Академический Документы

Профессиональный Документы

Культура Документы

Pipe Thickness Design Calculation 1500 MM

Загружено:

Satish Kumar Maurya0 оценок0% нашли этот документ полезным (0 голосов)

39 просмотров1 страницаPipe Thi

Оригинальное название

Pipe Thickness Design Calculation 1500 Mm

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPipe Thi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

39 просмотров1 страницаPipe Thickness Design Calculation 1500 MM

Загружено:

Satish Kumar MauryaPipe Thi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

303019573.

xls

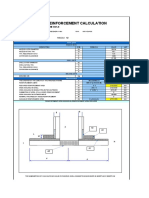

CALCULATION OF MINIMUM REQUIRED THICKNESS IN STRAIGHT PIPE

(ANSI B31.3 , PARAGRAPH 304.1)

xxxxxxxxxxxxxxxx

FOR 60" NOM. DIA. PIPE

DESIGN PRESSURE, P (PSIG) ::

DESIGN TEMPERATURE (DEG. F) :

MATERIAL GRADE :

BASIC ALLOWABLE STRESS, S (PSI) :

(AT DESIGN TEMP., TABLE A-1)

QUALITY FACTOR, E (TABLE 304.1.1) :

COEFFICIENT Y (TABLE 304.1.1) :

OUTER DIAMETER OF PIPE, D (MM) :

SUM OF ALLOWANCE, C (MM) :

(CORROSION, ERROSION, MECHANICAL)

MANUFACTURER'S MINUS TOLERANCE, Mtol (%) :

247

120

API 5L Grade X 42

25200

0.8

0.4

1524

1.6

0

12.5

RESULTS:

PRESSURE DESIGN THICKNESS, t (MM) :

t = (P x D) / 2 (SE + PY)

t =

MINIMUM REQUIRED THICKNESS, tm (MM) :

tm = t + c

tm =

MINIMUM REQUIRED THICKNESS, Tmin (MM) :

Tmin = 100 x tm / (100 - Mtol)

Tmin =

9.290481

10.89048

12.44626

SELECTED NOMINAL THICKNESS (MM) =

15

MECHANICAL PROJECTS

Page 1

K.P.MOHAMED ALI

Вам также может понравиться

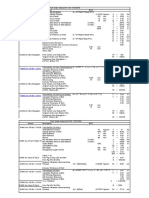

- ThicknessДокумент53 страницыThicknessRajul MuraliОценок пока нет

- Super CalculationsДокумент9 страницSuper CalculationsNoé MarínОценок пока нет

- AS4041 ASME B31 - 3 Pipe Wall ThicknessДокумент11 страницAS4041 ASME B31 - 3 Pipe Wall Thicknessamini_mohiОценок пока нет

- ASME II - Excel 1AДокумент196 страницASME II - Excel 1Arichward5Оценок пока нет

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Документ6 страницCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanОценок пока нет

- Pipe Wall Thickness (ASME B31.3)Документ12 страницPipe Wall Thickness (ASME B31.3)Rachmad HidayatОценок пока нет

- Design Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal PressureДокумент10 страницDesign Code: Asme B31.3 Process Piping - For Straight Pipe Under Internal Pressurefaisman100% (1)

- Calculation of Pipe Reinforcement ASME B31 3Документ4 страницыCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- SHELLДокумент6 страницSHELLSalz EngineeringОценок пока нет

- Pipes. Wall Thickness Calculation According ASME B31.3Документ125 страницPipes. Wall Thickness Calculation According ASME B31.3musaveerОценок пока нет

- If Any Data - Please Entry This Data: Equipment: Pressure VesselДокумент19 страницIf Any Data - Please Entry This Data: Equipment: Pressure VesselES RouzaОценок пока нет

- Nozzle Design CalculationДокумент1 страницаNozzle Design CalculationSachin55860% (1)

- AD 2000 HesapДокумент11 страницAD 2000 HesapBaşarŞenОценок пока нет

- ASME B31.3 - 2008 PipeCalculationДокумент6 страницASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Flange Asmeviii Div.1 App.2 Rev0Документ10 страницFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- Nozzle Calculations 01Документ32 страницыNozzle Calculations 01Rohith V VОценок пока нет

- Thickness Calculation of Pressure Vessel ShellДокумент16 страницThickness Calculation of Pressure Vessel ShellClaudia BonocoreОценок пока нет

- Reinf S1Документ2 страницыReinf S1tasingenieriaОценок пока нет

- Piping Wall Thickness Cal - Ver HT10.2-HTTEK FullДокумент47 страницPiping Wall Thickness Cal - Ver HT10.2-HTTEK Fullthinhvipro100% (1)

- Pipeextp-Asme Ug 28Документ1 страницаPipeextp-Asme Ug 28alvinchuanОценок пока нет

- Asme Sec 8 Div 1 - App 1-10Документ11 страницAsme Sec 8 Div 1 - App 1-10BibinBabuОценок пока нет

- Calculation of Wall Thickness MAWP API 5l x52 (Rev-2)Документ21 страницаCalculation of Wall Thickness MAWP API 5l x52 (Rev-2)YusepSúarðiОценок пока нет

- ASME VIII Calc - Shell - HeadsДокумент4 страницыASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Retirement ThicknessДокумент7 страницRetirement ThicknessKamal UddinОценок пока нет

- AS4041 ASME B31 - 3 Pipe Wall ThicknessДокумент8 страницAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Wall Thickness Calculation Followed B31.8 PDFДокумент3 страницыWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureДокумент1 страницаSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilОценок пока нет

- Asme B31.8 Nozzles CalcДокумент16 страницAsme B31.8 Nozzles CalcSAMER OSMANОценок пока нет

- Asme Viii Shell & Se HeadДокумент5 страницAsme Viii Shell & Se HeadSnr George RaczОценок пока нет

- Piping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Документ40 страницPiping & Bending and Straight Pipe - Required Minumum Wall Thickness Calculations (ASME B31.1 Power Piping 2010)Ahmet OVENОценок пока нет

- Thickness API 510Документ11 страницThickness API 510Aleiser Quevedo Acuña100% (1)

- Pipe Thickness Calculation AS Per ASME 31.3Документ11 страницPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRОценок пока нет

- Miter Bend Calculation: E W S D T' BДокумент4 страницыMiter Bend Calculation: E W S D T' BSong TaoОценок пока нет

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleДокумент25 страницPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidОценок пока нет

- ASME B31 8 Riser CalcДокумент12 страницASME B31 8 Riser CalcEmmanuel LawrenceОценок пока нет

- Middle East Petrochemicals Projects - tcm24-1518320Документ1 страницаMiddle East Petrochemicals Projects - tcm24-1518320Satish Kumar MauryaОценок пока нет

- HVAC Heat Load of A RoomДокумент2 страницыHVAC Heat Load of A RoomsamehОценок пока нет

- Shell Thickness Calculation: C WP F D WP TДокумент16 страницShell Thickness Calculation: C WP F D WP Tpatiltushar79Оценок пока нет

- Cong Thuc Tinh Toan Piping ThicknessДокумент108 страницCong Thuc Tinh Toan Piping ThicknessTruong Ngoc SonОценок пока нет

- Internal CoilДокумент2 страницыInternal CoilwhngomjОценок пока нет

- From Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaДокумент5 страницFrom Internet: Pipe Burst Working Pressure Calculator Barlow's FormulaDipakОценок пока нет

- Pipe Thickness Calculation PDFДокумент1 страницаPipe Thickness Calculation PDFHeny Martha67% (3)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantДокумент49 страницDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Оценок пока нет

- API 570 Exam CalculationsДокумент2 страницыAPI 570 Exam Calculationssnehal.deshmukhОценок пока нет

- Pipe Wall Thickness Calculations: Burnex Burner HeadДокумент16 страницPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156Оценок пока нет

- AST Heating Coil Design Calculation Rev 0Документ3 страницыAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- ASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcДокумент32 страницыASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcIonut FloricaОценок пока нет

- Pt. Pertamina Ep Asset 3 Field Jatibarang: Calculation SheetДокумент2 страницыPt. Pertamina Ep Asset 3 Field Jatibarang: Calculation Sheetrobiansah100% (1)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringДокумент4 страницыLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleОценок пока нет

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Документ1 страницаPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadОценок пока нет

- Thickness Calculation of Pressure Vessel ShellДокумент17 страницThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- Pipe Wall Thickness Calc Per ASME B31.8Документ1 страницаPipe Wall Thickness Calc Per ASME B31.8ktejankarОценок пока нет

- Pipe Thickness Calculations - : ClassДокумент1 страницаPipe Thickness Calculations - : ClassOluwachidiОценок пока нет

- Toriconical Head Ver 1.1Документ4 страницыToriconical Head Ver 1.1Iqbal AhmadsОценок пока нет

- (MN) (CR + Mo + V) (Ni + Cu) 6 5 15 + + Carbon Equivalent C +Документ1 страница(MN) (CR + Mo + V) (Ni + Cu) 6 5 15 + + Carbon Equivalent C +isnineОценок пока нет

- Appendix 1Документ22 страницыAppendix 1HudaFiHayyat0% (1)

- Pressure Vessel Inspection ReportДокумент34 страницыPressure Vessel Inspection ReportJinlong SuОценок пока нет

- Spectacle Blind FlangeДокумент3 страницыSpectacle Blind Flangel kishoreОценок пока нет

- 299 - Elliptical Head Design Tool Ver E4.01Документ1 страница299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaОценок пока нет

- Pipe Thickness Design Calculation 1500 MMДокумент1 страницаPipe Thickness Design Calculation 1500 MMSanda PribicОценок пока нет

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLДокумент13 страницCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedОценок пока нет

- B31 3 (Mygaz) - 1Документ1 страницаB31 3 (Mygaz) - 1Nasrul AdliОценок пока нет

- AbsorptionДокумент8 страницAbsorptionSatish Kumar MauryaОценок пока нет

- CleanAgent SHPPROДокумент21 страницаCleanAgent SHPPROmaruc08Оценок пока нет

- Amity International School, Saket Mental Maths Practice Sheet - 1 Name: - Class:II Sec: - DateДокумент4 страницыAmity International School, Saket Mental Maths Practice Sheet - 1 Name: - Class:II Sec: - DateSatish Kumar MauryaОценок пока нет

- Amity International School, Saket Class II Vocabulary Sheet: This/These/That/ThoseДокумент2 страницыAmity International School, Saket Class II Vocabulary Sheet: This/These/That/ThoseSatish Kumar MauryaОценок пока нет

- 235 GhaliДокумент5 страниц235 GhaliSatish Kumar MauryaОценок пока нет

- Muh 29 5 3 0407 17Документ12 страницMuh 29 5 3 0407 17widhisaputrawijayaОценок пока нет

- P 2003028 Eve HudДокумент12 страницP 2003028 Eve HudSatish Kumar MauryaОценок пока нет

- Pipe Sizes All SystemsДокумент2 страницыPipe Sizes All SystemsSatish Kumar MauryaОценок пока нет

- Amity International School, Saket Name: - Class I: - Date: - Addition Puzzle Q1) Solve The Given PuzzleДокумент5 страницAmity International School, Saket Name: - Class I: - Date: - Addition Puzzle Q1) Solve The Given PuzzleSatish Kumar MauryaОценок пока нет

- EntityДокумент1 страницаEntitySatish Kumar MauryaОценок пока нет

- How To Recover Windows LoaderДокумент15 страницHow To Recover Windows LoaderThea Marie SantarinОценок пока нет

- Trim Shop ScheДокумент4 страницыTrim Shop ScheSatish Kumar MauryaОценок пока нет

- Anna University, Chennai B.E. / B.Tech. Part Time Programmes Offered in The Affiliated Institutions of Anna University, Chennai Regulations 2014Документ1 страницаAnna University, Chennai B.E. / B.Tech. Part Time Programmes Offered in The Affiliated Institutions of Anna University, Chennai Regulations 2014dgk84_idОценок пока нет

- FMM Formulae ListДокумент7 страницFMM Formulae ListRajha Rajeswaran100% (1)

- PlumbingДокумент8 страницPlumbingMac ShaikОценок пока нет

- CH XBДокумент6 страницCH XBSatish Kumar MauryaОценок пока нет

- Amity International School, Saket: Class I Weekly Report (14.12.2015 To 17.12.2015) Subje CT Content TaughtДокумент2 страницыAmity International School, Saket: Class I Weekly Report (14.12.2015 To 17.12.2015) Subje CT Content TaughtSatish Kumar MauryaОценок пока нет

- Amity International School, Saket Name: - Class I: - Date: - Addition Puzzle Q1) Solve The Given PuzzleДокумент5 страницAmity International School, Saket Name: - Class I: - Date: - Addition Puzzle Q1) Solve The Given PuzzleSatish Kumar MauryaОценок пока нет

- آحاد مهندسیДокумент7 страницآحاد مهندسیBranden PowellОценок пока нет

- Test FiveДокумент1 страницаTest FiveSatish Kumar MauryaОценок пока нет

- Amity International School, Saket Holiday Homework of Class I For The Month of December 2015 - January 2016Документ2 страницыAmity International School, Saket Holiday Homework of Class I For The Month of December 2015 - January 2016Satish Kumar MauryaОценок пока нет

- Units of Viscosity PDFДокумент1 страницаUnits of Viscosity PDFArun BabuОценок пока нет

- Hazen Williams EquationДокумент1 страницаHazen Williams EquationSatish Kumar MauryaОценок пока нет

- Equivalent Length MethodДокумент1 страницаEquivalent Length MethodSatish Kumar MauryaОценок пока нет

- Pipe Support SpanДокумент4 страницыPipe Support SpanSatish Kumar MauryaОценок пока нет

- SI Base UnitsДокумент20 страницSI Base UnitsSatish Kumar MauryaОценок пока нет

- Inernal Act Dia CalcДокумент34 страницыInernal Act Dia CalcSatish Kumar MauryaОценок пока нет

- Design of Pressure Plastic PipeДокумент5 страницDesign of Pressure Plastic PipeAnonymous oVRvsdWzfBОценок пока нет