Академический Документы

Профессиональный Документы

Культура Документы

Project Execution Plan

Загружено:

jrladduОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Project Execution Plan

Загружено:

jrladduАвторское право:

Доступные форматы

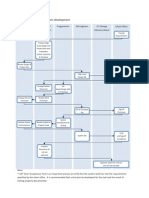

Execution Plan

Engineering Design Process Map

INPUTS

PROCESS

SUBPROCESSES

Sub-SubProcess

SUPPORT FUNCTIONS:

HUMAN RESOURCES, INFORMATION TECHNOLOGY,

LEGAL, FINANCIAL, PROJECT CONTROLS &

ESTIMATING (PCE), HEALTH, SAFETY & ENVIRONMENT

(HSE), QUALITY ASSURANCE (QA),

Contract Requirements & Project

Execution Plans

Statutory Requirements

Regulatory Requirements

Industry Codes & Standards

Engineering Plan

Project Procurement Plan

OUTPUTS

ENGINEERING & DESIGN

DEVELOP ENGINEERING PLAN (Started at Tender /Start Up Stages)

Establish Design Basis / Design Input

Develop /Review Cost-Time-Resource (CTR) Plans

Develop List of Technical Deliverables

Specifications (including list of applicable standard specs)

Drawings

Calculations

Technical Reports

Identify Design Verification Requirements (Verification Plan & Approvals Matrix)

Identify & Schedule Design Review Stages

Identify Interface Requirements

DESIGN EXECUTION

Conduct Studies & Technical Analyses

Design & Drafting

Manage Interfaces

Manage Regulatory & Statutory Requirements

Develop Technical Specifications & Input for Procurement / RFQs

QA & HSE Review and Input

Issue "Approved for Bid"

Develop Requisitions

Establish Equipment Criticality Ratings

Approve Purchase Orders (see Materials Management)

PERIODIC STATUS REPORTING

Engineering Plan

CTR's to Planning & Cost Control

Drawings, Specifications, Technical

Reports, Calculations, Data Sheets

Documents for Procurement

status for input into Project schedule,

cost analysis, MDR- Master Document

Register

TECHNICAL AUDITS

Change Requests

DESIGN CHANGE CONTROL

Design Revisions and Engineering Change Notices

Customer Requested Changes

Field Requested Changes

Integrity Management (may require re-HAZOP of changed area)

Decision Register

Engineering Plan

CONDUCT DESIGN REVIEWS

HAZOPS, HAZIDS, VIP- Value Improvement Practices

Design Verification Requirements as

Identified in

Engineering Plan or General

Engineering Procedures

and Check Lists

Design Verification and Design

Reviews Comments and

Actions for Design

Improvements

DESIGN VERIFICATION: verify outputs against inputs

Checking & Approvals of Deliverables

Internal Checking (self check, discipline check, inter-discipline checks)

Project Team Approvals (Lead Engineer & Project Manager)

Client Review / Approval

Third Party Verification (if required- may be internal resources outside the project)

P.E. Approvals

Regulatory and Statutory Comments / Approvals

Other Technical Assurance / Verification Activities as Required:

Alternative Calculations

PEER Review

Integrity Verification

Model Testing

Technical Assurance Audits

DESIGN FINALIZATION

Close Out Action Items from Design Reviews

Close Out Client Comments

Close Out Regulatory & Statutory Comments

Vendor & Subcontractor Document Approvals

Final Approvals

Revised Documents

Action Items &

Meeting Minutes

Comments and Actions for Design

Improvements

Verification Records

Drawings, Specifications,

Technical Reports, Calculations,

Data Sheets

Approved Documents

AFC Documents

Approved Documents

AFC DOCUMENTS: Issue Documents Approved For Construction "AFC"

Tech Support

Construction / Installation Needs

Contract Requirements

Project Execution Plans

PROVIDE TECHNICAL SUPPORT to Construction / Installation as Required

Develop Mobilization / Sail Away/ Installation Procedures

Develop Hook-Up Pre-Com, Commissioning, Test & Start -Up Procedures

& Engineering Plan

Performance Data

DESIGN VALIDATION

Validate results of construction, installation, HUC meet design requirements

Test/ Performance Results and Installation Surveys

ENGINEERING & DESIGN PHASE "LESSONS LEARNED" REVIEW

Construction Procedures

Installation Plans

Hook-Up Pre-Com, Commissioning, Test

& Start -Up Procedures

Design Validated

Continual Improvement

Opportunities Identified

"Know How" Captured

Вам также может понравиться

- Engineering Work Flow ChartДокумент1 страницаEngineering Work Flow ChartSanjib Deka83% (6)

- Project Planning ProcedureДокумент9 страницProject Planning ProcedureCristian Lukacs100% (6)

- Project Execution PlanДокумент25 страницProject Execution Planvnarveka90% (21)

- Project Execution PlanДокумент7 страницProject Execution PlanJOHNK100% (12)

- 84501-9200-9L-007 Rev-2 Contractor Progress Measurement RequirementsДокумент24 страницы84501-9200-9L-007 Rev-2 Contractor Progress Measurement RequirementsPeni M. Saptoargo86% (7)

- Planing Procedure Rev01Документ12 страницPlaning Procedure Rev01Olakanmiismail Alabi86% (7)

- Measure Project Progress with Weight FactorsДокумент19 страницMeasure Project Progress with Weight FactorsFalah Miftahul92% (12)

- Engineering Design QA: Holistic Workflow PhilosophyДокумент11 страницEngineering Design QA: Holistic Workflow PhilosophyMuhammad SaadullahОценок пока нет

- Project Control Engineering GuideДокумент35 страницProject Control Engineering GuideMasbooks100% (1)

- EPC Projects BasicsДокумент2 страницыEPC Projects Basicsmahmood75080% (5)

- Planning and Control Procedure for Main Construction WorksДокумент19 страницPlanning and Control Procedure for Main Construction Worksmasahin100% (3)

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanДокумент34 страницы5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- Produced Water Project Execution PlanДокумент89 страницProduced Water Project Execution PlanNoman Abu-Farha100% (2)

- PT Borneo Mitra Sinergi: Engineering PlanДокумент9 страницPT Borneo Mitra Sinergi: Engineering PlanaswarОценок пока нет

- Construction Execution Plan1Документ28 страницConstruction Execution Plan1Idaba100% (7)

- Project Execution Plan PDFДокумент84 страницыProject Execution Plan PDF1410200193% (27)

- Uzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureДокумент11 страницUzu-Sedo-Gen - Cw348814-00003 - r01 - Progress Measurement and Reporting ProcedureOkeyman0% (1)

- 2.20 - Appendix G - Project Coordination Procedure 170611dfДокумент65 страниц2.20 - Appendix G - Project Coordination Procedure 170611dfAlex Ciupitu83% (12)

- PDOC 596 PEP 01 Project Execution Plan Rev 3Документ90 страницPDOC 596 PEP 01 Project Execution Plan Rev 3Showki Wani80% (5)

- Initiate Review: Proposal Risk ChecklistДокумент3 страницыInitiate Review: Proposal Risk ChecklistGeetha_jagadish30Оценок пока нет

- Project Execution Plan for 55MW Geothermal Power PlantДокумент26 страницProject Execution Plan for 55MW Geothermal Power PlantMarzuqi Aqila100% (8)

- Project Execution Plan WoodsideДокумент3 страницыProject Execution Plan WoodsideDebashish Das100% (1)

- CWP Template PDFДокумент13 страницCWP Template PDFCristian ArayaОценок пока нет

- 0.a. Schedule Review, Rev1Документ10 страниц0.a. Schedule Review, Rev1sayafrands6252Оценок пока нет

- Environmental Restoration Project Execution PlanДокумент49 страницEnvironmental Restoration Project Execution PlanSunday Paul100% (1)

- Project Control System ManualДокумент134 страницыProject Control System ManualHamidullah Asady Wardak100% (2)

- Estate Services Project Execution PlanДокумент30 страницEstate Services Project Execution PlanHashim Habeed100% (5)

- 4S08 Project ControlsДокумент14 страниц4S08 Project Controlssaleem_b89% (9)

- Project (Time) Control For An EPC ProjectДокумент12 страницProject (Time) Control For An EPC ProjectcelalettinilhanОценок пока нет

- Project cost change approval processДокумент1 страницаProject cost change approval processsyafrands100% (1)

- Resource Allocation & Leveling LectureДокумент41 страницаResource Allocation & Leveling Lectureleong_guoОценок пока нет

- Project Control ProcedureДокумент21 страницаProject Control ProcedureSlamat Parulian Simamora100% (5)

- Planning Package For ProjectДокумент272 страницыPlanning Package For Projectyasser_abdalshafey75% (8)

- Deliverables Rule of ThumbДокумент4 страницыDeliverables Rule of Thumbk13672100% (9)

- PT BORNEO MITRA SINERGI – PROJECT EXECUTION PLAN FOR PIPELINE CONSTRUCTION SERVICESДокумент10 страницPT BORNEO MITRA SINERGI – PROJECT EXECUTION PLAN FOR PIPELINE CONSTRUCTION SERVICESaswar100% (5)

- EPC Project WBS PDFДокумент1 страницаEPC Project WBS PDFomda4wadyОценок пока нет

- Project Execution PlanДокумент52 страницыProject Execution PlanDr.Shahzada Irshad Mohammed100% (2)

- Project Execution Plan - KLEДокумент63 страницыProject Execution Plan - KLEDebashish Das80% (5)

- Schedule Management Plan TemplateДокумент10 страницSchedule Management Plan TemplateVick'y A'AdemiОценок пока нет

- S CurveДокумент5 страницS CurveAnonymous cQ13WWe100% (2)

- Project Control ToolДокумент40 страницProject Control ToolisolongОценок пока нет

- Progress Reporting Procedure DraftДокумент9 страницProgress Reporting Procedure DraftOhomina Josh100% (2)

- Epc Epcm ChartДокумент1 страницаEpc Epcm ChartSylvester Mokgokone Rakgate89% (9)

- Quest CCS Project Execution PlanДокумент69 страницQuest CCS Project Execution PlanGraco Calle100% (6)

- 202 Procedure 0-Project Execution PlanДокумент8 страниц202 Procedure 0-Project Execution PlanagaricusОценок пока нет

- Project Execution PlanДокумент24 страницыProject Execution PlanEka Satria100% (15)

- Project Execution PlanДокумент13 страницProject Execution Plansmshaidr100% (1)

- Project Engineering in Oil & Gas Industry SharedДокумент24 страницыProject Engineering in Oil & Gas Industry SharedKojiro Hadate100% (3)

- SR&ED Audit Preparation: InformationДокумент5 страницSR&ED Audit Preparation: InformationmetroroadОценок пока нет

- Basic DesignДокумент18 страницBasic DesignM AhmadОценок пока нет

- An Architect's Core ProcessДокумент1 страницаAn Architect's Core Processhmp90Оценок пока нет

- Design Documentation L4Документ27 страницDesign Documentation L4KOFI BROWNОценок пока нет

- Engineering Delivery MethodologyДокумент1 страницаEngineering Delivery Methodologysayafrands6252100% (1)

- Detailed Engineering Design PhaseДокумент8 страницDetailed Engineering Design Phaserenjithv_494% (18)

- Construction SupervisionДокумент18 страницConstruction Supervisionfhsn8480% (5)

- Sys Dev Flow5Документ1 страницаSys Dev Flow5JustinYUОценок пока нет

- Project Management Project MatrixДокумент2 страницыProject Management Project MatrixBruno CannasОценок пока нет

- Design and Development 1Документ4 страницыDesign and Development 1asderbvaОценок пока нет

- Design ProcessДокумент7 страницDesign Processrobert_kerr_29Оценок пока нет

- LR Norway Hull Foam Storage Design ReviewДокумент3 страницыLR Norway Hull Foam Storage Design ReviewFloyd BurgessОценок пока нет

- Appendix III 2B Tripura Cat 1Документ1 страницаAppendix III 2B Tripura Cat 1jrladduОценок пока нет

- 1.1 Annexure I and II of P4CCC19034Документ89 страниц1.1 Annexure I and II of P4CCC19034jrladduОценок пока нет

- Appendix III 2C Assam Cat 2Документ3 страницыAppendix III 2C Assam Cat 2jrladduОценок пока нет

- Appendix III 2B Assam Cat 2Документ1 страницаAppendix III 2B Assam Cat 2jrladduОценок пока нет

- 6.2 Annexure VII B Bidders Response Sheet Foreign BidderДокумент1 страница6.2 Annexure VII B Bidders Response Sheet Foreign BidderjrladduОценок пока нет

- 7.0 Annexure VIII Bid MatrixДокумент10 страниц7.0 Annexure VIII Bid MatrixjrladduОценок пока нет

- Appendix III 2B Assam Cat 2Документ1 страницаAppendix III 2B Assam Cat 2jrladduОценок пока нет

- Appendix III 2C Assam Cat 2Документ3 страницыAppendix III 2C Assam Cat 2jrladduОценок пока нет

- Appendix III 2B Tripura Cat 1Документ1 страницаAppendix III 2B Tripura Cat 1jrladduОценок пока нет

- 8.0 Annexure Ix Format For Power of AttorneyДокумент1 страница8.0 Annexure Ix Format For Power of AttorneyjrladduОценок пока нет

- 10.0 Appendix As Per Annexure IДокумент25 страниц10.0 Appendix As Per Annexure IjrladduОценок пока нет

- Supply & Install RO Water MakerДокумент10 страницSupply & Install RO Water MakerjrladduОценок пока нет

- DSJ400 Outlined SpecificationДокумент2 страницыDSJ400 Outlined SpecificationjrladduОценок пока нет

- 9.0 Annexure X Undertaking Declarition and Annexure IX Power of AttorneyДокумент10 страниц9.0 Annexure X Undertaking Declarition and Annexure IX Power of AttorneyjrladduОценок пока нет

- 10.0 Appendix As Per Annexure IДокумент25 страниц10.0 Appendix As Per Annexure IjrladduОценок пока нет

- 1.0 Invitation To BidДокумент7 страниц1.0 Invitation To BidjrladduОценок пока нет

- 8.0 Annexure Ix Format For Power of AttorneyДокумент1 страница8.0 Annexure Ix Format For Power of AttorneyjrladduОценок пока нет

- 7.0 Annexure VIII Bid MatrixДокумент10 страниц7.0 Annexure VIII Bid MatrixjrladduОценок пока нет

- Shukrashis: Name: Date of Birth: Time of Birth: Place of BirthДокумент1 страницаShukrashis: Name: Date of Birth: Time of Birth: Place of BirthjrladduОценок пока нет

- Markwet AnalysisДокумент2 страницыMarkwet AnalysisjrladduОценок пока нет

- 3.0 Annexure IV Bid Evaluation CriteriaДокумент7 страниц3.0 Annexure IV Bid Evaluation CriteriajrladduОценок пока нет

- 6.1 Annexure VII A Bidders Response Sheet Indian BidderДокумент1 страница6.1 Annexure VII A Bidders Response Sheet Indian BidderjrladduОценок пока нет

- 4.0 Annexure V Special Terms and ConditionsДокумент4 страницы4.0 Annexure V Special Terms and ConditionsjrladduОценок пока нет

- GrammarДокумент1 страницаGrammarjrladduОценок пока нет

- Farm Layout ModifiedДокумент1 страницаFarm Layout ModifiedjrladduОценок пока нет

- NSE Maruti Suzuki Ind 1M: O H L CДокумент1 страницаNSE Maruti Suzuki Ind 1M: O H L CjrladduОценок пока нет

- Elliott WaveДокумент24 страницыElliott WavejrladduОценок пока нет

- Press Release Q4FY19 Crores FinalДокумент7 страницPress Release Q4FY19 Crores FinaljrladduОценок пока нет

- Authorized Real-Time Data Vendors ListДокумент1 страницаAuthorized Real-Time Data Vendors ListjrladduОценок пока нет

- Inquiry For NR13 Qualified Engineering: OthersДокумент4 страницыInquiry For NR13 Qualified Engineering: OthersjrladduОценок пока нет

- Process Flow MapДокумент18 страницProcess Flow MapCal90% (10)

- Introduction To Non Conventional MC ProcessДокумент18 страницIntroduction To Non Conventional MC ProcessSanjeev Kumar GhaiОценок пока нет

- Enterprise Resource Planning - ERP: Kevin Cowell Natthawut Lertpitayakun Isabelle Mertha Xiaoguang YouДокумент74 страницыEnterprise Resource Planning - ERP: Kevin Cowell Natthawut Lertpitayakun Isabelle Mertha Xiaoguang Youvishnuvr143100% (1)

- Material Handling: By: Josh ConleyДокумент20 страницMaterial Handling: By: Josh ConleyDocMoodyОценок пока нет

- The 10 Steps of The Procurement CycleДокумент3 страницыThe 10 Steps of The Procurement Cycleleekwal_momand100% (1)

- Priyanka ChauhanДокумент2 страницыPriyanka ChauhanVikas YuriОценок пока нет

- Production and Operations ManagementДокумент194 страницыProduction and Operations ManagementAmit KumarОценок пока нет

- MaximoДокумент12 страницMaximoFazal KhanОценок пока нет

- Pashu Khadya Company Limited (PKCL)Документ6 страницPashu Khadya Company Limited (PKCL)Rahul GandhiОценок пока нет

- PSM1Документ37 страницPSM1JMDREENA100% (17)

- Just in Time Jit Back FlushДокумент16 страницJust in Time Jit Back FlushSunsong31Оценок пока нет

- Lean Production and Agile Manufacturing ExplainedДокумент89 страницLean Production and Agile Manufacturing Explainedhemendra waswaniОценок пока нет

- 4M Sheet FormatДокумент2 страницы4M Sheet FormatJetesh Devgun87% (38)

- MAW KitДокумент3 страницыMAW KitdrustagiОценок пока нет

- FTQ OverviewДокумент65 страницFTQ Overviewcristirina2000100% (1)

- E-Procurement Technology Boosts Dubai Municipality OperationsДокумент40 страницE-Procurement Technology Boosts Dubai Municipality OperationsSanjay MishraОценок пока нет

- Mico BoschДокумент70 страницMico Boschasra_ahmed100% (4)

- Operational Practices of Lean Manufacturing: Potentiating Environmental ImprovementsДокумент31 страницаOperational Practices of Lean Manufacturing: Potentiating Environmental ImprovementsSANGAMESWARAN U 19MBR089Оценок пока нет

- GE8077 – INTRODUCTION TO TOTAL QUALITY MANAGEMENTДокумент12 страницGE8077 – INTRODUCTION TO TOTAL QUALITY MANAGEMENTsafina rahmanОценок пока нет

- 5S: The Secret to Japanese SuccessДокумент39 страниц5S: The Secret to Japanese SuccessNerizza SomeraОценок пока нет

- JobДокумент4 страницыJobNeha SmritiОценок пока нет

- Unilever's WCM and EEM Project Alignment MethodologyДокумент40 страницUnilever's WCM and EEM Project Alignment MethodologyHermanManru100% (1)

- 9.collection of Solid Waste Transfer and TransportДокумент21 страница9.collection of Solid Waste Transfer and TransportLim Boonchin100% (1)

- Centrifugal Castings BrochureДокумент4 страницыCentrifugal Castings BrochureasndmpОценок пока нет

- Alat Tambahan SemenДокумент13 страницAlat Tambahan SemenNuril HidayatiОценок пока нет

- Practice Problems: Chapter 14, Material Requirements PlanningДокумент7 страницPractice Problems: Chapter 14, Material Requirements Planningkavindra singhОценок пока нет

- Improving The Productivity of Sheet Metal StampingДокумент6 страницImproving The Productivity of Sheet Metal Stampingkarla caaroОценок пока нет

- Case Study WhirlpoolДокумент12 страницCase Study WhirlpoolHarsh SaxenaОценок пока нет

- BSCM 1 PDFДокумент54 страницыBSCM 1 PDFmenages100% (5)

- Calculating Product Costs and Prices Using Activity-Based CostingДокумент2 страницыCalculating Product Costs and Prices Using Activity-Based CostingSholahuddin Al AyyubiОценок пока нет