Академический Документы

Профессиональный Документы

Культура Документы

Compare kiln capacities and specifications

Загружено:

gvrrИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compare kiln capacities and specifications

Загружено:

gvrrАвторское право:

Доступные форматы

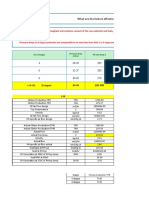

KILN COMPARISON

Description

Crusher:

Make

Type of crusher

Installed capacity

Operating capacity

Drive rating

TPH

TPH

KW

Madras Cements

Line - 1

Madras Cements

Line - 1

SHREE CEMENTS SHREE CEMENTS

Unit - 1

Unit - 2

UTLRATECH CEMENT VASAVADATTA CEMENTS VASAVADATTA CEMENTS

Tadipatri

Unit - 1

Unit - 2

PENNA CEMENTS

GANESH PAHAD

M/s MMD Ltd, UK

M/s MMD Ltd, UK

L & T Ltd

L & T Ltd

HAZEMAG

Hazemag

L & T:APCM 1615

Roller

1000

900

2 X 250

Roller

300

250

250

Single rotor impactor

Not in operation

Not in operation

500

Single rotor impactor

800

500

950

APPM 2022

1200

1300

950

Impact

800

800

1000

Impact

350

280

330 + 550

Loesche LM 38.3

Loesche LM 38.3

FLS, Atox 37.5

MPS4750B

Peiffer Germany

FLS Atox 50

Raw Mill:

Make

Type of Mill

Installed capacity

Operating capacity

Type of separator

Drive rating

Fan rating

VRM

220

235

LSKS 55

1750

1750

VRM

225

235

LSKS 55

1750

2200

VRM

180

225

Dynamic RAR 3S

1600

1110

VRM

300

370

Dynamic

2710

2400

VRM

265

325

RAR 50

4100

3200

Product fineness (Residue) %

15 to 20% on 90

15 to 20% on 90

15 to 18% on 90

1.8 to 3.0% on 212

20 to 23% on 90

Coal Mill:

Make

Type of Mill

Installed capacity

Operating capacity

Type of separator

Drive rating

Fan rating

Loesche LM 20.2

VRM

23

25

LKS 40 ZD

400

750

Loesche LM 20.2

VRM

23

27

LKS 36 ZD

400

750

FLS

VRM

25 (with coal)

10 (with petcoke)

Dynamic RAKM 236

300

220

FLS

VRM

38 (with coal)

20 (with petcoke)

Dynamic

500

585

FLS Atox 50

VRM

70

72

RAKM 32.5

950

950

25 to 30% on 90

25 to 30% on 90

2.5 to 3.5% on 90

2.6 to 3.8% on 90

Fuller - USA

3000

3300

3.75 X 57 m Long

5

Fuller - USA

3000

3300

3.75 X 57 m Long

5

L & T, FLS

1800

3250

3.95 X 56 m Long

4

TPH

TPH

KW

KW

TPH

TPH

KW

KW

Product fineness (Residue) %

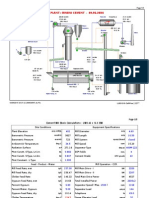

Kiln:

Make

Installed capacity

Operating capacity

Kiln Dimensions

No. of pre-heater stages

Overall PH pressure drop

PH Fan rating

Kiln volumetric loading

Cooler:

Make

Capacity

No. Of cooler fans

Cooler area

Cooler vent fan rating

Cooler sp. Loading

TPD

TPD

m

Polysius

Polysius

WIL

Two chamber Central

discharge closed circuit

VRM

VRM + Ball mill

ball Mill

140

210+50

135

145

270

200

Static

Dynamic

Dynamic SD-110

2000

2850

2 * 1500

1200

2000

750

28 to 29% on 90 & 8.5 to 28 to 29% on 90 & 8.5 to 22 to 24% on 90 &

9.0% on 212

9.0% on 212

6 to 7% on 212

14.0% on 90

Polysius

VRM

19

17 to 19

Static

315

215

14.5/0.8 Main & 19.5/1.6

PC

Polysius

VRM

26

22 to 26

Dynamic

400

350

14.5/0.8 Main & 19.5/1.6

PC

WIL

Closed circuit ball mill

16

22

Static

600

132

22 to 24% on 90 & 2

to 3% on 212

KHD

3700

4500

4.40 X 60 m Long

6, double string

FLS

6500

8000

4.75 X 75m Long

6

Polysius

1500

2400

3.60 X 56m Long

5

Polysius

2000

3500

4.00 X 60 m Long

5

WIL

2200

3100

3.60 X 54m Long

5

650-700 Kiln string

&700 to 750 - Pyro

string

2400 & 1425KW

7.18

500

1200

5.20

550

1500

5.73

850

1500

6.96

fls coolax

8000

16

141

585

56.7

Polysius IKN

2282

7

52

132

43.9

Polysius IKN

3450

8

65

250

53.1

WIL, CIS-MFR

2200

6

55.69

160

55.7

mmWG

KW

t/d/m3

710 (at fan inlet)

1750

6.57

605 (at fan inlet)

1750

6.57

600 (at fan inlet)

1600

5.86

600 - Kiln string & 850

- Pyro string

1600 & 770

7.37

TPD

Nos

m2

KW

T/d/m2

Fuller CIS-CFG-RFT

3300

10

47.52

250

69.4

SF Crossbar cooler

3300

5

71.72

175

46.0

FOLAX

1800

7

72

225

25.0

KHD

3700

10

92

365

40.2

Вам также может понравиться

- High VM Coal With 3% SulphurДокумент1 страницаHigh VM Coal With 3% SulphurIrshad HussainОценок пока нет

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesДокумент3 страницыRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliОценок пока нет

- False air measurements at Ambuja Cements Rabriyawas plantДокумент665 страницFalse air measurements at Ambuja Cements Rabriyawas plantSantanu PachhalОценок пока нет

- Finish Grinding Ball Mill Interlocks-V0.0Документ5 страницFinish Grinding Ball Mill Interlocks-V0.0Junaid MazharОценок пока нет

- Air Slide Data SheetДокумент2 страницыAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdОценок пока нет

- Heat Balance DataДокумент6 страницHeat Balance DataOuaddani amineОценок пока нет

- Fan Flow - CementДокумент5 страницFan Flow - CementharikrushnaОценок пока нет

- Cement raw material gas flow balance sheetДокумент4 страницыCement raw material gas flow balance sheetAli Hüthüt100% (1)

- Optimize cement kiln grate speed productionДокумент3 страницыOptimize cement kiln grate speed productionrudye kardunОценок пока нет

- Presep Air Separator VTP enДокумент6 страницPresep Air Separator VTP enBrunoОценок пока нет

- CEMENT MILL NO 2 DATASHEETДокумент2 страницыCEMENT MILL NO 2 DATASHEETThaigroup CementОценок пока нет

- Preheater Cyclone Dsigns: Tube Dia X EntryДокумент6 страницPreheater Cyclone Dsigns: Tube Dia X EntrynileshОценок пока нет

- Combustion Air Fan CalculationДокумент2 страницыCombustion Air Fan CalculationVijay BhanОценок пока нет

- Clinker CoolersДокумент17 страницClinker Coolersemad sabri0% (1)

- Raw Grinding Ball Mill Interlocks-V0.0Документ2 страницыRaw Grinding Ball Mill Interlocks-V0.0Junaid MazharОценок пока нет

- Calculation of Grindability From Bond'S Work Index PlantДокумент2 страницыCalculation of Grindability From Bond'S Work Index PlantAnoop TiwariОценок пока нет

- Heat Balance Kiln & Cooler P 6: InstructionsДокумент32 страницыHeat Balance Kiln & Cooler P 6: Instructionstika100% (1)

- RPM Kiln Vs FDДокумент2 страницыRPM Kiln Vs FDTIRIANTOОценок пока нет

- Pheater Heat BalanceДокумент2 страницыPheater Heat BalanceRaji SuriОценок пока нет

- Weigh Feeder MechanicsДокумент1 страницаWeigh Feeder MechanicsVijay Bhan67% (3)

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationДокумент24 страницыRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelОценок пока нет

- Loesche Grinding Plants for Coal GasificationДокумент45 страницLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- LINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAДокумент44 страницыLINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAirfanОценок пока нет

- Heat-Up Schedule As Per RequirementДокумент1 страницаHeat-Up Schedule As Per RequirementVijay BhanОценок пока нет

- VRM Fan ..Документ2 страницыVRM Fan ..harikrushnaОценок пока нет

- Fan Curves Explained: Power, Speed, Pressure & VolumeДокумент1 страницаFan Curves Explained: Power, Speed, Pressure & VolumeVijay BhanОценок пока нет

- Modefied Cooler2Документ71 страницаModefied Cooler21977jul100% (2)

- Rajashree Cements Line-III Clinker Cooler Project Data 2005Документ10 страницRajashree Cements Line-III Clinker Cooler Project Data 2005Irfan AhmedОценок пока нет

- Study of The Grinding Balls Distribution Inside The MillДокумент2 страницыStudy of The Grinding Balls Distribution Inside The Millsempatik721Оценок пока нет

- Kiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTДокумент3 страницыKiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTBùi Hắc HảiОценок пока нет

- Technical Specification of VSK PDFДокумент28 страницTechnical Specification of VSK PDFmaran.suguОценок пока нет

- CM - 2 Heat BalanceДокумент2 страницыCM - 2 Heat BalanceThaigroup CementОценок пока нет

- Flow Conversion To Normal Meter Cube Per HourДокумент2 страницыFlow Conversion To Normal Meter Cube Per HourIrfan AhmedОценок пока нет

- Kiln Performance & Efficiency FactorsДокумент13 страницKiln Performance & Efficiency FactorsBùi Hắc HảiОценок пока нет

- Overall Heat Balance - 11.08.2008Документ8 страницOverall Heat Balance - 11.08.2008Tamer FathyОценок пока нет

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Документ6 страницRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiОценок пока нет

- Clinker Production Caliculation ProgramДокумент3 страницыClinker Production Caliculation Programvvijaybhan100% (1)

- Rawmix DesignДокумент3 страницыRawmix DesignavisgopОценок пока нет

- Modern Cement Grinding Systems ComparedДокумент14 страницModern Cement Grinding Systems ComparedCao Ngoc AnhОценок пока нет

- Math Cement PackageДокумент26 страницMath Cement PackageKarthik VkОценок пока нет

- 15th NCB Technical PaperДокумент10 страниц15th NCB Technical PaperSalah RomdaniОценок пока нет

- Calculation of Max. Ball Size: Plant: Mill Nr. Mill SizeДокумент1 страницаCalculation of Max. Ball Size: Plant: Mill Nr. Mill SizeAbul QasimОценок пока нет

- HOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSДокумент4 страницыHOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSMohd AliОценок пока нет

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Документ2 страницыVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- Kiln Area Learning ReportДокумент24 страницыKiln Area Learning ReportAbasiemekaОценок пока нет

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportДокумент2 страницыNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedОценок пока нет

- Kiln Audit - Required Measurement ToolsДокумент1 страницаKiln Audit - Required Measurement ToolsVijay BhanОценок пока нет

- Cement Separator & Ball Mill OptimizationДокумент29 страницCement Separator & Ball Mill OptimizationAdelezzat OmranОценок пока нет

- Rotary Kiln Data SheetДокумент14 страницRotary Kiln Data SheetsreeganeshrОценок пока нет

- MHR21924 CMC Chapter CCДокумент48 страницMHR21924 CMC Chapter CCDede KaladriОценок пока нет

- SP Line III GenerationДокумент5 страницSP Line III Generationhmaza shakeelОценок пока нет

- ESP Operation: Charging Particles & Collecting DustДокумент14 страницESP Operation: Charging Particles & Collecting DustBrayan AguileraОценок пока нет

- Cooler Balance 1Документ17 страницCooler Balance 1Tamer Fathy100% (1)

- Bypass SystemДокумент9 страницBypass SystemirfanОценок пока нет

- The Cement Grinding Office: Home About Us Services Mining AreaДокумент3 страницыThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarОценок пока нет

- Cement MillДокумент28 страницCement Millsaji kumar100% (2)

- Kiln Eval Line IДокумент1 страницаKiln Eval Line IRaji SuriОценок пока нет

- Vanzetti Cryogenic Pumps & Technology GuideДокумент0 страницVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiОценок пока нет

- Optyma CU Leaflet - 46CДокумент8 страницOptyma CU Leaflet - 46CRahul PatilОценок пока нет

- TMT Dkmhpn141a102Документ4 страницыTMT Dkmhpn141a102seaqu3stОценок пока нет

- Preview Jeernakosa Vyadhulu 38091Документ15 страницPreview Jeernakosa Vyadhulu 38091gvrrОценок пока нет

- Anchor DesignДокумент20 страницAnchor DesigngvrrОценок пока нет

- Checkbook Reconciliation: Total Withdrawals OutstandingДокумент24 страницыCheckbook Reconciliation: Total Withdrawals OutstandingrewalОценок пока нет

- VasudhaFeb - 2012 PDFДокумент57 страницVasudhaFeb - 2012 PDFgvrrОценок пока нет

- Heat Output CalculationsДокумент17 страницHeat Output CalculationsgvrrОценок пока нет

- Vemana Poem's (English&Telugu)Документ102 страницыVemana Poem's (English&Telugu)gururajap81% (31)