Академический Документы

Профессиональный Документы

Культура Документы

Rotary Pump Data Sheet

Загружено:

Ruzi Falahi KautsarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rotary Pump Data Sheet

Загружено:

Ruzi Falahi KautsarАвторское право:

Доступные форматы

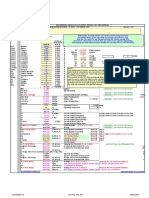

ROTARY PUMP (API 676-2ND) DATA SHEET U.S.

CUSTOMARY UNITS

Job No.

Imo Pump

Date

No

Data Sheet No.

By Revision

1710 Airport Road

Date

Monroe North Carolina 28111 USA

By

1 APPLICABLE

TO:

PROPOSAL

PURCHASE

AS BUILT

2 FOR

Chevron Pipeline Company

UNIT

3 SITE

San Ardo Pump Station - Monterey County, CA

NO. OF PUMPS REQUIRED

4 SERVICE

Crude Oil Shipping Pumps

5 MANUFACTURER

6 NOTE:

SIZE AND TYPE

Imo Pump

Three (3)

DLH12DHDT-400P (Final Model by Vendor)

SERIAL NO.

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER

BY MANUFACTURER

GENERAL

7

8 NO. MOTORS DRIVEN

Three (3)

9 PUMP ITEM NO'S

P-5, P-6, & P-7

OTHER DRIVER TYPE

10 MOTOR ITEM NO'S

M-5, M-6, & M-7

DRIVER ITEM NO'S

GEAR ITEM NO'S

11 MOTOR PROVIDED BY

Pump Vendor

DRIVER PROVIDED BY

GEAR PROVIDED BY

12 MOTOR MOUNTED BY

Pump Vendor

DRIVER MOUNTED BY

GEAR MOUNTED BY

DRIVER DATA SHEET NO.

GEAR DATA SHEET NO.

13 MOTOR DATA SHEET NO.

OPERATING CONDITIONS

14

15 x CAPACITY @ PT (GPM):

115-320

16

115-320

@ MAXIMUM VISCOSITY

LIQUID

x

@ MIN. VISCOSITY

115-320

MAXIMUM

2000

NORMAL

MINIMUM

1000

19 x SUCTION PRESSURE (PSIG):

20

MAXIMUM

100

MINIMUM

MAXIMUM

1975

24

MAX

SPECIFIC HEAT

0.44

VISCOSITY (SSU)

98 cSt.

0.983

200

MIN

MAXIMUM

140 (See Note)

1.00

MINIMUM

0.9

Cp (BTU/lb F)

MINIMUM

177 cSt.

MAXIMUM

CORROSIVE/EROSIVE AGENTS

MINIMUM

23 x NPSH AVAILABLE (FT.)

##

SPECIFIC GRAVITY

25

San Ardo Heavy Crude Oil

21 x DIFFERENTIAL PRESSURE (PSI)

22

TYPE OR NAME OF LIQUID

x PUMPING TEMPERATURE (F):

17 x DISCHARGE PRESSURE (PSIG):

18

Approved

CHLORIDE CONCENTRATION (PPM)

900

55

HYDRAULIC HP

H2S CONCENTRATION (PPM)

LIQUID

100 PPM

x FLAMMABLE

TOXIC

OTHER

25

26

27 x RATED CAPACITY (GPM)

SITE AND UTILITY DATA

PERFORMANCE

115-320

LOCATION

28 x

NPSH REQUIRED (FT.)

6.50 NIPR

29 x

RATED SPEED (RPM)

680 - 1707 @ 180 F, 700 - 1740 @ 200 F

30 x DISPLACEMENT (GPM)

31 x

32

SITE DATA

UNUSUAL CONDITIONS

BHP @ MAXIMUM VISCOSITY

435 @ 180 F

34 x

BHP @ RELIEF VALVE SETTING

474 @ 180 F

35 x

MAXIMUM ALLOWABLE SPEED (RPM)

36 x MINIMUM ALLOWABLE SPEED (RPM)

DUST

39

CONNECTIONS

40

SUCTION

41

DISCHARGE

42

GLAND FLUSH

43

DRAINS

44

VENTS

OTHER

600

UTILITY CONDITIONS

45

JACKET

ELECTRICITY

ANSI

RATING

FACING

POSITION

##

CONTROL

SHUTDOWN

24VDC

24VDC

HERTZ

60

60

DC

DC

PHASE

1500

RF

Top

COOLING WATER

Top

TEMP F

MAX

Side

PRESS. (PSIG)

MIN

INLET

RETURN

DESIGN

MAX

MAX

MIN

PRESSURE (PSIG)

INTRN'L GEAR

EXTRN'L

GEAR

APPLICABLE SPECIFICATIONS:

TWIN-SCREW

VANE

3-SCREW

PROGRESSING CAVITY

API 676 POSITIVE DISPLACEMENT PUMPS - ROTARY

x

49 GEAR TYPE

OTHER

120VAC

INSTRUMENT AIR

48

51

II

SOURCE

47

SPUR

HEATING

Top

RF

20

480

46 PUMP TYPE:

50

DRIVERS

RF

600

DIV

VOLTAGE

600

*1/2NPT

SALT ATMOSPHERE

3/4"

GROUP

TROPICALIZATION REQD

FUMES

1930 @ 180 F, 2000 PSI

CONSTRUCTION

SIZE

UNDER ROOF

1

RANGE OF AMBIENT TEMPS:MIN/MAX

33 x

38

ELECTRICAL AREA CLASS

87.3 - 94.9 @ 180 F

MECHANICAL EFFICIENCY (%)

37

UNHEATED

WINTERIZATION REQD

115-320

VOLUMETRIC EFFICIENCY (%)

x OUTDOOR

INDOOR

HEATED

HELICAL

F:\Auctions and Private Sales\2010 Online Auctions\2010.10.27\Chevron - 2009.08.31 - Pumps

GOVERNING SPECIFICATION (IF DIFFERENT)

Chevron 676 Exceptions

REMARKS:

& Misc - Kettleman, CA - Dave M\Field Services\Attachments\[San Ardo API Data Sheet BB 7-19-06.xls]API676

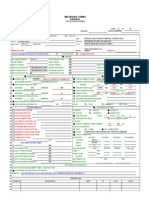

Job No.

Imo Pump

Date

No

Data Sheet No.

By Revision

1710 Airport Road

Date

Monroe North Carolina 28111 USA

By

CONSTRUCTION (CONTINUED)

MATERIALS

x

2 CASING

3 x

MAXIMUM ALLOWABLE PRESSURE:

4 x

HYDROSTATIC TEST PRESSURE:

2200

4500

STEAM JACKET PRESSURE:

ROTOR MOUNT

BTWN.

TIMING GEARS

YES

BEARING TYPE:

RADIAL

LUBRICATION TYPE:

10

PUMPED FLUID

11

250

AMB

BEARINGS

F

F

END PLATES

Fabricated Steel

ROTOR (S)

Nitrolly 135 Gas Nitrided to Rockwell C

OVERHUNG

VANES

NO

SHAFT

THRUST

OIL

FLOOD

Ball

SLEEVE (S)

GLAND

GREASE

TIMING GEARS

SPECIAL MATERIAL TESTS

Sealed Ball Bearing

LOW AMBIENT TEMP. MATERIALS TESTS

MANUFACTURER AND MODEL

Crane

15

MANUFACTURER CODE

CF-SP--77302-2 Rev. C

16

API 610 SEAL FLUSH PLAN

17

API 610 SEAL CODE

18

PACKING:

QA INSPECTION AND TEST

8-1

COMPLIANCE WITH INSPECTORS CHECK LIST

x CERTIFICATION OF MATERIALS

FINAL ASSEMBLY CLEARANCES

LANTERN RING

MFR. AND TYPE

SURFACE AND SUBSURFACE EXAMINATIONS

NO. OF RINGS

RADIOGRAPHY

DRIVE MECHANISM

20

21 x DIRECT-COUPLED

ULTRASONIC

V-BELT

COUPLING MANUFACTURER

GEAR

MAGNETIC PARTICLE

LIQUID PENETRANT

Thomas Series 71

DRIVERS

23

CLEANLINESS PRIOR TO FINAL ASSEMBLY

24 x MOTOR:

HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES

25 x

MANUFACTURER

26 x

TYPE

27 x

FRAME NO.

28

FURNISH PROCEDURES FOR OPTIONAL TESTS

Reliance

Horizontal

TESTS

CONSTANT SPEED

30 x

HP

31 x

VOLTS

32 x

HERTZ

33 x

ENCLOSURE

35

MEHANICAL

500

RPM

1800

480

PHASE

60

SERVICE FACTOR

42

43

44

PREPARATION FOR SHIPMENT

x DOMESTIC

EXPORT

EXPORT BOXING REQ'D

x OUTDOOR STORAGE MORE THAN 6 MONTHS

TEFC

WEIGHTS (LBS)

PUMP

2800

BASE

1500

UNITS

x U.S. CUSTOMARY

RELIEF VALVES BY PUMP MFRG

x

SI

n/a

DRIVER

INTERNAL

BY PUMP MANUFACTURER

EXTRNL.

SUBSOLE PLATES BY PUMP MANUFACTURER

x DRAIN-RIM

DRAIN-PAN

OTHERS

PIPING FOR COOLING/HEATING FURNISHED

BY:

PUMP VENDOR

OTHERS

x PROVIDE TECHNICAL DATA MANUAL

5 Copies, No CD

*Vent for Gland to have 1/2" NPT with Pipe Nipple and mounted Pressure Switch, supplied by Pump Vendor.

45 REMARKS

46

Pump to be furnished with Inboard and Outboard RTD's.

47

Provision to be supplied for quantity one Vibration Sensor Sensor, supplied and mounted by Chevron in field.

48

Pump must be suitable for second pipeline flush application. Pump and motor to be rated for 2000 PSI Discharge on KLM Crude viscosity 13.1-37.1 cSt.

49

Note: Motor will be torque controlled during cold start condition at 140 F, viscosity of 726 cSt.

50

Pump Vendor to Supply 2-Year Extended Warranty on Babbitt Rotor Housing

51

TBD

x SUITABLE FOR EPOXY GROUT

EXTENDED FOR

PIPING FOR SEAL FLUSH FURNISHED BY:

x PUMP VENDOR

GEAR

BASEPLATE

OTHER PURCHASER REQUIREMENTS

39

41

NPSH

OTHER (SEE SEPARATE DATA SHEETS)

38 NAMEPLATE

OBS

RUN

Chevron Spec. DRI-DS-1824

37

40

WIT

PERFORMANCE

STEAM TURBINE

36

REQ'D

HYDROSTATIC

G5012 Z

29 x VARIABLE SPEED

34 x

Fabricated Steel

BEARING HOUSING

14

22 x

(S)

OIL MIST

13 x MECHANICAL SEALS

19

Fabricated Steel

RING OIL

LUBRICANT TYPE

CASING

x STATOR

CONSTANT LEVEL OILERS

EXTERNAL

12 x

PSIG @

PSIG @

PSIG

Approved

Вам также может понравиться

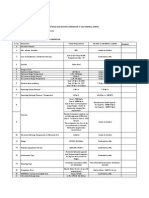

- API STD 676-2009 - Hoja de RequisiciónДокумент28 страницAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroОценок пока нет

- 674 Reciprocating Pump DatasheetsДокумент6 страниц674 Reciprocating Pump DatasheetsAKSHEYMEHTAОценок пока нет

- DAT Centrifugal PumpДокумент5 страницDAT Centrifugal PumpEDUARDOОценок пока нет

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Документ2 страницыMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqОценок пока нет

- Api 676 UsДокумент2 страницыApi 676 UsAbhai Gupta100% (1)

- Filter CalculationДокумент4 страницыFilter CalculationRashmi RanjanОценок пока нет

- Compressor Performance CalculatorДокумент28 страницCompressor Performance CalculatorEslamShebl100% (2)

- Pressure Drop CalculationДокумент30 страницPressure Drop CalculationEbby Onyekwe100% (1)

- Api 617Документ14 страницApi 617ecsuperal100% (1)

- Claus Process CalculationДокумент105 страницClaus Process CalculationDaniel SetyadiОценок пока нет

- PSV SizingДокумент8 страницPSV SizingMinh DoОценок пока нет

- Calculation Cover SheetДокумент3 страницыCalculation Cover SheetKids StrolaОценок пока нет

- TR0038-3 - Valve-ActuatorsДокумент49 страницTR0038-3 - Valve-ActuatorsMaffone NumerounoОценок пока нет

- Line Sizing ProgramДокумент14 страницLine Sizing ProgramYakubuОценок пока нет

- Valve Sizing SelectionДокумент15 страницValve Sizing SelectionbariОценок пока нет

- Valve SizingДокумент6 страницValve Sizingcarlosiq37Оценок пока нет

- Liquid Line SizingДокумент12 страницLiquid Line Sizinglolofm25Оценок пока нет

- Calculation Sheet For Pump Hydraulic (Fps Unit)Документ1 страницаCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiОценок пока нет

- (API 674-2nd) Reciprocating PumpДокумент6 страниц(API 674-2nd) Reciprocating PumpadistiОценок пока нет

- Pump Specification Data SheetДокумент3 страницыPump Specification Data SheetMelvin MagbanuaОценок пока нет

- HeatExchanger ReportДокумент5 страницHeatExchanger ReportNur Izzati KamrulnizamОценок пока нет

- Sizing of Restriction OrificesДокумент4 страницыSizing of Restriction OrificesYakubuОценок пока нет

- Pump Sizing ParametersДокумент1 страницаPump Sizing ParametersBramJanssen76Оценок пока нет

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientДокумент9 страницPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRapee PuaksungnoenОценок пока нет

- Liq Expansion CalculationsДокумент4 страницыLiq Expansion CalculationsGary JonesОценок пока нет

- Vapour Recovery UnitДокумент129 страницVapour Recovery UnitSrinivas BobbyОценок пока нет

- Pumps Calculations 1409Документ6 страницPumps Calculations 1409ejzuppelli8036Оценок пока нет

- Strainer Screen & Mesh Selection GuideДокумент4 страницыStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Instrumentation GPSA HandbookДокумент6 страницInstrumentation GPSA HandbookmusaveerОценок пока нет

- Orifice Plate Sizing PDFДокумент18 страницOrifice Plate Sizing PDFalexmuchmure2158Оценок пока нет

- How To Size Piping For Pump-Discharge ConditionsДокумент8 страницHow To Size Piping For Pump-Discharge Conditionssateesh chand100% (5)

- Equipment Design BasisДокумент4 страницыEquipment Design BasisAnjani GantiОценок пока нет

- KSB MIL Control Valves Specification V0998-SPECДокумент36 страницKSB MIL Control Valves Specification V0998-SPECNutan PowerОценок пока нет

- PumpSizing SelectionДокумент18 страницPumpSizing SelectionJessicalba LouОценок пока нет

- The Weby's: PSV Selection For BeginnerДокумент15 страницThe Weby's: PSV Selection For BeginnerShanmuga MuthukumarОценок пока нет

- StrainerДокумент2 страницыStrainerRanjithОценок пока нет

- DHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageДокумент61 страницаDHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageThanh Tin NguyenОценок пока нет

- Pump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignДокумент19 страницPump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignJОценок пока нет

- Draining Time (Gravity Flow)Документ2 страницыDraining Time (Gravity Flow)Saeid Rahimi MofradОценок пока нет

- Specification For Centrifugal Pumps White Oil TerminalДокумент96 страницSpecification For Centrifugal Pumps White Oil TerminalJackfusionОценок пока нет

- Calculate Flow Rate From Differential PressureДокумент27 страницCalculate Flow Rate From Differential PressureThang Hoang Anh100% (1)

- Curriculum Vitae: Personal Details Name Selvan. C.JДокумент4 страницыCurriculum Vitae: Personal Details Name Selvan. C.JLe Thanh HaiОценок пока нет

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Документ41 страницаTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGОценок пока нет

- PSV Calculations & FlareДокумент147 страницPSV Calculations & FlareAnonymous q95lwCg100% (2)

- Process Design Training: Line SizingДокумент44 страницыProcess Design Training: Line SizingAnonymous fwKgPAW50% (2)

- Orifice Plate Calculator Pressure Drop CalculationДокумент6 страницOrifice Plate Calculator Pressure Drop Calculationlutfi awnОценок пока нет

- Oil Cooler - Pre Design Data SheetДокумент3 страницыOil Cooler - Pre Design Data SheetSakthi VelОценок пока нет

- Control Valve SizingДокумент3 страницыControl Valve SizingN. S. PanditОценок пока нет

- Instrument Process Datasheet (IPDS)Документ3 страницыInstrument Process Datasheet (IPDS)Vraja KisoriОценок пока нет

- Centrifugal DesignДокумент44 страницыCentrifugal DesignJeyaraj LawerenceОценок пока нет

- Manual On Chilled Water Pump CalculationsДокумент18 страницManual On Chilled Water Pump CalculationsImas Mnu AbdОценок пока нет

- 4-10 Vacuum Stress in Pipe PDFДокумент11 страниц4-10 Vacuum Stress in Pipe PDFChristopher BrownОценок пока нет

- Hoja de Datos API-674Документ5 страницHoja de Datos API-674texwan_Оценок пока нет

- API 674 Pump Data SheetДокумент5 страницAPI 674 Pump Data SheetEason Ng100% (2)

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsДокумент10 страницReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Pump DatasheetДокумент10 страницPump DatasheetPaulusIwan100% (1)

- DATA SHEET MULTIPHASE PUMP REV0 BornermanДокумент5 страницDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- API 674 Pump Data SheetДокумент5 страницAPI 674 Pump Data SheetFahmi AtriadiОценок пока нет

- Fire Fighting Pupms Data SheetДокумент18 страницFire Fighting Pupms Data SheetnourfarmajidОценок пока нет

- Technical Comparison Format - Process Gas Reciprocating CompressorДокумент11 страницTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- ChecklistДокумент2 страницыChecklistRuzi Falahi KautsarОценок пока нет

- Penomoran DokumenДокумент1 страницаPenomoran DokumenRuzi Falahi KautsarОценок пока нет

- Ta 10091001058Документ20 страницTa 10091001058Ruzi Falahi KautsarОценок пока нет

- Chord From This MomentДокумент2 страницыChord From This MomentRuzi Falahi KautsarОценок пока нет

- Tk-4082 Research Project of Bioprocess Engineering 1Документ1 страницаTk-4082 Research Project of Bioprocess Engineering 1Ruzi Falahi KautsarОценок пока нет

- Process Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyДокумент8 страницProcess Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyRuzi Falahi KautsarОценок пока нет

- HG Sundstrand 20series Catalog 2013 Web PDFДокумент34 страницыHG Sundstrand 20series Catalog 2013 Web PDFWidiMufantoОценок пока нет

- HyfrauliqueДокумент108 страницHyfrauliquelionel henriquesОценок пока нет

- Datasheet For FiltersДокумент13 страницDatasheet For FiltersAntonio MendesОценок пока нет

- Roughing PumpДокумент37 страницRoughing PumpgabrielobОценок пока нет

- MD-217-7000-EG-ME-SPC-0002 - Fuel Tanks and PumpsДокумент11 страницMD-217-7000-EG-ME-SPC-0002 - Fuel Tanks and PumpsUmair RazaОценок пока нет

- Dokumen - Pub - A Dictionary of Mechanical Engineering 9780199587438Документ1 237 страницDokumen - Pub - A Dictionary of Mechanical Engineering 9780199587438nestorОценок пока нет

- Manualdemontagemecalibragemdebombavezexel 150821011345 Lva1 App6892 PDFДокумент71 страницаManualdemontagemecalibragemdebombavezexel 150821011345 Lva1 App6892 PDFMichael Wohali0% (1)

- Centrifugal Pumps PDFДокумент114 страницCentrifugal Pumps PDFNovancy100% (2)

- CETOP EduBook GeneralДокумент33 страницыCETOP EduBook GeneralManuel VizcarraОценок пока нет

- Spec Loader Hitachi Ex2500-6Документ14 страницSpec Loader Hitachi Ex2500-6Zdulkurnain MuhamadОценок пока нет

- Saudi Standards, Metrology and Quality Org. (SASO)Документ17 страницSaudi Standards, Metrology and Quality Org. (SASO)Edwin Alexander Perilla RamirezОценок пока нет

- Norsok n-003 Actions and Action EffectsДокумент60 страницNorsok n-003 Actions and Action EffectsnicОценок пока нет

- STS-040 Mi3007 6in STS Series375 D8 WebДокумент8 страницSTS-040 Mi3007 6in STS Series375 D8 Webrhusseinpos4765Оценок пока нет

- Electric Submersible Pump BasicsДокумент146 страницElectric Submersible Pump BasicsAbhoe Stank100% (6)

- Mini Project TopicsДокумент15 страницMini Project TopicsKalai SelvanОценок пока нет

- TLD WSP-900 Water Truck SpecsДокумент2 страницыTLD WSP-900 Water Truck SpecsPhat DinhОценок пока нет

- Pump Training Slides Slides 1 - 20Документ20 страницPump Training Slides Slides 1 - 20Jegede OluwaseunОценок пока нет

- Innovative Hydraulic Design-IHDДокумент9 страницInnovative Hydraulic Design-IHDAlissaFlashОценок пока нет

- EH-SolutionsLibrary 999902104 1Документ16 страницEH-SolutionsLibrary 999902104 1Alfonso Lopez toroОценок пока нет

- Pemco OperationsДокумент76 страницPemco OperationsRodrigo PereiraОценок пока нет

- Connect Touch - Aquaciat LD IldДокумент44 страницыConnect Touch - Aquaciat LD Ildumarmirza83Оценок пока нет

- E-Notes PDF All-Units 20052019041653PM PDFДокумент164 страницыE-Notes PDF All-Units 20052019041653PM PDFaadil agavanОценок пока нет

- Hydraulic Unit: C P B M 0 0 0 - 2Gh - 1Документ14 страницHydraulic Unit: C P B M 0 0 0 - 2Gh - 1MoshMedОценок пока нет

- Water Treatment Plant DesignДокумент36 страницWater Treatment Plant Designnopime100% (3)

- Hydraulic GoTo 2016-4Документ210 страницHydraulic GoTo 2016-4Tecno Industrias C.A.Оценок пока нет

- Specification For Internal Gear Pumps: 1.0 General DescriptionДокумент7 страницSpecification For Internal Gear Pumps: 1.0 General DescriptionHassan ShafiqueОценок пока нет

- Procedure For Bearing Replacement - OdtДокумент3 страницыProcedure For Bearing Replacement - OdtAugustine Porbeni100% (1)

- Presentation On - : Horizontal Centrifugal PumpДокумент78 страницPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Cal Val Refile ValveДокумент1 страницаCal Val Refile Valvesourav samadderОценок пока нет

- 02 - Triplex PumpsДокумент83 страницы02 - Triplex PumpsJitendra GautamОценок пока нет