Академический Документы

Профессиональный Документы

Культура Документы

GHD Report On Alternatives For Chatsworth

Загружено:

massieguy0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров28 страницComparative Evaluation of Alternative Septage Management Options for the Township of Chatsworth - January 28, 2016 Report by GHD Limited (an engineering consulting company)

Оригинальное название

GHD Report on Alternatives for Chatsworth

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документComparative Evaluation of Alternative Septage Management Options for the Township of Chatsworth - January 28, 2016 Report by GHD Limited (an engineering consulting company)

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров28 страницGHD Report On Alternatives For Chatsworth

Загружено:

massieguyComparative Evaluation of Alternative Septage Management Options for the Township of Chatsworth - January 28, 2016 Report by GHD Limited (an engineering consulting company)

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 28

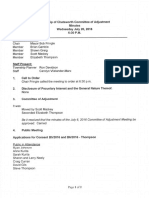

Deputation

10:30 a.m. Mike Muffels of GHD Limited

Regarding the comparative evaluation of alternative

septage management options

6

Memorandum

To:___Wit Moor, Township of Chatswosth Ref No: 11102058.06

AH

‘From: __ Mike Mutelsnas Date: January 28, 2016

Re: Comparative Evaluation of Atemative Septage Management Options

‘Township of Chatsworth

4. Introduction

(On December 2, 2015, the Township of Chasworth (Township) Council resolved 10 retain GHD to complete

‘2 comparative evahiation of atemative septage management options. The purpose ofthis echnical

‘memorandum isto summarize the ndings ct the comparative evalustion

2. Regulatory Review

24 Municipal Class Environmental Assessment

“There ae three schedules of projects underthe Muriepa Class Environmental Assessment (EA) thst SPBly

tothe septage management options evalusled below:

+ Schedule A: Pre-Approved Actives - The proponent may proceed without flowing the procedures set

fat inthe Municipal Water and Wastewater Projects Class EA. Examples of actives rested to septge

‘management incuce:

‘iepose of tite, oF manage biosds onan inter bass (2.9. further treatment in crying beds,

‘composting, temporary holding at tanser stations) a

a. Anexsting sewoge treatment lan whore the biosolids is generates

»b. An existing landil sit, incinertor or organic sol condoning ite, where the biosolids i tobe

tized or sispocod ot

+ Establish anew biososds organic sll condoning ste

«+ Increase sewage treatment plant capac beyond rated capacity trough improvements to operations

‘and maintenance actites only, but wihout constuction of works to expand, mad or retro the pant

tthe cute the recehing water boy, with no increase ott mass loading to receiving war body

‘28 identified in the Enveonmental Comalance Approval (ECA).

+ Schedule B: Actives Subject fo the Screening Process ~ The folowing example Schedule B activites,

having completed Phases 1 and 2 ofthe planning process, are approved subject to Screening:

rtabl sewage ow equalzatontankage in existing sewer system or at exiting sewage

treatment plants, ora existing purping stations for influent andlor efent contr

‘Ade edational lagoon calls 0: establish new lagoons, or instal new or adonal sewage storage

tanks at an existing eouage sytem, where and scquistion i required but existing rated capacity

il not be exceeded.

Establsh biosolids management facies at

‘8. Asewage treatment plant where the biosolids were not generated

'b. An exiting tnd te, incinerator or organic sl conditioning ste where the biosokds are not to

be cisposed of nor utized.

1+ Schedule : Atvtes Subject tothe Full Panning Process ofthe Class EA:

Construct new sewage system, including otal to receiving waterbody andlor a constructed

wetland for reatment

Construct new sewage treatment panto expand existing sewage treatment plant beyond existing

rated capacty including otal to receiving waterbody.

Estabish new lagoons or expand exiting lagcons or install ew oradltional sewage storage tanks

which wil increase beyond existing rated capacty.

Provide for land application of sewage fluent rough spray irgation system or verand ow.

Estabish a new biosolids landfil te or now biosolids incineration sit for purposes of biosolids

disposal

Estabieh new transfer statin or new storage lagoon not locate at @ sewage treatment plat,

Incinerator, landil ste, or organic so condtoning 29, or purposes of biosolids management.

22 Environmental Protection Act, Ontario Water Resources Act and Clean Water Act

‘The Environmental Protection Act (EPA, 2002) regulates the handing, tensportaton, storage, daposal and

treatment of senage and septage. The folowing approvals may be required or require amendment

+ Atuled Sewage (Septage) Waste Management Systom ECA is required to haul and transport sewage

biosolids and sertage

+ AlHauled Sewage (Seotage) Waste Disposal Ste ECA is requred fra storage or pose! faci.

1+ AHlauled Sewage (Septage) Waste Management System ECA is requires to land apoly septage.

+ An AWNoise ECA,

+ ASeeton 53 Approval under the Ontario Water Resources Act (OWRA) may be required for stormwater

‘management,

+ Land application of untested septage fs considered drinking water threat under he Ciean Water Act

(2006). As source water protection plans are completed this may cestct future end application of

untreated septage

ey 2

3. Septage Estimates

‘GHD reviewed the ftowing documents inorder to conf the septage estimates forthe Township:

1. Anmeroble Treatment of SeptageBiotoids to Produce Blogs, Electrical Power and Tested Blosoids

(Gune 15, 2006) prepared by Henderson Paddon 8 Associates Lid (now WSF)

2. Design Brief Angerobic Treatment of Septage/Com StoverBiosobd to Produce Blogss, Electrical

Power and Treated Bosoids (Febriary 2010) prepared by GENIVAR Constants LP (now WSP)

3. Sludge Management Pin forthe Municipalities of Grey County (March 2004) prepared by Henderson

PParidon & Aasocistes Li. (now WSF)

‘All sepiage estimates generated sines the 2004 Stadge Management Plan forthe Municipalities of Grey

‘County nave been bated onthe estimates generated in the 200¢ repr; 3s wee the estates generated for

this stidy, Table 2.1 summarizes the populston projections assured for this stoy, namely between 8 480,

‘and 6,960 over the next 10-20 years ofthe planning horizon of this study

Table 312016 and 2096 Population Projections

2001 Census)’ 6.280

2006 Census)’ 6,982 0.35%

2011 (Census)! 0437 0.4%

2016 Projected’ 6.482 04%

2096 Projected" 6.950 0.25%

Notes:

1. tputwww'?2sttcan ge.calconsus-recensemen/2011idppdproteait/page cfm ?LangrE&Geot=™CSD

‘Code! =35420378Ge02-CD&Code2=95428Data=CountSSearchTex=Chatswortt SearchiType=Begin

st SearchPR-018B1=AllsCustor=BTABIO™1

12. 2018 projected population annual increase from 2011 assumed tobe the same asthe annual increase in

zon

3. 206 projected population annual inrease from 2016 conservatively asumed tobe between the annua

increase i 2008 and 2011,

“Tobie 3.2 summarizes the estimates generated forthe number of septic sytoms and annua volume of

septage. For the purposes ofthe etudy, twas estimated that 4, 100-4300 m* of septage wal be generated

“annual fom 2840-2050 septic aystems inthe Township. The average septic tank size forthe Township

based on a weighted average le 4.3m and conservatively 1,000 tanks could be pumped oxtin any given

yea.

eee :

Tle 32 Estimate of Septage Goneated Annually

‘Aseumed Once every 3years Oncaperyear Once-every Once Once every

Pump-Out Byears” every? years

Frequency” years

Number of 238 8 a at 2m gee

Septic

Tenis in

2003"

Estimated 2301 8 ™ 2 m2 88

Sete

Tanks

2016"

‘Sept

Tanks in

2008"

Septic 797-838 1344 2526 4143 55D 883-81

Tonks

Pumped

‘annually

Estimates 3.188 159 198 300 ms sot

Volumes

2016 (m’)

Estimated 3382 167 208 ur zr 4att

Voume in

2086 (")

Notes:

1. Source: Saige Management Plan forthe Municipaliies of Grey County (March 2004 prepared by

Henderson Paddon & Associates Li. (Pow WSP)

2. Annval increase nthe number of septic tanks assumed to be the same asthe cortesponding annual

Population increase

“The Township co-owns an anaerobic digestion sewage and septage treatment acy (Bodigestr) wih the

“Township of Georgian Bf. As part of ths study GHD took the Township of Georgian Bluffs seplage ito

‘coniceaton where economies of scale existed that could benefit both the Township of Chatsworth and the

Township of Georgian Bl. Using the same metnodlogy in Table 3.2, was detetined that the Township

‘of Georgian Bis will have between 1,500 and 1.600 septic systems wth an annual sepage cofetion

uantty of 6380-8 760m

4, Alternative Septage Management Options

44 Existing Septage Disposal Facilities

At present, septage ls lposed of none of wo ways

1. Land appleaton thie ie the cheaper and the most predominant septage disposal opton exercised by

ratepayers nthe Township. This isthe tats quo option.

2, Blodigster: in partnership withthe Township of Georgian Blt the Township owns and operates an

“anaerobic gestion treatment feity, the Biodigeser, wich was constructed in 2011 specealy forthe

‘septage and wastewater generated wihin the Townships of Chatsworth and Georgian Bits. The

Biodigeser is located in the Township of Georgian Bis at 052111 Siderosd 3 (Lot 4 Concession) in

‘he former township of Dery. This option Ison average more than 33 percent more expensive than the

land epplication option, as outined inthe following section, and so most ratepayers do not elect to send

their septage to the Blcigester, When was constructed the Township anticipated tht the Province of

‘Ontario would be banning the practice of septage land aplication, however the ban has not yet

smatenaizes

42 Alternative Septage Management Options

Below ists of aerative septage management options tht were considered as prt ofthe Stody.

[Atoratve 1 Status Quo ~ Transport sptage for land application. Continue to use

septage for land sppication at approved sts a is curently permed under

the Environmental Prtecion Act unl such me as thee i a regulation

change prohiling this practice. Ths pracice currently costs between $140

‘and $200 per pump out inthe Township.

‘Atemative2 Transport eeptage tothe Biosigestr. This sso an option thats curently

valle nthe Township and used bya smal umber of retepayers. This

practice curenty cots the same as Atomatve 1 plus the tip foe atthe

Blodigestr, whic s $25 perm’ o apprcximately $108 per pump out

‘Aternatve 3 Transport septage to a private septage treatment or stbitzaton fcity wth

capacty, for example the Lystok fait in Dundalk.

[Atemative 4 Conse and operat a soptage transferidewatring station in combination

wh transportation to nearby municipal wastewater teetrent plat wih

‘capa, such asthe Owen Sound Wastewater Treatment Plant, Meaford

‘Wastewater Treatment Plat or Colingwood Wastewater Treatment Plant

‘AteratveS Construct and operate an stemative local septage treatment or stabilization

‘city:

2) Composting fecity

1) Treatment trench

©) Lime stabilization facaty

1) Lagoon stabilization facity and Liui inition or Spray Ingato ld

[Atematve 8 Transport septge tothe Bodigester wih a mobile dewatering tuck.

[Atemative7 Transport septage to the Lystok facity wih 2 moble dewatering tuck.

‘Aterative 8 Transport soptage toa nearby municipal wastewater treatment plant wih

mobile dewatering tuck.

‘Atematve 9 Transport sepiage toa dewatered septage composting faci.

‘Ateratve 10 Transport septage from he Township and neighbouring townships

(G2. Township of Georgian Blu) othe Blodgestr with a mobile

‘dewatering truck, simio to Option 6 but utzing mere ofthe tucks capacty

to rate further economies of scale. The moble dewatering tuck size

assumed for ht study wil have adonal capscy that can be used to

colect rom neighbouring township o offset the costs of he unit

‘Aterative 11 Transport soptage fom the Township and neighbouring townships to 0

vate saptage treatment fact (Le. Lystok) witha mobile dewatering ruck,

‘Sinilr to Option 7 bu utilizing more ofthe capacity of the ruck. The mobile

‘dewatering truck size assumed fr this study wil have adtionelcapacty

that canbe used to calet fom neighbouring townships to fet he costs

ofthe unt

424 Akernative 1: Status Quo —Land Application

“This lterative is considered a baseline condition for comparison with other aternatves. Ratepayers are

current enarged $140 ~ $200 per pump out.

While the Ontario Minty ofthe Envronment and Cimate Change (MOECC) have confirmed tha they are

reviewing the septage management program inthe Province, GHD does not anipate that a provinco-wide

bn onthe practes wil be implemented in he foreseeable future. Land application of unrated septoge is

tod ae 2 potential rnking water threat inthe Clean Water Act (2008) but rik f inadequate sutabe land

forthe continue practice of and appleaton inthe rualownhipis considered to be very low. The sats

‘00 atemative is considered a viable and cost effective atlemativ forthe purposes ofthis stud.

422 Altomative 2: Blodigester

‘Aterative 2 isan exting option that s minimal sized bythe ratepayers due os adtonal cost. In

2014, of the apprxamatoly 10,300 m’ of septage generated in bth the Townships of Chatsworth and

Georgian Bis, 1.250 m"or 12 percent was desvered to the Blodigestr.

‘Ther is 2 $25 per tip ee fo septage atthe Biodigesero offset capital and operating cost forthe

faclty. Ths tp fe transates to approximately $108 per pup out for an average septic tank sizeof 4.3m”

“This fei typically applied ontop of the $40 — $200 per standard pump out fee charged by the septege

haulers; for total pump out ost of $248 - $308. This ateratve is alsoincided primary for comparison

wit other atmatives as thas been demonstrated, under the curent regulator regime, tobe unpopular

wi he catepayers ove to ts cost

423 Alternative 3: Lystek Facity

‘Since the Biosigester was constructed, Lystek has constructed a biosolids testment fact oughly 45 km

‘south of Chatsworth ner Dundalk, nario, The Lystek facity employs patente thermal, mechanical and

‘eal sabato process that converts dewatered biosolids, as well as oer cxganic wastes Such as

‘eplage, no a ferizer product wich ie marketed to local agcutral operations under the name Lytearo

Bioferiize GHD understands thatthe Township Ie famlir withthe Lystekfecty andthe Lystegro product

‘and has explored ths option previously

Lystek has confmed thai facity can stil accept septage rom the Township s0 fog 28s sereened pict

to being delivered. Esimated ip fees, which woud need to be negotiated with Lystek, used forthe purposes

‘ofthis comparative evaluation are:

‘+15 perm for screened raw septage (not dewatered)

1+ $60 parton for dewatered septage

For Atematve 3, GHO assessed the sub-optons of constructing @new screening an tanker trae transfer

‘acy vorsus vtizing the existing infrastructure atthe Biolgestr asa screening and transfer fait.

Modifications tothe Biosigesterseptage reception facies would be required, but the faciy has an existing

storage tank that could be used for fow equalization buffering, Conceptual capa and operating costs for

intestruture required for these two sub-optons are summarized in Table 4.1

able 41 Conceptuat Capt and Operating Costs for Atratve 3

‘Conceptual Capt Cost 400.000 $260,000

‘Annual Operating Cost 40.000 25,000

auivalent Annual Cost (EAC)(9%, $6,000 $40,000

20 years)

EAC per Pump Out 388 0

undp Distance trom Lys 20km 140 km

Notes

1. Copal cots do not inclu land purchase pie or taxes,

2. Annual operating costs asst med to be 10 percent of capt costs

_Atematve 3 would be requires tofllow he fl lass EA process and obtain @ new waste disposal te

ECA. Atermaive 2 sa pre-aperoved activ under the Environmental Assessment Act but may require an

‘amendment the existing ECA

42.4 Altemative 4: Transport to Municipal WWTP via @ Transfer Station

CGHO explored transporting septge to thee area municipal wastewater treatment pants, including

“+ Meofort Wastewater Treatrent Plant curently restricted by bylaw to only accepting Sepge rom win

the borders ofthe Muniipaly of Meaford

+ Owen Sound Westewater Treatment Plant current undergoing a major upgrade and expansion that

doesnot incude provisions forte treatment of significant quantties of sepage from outside ts

‘municipal boundaries. To conslder his option futher the Township will need to make a fom request

‘Gwen Sound to determine # hey would be open to exploring this option.

+ Colingwood Wastewater Teatment Pan this isthe furthest of he thes WWTP, approxmataly

+40 km roundip. Colingwood does accept septage; however, the ably of Colingweod to accept

4100 percent ofthe Township's septage would need to be confrmed trough a formal request to

Ccotingwood

Conceptual capital and operating costs for sreening and transfer fait infrastructure requied for

‘Aternative 4 is similar to Aeratie 28 above, namely $68 per pump out. This atemate is more expensive

‘than land application but woud enable the cicontinuation of the practice of land application.

425 Alternative §: Localized Septage Treatment Facility

As part ofthis study, GHD explored four altemaiveseptagetreetment options sutable forthe Township,

including:

+ Altemative 2: Composting Facity— Composting is feasible atemativ forthe soi fraction ofthe

‘sepage. Ample bulking amendment, suchas woodchips, yard waste o cardboard is required to

‘balance the C1 rato septage and increase the porosity of tho mater o promote the aerobic

biological processes need to achive stabiization ofthe septage.

Raw soptage requires a dewatering sep suchas drying bed, treatment tench or mechanical separation.

‘Adryng bos utizes a layerof woodchips as ne of the ita ayers; these wood chips can then be used

12s the baking amendnent forthe composting operation. The quits fom mechanical separation wil

require further weatment on or oft. GHD has assumed a windrow composting system for this study

‘28 this ea lower cost option compared oan in-vesse! system, Pils are mechanical tumed petodeally

ih 2 front-end load era windrow turning machine to erease oxygen exposure,

“The 2012 Ontario Compost Quality Standards permit the use of dewatered coptage asa feedstock nthe

production ofA and Blevel composts, provided metals concentrations do nct exceed spectied levels;

but not AA compost. evel compost, which ean be comprised of st most 25 percent dwb' of dewatered

‘septage is exempt fram Part Vo the EPA and Ontario Regulation (0.Feg}) 347 and canbe soli 2s an

Unrestricted use prodst provided tis labeled as containing dewatered sepage.B level composts stil

considered a wast ad isnot exempt rom Pat V ofthe EPA and O.Reg, 847. B eve compost canbe

land applied as a Now Agicuturl Source Matra (NASM) under the Nutrient Management Act (NMA),

similar to how the digstate fom the Biodgester i curently managed. Both A and B level compost must

‘0 meet foreign mater, shaep foreign matter, pathogen reduction, meals and maturity requrements|

pected in the Standards, A matuty requirement that has been ctu or esting composting

‘operation to achieves maintaining the compost t greater than 40% moisture forthe etre compost

‘krng period. This stingent equiement coupled withthe cther compost qualty requirements make this

‘option technically cet to operate succesful.

+ Altemative Sb: Treatment Trench ~Trestment or dewatering trenches are more commonly found inthe

rural reas in notheer Ontario where they have been used since 1870, A dewatering tench consists of a

long, narow tench thats excavated in permeable sol to alow the qui faction ofthe sepiage to

nitrate into the grou and evaporate. Treatment renches area reaivel iow cost septage treatment

‘option but very few have sucesshilly been permite bythe MOECC. They require relatively ange

footprint but are relatetyo28y to operate and could be managed by Township staf. The sods left nthe

trench after the iquid action has nflvted and evaporated can be dec land applied or ested

further (8. compost)

‘Avsible MOECC treutment tench design guidelines are provided in Attachment fend a sizing

‘calelation is summarized inthe table below.

* Dry Weight Basis

Tabb 42

Concepts! Treatment Tench Sting

‘Annual eptage volume

Maximum Tresch Use

“otal Tench Volume

Distance Betwoen Trenches

Front Depth

End Depth

Length (20 —75:m)

Wath (1.5 buldoze blade widths)

Single TrenchVolume

Number of Trenches

‘Ste Length

‘Ste wa

Minimum Site Arca

4300 m?

“4 8es tench vlume in

‘2 month period

44100

15m

018m

10m

75m

4m

sam

8

200m

200m

4a (10.20)

“+ Altemative Sc ime Stabitzatio Faclly~ simlar to the W-Vro System included in the 2004 Grey

‘County Sepiage Management Plan. These systems apply Ime to dewatered septage to raise the pH to

stabilize the stage prot land appcation. The Niro Syston is capable of producing a marketable

ferlicer product Water ftom the dwaterng process woud requ further estment ono of-e, This

Stemative requires the smallest footprint of the four localized treatment optons in Atemative 5

“+Alternative 6 Lagoon Stabization Facility and Liquid Infitation or Spay tigation Field - this

‘ternative is slr to the Georgian Bis onginel Sunset Sirp sewage treatment fait tthe ste

‘were the Bodgester is co-ocated. The lagoons can be designed as facultative lagoons whe require

‘more area or incorporate an aeration cal wich reduces the feciprint but Increases the energy anc

operating cost.

localized treatment ternative would be sted close tothe center ofthe Township, wih bis towards

larger communities nthe Township, to minimize tucking distances. Alernaive§ woul be required to flow

‘he ull Class EA penning process (Schedule C) unless was sted at an existing eewage eatment plat,

land ste or organ soil condoning ste, Conceptual capa and opersing cost estimates foreach of the

‘above localized tecment options are summarized in Table 43 below.

0

Table 43 Conceptual Capita and Operating Cost for Localized Treatment Options

52 Composting inc, ‘51500000 $150,000 szarant 48

watering

Se! Composting — exc. $250,000 140,000 356235 $6

‘watering

5 Treatment Trench $200,000 $20,000 sera $30

Se Line Stabitzstion $1500.90 $180,000 serait sos

‘54 Lagoon Stabitzaton $1,500,000 $160,000, serait see

428 Altemative 6: Mobile Dewatering Truck to the Biodigester

[Amobte dewatering ruck s 2 spt tank vacuum ruck with integrated on-board dewatering equipment

‘Septage is pumped from the este tank through the dewatering uni. which may include an automatic

polymer dosing sytem. The fitered Inui are retumed othe septic tank. The dewatered sods are then

pumped tothe tk’ tank, Amabile dewatering truck, wth polymer dosing, is capable of approximately

10 percent volume reduction tthe cllected sepage. A radttonal pump truck can hoks2~3 septic tanks. A

“72m capacty bie dawatering rack can hold approximately 25 seplc tanks. This reduces septoge

‘haulage coats signficety. Ts makes more ease for the moble dewatering tuck to haul sptage

longer distances andor compete more pump ous over period of ime. However, mobile dewataring tucks

fre moce expensive than tredional pump aut ruck, aprepimataly double the cost ofa trations pump

truck

Mobile dewatering tucks are ot naw. This option was considered inthe 2004 Grey County Septoge

Management Pan but the tecinology avaiable a that ime was writen of as problematic and expensive. n

2010, Antigonish County in Nova Sects purchased 2 mobile dewatering tuck from ABCO Industries” in

Lunenburg, Nova Seo. In 2014, Dave Myers an opera for Antigonish County was quoted as saying,

"The tuck has pecfonmed 8 we had hoped for end has alowed us o grey reduce our costs.” Other

‘municipalities in Nova Scot have aleo sine purchased dewatering tucks fom ABCO Industries. GHD

Understands that ABCO Industries i curently in negotiations withthe rst cent n Ontariotopurchaes the

nt

* tpn abeocaldewateing-oqupment hin!

® np: tpomag,comlediori2014/02bosolds_management and headworks2

“The truck cote approximately $450,000. Phmer dosing requirements vary but are approximately

45 gallons per 270 pump ous. A45 gallon drum of the polymer speci formulated for ABCO Industries is

‘approximately $1200

427 Aterative:

bile Dewatering Truck tothe Lystok Facility

“Similar to Aternative 3 but wizing a mobile dewatering truck; see Section 42.6 fora summary ofthe mobile

‘dewatering tuck.

428 Alternative 6: Mobile Dewatering Truck toa Municipal Wastewater Treatment Plant

‘Siar to Atematve 4 but utlicing a mabe dewatering tuck in place of @tansfr ston; se Section 4.2¢

fora summary a he mobile dewataring tuck,

429° Attomativ

Mobile Dewatering Truck to a Dewatered Septage Composting Facily

‘Atorative © snr to Alternative 4 but ullizes 2 mobile dewatering truck o deliver dewatered septge to

‘a composting feity for treatment se Section 4.26 fora summary of the mobile dewatering tuck.

42.40 Altemative 10: Collect Additional Septage Outside ofthe Township with a Mobile Dewatering

“Truck and Dover tothe Biodigester

For the purposes of this evaluation, GHD has assumed that in any gen yer 1,000 pump outs may be

‘eauired in the Township and that a mable dewatering tuck thats delivering to a rater or treatment

feclitycan operate comfortably 200 days ofthe year. This would require # moble dewatering tuck to

‘average § mp ou pe day. This 's the same average used for radon pump tucks that ypically need

to unadispread ther tarks 1-2 tres per day. As an example, the average pump ous per days

Increased o6, of erate fhe tuck I operated an addtional 40 days nthe year or some combination

‘hereof, an addtonal 200 sep ystems can be serviced in a year, Utlting more ofthe capacity of the

‘ruck wl bring down the pup out costo individual ratepayers and generate acktonal revenves forthe

Townsti.

42:11. Atemative 14: Collect Addtional Soptage Outside ofthe Township with a Mobile Dewatering

‘Truck and Deliver tothe Lystok Facilty

‘Smart Aterative 10, Aterative 11 Is intended to demonstrate the impact of maximizing the capacty of

the mobile dewatring tuck to increase revenue to the Township and decrease costs to ratepayers inthe

Township.

5. Comparative Evaluation of Alternatives

“The folowing setons provide a description ofthe evaluation methodology, incusing cteria selection, and

the rut ofthe comparative analyis forthe atornatvesientfed in Section 4

54 Evaluation Methodology

“Thee primary erteria, namely social environmental and economic, were used to evaluate each atestive

|Witin each primary criterion, a numberof sub-crtera were used to determine the merits and detiments of

7 ateratves. The sub-tteria are both qualitative (eg, visual esthetics) and quartative (2.9 Mecyce

‘este. The thre pear ereria and her associated sub-rteria are summarized in Table 51 below.

Table 51 Evaluaton crtena

‘Social ‘Communty

Public Hoan & Safty

Land Use

Envtonmental Energy Consumption

(Greenhouse Gas Emissions

Resource Use

‘Waste Generation

‘Water Resources

Visual Aesthotics

‘Nuisance Odour

Economic Lie Cycle Costs

Far each sub crteron under the Social and Environment cits, score was provided based on a Superior,

1.0, Fair 0.5, and lnferor~0.0 scoring sytem Life Cyc Costs were weighted bya factor ofS to

balance out te weighting across the three primary criteria. Life Cycle Costs were also ranked fom 1 10 10.

“The prefered aecraive was determined based on the highest overall scoring total. Table 5.2 proves 8

‘summary of the comparative evaluation resus

52 Soclal Comparative Evaluation

524 Community

“This sub-cteror addresses the value of preserving and enhancing the existing community inctding green

space, privacy, quay of He, low population density, dark skies and url ambience,

“Te residents inthe Township are familar wth the current septage management procedies. is unlikely

that their ives wil be daturbed by the conned practice of septage spreading. However, the Blodigestr fs

«2 source of contoversy inthe communty, den par to unantipatod costs of the fait, and flue to

‘dress the Biodgester sues wil key have further Impact on residents Ives inthe community.

‘Ateratives that o not involve the construction of another septage Weatmen facity and that bth eliminate

land application ef soptage and addresses the Biodigeser issues wil be the most favoured by the

tame cy

‘community, Bulging 2 second eeptge treatment facily is expected to further cstur the qualtyof Me for

‘he residents

1522 Public Health and Safety

“Tis suberterin aderesses pubic heath and safety consideration foreach aematve

Any option thats reviewed and approved by the MOECC is considered to have ata score of at east fa. A

‘ofthe options considered would be or have been approved bythe MOECC under the appropriate

‘croumstances, The Treatment Trench, Atenative 8, is considered the rskiest in terms public heath and

‘safely and willbe the mst challenging to obtain the necessary approvals to implement.

‘Any option that involves treatment pret the appication of septage to land is considered superion

523. Land Use

“Tis sub-ceron addresses whether he atematve woul be compatible wih existing surrounding and use,

‘Option that involve the direct application of aw septage to sol, namely Atematives (Status Quo) and 8

(Treatment Trench, ans options that involve the sting of @new soptageteatmet fait are considered

inferior to options that involve no change o land use the community (0.9, mobile dewter tuck

ateratives)

524 Regulatory Obligations

“This sub-eneron axresses whether adstonl regulatory obigatons such as permit amendments or

increased reporting would be required to estabish an aternative

Alternatives that involve the contruction of @ new transferor restment fact wil have the most onerous

panning and permiting obigations. Using the Bioigester asa transfer facy wi requre upgrades that

nay inger an amendment to the ECA but no Clas EA requrements, A now Hauled Sewage (Sepiage)

‘Waste Management ECA wil be required to operate a mobile dewatering tuck.

53 Environmental Comparative Evaluation

53.4 Energy Consumption

‘This sub-eterionaddesses the energy used to process septage at each faci

“The Bodigester generates more energy than Itconsumes, this is considered superior. Larger teatment

{acities generally uz less energy per volume treated smater systems,

522 Greenhouse Gas Emissions

‘This quantitate sub-iterion, based on detance traveled, addresses the transportation lated GHG

emission associted wth each aternatve

533 Resource Use

“This eub-crterion adresses the opportunity to combine soptage treatment with cher waste processing

methods.

[Ateratves that involve the co-reatment of mutiple sources of waste and wastowatar are prefered. The

status quo sternative was scored as far as # provides valve asa ferizer while as its being stabilized over

time by natural processes.

534 Waste Generation

‘This sub-eterion adresses the total quanty of waste generated under each atemativ,

“The fal dieposal of unreated or vealed septage under al ofthe ateratives provides for some degre of

benefeial re-use, ARerratives that generate an unrestcted use fertizer product are prefered,

535 Water Resources

“This sub-rterion addresses the potential impact to surface water and groundwater resources foreach

‘atematve,

‘Ateratives that involve contact wi untreated septage to sol are considered to have the greatest sk to

‘surface and groundwater. The Lystokaloratves provide the highest degree of treatment and therefore are

‘considera to be the lowest nak. The remaining atematves were scored to have a fai level of sk.

536 Visual Aesthetics

‘This eub-eterion adresses the potntal sual impact ofeach atematve,

Ateratives that involve no new ifastructure are the mos prefered, flowed by enclosed bulings or

tanks. Treatment aeratives thal avlve larger open areas to handle the septage (eg. lagoons, enches

‘and compost windows) are the leas prefered

537 Nuisance Odeur

“This sub-erterion adresses the pont nuisance dour impact ofeach alternative,

"Nuieance odour was stored smi 0 visul aesthetics

54 Economie Comparative Analysis,

SAA Lifecycle Costs

‘This sub-eterion adnate the life cyte cost of establishing and operating each alternative expressed as

‘an Equivalent Annual Cost (EAC) to normalize the diferent sevice Ives of infrastructure versus equipment.

‘The cost estates previed inthis stuty ar intonded tobe for comparative evaluation purposes. The cost

estimates ae considered o be +70%i-50% sccurte. Table .3 summarize the capa an operating costs

for each atemative ar sub-aternatve.

scree 6

‘The EAC ofthe status quo ateratve fs $185 per pump out and ths remains among the mast cost efecive

alternatives, Table 54 Below lt the erative in order of increasing EAC.

Table $2. Aternatives Listed in Order of Equivalent Annual Cost

85 Atemate 1 Status Quo

sie

=e oS

50 Atemative > Localized Septage TrestmentFecity $250 2%

(restment Trench)

415 Atemative 8 Mobile Dewatering ruck to WWTP sas 1%

95 Atemative? Mobile Dewatering Truckto Composing «$275 41%

Fecity

405 Atemative2Bodigestor $208 53%

95 —Atemative3a_Transporto Lystek Facty aa Transfer «$328. 67%

Station

10.0 Atemative 3b Transporto Lystek Fact via Biodgester $370 90%

80 Atematve 4 Transportto Municipal WWTP va a Transfer $280 100%

‘Station

50 Atematve § Local Seplage Tretment Facity sar 118%

acd ‘(Compost Lime, Lagoon)

‘Those ateratves that contibuted revenue tothe Blosigesterfcity ware scored higher han ateratves

it sinar costs whore tip ees didnot go tothe Township. tip ee of $50 per tonne atthe Bodigstor was,

{etfor the dewatered saptage ff the mobile dewatering truck to maximize revenue forthe Biodgestr while

‘mainsiningovoral pump ou cost the ame asthe status quo opin. In adton to tp fe revenue,

supplying the Biodgestr wah addon feedstock alg increases the electcty generated and the revenues

from the sale of electri. Tho cogeneration uni eurrenty runing at approximtely 60 percent capac

eee 16

“Table 52 includes an actions column onthe far right that was included to demonstrate that wo mobile

dewatering tucks would be capble of sencing all othe septic systems inthe Townships of Chatswort

and Georgian Bits.

55 _Proferred Septage Management Aitemative

“The highest scored atematveas summarized in Tables 6.316 he usization of a mobile dewatering truck

reduce the septage pump out costs to ratepayers and deliver othe Bioigester. The prefered aterative

invoWes collecting adaona septage from outside the Township to futher reduce costs to ratepayers and

Increase revenues forthe Blocgester. A mobile dewatering ruck has the potenti to make delvery tthe

Blodigester cost compettve wth the status quo land application altoratve,

Delivery to the Lystekfacty alo scored high ands ela rice (well within the margins of ror ofthe

cost estimates) to delivery to te Bidigester.

6. Recommendation

‘Based onthe comparative evlustion of the septage management statis, GHD ecommends the

folowing

1. Complete a detaed cost satiate and feasibly study for utiizing a mobile dewatering tuck forthe

collection ofa septage inthe Township.

aN

Ey

step gees 3 B

atsh seers 22

senh sestaach 22

seth sisissce 22

seetk aestescp 22

seoap agssszeh 22

see ses2229}

i seersesh a3

sash sasaesap 23

i sgan ae Jar) ee

PXCC TU aay

FRM OF EIIRONENENT

‘5- LAND DISPOSAL BY DEWATERING TRENCHES,

General

‘Dewatering wenches are in essence exflition systems. They at as» carried contact area for surface

‘influ. The purpose ist lowiy introduce the liquid portion w the sol so thar the si bacteria can

‘ffsctively trear the liquids in th aerated zoe.

‘Du to the lack of spreading sits and or the lack of sewage treatment plats with capaciy to wear hauled

‘sewage in some areas ofthe Province, it was necessary to develop a method of resting hauled sewage that

‘was economical, effective and pracical,

Past Use

‘Dewatering systems have boen ia use in Nonher Ontario since 1970. Expetience has show tht shallow

‘arrow long trenches perform best. Deep wide pits do nat evaporate quicly and usualy workon 11

1.5 memes head which foees the liquid wouph the clogging mat ad ito the ol, Failures result fom the

sludge build up. ‘The main action i anaerobic and

posal bed do not adequnely reat the hauled sewage

‘and the lack of sll bacteria below I m shallow nszrow

‘wenches address the unsarrated zone and are located inthe sis containing 95% ofthe sil bacteria

‘needed w tear the hauled sewnge,

‘The flowing design considerations were developed ftom many years af experience from systems which

‘have worked wll and fiom systems which have filed but provide valuable information.

Basie Considerations for Site Applications

Large Sites - Consider the following for large dewatering ses:

1. Obuain a complete application.

2 sure thatthe land use is compatible wit local zoning and land use.

3. Address:

(A) Key map (150,000) mpographic, Tlusuaing the gmneral ste location,

(®) —_Actial photographs if available for drainage and oter impact consderaions.

(©) Site map indicating roads, watercourses, surface dinage, proposed beds plus

‘mre development, test wells, contours, and adjacent properties.

2 ects

FON OF ERENT

(D) Soils study, pe, depth, characteris, treatment capbilies and flow

capabiies,

©) Wate drainage, surface, ond subsurface, hydewulic gradiat, eaten,

Operational Plan - propose method of operation, snquence of trench use, odour

contol nse schedule, signing and site closure.

SA Distances

‘Because ofthe similacy to lagoons dewatering ses use the same or greater distance standards forthe

‘operational portion of the ste This s done using established eiteiacurrenty in use in Ontario, These

Вам также может понравиться

- Agenda Council Meeting September 7, 2016 With LinksДокумент1 страницаAgenda Council Meeting September 7, 2016 With LinksmassieguyОценок пока нет

- Adjustment and Planning Meetings September 7, 2016 With Links To Supporting DocumentsДокумент1 страницаAdjustment and Planning Meetings September 7, 2016 With Links To Supporting DocumentsmassieguyОценок пока нет

- List of Information Items For September 7, 2016 Council MeetingДокумент1 страницаList of Information Items For September 7, 2016 Council MeetingmassieguyОценок пока нет

- Rezoning - Martin SchoolДокумент16 страницRezoning - Martin SchoolmassieguyОценок пока нет

- B8 - 2016 Severance App'n Robson RD (Thompson)Документ5 страницB8 - 2016 Severance App'n Robson RD (Thompson)massieguyОценок пока нет

- July 20, 2016 Committee of Adjustment MinutesДокумент2 страницыJuly 20, 2016 Committee of Adjustment MinutesmassieguyОценок пока нет

- Sept 7, 2016 Adjust AgendaДокумент1 страницаSept 7, 2016 Adjust AgendamassieguyОценок пока нет

- Aug 17, 2016 Plan MinutesДокумент3 страницыAug 17, 2016 Plan MinutesmassieguyОценок пока нет

- Report WTR 16-16Документ4 страницыReport WTR 16-16massieguyОценок пока нет

- Agreement With Sus-Global Re Bio-DigesterДокумент47 страницAgreement With Sus-Global Re Bio-DigestermassieguyОценок пока нет

- Sept 7, 2016 Council AgendaДокумент1 страницаSept 7, 2016 Council AgendamassieguyОценок пока нет

- Accounts To Sept 1, 2016Документ14 страницAccounts To Sept 1, 2016massieguyОценок пока нет

- Aug 17, 2016 Council MinutesДокумент9 страницAug 17, 2016 Council MinutesmassieguyОценок пока нет

- Sept 7, 2016 Plan AgendaДокумент1 страницаSept 7, 2016 Plan AgendamassieguyОценок пока нет

- Quote - Community Centre FurnaceДокумент1 страницаQuote - Community Centre FurnacemassieguyОценок пока нет

- Culvert QuotesДокумент4 страницыCulvert Quotesmassieguy100% (1)

- Agenda 11.3 Cat Grader RepairДокумент1 страницаAgenda 11.3 Cat Grader RepairmassieguyОценок пока нет

- Agenda 13.1 - Canada 150 Amending AgreementДокумент5 страницAgenda 13.1 - Canada 150 Amending AgreementmassieguyОценок пока нет

- Report Fire 08-16Документ8 страницReport Fire 08-16massieguyОценок пока нет

- Report Building 08-16Документ3 страницыReport Building 08-16massieguyОценок пока нет

- By-Law 2016-75 Connecting LinkДокумент1 страницаBy-Law 2016-75 Connecting LinkmassieguyОценок пока нет

- Agenda 10.2 GM BluePlanДокумент3 страницыAgenda 10.2 GM BluePlanmassieguyОценок пока нет

- Agenda 11.1 SVCA ReportДокумент1 страницаAgenda 11.1 SVCA ReportmassieguyОценок пока нет

- Report RDS 15-16 Watch For Children SignsДокумент2 страницыReport RDS 15-16 Watch For Children SignsmassieguyОценок пока нет

- Agenda 10.1 OCIF Funding RedesignДокумент13 страницAgenda 10.1 OCIF Funding RedesignmassieguyОценок пока нет

- Agenda 11.2 - Damage Compensation RavensДокумент4 страницыAgenda 11.2 - Damage Compensation RavensmassieguyОценок пока нет

- Agenda 13.2 - Connecting LinkДокумент4 страницыAgenda 13.2 - Connecting LinkmassieguyОценок пока нет

- By-Law 2016-74 Canada 150 Amending AgreementДокумент1 страницаBy-Law 2016-74 Canada 150 Amending AgreementmassieguyОценок пока нет

- Agenda 10.3 VolunteersДокумент1 страницаAgenda 10.3 VolunteersmassieguyОценок пока нет

- Agenda 11.4 Winter SandДокумент1 страницаAgenda 11.4 Winter SandmassieguyОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)