in c/c 11 in c/c

Prof. Dr. Qaisar Ali

Use #8 @ 11 c/c (Max. Spacing must not exceed 3h or 18)

Reinforced Concrete Design II

49

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Drafting Details for Slab

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

50

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Drafting Details for Beam

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

51

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Mu

(kip-ft)

As

(in2)

Asmin

(in2)

Asmax

(in2)

Bar

used

Exterior +

668.5

6.87

2.97

11.88

#8

9 (5 +4)

Interior

731.95

8.30

2.97

11.88

#8

12 (6 +6)

Interior +

190.55

1.93

2.97

11.88

#8

4*

Section

Drafting Details for Girder

(6+6) #8 Bars

2 #8 Bars

13'-0"

5 #8 Bars B

(5+4) #8 Bars

5 #8 Bars

7'-0"

2'-9"

#3,2 legged

@ 3" c/c

#3,2 legged @ 9" c/c

#3,2 legged

@ 3" c/c

#3,2 legged

@ 9" c/c

L2

L1

EXTERIOR (G1)

2 #8 Bars

#3,2 legged stirrups @ 9" c/c

5 #8 Bars

INTERIOR (G2)

18"

SECTION A-A

6"

18"

#3,2 legged stirrups @ 3" c/c

6"

#3,2 legged stirrups @ 9" c/c

36"

5 #8 Bars

18"

SECTION B-B

(6+6) #8 Bars

6"

#3,2 legged stirrups @ 9" c/c

36"

(5+4) #8 Bars

36"

#3,2 legged

@ 3" c/c

(6+6) #8 Bars

2 #8 Bars

6"

36"

# of

bars

SECTION C-C

5 #8 Bars

18"

SECTION D-D

*Note: at Sec C-C 4 bars are required from calculation but for practical feasibility we shall provide 5 bars as shown in the figure

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

52

26

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Drafting Details for Column and Footing

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

53

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

In the subsequent slides the same hall has been analyzed and

designed for beams and girders supported on columns instead of walls.

Structural Plan:

Beam

C1

Girder

C2

C3

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

54

27

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Frame Analysis for Beam

2D frame can be detached from a 3D system as follows:

Wu = 2.41 k/ft

29.25

29.25

20

Column Size = 18 18

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

55

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Frame Analysis for Beam

Using ACI moment coefficients for analyzing the frame:

1/14

1/14

Wu = 2.41 k/ft

29.25

29.25

1/16

20

20

20

1/16

=

1/9

Note: Interior support conditions for the beam (if supported on column, or on roller)

does not effect analysis results.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

56

28

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Frame Analysis for Girder

2D frame can be detached from a 3D system in the following

manner:

1.0 k/ft

81 k

40 k

10

81 k

10

81 k

81 k

10

20

10

81 k

10

81 k

81 k

10

10

20

20

81 k

10

40 k

10

20

Girder

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

57

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Frame Analysis for Girder

Analysis of Girder

1.0 k/ft

81 k

40 k

81 k

81 k

81 k

81 k

81 k

81 k

81 k

40 k

Mu (Exterior +)

Mu (Interior+)

10

10

20

10

10

20

10

10

10

20

10

10

20

Mu (Interior -)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

58

29

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Slab Design

Design of slab for beams supported on column will be same as

that of beams supported on walls.

Main reinforcement = #3 @ 9 c/c (positive & negative)

Shrinkage reinforcement = #3 @ 9 c/c

Supporting bars = #3 @ 18 c/c

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

59

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Beam Design

Mu (+ve) = 1767 in-kips

Mu,ext (-ve) = 1546 in-kips

Mu,int (-ve) = 2749 in-kips

As (+ve) = 2.36 in2 (3 #8 bars)

As,ext (-ve) = 2.19 in2 (3 #8 bars)

As,int (-ve) = 4.18 in2 (6 #8 bars)

The shear reinforcement is not affected and hence it will be the

same as in the previous case (beams supported on walls)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

60

30

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Girder Design

Mu (Exterior +)

Mu (Interior+)

Mu (Interior -)

Section

Mu

(kip-ft)

d

(in.)

b

(in.)

As

(in2)

Asmin

(in2)

Asmax

(in2)

Bar

used

# of

bars

Exterior +

614.64

33

92.25

6.31

2.97

11.88

#8

Interior

726.03

33

18

8.23

2.97

11.88

#7 + #8

6+6

Interior +

217.96

33

92.25

2.21

2.97

11.88

#8

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

61

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design

Design of C1 (already done on slides 39 to 41)

8 #6 bars, #3 ties @ 9 c/c

Design of C2 (do it yourself)

Design of C3

Prof. Dr. Qaisar Ali

Design of column C3 is carried our in subsequent slides.

Reinforced Concrete Design II

62

31

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C3)

Pu = 35.25 kip

Mu = 1546.43 in-kip

Pu

Mu

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

63

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C3): Using ACI Design Aids

c

gh

Main Reinforcement Design

Size:

18

18 in. 18 in.

Loads:

18

Pu = 35.25 kips

Mu = 1546.43 in-kips

fc = 3 ksi,

fy = 60 ksi

Calculate the ratio g , for 2.5 in. cover: g = (18 2(2.5)) /18 = 0.72

Calculate Kn, Kn = Pu/(fcAg) = 35.25/(0.65 3 324) = 0.06

Calculate Rn, Rn = Mu/(fcAgh) = 1546.43/(0.65 3 324 18) =

0.14

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

64

32

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C3)

Main Reinforcement Design

For given material strength,

the

column

strength

interaction diagram gives the

following reinforcement ratio:

r = 0.018

Ast = 0.018 324 = 5.83

in.2

Using 8 #8 bars

Strength Interaction Diagram (ACI Design Handbook)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

65

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C3)

Tie Bars:

Prof. Dr. Qaisar Ali

Using 3/8 (#3) tie bars for 3/4 (#6) main bars (ACI 7.10.5),

Spacing for Tie bars according to ACI 7.10.5.2 is minimum of:

16 dia of main bar =16 3/4 =12 c/c

48 dia of tie bar = 48 (3/8) =18 c/c

Least column dimension =18 c/c

Finally use #3, tie bars @ 9 c/c

Reinforced Concrete Design II

66

33

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C3)

Drafting

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

67

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Column Design (C1 and C2)

Drafting

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

68

34

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design

Design of footing for the column C1 has already been done (refer to

slides 42 to 49)

Do design of footing for column C2 and C3 yourself.

Details of reinforcement are presented in the subsequent slides.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

69

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design for C1

Prof. Dr. Qaisar Ali

Drafting

Reinforced Concrete Design II

70

35

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design for C2

Drafting

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

71

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Problem

Footing Design for C3

Prof. Dr. Qaisar Ali

Drafting

Reinforced Concrete Design II

72

36

Department of Civil Engineering, University of Engineering and Technology Peshawar

References

ACI 318

Design of Concrete Structures 13th Ed. by Nilson,

Darwin and Dolan

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

73

Department of Civil Engineering, University of Engineering and Technology Peshawar

The End

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

74

37

Вам также может понравиться

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Slab DesignДокумент20 страницSlab Designmanoj_structureОценок пока нет

- One Way Continuous SlabДокумент5 страницOne Way Continuous SlabBia MughalОценок пока нет

- Ex 7b, One Way SlabДокумент3 страницыEx 7b, One Way SlabMohafisto SofistoОценок пока нет

- Analysis and Design of Cantilever Solid Slab (First Floor Slab)Документ23 страницыAnalysis and Design of Cantilever Solid Slab (First Floor Slab)Haftom GebreegziabiherОценок пока нет

- One Way Slab DSMДокумент35 страницOne Way Slab DSMIthihas SeventyoneОценок пока нет

- Design of One Way SlabДокумент13 страницDesign of One Way SlabAhmad PooladiОценок пока нет

- Series and Parallel Circuits WorksheetДокумент7 страницSeries and Parallel Circuits WorksheetDaryl Langamon Uy CruzОценок пока нет

- One Way Solid Slab DesignДокумент26 страницOne Way Solid Slab DesignJohn Mejia50% (4)

- Anglo vs. ValenciaДокумент5 страницAnglo vs. ValenciaAnonymous KaNu0py71Оценок пока нет

- Design One Way SlabДокумент22 страницыDesign One Way Slabjohn rey toledoОценок пока нет

- Lateral Loads ResistanceДокумент23 страницыLateral Loads ResistanceAbdelrahman Hassan El-MallaОценок пока нет

- Revised Paper Group14Документ360 страницRevised Paper Group14Joy lauriaОценок пока нет

- 19JUL12-Appleton Marine SparepartsДокумент3 страницы19JUL12-Appleton Marine SparepartsScott HughesОценок пока нет

- Series Parallel CircuitДокумент12 страницSeries Parallel CircuitAli100% (1)

- RC One Way Slab Design (ACI318)Документ2 страницыRC One Way Slab Design (ACI318)Bunkun15100% (1)

- Worksheet 6.1 PDFДокумент1 страницаWorksheet 6.1 PDFanuelisajoseОценок пока нет

- LOCAL BUCKLING2 VisualBeeДокумент24 страницыLOCAL BUCKLING2 VisualBeeMart Brevin BitonОценок пока нет

- Lateral Loads (WindSeismic)Документ16 страницLateral Loads (WindSeismic)Erika PitoyОценок пока нет

- Shearwall DesignДокумент72 страницыShearwall DesignRemembr EmilzОценок пока нет

- Draft For Preterm LaborДокумент31 страницаDraft For Preterm LaborKimberly Jose100% (1)

- Two Way Slab CalcsДокумент2 страницыTwo Way Slab CalcsMarkОценок пока нет

- Acacia Structural AnalysisДокумент38 страницAcacia Structural AnalysisJoshua LopezОценок пока нет

- RCD IntroductionДокумент24 страницыRCD IntroductionJohn Mortel AparicioОценок пока нет

- Indetermine StructureДокумент8 страницIndetermine Structuremaloy100% (1)

- Reinforced Concrete FootingsДокумент13 страницReinforced Concrete FootingsMike MatshonaОценок пока нет

- Design of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerДокумент5 страницDesign of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerMohammad Taha PumbayaОценок пока нет

- Seismic Structural EngineeringДокумент11 страницSeismic Structural EngineeringMuhammad AbubakarОценок пока нет

- Probset MidtermДокумент30 страницProbset MidtermAndrea MagtutoОценок пока нет

- III Year 2 Marks 16 Marks MinДокумент143 страницыIII Year 2 Marks 16 Marks MinnaveenОценок пока нет

- 4 Partial Loss of PrestressДокумент51 страница4 Partial Loss of Prestresslester john bacudioОценок пока нет

- Problem Set No.2 Engineering Statistics MSCE 501Документ1 страницаProblem Set No.2 Engineering Statistics MSCE 501jansenrosesОценок пока нет

- Design of Compression MembersДокумент24 страницыDesign of Compression Membersmoganna73Оценок пока нет

- Module 3 - Orifice Flow Lesson 1Документ5 страницModule 3 - Orifice Flow Lesson 1Aica AtendidoОценок пока нет

- SRS One Way Slab Design WSMДокумент17 страницSRS One Way Slab Design WSMKaustubh JadhavОценок пока нет

- Structural Analysis For San Roque ProjectДокумент250 страницStructural Analysis For San Roque ProjectAdrian PachecoОценок пока нет

- Chapter 3 - LoadsДокумент43 страницыChapter 3 - Loadsmorteza0% (1)

- Staad Pro-Modeling of A Grid BeamДокумент7 страницStaad Pro-Modeling of A Grid BeamV.m. Rajan0% (1)

- Lecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) - 2Документ64 страницыLecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) - 2Ragah SammiОценок пока нет

- TP04 Flores PDFДокумент11 страницTP04 Flores PDFJefreyMatuanMondranoОценок пока нет

- Session 1 - Lateral Loads - NSCP 2015Документ49 страницSession 1 - Lateral Loads - NSCP 2015HahahahahahahahahaОценок пока нет

- Structural EngineeringДокумент49 страницStructural EngineeringDaya Kiran100% (1)

- Plastic Analysis of Framed StructuresДокумент65 страницPlastic Analysis of Framed Structuresgirma kebedeОценок пока нет

- Wind Load Design NSCP 2015 PDFДокумент6 страницWind Load Design NSCP 2015 PDFOliver Pocdol AmantilloОценок пока нет

- MEC 257 - Chapter-02 Shawkut SirДокумент126 страницMEC 257 - Chapter-02 Shawkut SirOlger Garcia100% (1)

- Combined FootingДокумент12 страницCombined FootingmyОценок пока нет

- Chapter 1 - IntroductionДокумент26 страницChapter 1 - IntroductionEvo LanzОценок пока нет

- Seismic EvaluationДокумент33 страницыSeismic EvaluationAshish Gone100% (1)

- Diaphragms For Gravity Loads (AASHTO)Документ14 страницDiaphragms For Gravity Loads (AASHTO)FAIZAN AHMEDОценок пока нет

- Planning, Analysis and Design of (G+5) Hospital Building Using STAAD - ProДокумент8 страницPlanning, Analysis and Design of (G+5) Hospital Building Using STAAD - ProIndhuManiyan100% (1)

- Reinforced Concrete DesignДокумент29 страницReinforced Concrete DesignChristian Angelo ButacОценок пока нет

- Design CriteriaДокумент6 страницDesign CriteriaJomin Dennis Miembro100% (1)

- ch-6 One Way SlabДокумент12 страницch-6 One Way SlabameerОценок пока нет

- 4 Storey Apartment BuildingДокумент2 страницы4 Storey Apartment BuildingrbalmodalОценок пока нет

- EEI CorporationДокумент4 страницыEEI CorporationHJTANОценок пока нет

- Module 002 CE ELECT 5S-Structural Framing Concepts and Preliminary SizingДокумент13 страницModule 002 CE ELECT 5S-Structural Framing Concepts and Preliminary SizingCeasar MerialesОценок пока нет

- Lecture 4 - House DesignДокумент18 страницLecture 4 - House Designkkhan_451062Оценок пока нет

- Design of Reinforced Concrete Shear WallДокумент15 страницDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- L-03 Analysis and Design of One-Way Slab System (Part-II) (Aug 2016) (Colored)Документ37 страницL-03 Analysis and Design of One-Way Slab System (Part-II) (Aug 2016) (Colored)engineersalam786Оценок пока нет

- SE Prep - Day 2 - ErrataДокумент15 страницSE Prep - Day 2 - ErratabmxengineeringОценок пока нет

- Toyota Axio/Fielder Manual Translated in EnglishДокумент377 страницToyota Axio/Fielder Manual Translated in EnglishHidayat Ullah86% (7)

- International Relations Notes by SIR RIAZ AHMEDДокумент37 страницInternational Relations Notes by SIR RIAZ AHMEDHidayat Ullah100% (2)

- KPPSC Character Certificate FormДокумент1 страницаKPPSC Character Certificate FormHidayat UllahОценок пока нет

- The Judicial System of PakistanДокумент37 страницThe Judicial System of PakistanSarvinRudraОценок пока нет

- KPK Tehsil Municipal Officer (TMO) Syllabus 2017-2018Документ1 страницаKPK Tehsil Municipal Officer (TMO) Syllabus 2017-2018Hidayat UllahОценок пока нет

- Realism and Neo-Structural RealismДокумент4 страницыRealism and Neo-Structural RealismHidayat Ullah100% (1)

- Leaning Tower of Pisa v2.0Документ22 страницыLeaning Tower of Pisa v2.0Hidayat UllahОценок пока нет

- L-07 Introduction To Prestressed Concrete (Coloured)Документ20 страницL-07 Introduction To Prestressed Concrete (Coloured)Hidayat UllahОценок пока нет

- RCD-II Final Term Past Papers PDFДокумент5 страницRCD-II Final Term Past Papers PDFHidayat UllahОценок пока нет

- L-08 Introduction To Bridge Engineering (Coloured)Документ41 страницаL-08 Introduction To Bridge Engineering (Coloured)Hidayat UllahОценок пока нет

- L 05 Analysis and Design of Two Way Slab Without BeamsДокумент57 страницL 05 Analysis and Design of Two Way Slab Without BeamsHidayat Ullah100% (2)

- L-06-EQ-Resistant-Design-of RCC StructuresДокумент62 страницыL-06-EQ-Resistant-Design-of RCC StructuresAbdul Hamid BhattiОценок пока нет

- L-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Документ63 страницыL-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Hidayat Ullah100% (3)

- L 02 Analysis and Design of One Way Slab System Sep 2015Документ45 страницL 02 Analysis and Design of One Way Slab System Sep 2015Hidayat Ullah100% (1)

- L 01 Introduction RCD 2Документ31 страницаL 01 Introduction RCD 2Hidayat UllahОценок пока нет

- Lecture 1 - Curves (Simple & Compound) PDFДокумент73 страницыLecture 1 - Curves (Simple & Compound) PDFHidayat Ullah92% (164)

- Chudamani Women Expecting ChangeДокумент55 страницChudamani Women Expecting ChangeMr AnantОценок пока нет

- Module 5Документ14 страницModule 5shin roseОценок пока нет

- 2023 2024 Syllabus PDFДокумент23 страницы2023 2024 Syllabus PDFRika DianaОценок пока нет

- (Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsДокумент5 страниц(Polish Journal of Sport and Tourism) The Estimation of The RAST Test Usefulness in Monitoring The Anaerobic Capacity of Sprinters in AthleticsAfizieОценок пока нет

- Pull Cord Switch JayashreeДокумент1 страницаPull Cord Switch JayashreeNCОценок пока нет

- Operator's ManualДокумент110 страницOperator's ManualAdam0% (1)

- HPSC HCS Exam 2021: Important DatesДокумент6 страницHPSC HCS Exam 2021: Important DatesTejaswi SaxenaОценок пока нет

- Nursing Assessment in Family Nursing PracticeДокумент22 страницыNursing Assessment in Family Nursing PracticeHydra Olivar - PantilganОценок пока нет

- GST RATE LIST - pdf-3Документ6 страницGST RATE LIST - pdf-3Niteesh KumarОценок пока нет

- Su Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFДокумент4 страницыSu Poder en El Espiritu Santo Your Power in The Holy Spirit Spanish Edition by John G Lake PDFRodrigo MendezОценок пока нет

- Corrosion Performance of Mild Steel and GalvanizedДокумент18 страницCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlОценок пока нет

- Amerex Ansul Badger Ul Catalogo Por PartesДокумент37 страницAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresОценок пока нет

- Circuit Construction: Assignment 3Документ45 страницCircuit Construction: Assignment 3ali morisyОценок пока нет

- P6 - TT2 - Revision Test 2021-2022 Page 1 of 11Документ11 страницP6 - TT2 - Revision Test 2021-2022 Page 1 of 11Nilkanth DesaiОценок пока нет

- Entrepreneurial MotivationДокумент18 страницEntrepreneurial MotivationRagavendra RagsОценок пока нет

- 12 Logarithm Approximate FloatingДокумент6 страниц12 Logarithm Approximate FloatingPhilippe Englert VelhaОценок пока нет

- CH 1 Viscous Fluid Flow Part 1Документ29 страницCH 1 Viscous Fluid Flow Part 1Ammar WahabОценок пока нет

- Unit 20: TroubleshootingДокумент12 страницUnit 20: TroubleshootingDongjin LeeОценок пока нет

- 3-A Y 3-B Brenda Franco DíazДокумент4 страницы3-A Y 3-B Brenda Franco DíazBRENDA FRANCO DIAZОценок пока нет

- CLT Apllications NewestДокумент49 страницCLT Apllications NewestMackBrideОценок пока нет

- Unit 1 Building A Professional Relationship Across CulturesДокумент16 страницUnit 1 Building A Professional Relationship Across CulturesAlex0% (1)

- Buddha Mind PDFДокумент32 страницыBuddha Mind PDFVishal GadeОценок пока нет

- MCFKTP G3 S2 SC Number Pattern PuzzlesДокумент5 страницMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoОценок пока нет

- Project Report For Tunnel ExcavationДокумент19 страницProject Report For Tunnel ExcavationAbhishek Sarkar50% (2)

- UpdateJul2007 3julДокумент10 страницUpdateJul2007 3julAnshul SinghОценок пока нет

- PV Power To Methane: Draft Assignment 2Документ13 страницPV Power To Methane: Draft Assignment 2Ardiansyah ARОценок пока нет

- Chapter 9Документ28 страницChapter 9Aniket BatraОценок пока нет

- What Is Urban PlanningДокумент33 страницыWhat Is Urban PlanningDivine Grace FernandoОценок пока нет

- Exemption in Experience & Turnover CriteriaДокумент4 страницыExemption in Experience & Turnover CriteriaVivek KumarОценок пока нет

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullДокумент10 страниц(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarОценок пока нет