Академический Документы

Профессиональный Документы

Культура Документы

Classic 3 Plan

Загружено:

Michele PacilliАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Classic 3 Plan

Загружено:

Michele PacilliАвторское право:

Доступные форматы

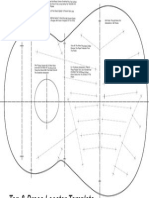

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Certain Luthiers Tune The Top By Making The Top

Progressively Thinner As It Reaches The Guitar Edge

And Remain Full Thickness At The Top. If You Do

This Do Not Reduce The Edges Below 2.2mm And

Make The Center Slightly Thicker.

60.7

34.7

109.8

2 3/8"

1 3/8"

4 5/16"

21

4

52. /16"

h=5

mm

4.8

3/16"

h=5m

660.0

25 31/32"

373.5

1 9/16"

14 23/32"

1 7/32"

Shaded Area Indicates 1/16" Cedar

Bridge Plate Glued To The Underside Of

The Top Place. Notch Fan Bracing Over

The Top Of The Bridge Plate.

h=5mm

9 5/32"

232.2

3 7/16"

87.7

1 21/32"

2 21/32"

R 42.1

67.3

11 3/32"

282.0

1 1/2"

38.0

2"

50.8

2 1/2"

63.5

2 3/32"

53.2

1.77

2 9/16"

65.1

1.77

2 7/8"

5/8"

15.9

7.9

5/16"

h=5mm

1 15/32"

1 3/8"

1 3/8"

21.8

27/32"

20.8

13/16"

4.8

31/32"

34.9

34.9

21/32"

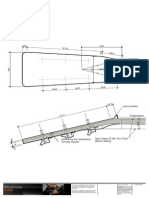

Classical Guitar Bridge Complete

With Tie Block, Saddle Channel And

Either Bone Or Ivory Saddle. Center

On 660mm Scale Length Both

Vertically and Horizontally.

3/16"

R 36.8

128.6

5 1/16"

Fret Wire Detail

Cut Slots Into Headstock After Drilling Holes For

Machine Head Rollers. Make A Template To

Locate Holes And Drile Precisely With A Drill

Press. Cut String Ramps In With A Round Rasp

and Final Shape With Sandpaper Wrapped Around

A Dowel.

Note: Be Sure To Check The Actual Roller Spacing

For Your Tuning Machines Before Making The

Template and Layout. They Vary Slightly From Mfr.

To Mfr.

Butt The Rossette Reinforcing Plate

Into The Sides Of The Braces. Do Not

Extend Beneath Braces Or on Other

Side Of Braces

h=5m

Rossette (Shaded) - Usually

Prefabricated. But You Can Make

Them Yourself.

The Center Joint Is One Of The Most

Important Joints On The Guitar For Both

Top And Back Plates. Consider Using Our

Plate Joining Jig For Hairline Joints In Record

Time

String Ramps

37.0

All Fan Braces

3mm wide

25.0

73.0

5/8"

15.9

5/16"

21

7.9

h=5mm

Dashed Lines Indicate Outline Of

Neck Block Where It Meets The

Top.

9

59. 1/32"

Re-Constituted Ivory Or Excellent Quality

Bone For the Nut.

3 3/32"

39.7

78.5

Depth Of Holes For Rollers Can

Vary With Tuning Machine Mfr.

Dashed Line Indicates Rossette

Reinforcement Strips. 1.5mm Thick

30.7

1 7/16"

1.2

1/32"

14 1/2"

1/2"

368.5

12.7

3 3/8"

31/32"

1 5/32"

Scale Length

85.7

25.0

29.1

21

20.8

13/16"

0

54. /8"

Brace Key Numbers. Refer To

Brace Diagram Plan For

Bracing Layouts

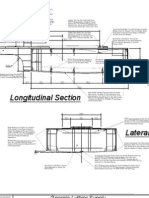

Back Block or Butt Block. Vertical Grain

Cedar Or Spruce Minimum 20 Grains/

In. Some Luthiers Shave This Block or

Angle It Away From The Top As This

Block Often Gives A Guitar A "Hump"

In The Top And Can Cause Cracking.

C

F

h=5

mm

Guitar Plan View

Optional Independent Side Braces - Refer To Latteral

Section For More Info. Spread Evenly Around The

Sides Of The Guitar. Refer To Section For The Exact

Profile. Usually Between 6 and 8 Are Used. These

Are Shaped Similar To A Brace Out Of The Same

Material As The Top Braces. Put In Place Just Prior

To Glueing The Back Plate To The Sides.

Kerfed Lining Made From Either Basswood Or Cedar.

Many Spanish Classicals Use Solid Kerfing For The

Back Plate Attachment. If You Choose To Do That

Make Sure The Kerfing Is Pre-Bent Prior To Gluing. Do

Not Introduce Stress Into The Guitar.

Note: Bracing Shown Here Is The

Actual Placement Of The Bracing

On The Interior Side Of The Top

Plate. This Bracing Is Not Shown

In Xray Mode. Refer To Photograph

On Section Sheet.

494.4

19 15/32"

Materials:

This is a short-form or outline on the basics of guitar construction and is intended to give you a guide to getting

started. We will be publishing a complete Guitar Building Handbook which will be a very detailed instructional

manual. Until that time, be sure to visit our very informative articles at www.ultimate-guitar-building, and http://

ultimate-guitar-online.ultimate-online-services.com/zencart/, which is our plan and material store and we will be

offering many guitar information articles there as well.

Tonewoods: Assemble the proper materials before you begin your project. If you don't have your tone wood

already, check out our ever-growing supply of tonewoods. We carry the basics such as Walnut, Maple and Genuine

Mahogany for the more modest guitars, but also cater to guitar builders wishing to purchase some of the more

exotic species such as Bubinga, Zebrawood, Paduck, Koa and much more. If this is your first guitar, you may want

to try wood that is a bit less expensive for your first try, such as Sapale for backs, or American Walnut, which is

another good choice. These along with Genuine Mahogany are available for about half to a third or less of the price

of some of the exotics. A popular choice for a great flatpick acoustic guitar is a good set of Genuine Mahogany with

straight grain - this was used on the classic Martin D18's and is still popular today. A bonus for these woods is that

they are easy to bend, sand, finish and stain, so give them a try.

Be sure to check the size of each plate that we list as some of them are not appropriate for the big bodied guitars

such as the Jumbo & Grand Auditorium. Our tops and backs are book-matched for grain pattern and we search out

the most flattering grain patterns. All of our wood is planed to 3.6mm and you can use the full dimension as listed as

there are not splits or other imperfection to be concerned about.

Neck Wood: Neck blanks are usually constructed of Spanish Cedar or one of the Mahogany woods such as African

Mahogany or Genuine Mahogany. One of the best methods of construction of a classical guitar neck is by adding a

10mm (3/8") wide Ebony strip that is laminated as an integral part of the guitar neck.

Fretboards: I prefer Ebony fretboards, expecially for classical guitars. You can use Rosewood to save a few dollars

but it is usually not worth it.

Brace Wood: We also handle brace wood for tops and backs. Typically top bracing is the same species as the top

and it should be vertical grain, with at least 16 grains per inch. Back bracing is typically from the Spruce family, but

the same brace wood as the top plate also is very workable and pleasing to the eye.

You will also need additional wood to make up the purfling around he edges and you will need maple or some other

type of white wood if you want white stripping accents for your purfling. Usually the outer layer of purfling or binding

is thickest - 2mm or more and is made from the same wood as the guitar back and sides. Another popular option is

the use of plastic bindings - not for classical guitars though. Many luthiers experiment with accents woods for the the

binding as well.

We did not get into the details of how purfling is put on this guitar as that is more of a construction issue and not a

guitar plan issue. We will list detailed methods in our guitar construction handbook on this subject.

Frets: Buy good fret stock with at least 18% silver content.

Nuts and Saddles: Bone, bone or bone. No plastic. Only use the best quality bone you can get. Ivory? Even Better

Tuning Machines: Make sure they have good plating on them and the metal is a heavy gauge. Either a good grade

of silver or gold plated tuners are approbriate for a high quality custom made guitar.

Bridge: I prefer to make my own out of Ebony to match the fretboard. Often a very appealing option is a Rosewood

Bridge, which is very attractive. Consider matching the headpiece wood to the bridge wood.

Interior blocking for neck and butt blocks: This wood should probably match your neck material of choice. Grain

should be vertical and no knots. We have and will be carrying a wide array of these accessories for your guitar

building needs.

Tips and Techniques:

Always make sure your tools are razor sharp and not dull. Buy good sharpening stones or sharpening grinders such

as the Tormek or the JoolTool sharpening systems. It is also important to knock off the burr on your chisels and

other hand tools.

If you use stationary tools, make sure the blades on your bandsaw, table saw, jointer etc. are also very sharp and

you do not have to force wood through the machines. If given a choice, always use carbide-tipped blades. Some of

these hardwoods are tough to cut without a good carbide blade. Setup of power tools is extremely important too follow included directions or obtain good books on proper setup of bandsaws, table saws etc. You can't believe what

a difference this will make.

You can never have enough jigs, templates etc. in guitar-making. If you plan to continue beyond your first guitar and

make several others, templates and jigs are a must more making your work a lot easier. Be sure to check out our

extensive line of Guitar Building Tools to help you build more quickly and accurately and concentrate on technique

and improving the sound and balance of your guitars.

If you are starting from scratch in your building endeavors, make sure you make excellent quality Inside Forms and

Workboards for your guitar. If you make your guitar forms from our plans, you will increase your build rate and

continually have consistent builds.

Put together the Guitar Templates that you will need at a bare minimum. You should have a template to trace your

basic guitar body shape, your top and back brace locations, the neck and foot profile and the headstock layout,

showing all the drilling locations for the tuning machine rollers and string slots. Also it comes in handy to have back

brace curvature templates, brace scalloping patterns, fret slot location templates and bridge templates.

There are a lot of great little tools and gadgets available for Guitar Lutherie - Here are a few:

Thumb Planes - These are also called violin finger planes.

Spindle Sander - This is a tabletop stationary tool.

Dremel Router with roller bearing bushings - or other small hand-held mini-router.

GoBoard Gluing Jig for gluing back and top plate bracing quickly and easily in about 10 to 20% of the time of the

usual clamps.

Heated Side Bender: This is probably the one tool that you will absolutely need to easily and quickly bend your

sides, which is one of the more important projects in a guitar building project. You will also need Guitar Form Inserts

to complete the bending process.

Neck Assembly Jig: This will help you saw the scarf joint for your guitar headpiece and glue the headpiece and the

heel block stack without any shifting during clamping and you will achieve very consistent results eliminating time

and frustration.

Plate Joining Jig: This all-important jig is a great way to get the best and strongest possible joint for one of the

hardest to glue joints on the guitar.

We offer these tools and many more pre-built and assembled guitar tools, as electronic plans where you build them

yourself and hardware sets so yo can get all of the necessary hardware and just supply the wood and labor yourself.

Make sure your shop is held an a very constant humidity level all year long. Never vary more than 5% between 45

and 55%. This will minimize cracking, shrinkage and give overall durability to guitars you plan to sell or gift.

Some of the other great little tools I love are:

Japanese Saws that cut both ways

Lots of the German Cam Clamps - both 6" and 8"

1" Spring Clamps - A whole 2# coffee can full of these

A great set of instrument maker's chisels in 1mm 2mm 4mm and 6mm sizes

Fret file, dovetail saws, fret end dressing tool, fret rocker etc.

Methods:

Start by sanding your top plate, back plate and sides to rough thickness (within 1mm of final thickness). For top

plates of classical guitars, shoot for approximately 2.4 to 2.5mm (3/32), depending on wood species and stiffness of

the top. Backs and side should be about the same or a little bit thinner, but not much, again depending of the wood

species. Carefully glue the center joints of the back and sides together with a Plate Joining Jig.

To prepare the joints, sand carefully with sandpaper glued to a perfectly straight edge. I like to use adhesive backed

sandpaper in rolls and stick it to the side of a 24" metal-faced level. Trim the sandpaper carefully. Use 120 grit paper

and do not use a lot of force. The plates are joined most easily with the cam-action of the jig while using retainer bar

the top of the jig to keep things in alignment. By using our jig, you dont need to mess with wax paper or other

methods to keep the glue from sticking as we use HDPE non-stick plastic for the jig base and center retainer.

Once glued (If you use one of the exotic woods, be sure to get all of the resin out of the wood with acetone before

you glue anything. If you need to thickness sand your wood you can use jack planes, scrapers or dual action

sanders. See our articles for much more detail on this.

When I started out making guitars, I couldn't afford all the expensive stationary sanders etc,, that makes the work so

simple now. I used to get one side of the plate completely flat, then I would chuck up a small bit in the drill press and

set it to stop at the desired thickness of my plate + about .2mm. I would then drill dimples over the entire surface of

the unfinished side and simple sand until all of the dents were gone - pretty slick! Just make sure that the drill press

depth gauge doesnt slip!

After you have your thickness completed on the top plates. trace the guitar contour and carefully cut the outline out.

Make the cut line at least 2mm outside the line to give you some room to work later on.

Now is the time to bend your sides - a pretty scary operation if you are bending $300 side sets. Use either Heated

Side Bender with a Heating Blanket or on a bending iron. You can also boil the sides and clamp them to an

Unheated Side Bender for a few days to a week. Be sure to over-bend a bit to allow for spring-back. If you are going

to go into a bigger production of guitars than just a few now and then, you will want to get several benders in your

shop and constantly be loading these benders with wood side materials.

While the sides are curing, rout the channel for the rosette trim in the top plate and insert and glue those pieces. I

use a Dremel router with a steel stud sticking up through the center of the soundhole (the sound hole is not cut out

at this point.). I do this right on my Plate Joining Jig so to save space and utilize its large base. Once the rosette is

installed, rout out the soundhole with the router too. Carefully round the edges of the the soundhole with sand paper.

Now is the time to install all of your bracing on the top and back. As I mentioned I use GoBoard Gluing Jig and I

have plenty of fiberglass clamping rods handy to do this. This jig works fast and really secures the bracing evenly

and uniformly over the entire surface of the top or back plate. It also gives you a lot of finger space to allow gluing all

of the braces in a single operation without a lot of clamps to work around, and glue squeeze-out cleanup is a snap.

Typically the braces are only roughed-out for their final shaping is done after they are glued, but by using the

GoBoard Rods the braces can be totally finished and you only need to touch them up - so another time-saver. After

the glue is mostly dry, remove the plate and get all of the glue squeeze out off the bracing and plate with a sharp

small chisel. The glue should be dry enough to not be liquid but not fully adhered to the wood.

Methods - Continued:

Now you should assemble the guitar neck. As mentioned before you can use an assortment of guitar wood, but

make sure it is good strong hardwood. Cut the portion to be used for the neck right down the center and flip the

pieces so the grain is opposed on each half. Add your center strip if desired and glue up. After the neck assembly is

dry, square it up and you can use the Neck Assembly Jig to run it through your band saw to cut the exact scarf joint

angle. Do the same with the headpiece. Cut the headpiece to desired thickness.

Methods - Continued:

Next is the time to trim the plates, rout purfling grooves around the edges of the guitar and fit the purfling. With

groove cleaned out, nice tight fit and everything cut to length, glue on the purfling. When using wood purfling, be

sure to prebend the wood so it will fit with as little stress as possible.

Glue the purfling with your glue, and bind to the channel with the same upholstery tape as was used for the top and

back. This can also be done with the guitar inside the inside form if you desire.

Place the neck, the headpiece and the stacked heel blocks in the jig and glue them all together. This is a snap with

the Assembly Jig.

Rough sand the sides, back and top plates and round the edge of the purfling.

Next rough-cut the heel and foot/headblock shape of the neck on the bandsaw, keeping things true and plumb.

Remember to always cut a bit outside the lines to allow for slight error. Now rough cut the headpiece after tracing

with your headstock template. Sand the sides to final shape and size and drill you machine head holes in the

headpiece. Drill the holes for the string slots in the peghead. I prefer to use a Forstner Bit for nice clean holes.

Follow up with a jig saw with a fine cutting blade to connect the holes. Make this cut about 1mm outside the line and

sand to the line with thin sanding sticks.

Next sand the fingerboard to thickness, cut to correct width and final sand the edges on a stationary belt sander. Cut

the fret grooves and locate the fretboard on the neck. Lightly clamp it and drill 2 small holes down through the fret

groove at the body and nut ends of the fretboard. Place small locator nails in the holes and double check the

fingerboard location before gluing. Double check all the lateral and vertical locations with a precise straight edge.

Now install any edge binding on the fretboard that you may wish to install. Final sand everything and make sure the

fretboard is dead level. Glue the fretboard in place.

Next rough-shape the neck with a 4-way rasp, using the rough cut blade. Get the neck to within about 1/16" of final

thickness and width. Carefully shape the heel, constantly checking your progress against the template you made.

Final shape the neck to the fretboard size, shape the heel and finish sand. Place a heel trim on the bottom of the

heel. Dry-fit the tuning machines and make any adjustments so there is no binding or forcing in place. Fit the nut

and bridge. Mark the bridge location with a light pencil or scribe mark. You finish the guitar with the bridge in place.

You will have to use deep reach clamps to glue the bridge in place. It is best to place masking tape around the

perimeter of the bridge to allow easy glue cleanup.

Cut the slots in the neck for the sides to fit into the neck joint between the heel and the headblock/foot assembly.

This is easiest to do with Back Saws, Japanese Hand Saws etc. The trickiest part of this slot is that it needs to

match the curve of the sides that will fit into the slot without play. I cut the slot a bit narrow and then adhere a piece

of adhesive backed sandpaper to a metal scraper or a piece of an old handsaw blade.

Next shape the bottom of the foot. This too is a tricky operation and it is easy to oversand the foot bottom and then

you are faced with laminating a thin piece of wood on the bottom of the foot and start over. It works best to make an

arch jig that reverse matches the bracing arch and constantly check your work with this jig with your guitar in the

inside mold. Just work at it with sanding blocks, a little at a time and you can get it perfect.

Be sure to flatten the upper neck surface to prepare it for the fretboard. After rough shaping the neck, you should

keep about 2mm of neck wood on either side of the fret board so once the fret board is in place you can easily

shape the neck to the fretboard.

With the sides rough-cut to contour, using our Guitar Side Template, glue in the lining to receive the back plate. This

lining can be either kerfed lining or solid pre-bent lining. Glue with wooden clothespins with rubber bands wrapped

on them to strengthen their tension or use mini spring clamps. Make sure you have even glue squeeze out and

clean it up as you did on the braces. Extend the kerfing slight above the guitar sides.

Now fit the back to the sides and neck with the side following the contour of the inside form. Since the braces for the

back are slightly arched (about 4 to 6 mm ) carefully mark the trim marks for the sides. This will vary with every

aspect of the guitar because the inherent nature of it's shape. The kerfing will also need to have the top slights

contoured to fit tightly to the guitar back plate. Do this with a long sanding stick that reach completely across the

guitar. Place a block on the opposite end of the sand paper to compensate for the arch and shape the kerfing.

Glue the bridge after carefull dryfitting. If you use some of our Cam Clamps. You will need three of them, at least 8"

long. You will also need special cauls that you can make a temporary "bridge" to protect the fragile fan bracing

inside the guitar.

Give all wood surfaces a final sanding with 220 grit sandpaper, install the frets and prepare to install the finish.

There are many different opinions on finish material from urethane to varnish to lacquers. Do your research and

decide on what suite you best. Remember the thinner the finish the better sound you will get with a solid wood

guitar.

Finishing is a whole different operation in and of itself is too lengthy to discuss in this format. I suggest you get a

good book on instrument finishing from one of the suppliers.

This was a quick overview of guitar construction and I have not had the room to go into any great detail on anything.

At Ultimate Guitar OnLine, we plan on publishing an ebook on guitar construction in the near future, so watch for

that.

Good Luck and most of all HAVE FUN!

Check Us Out At:

Once the braces have had at least a couple of hours to dry, final shape and sand them with 220 sandpaper until

satin smooth.

Ultimate Guitar Store

www.ultimate-guitar-online.com

http://ultimate-guitar-building.com

david@ultimate-guitar-online.com

When it comes time to glue the bracing on the back plate you should use an brace arch insert in the GoBoard. This

jig will aid you in gluing your back braces at the perfect arch so your back plate will have the perfect arch or crown.

Our sites have a LOT of tips on such things as fret installation, neck adjustments and recommendations etc. Check

out the articles and come back often as we are adding content all the time.

Look at www.ultimate-guitar-online.com/woodworking-hand-tools.html for hand tools required and:

www.ultimate-guitar-online.com/woodworking-power-tools.html for stationary tools recommended.

Above all else make sure everything fits together perfectly before gluing. Do not force anything as stress is a guitar

ruins the tone. When in doubt take a few extra hours of sanding, trimming, and pre-assembly to get everything as

perfect as you can. Our Guitar Templates and Inside Forms can get you a long way down this road.

Note For Detailed Construction Instructions

Refer To Our Book "Guitar & Ukulele Construction

Handbook @ http://shopglss.com

This Drawing or Drawings Are To Used For One Use Only

And Not Reproduced For Any Other Purpose Than

Construction Of This Particular Instrument, and a One Time

Reproduction Only is Allowed

Reproduction, Distribution or Sales For Any Other Use Is

Strictly Prohibited And Falls Under U.S Copyright Laws For

David VerBurg AIA c 2013

This Sheet Size Is Metric A0 Size Overall Size is 1189mm x

841mm With 15mm Borders On All Sides. For USA

Customers Print On Architectural "E" (36" x 48") Without

Resizing For 1:1 Printout.

Georgia Luthier Supply

Classical Guitar Plan #3

Date: Feb. 2010

Revisions: Dec 13, 2013

Unless Noted Otherwise,

These Plans Are Drawing

Full Scale. They Are

Labeled in mm and

Fractional Inches

Sheet Number

C1

Вам также может понравиться

- Livro Antonio de Torres Guitar Maker His Life and Work J. L - RomanillosДокумент377 страницLivro Antonio de Torres Guitar Maker His Life and Work J. L - RomanillosCassio Ribeiro Silva67% (15)

- Guitar Fe18 Antonio de TorresДокумент1 страницаGuitar Fe18 Antonio de Torresandua40100% (7)

- Luthieria - Selmer Maccaferri NeckДокумент9 страницLuthieria - Selmer Maccaferri Neckmandolinero67% (9)

- Archtop Guitar PlansДокумент1 страницаArchtop Guitar PlansBart Stratton83% (6)

- ManZer GuitarsДокумент18 страницManZer Guitarsdedalus777100% (5)

- Ukelele Tenor PlanosДокумент1 страницаUkelele Tenor PlanosBROSHER100% (2)

- Guitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeДокумент1 страницаGuitar Inside Mold - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (3)

- Voicing Steel String Guitar TopsДокумент12 страницVoicing Steel String Guitar Topsandrea_albrile100% (1)

- Kasha Guitar PlanДокумент1 страницаKasha Guitar PlanAndrey BalalinОценок пока нет

- Construction Notes For A Steel String Guitar - SampleДокумент32 страницыConstruction Notes For A Steel String Guitar - SampleDennistoun75% (4)

- Soundboards DF PDFДокумент17 страницSoundboards DF PDFalberto reyes100% (2)

- Antonio de Torres Guitar Maker His Life and WorkДокумент5 страницAntonio de Torres Guitar Maker His Life and Workclazzyo50% (2)

- Guitar Terms Crossword and Vocab QuizДокумент4 страницыGuitar Terms Crossword and Vocab QuizdmcummingОценок пока нет

- Know Your Gear Electric Inspection SheetДокумент2 страницыKnow Your Gear Electric Inspection Sheeteffevi100% (1)

- Classic 2 TemplatesДокумент1 страницаClassic 2 TemplatesDaniel Garfo100% (3)

- Classic3plan 3Документ1 страницаClassic3plan 3Michele PacilliОценок пока нет

- Progetto TorresДокумент1 страницаProgetto TorresMichele Pacilli50% (2)

- Master Class Guitar MakingДокумент50 страницMaster Class Guitar MakingCharles Alfaro83% (18)

- 11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFДокумент22 страницы11 Free Guitar Plans, 20 Guitar Building Jigs and 35 More Resources For Newbie Luthiers - PDFBatik Kambangsri100% (4)

- 16 Archtop Guitar BuildДокумент123 страницы16 Archtop Guitar Buildluis7oliveira_2100% (4)

- Ostberg Neil - Classical Guitar Construction in The Style Antonio TorresДокумент421 страницаOstberg Neil - Classical Guitar Construction in The Style Antonio TorresRenata67% (3)

- (Luthieria) Acoustic Guitar MakingДокумент63 страницы(Luthieria) Acoustic Guitar MakingKa LuthieriaОценок пока нет

- Ukulele ConcertДокумент1 страницаUkulele Concertakomac100% (3)

- La Guitare Friederich Et Leipp Bulletin Gam 92 - EnglishДокумент18 страницLa Guitare Friederich Et Leipp Bulletin Gam 92 - EnglishVlad100% (1)

- Washburn PricesДокумент5 страницWashburn PricesMauricio Rendón100% (1)

- Music: First Quarter - Module 3 Musical Instruments of Cordillera, Mindoro, Palawan, and The VisayasДокумент31 страницаMusic: First Quarter - Module 3 Musical Instruments of Cordillera, Mindoro, Palawan, and The VisayasGenieva Dado Angcot100% (4)

- Guit 0917Документ156 страницGuit 0917jmpcaster100% (2)

- Classic3plan 2Документ1 страницаClassic3plan 2Michele Pacilli100% (1)

- Bolt On Acoustic Guitar NeckДокумент1 страницаBolt On Acoustic Guitar NeckJayMorgan50% (2)

- Martin V Joint NeckДокумент1 страницаMartin V Joint Neckandua40100% (2)

- Archtop Build Journal - Fifth Edition - (Low Res)Документ122 страницыArchtop Build Journal - Fifth Edition - (Low Res)Jose Maria Hidalgo100% (1)

- Introduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarОт EverandIntroduction to Kit Acoustic Guitars (or) Life is Short...Build a GuitarРейтинг: 1 из 5 звезд1/5 (1)

- Top Plate Brace Layouts: Classical Guitar Plan #3Документ1 страницаTop Plate Brace Layouts: Classical Guitar Plan #3Michele PacilliОценок пока нет

- Guitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeДокумент1 страницаGuitar Inside Mold - Side View 1937 Hauser Classical Guitar ShapeDaniel GarfoОценок пока нет

- Guitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeДокумент1 страницаGuitar Assembly Work Board - Top View 1937 Hauser Classical Guitar ShapeDaniel Garfo100% (1)

- Bracing Styles For Classical Guitars - This Is Classical GuitarДокумент9 страницBracing Styles For Classical Guitars - This Is Classical Guitarmenique100% (1)

- Making A Classical GuitarДокумент45 страницMaking A Classical GuitarRalie Ralev100% (5)

- Acoustic Guitar InnovationsДокумент27 страницAcoustic Guitar InnovationsAugusto Espejo100% (1)

- Make Your Own Spanish Guitar (1957)Документ40 страницMake Your Own Spanish Guitar (1957)Erdem Kapan100% (2)

- Instructions Neck AngleДокумент21 страницаInstructions Neck Angleandua40100% (2)

- Rosettes PDFДокумент7 страницRosettes PDFjuvemoraisОценок пока нет

- Cultural Origins of The Modern Guitar: by R. E. BruneДокумент13 страницCultural Origins of The Modern Guitar: by R. E. BruneGiovanni Cenci100% (1)

- Double Top BuildingДокумент18 страницDouble Top BuildingaboutsoundcraftОценок пока нет

- Tonewood Technical DataДокумент24 страницыTonewood Technical DataCaps Lock100% (4)

- The Acoustics of The Steel String GuitarДокумент418 страницThe Acoustics of The Steel String Guitaraboutsoundcraft100% (3)

- Classic3plan 2 PDFДокумент1 страницаClassic3plan 2 PDFarantxa16Оценок пока нет

- French PolishingДокумент34 страницыFrench Polishingaboutsoundcraft89% (9)

- Heating Cartridge Installation GuideДокумент1 страницаHeating Cartridge Installation Guidepeter100% (1)

- April 2015 Professional Guitar Price ListДокумент1 страницаApril 2015 Professional Guitar Price ListAndrey BalalinОценок пока нет

- Archtop Guitar ManualДокумент123 страницыArchtop Guitar ManualCarlo351100% (13)

- Curso Luthier by Johnny GuitarДокумент95 страницCurso Luthier by Johnny GuitaradmlewisОценок пока нет

- Guitar Makers: The Endurance of Artisanal Values in North AmericaОт EverandGuitar Makers: The Endurance of Artisanal Values in North AmericaОценок пока нет

- Guitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsОт EverandGuitar Shapes Navigator: Measuring the shapes of the guitar and the positions of its elementsОценок пока нет

- The Uke Book Illustrated: Design and Build the World's Coolest UkuleleОт EverandThe Uke Book Illustrated: Design and Build the World's Coolest UkuleleРейтинг: 5 из 5 звезд5/5 (1)

- Clapton's Guitar: Watching Wayne Henderson Build the Perfect InstrumentОт EverandClapton's Guitar: Watching Wayne Henderson Build the Perfect InstrumentРейтинг: 4 из 5 звезд4/5 (25)

- The Guitar Story: From Ancient to Modern TimesОт EverandThe Guitar Story: From Ancient to Modern TimesРейтинг: 3.5 из 5 звезд3.5/5 (4)

- GuitarДокумент11 страницGuitarvakarmeОценок пока нет

- How To Build A Basic Cigar Box GuitarДокумент7 страницHow To Build A Basic Cigar Box GuitarLeon Claassen100% (1)

- Making A Guitar Neck PDFДокумент8 страницMaking A Guitar Neck PDFhoskencues100% (1)

- Guitar DimensionsДокумент4 страницыGuitar DimensionsWalied SamiОценок пока нет

- The Tennessee Music BoxДокумент7 страницThe Tennessee Music Boxkewlboy24100% (2)

- Power Tour Electric GuitarДокумент12 страницPower Tour Electric GuitarOmar SánchezОценок пока нет

- Andrew Glynn Portfolio 2014Документ14 страницAndrew Glynn Portfolio 2014Andrew GlynnОценок пока нет

- ViolinДокумент22 страницыViolinCésar Cortés GutiérrezОценок пока нет

- Ibanez Catalog 2014 PDFДокумент49 страницIbanez Catalog 2014 PDFDominiqueVermuyten100% (1)

- 1999 Bourgeois A-350 - PrototypeДокумент8 страниц1999 Bourgeois A-350 - PrototypeBetoguitar777Оценок пока нет

- Electric Bass BB Series: LEG1004CB Printed in Japan This Document Is Printed On Chlorine-Free (ECF) Paper With Soy InkДокумент9 страницElectric Bass BB Series: LEG1004CB Printed in Japan This Document Is Printed On Chlorine-Free (ECF) Paper With Soy InkaeroglideОценок пока нет

- Scale PentatonicheДокумент7 страницScale PentatonicheSandro FantiniОценок пока нет

- Guitar Fretboard and Scales For Beginners - James HaywireДокумент172 страницыGuitar Fretboard and Scales For Beginners - James HaywireOscar Roche100% (5)

- The Guitarist's Guide To The CAGED SystemДокумент11 страницThe Guitarist's Guide To The CAGED Systemzogiva100% (3)

- 2015 Washburn Guitars CatalogДокумент64 страницы2015 Washburn Guitars CatalogjoaotostesОценок пока нет

- Violin Left Hand ChecklistДокумент1 страницаViolin Left Hand ChecklistNikkia CoxОценок пока нет

- Catalogo Suhr PDF - XLSXДокумент15 страницCatalogo Suhr PDF - XLSXoscarmstrugaОценок пока нет

- 1997Документ5 страниц1997Leonardo CamachoОценок пока нет

- 2013 Gretsch CatalogДокумент41 страница2013 Gretsch CatalogNick1962100% (2)

- RBX 774Документ10 страницRBX 774Tercio MouraОценок пока нет

- Guitar ErgonomicsДокумент5 страницGuitar Ergonomicspeterjohnbailey100% (1)

- 2021 Eastman AR-605CEDДокумент8 страниц2021 Eastman AR-605CEDBetoguitar777Оценок пока нет

- Guitar/The Basics: Book ReadДокумент10 страницGuitar/The Basics: Book ReadgernОценок пока нет

- 2016 Charvel CatalogДокумент36 страниц2016 Charvel CatalogFabiano SilvaОценок пока нет

- U.S. Pat. 8,637,753, Inventor Dean Zelinsky, Z-Glide Neck, 2014.Документ8 страницU.S. Pat. 8,637,753, Inventor Dean Zelinsky, Z-Glide Neck, 2014.Duane BlakeОценок пока нет

- Caractéristiques Gretsch G5655 TGДокумент6 страницCaractéristiques Gretsch G5655 TGJean-Philippe LabrousseОценок пока нет

- Playing Through The Blues PDFДокумент50 страницPlaying Through The Blues PDFFrancisco Lopez RodriguezОценок пока нет

- Schecter Catalog 2012Документ38 страницSchecter Catalog 2012Michael HavelockОценок пока нет