Академический Документы

Профессиональный Документы

Культура Документы

General Notes

Загружено:

Godino ChristianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

General Notes

Загружено:

Godino ChristianАвторское право:

Доступные форматы

TEXAS FIRM REGISTRAGTION NO.

F-12745

4800 SUGAR GROVE, SUITE 315

STAFFORD. TEXAS 77477

T 713.933.1041

F 713.458.7758

www.ensighthayneswhaley.com

EHW-15-501-A

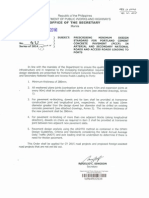

GENERAL STRUCTURAL NOTES

Issue

No.

Date

2

06.00

SHOP DRAWINGS

05.00

CONCRETE MASONRY

04.00

CONCRETE

03.00

STRUCTURAL STEEL

02.00

FOUNDATION AND SLAB ON GRADE

01.00

GENERAL

06.01

SHOP DRAWINGS SHALL BE PREPARED AND SUBMITTED FOR REVIEW TO THE

STRUCTURAL ENGINEER FOR EACH STRUCTURAL BUILDING MATERIAL AS

INDICATED IN THE STRUCTURAL GENERAL NOTES AND/OR THE CONTRACT

SPECIFICATIONS. SEE THE CONTRACT SPECIFICATIONS, IF PROVIDED, FOR

SUBMITTAL PROCEDURES AND ADDITIONAL INFORMATION.

05.01

MASONRY CONSTRUCTION SHALL BE PERFORMED IN ACCORDANCE WITH ACI 531

"BUILDING CODE REQUIREMENTS FOR CONCRETE MASONRY CONSTRUCTION".

04.01

03.01

02.01

THE STRUCTURE IS DESIGNED IN ACCORDANCE WITH THE INTERNATIONAL

BUILDING CODE, 2012 EDITION.

STRUCTURAL STEEL TUBING SHALL CONFORM TO ASTM A500, GRADE B.

01.02

THE DESIGN GRAVITY LOADS ARE AS FOLLOWS:

03.02

SHOP DRAWINGS SHALL USE DRAFTING LINE WORK AND LETTERING THAT IS

CLEAR AND LEGIBLE. SHOP DRAWINGS SHALL NOT CONTAIN REPRODUCTION OF

THE CONTRACT PLANS OR DETAILS WITHOUT THE CONSENT OF THE ARCHITECT

OR ENGINEER OF RECORD.

05.03

03.03

STRUCTURAL STEEL PIPE SHALL CONFORM TO ASTM A53, TYPE E OR S GRADE B

OR ASTM A501. MILL TEST REPORTS FOR STEEL PIPE SHALL BE SUBMITTED FOR

REVIEW.

THE SUBSURFACE INFORMATION AND FOUNDATION DESIGN ARE BASED ON A

REPORT PREPARED BY GESSNER ENGINEERING, PROJECT NO. 15-0717, DATED

SEPTEMBER 14, 2015 WITH ADDENDUM LETTERS DATED NOVEMBER 6, 2015 AND

NOVEMBER 24, 2015. THE CONTRACTOR SHALL PERFORM EXCAVATIONS,

FOOTING CONSTRUCTION, AND PREPARATION OF THE SUBGRADE UNDER THE SLAB

ON GRADE IN ACCORDANCE WITH THE RECOMMENDATIONS CONTAINED IN THE

GEOTECHNICAL REPORT AND THE PROJECT SPECIFICATIONS.

01.01

CONCRETE MASONRY CONSTRUCTION SHALL HAVE A MINIMUM COMPRESSIVE

STRENGTH (F'M) OF 1500 PSI ON THE NET CROSS SECTIONAL AREA AT 28 DAYS.

STRUCTURAL STEEL WIDE FLANGE SHAPES SHALL CONFORM TO ASTM A992,

GRADE 50 EXCEPT AS NOTED. OTHER STEEL SHAPES, PLATES, ANGLES AND

CHANNELS SHALL CONFORM TO ASTM A36.

05.02

CONCRETE IN THE FOLLOWING AREAS SHALL HAVE NATURAL SAND FINE

AGGREGATE AND NORMAL WEIGHT COARSE AGGREGATES CONFORMING TO ASTM

C33, TYPE I PORTLAND CEMENT CONFORMING TO ASTM C150, AND SHALL HAVE

THE FOLLOWING COMPRESSIVE STRENGTH (FC') AT 28 DAYS:

06.04

SHOP DRAWINGS SHALL SHOW CLEAR AND COMPLETE INFORMATION FOR THE

FABRICATION (DETAIL SHEETS AND/OR MATERIAL LISTS) AND INSTALLATION.

06.05

06.06

06.07

06.08

06.09

06.10

05.04

ALLOW A MINIMUM OF (2) WEEKS FOR REVIEW OF EACH SET OF SHOP

DRAWINGS.

CONTRACTOR SHALL REVIEW THE SHOP DRAWINGS SUBMITTED BY THE

SUBCONTRACTOR AND COORDINATE SHOP DRAWINGS WITH ALL TRADES.

CONTRACTOR SHALL ANSWER ALL QUESTIONS OR CLARIFICATIONS BY THE

SUBCONTRACTOR BEFORE SUBMITTING TO ENGINEER REVIEW. ANY QUESTIONS

THAT THE CONTRACTOR ANSWER WITH THE INFORMATION ON THE DRAWINGS

SHALL CLEARLY BE MARKED FOR THE ENGINEER FOR REVIEW.

CONTRACTOR IS RESPONSIBLE FOR VERIFYING ALL DIMENSIONS, AND SHALL

NOTIFY ARCHITECT OF ANY DISCREPENCIES IN COORDINATION WITH THE

ARCHITECTURAL DOCUMENTS OR THOSE OF OTHER DISCIPLINES.

05.05

GROUT SHALL CONFORM TO ASTM C476 AND SHALL HAVE A COMPRESSIVE

STRENGTH OF 2500 PSI ON THE NET AREA AT 28 DAYS.

05.06

REINFORCEMENT SHALL CONFORM TO THE STANDARDS SPECIFIED IN THE

CONCRETE NOTES. REINFORCEMENT SHALL BE LAP SPLICED A MINIMUM OF 36

BAR DIAMETERS UNLESS NOTED OTHERWISE.

05.07

REVIEW OF THE SHOP DRAWINGS BY THE ENGINEER IS FOR GENERAL

CONFORMANCE TO THE STRUCTURAL DRAWINGS. APPROVAL OF THE SHOP

DRAWINGS BY THE ENGINEER DOES NOT RELIEVE THE CONTRCTOR FOR ANY

ERRORS IN DIMENSIONS OR MATERIALS INDICATED IN THE ON THE SHOP

DRAWINGS.

IF THERE IS ANY DISCREPENCY BETWEEN THE STRUCTURAL DRAWINGS AND

THE SHOP DRAWINGS, THE INFORMATION SHOWN ON THE STRUCTURAL

DOCUMENTS SHALL GOVERN. INFORMATION THAT IS NOT INDICATED ON THE

SHOP DRAWINGS SHALL BE OBTAINED FROM THE STRUCTURAL DRAWINGS.

MORTAR SHALL CONFORM TO THE REQUIREMENTS OF ASTM C270, TYPE M OR S.

TYPE M MORTAR SHALL BE USED IN BELOW GRADE APPLICATIONS AND SHALL

OBTAIN AN AVERAGE COMPRESSIVE STRENGTH OF 2500 PSI AT 28 DAYS. TYPE S

MORTAR MAY BE USED IN ABOVE GRADE APPLICATIONS AND SHALL OBTAIN AN

AVERAGE COMPRESSIVE STRENGTH OF 1800 PSI AT 28 DAYS. THE SAME MORTAR

SHALL BE USED FOR BOTH WYTHES OF CAVITY WALL CONSTRUCTION.

PROVIDE 2-#5 CONTINUOUS IN BOND BEAMS UNLESS INDICATED OTHERWISE.

PROVIDE CORNER BARS OF EQUIVALENT SIZE LAPPED AT CORNERS AND

INTERSECTIONS OF WALLS.

05.08

MASONRY CORES CONTAINING VERTICAL REINFORCEMENT SHALL BE GROUTED

SOLID.

05.09

FOR LIFTS GREATER THAN 4 FEET, HIGH LIFT GROUTING TECHNIQUES SHALL BE

UTILIZED.

05.10

PROVIDE 1-#5 VERTICAL AT ENDS, CORNERS, AND INTERSECTIONS OF WALLS.

05.11

CELLS TO BE GROUTED SHALL BE CLEAN AND FREE OF EXCESS MORTAR AND

FOREIGN MATERIALS.

05.12

IN CONCRETE SUPPORTING MASONRY WALLS, EMBED DOWELS TO MATCH SIZE

AND LOCATION OF VERTICAL MASONRY REINFORCEMENT.

05.13

LINTELS SHALL BEAR ON MASONRY WALLS A MINIMUM OF 8" AT EACH END. FOR

CMU WALLS, PROVIDE TWO GROUTED CORES EACH SIDE OF OPENING FULL

HEIGHT OF WALL AND REINFORCE EACH OF THE TWO GROUTED CORES WITH

1-#5 VERTICAL EXTENDING FROM THE FOUNDATION TO THE POINT OF LATERAL

SUPPORT FOR THE WALL ABOVE THE LINTEL LOCATION. THE FOLLOWING

LINTELS MAY BE USED ONLY WHEN THE HEAD OF THE MASONRY OPENING IS

BELOW FLOOR OR ROOF BEARING ELEMENTS A MINIMUM DISTANCE OF 75% OF

THE LINTEL SPAN:

CLEAR

SPAN PER

WYTHE

STEEL ANGLE

LINTEL FOR 4"

CMU WYTHE

CMU LINTEL

PER CMU WYTHE

(FM'= 1500 PSI)

PRECAST CONC.

LINTEL PER CMU

WYTHE

(FC'= 3000 PSI)

0'-0" - 4'-0"

L3-1/2 x 3-1/2 x 1/4

8" DEEP W/ (2) #4

BOTTOM

8" DEEP W/ (2) #4

TOP & BOTTOM

4'-0" - 6'-0"

L5 x 3-1/2 x 5/16

8" DEEP W/ (2) #5

BOTTOM

8" DEEP W/ (2) #4

TOP & BOTTOM

16" DEEP W/ (2) #4

BOTTOM

8" DEEP W/ (2) #4

TOP & BOTTOM

16" DEEP W/ (2) #5

BOTTOM

8" DEEP W/ (2) #5

TOP & BOTTOM

6'-0" - 8'-0"

8'-0" - 12'-0"

L5 x 3-1/2 x 3/8

L6 x 3-1/2 x 1/2

TEMPORARY SHORING OF LINTELS MUST BE PROVIDED UNTIL MASONRY HAS

CURED. EDGES OF MASONRY OPENINGS SHALL NOT BE LOCATED CLOSER THAN

50% OF THE LINTEL SPAN FROM ENDS OR CORNERS OF WALLS OR MASONRY

CONTROL JOINTS.

05.14

CONTROL JOINTS SHALL BE PLACED IN THE MASONRY CONSTRUCTION SUCH THAT

THE PANEL LENGTH TO HEIGHT RATIO OF THE WALL DOES NOT EXCEED 1.5, AND

THAT THE MAXIMUM PANEL LENGTH OF WALL DOES NOT EXCEED 25 FEET.

ADDITIONAL JOINTS SHALL BE PLACED WHERE ABRUPT CHANGES IN WALL

SECTIONS OCCUR.

04.02

04.03

04.04

04.06

MINIMUM CONCRETE COVER PROTECTION FOR REINFORCEMENT BARS SHALL BE

AS FOLLOWS: (SEE ACI 318 SECTION 7.7 FOR CONDITIONS NOT NOTED)

CONCRETE EXPOSED TO WEATHER

#5 BARS AND SMALLER

1-1/2 INCHES

ALL OTHER BARS

2 INCHES

CONCRETE CAST AGAINST EARTH

3 INCHES

GRADE BEAMS:

TOP

1-1/2 INCHES

BOARD FORMED SIDES

2 INCHES

EARTH FORMED SIDES

3 INCHES

BOTTOM

3 INCHES

SLABS ON GRADE

SINGLE LAYER OR TOP LAYER

2 INCHES

BOTTOM LAYER CAST AGAINST SOIL

3 INCHES

BOTTOM LAYER NOT CAST AGAINST SOIL

2 INCHES

COLUMNS

1-1/2 INCHES

PILASTERS & PLINTHS

2 INCHES

BEAMS

1-1/2 INCHES

WALLS BELOW GRADE (BACKFILLED SIDE)

2 INCHES

WALLS BELOW GRADE (NO BACKFILL)

3/4 INCHES

PROVIDE STANDARD BAR CHAIRS AND SPACERS AS REQUIRED TO MAINTAIN

CONCRETE PROTECTION SPECIFIED.

04.07

04.08

04.09

HORIZONTAL JOINT REINFORCEMENT SHALL BE USED IN THE MASONRY

CONSTRUCTION. SUCH JOINT REINFORCEMENT SHALL BE PLACED AT 8 INCHES

ON CENTER VERTICALLY IN WALLS BELOW GRADE AND AT 16 INCHES ON CENTER

VERTICALLY IN WALLS THAT ARE ABOVE GRADE. HORIZONTAL JOINT

REINFORCEMENT SHALL BE FABRICATED FROM GALVANIZED COLD-DRAWN STEEL

WIRE CONFORMING TO ASTM A82. REINFORCEMENT SHALL CONSIST OF TWO OR

MORE SMOOTH OR DEFORMED LONGITUDINAL WIRES NO. 9 GAGE OR LARGER,

WELD CONNECTED WITH NO. 12 GAGE OR LARGER CROSS WIRES. GALVANIZE

COATING SHALL CONFORM TO ASTM A116 AND SHALL BE APPLIED AT A WEIGHT

OF NOT LESS THAN 1.5 OUNCES PER SQUARE FOOT OF UNCOATED WIRE

SURFACE. THE OUT-TO-OUT SPACING OF THE LONGITUDINAL WIRES SHOULD BE

1-5/8 INCHES LESS THAT THE WIDTH OF THE MASONRY UNITS. THE DISTANCE

BETWEEN THE WELDED CONTACTS OF THE CROSS WIRES WITH EACH

LONGITUDINAL WIRE SHOULD NOT EXCEED 6 INCHES AND 16 INCHES FOR

SMOOTH AND DEFORMED LONGITUDINAL WIRES RESPECTIVELY.

04.10

MASONRY CONSTRUCTION SHALL BE INSPECTED DURING THE VARIOUS WORK

STAGES BY A QUALIFIED SPECIAL INSPECTOR. INSPECTION SHALL INCLUDE

CHECKING FOR COMPLIANCE WITH PROJECT DRAWINGS AND SPECIFICATIONS,

INCLUDING, BUT NOT LIMITED TO RECORDING OF THE FOLLOWING:

04.13

B.

PROPORTIONING, MIXING, AND CONSISTENCY OF MORTAR AND GROUT.

C.

LAYING, MORTARING, AND GROUTING OF MASONRY UNITS AND ELEMENTS.

D.

CONDITION, GRADE, SIZE, SPACING AND PLACEMENT OF REINFORCEMENT.

E.

INSPECTION OF GROUT SPACE IMMEDIATELY PRIOR TO CLOSING OF

CLEANOUTS.

F.

SIGNIFICANT OR UNUSUAL CONSTRUCTION LOADS ON MASONRY

STRUCTURAL ELEMENTS.

G.

WHEN AMBIENT TEMPERATURE FALLS BELOW 40 DEGREES F OR RISES

ABOVE 100 DEGREES F, A COMPLETE RECORD OF WEATHER CONDITIONS

AND OF PRECONDITIONING AND PROTECTION GIVEN TO MASONRY

MATERIALS, AND PROTECTION AND CURING OF COMPLETED WORK,

SHALL BE MAINTAINED.

H.

BARS SHALL NOT BE TACK WELDED, WELDED, HEATED OR CUT UNLESS

INDICATED ON THE CONTRACT DOCUMENTS OR REVIEWED BY THE STRUCTURAL

ENGINEER. CONCRETE REINFORCEMENT BARS SHALL CONFORM TO ASTM A615:

#6 BARS AND SMALLER

#7 BARS AND LARGER

05.16

QUALITY AND TESTING OF MASONRY UNITS AND MATERIALS FOR

MORTAR, GROUT, AND MAKING OF PRISMS WHEN REQUIRED.

DETAILING OF CONCRETE REINFORCEMENT BARS AND ACCESSORIES SHALL

CONFORM TO THE RECOMMENDATIONS OF ACI 315 "DETAILS AND DETAILING OF

CONCRETE REINFORCEMENT" AND ACI SP-66 "DETAILING MANUAL". PLACING OF

REINFORCING BARS SHALL CONFORM TO THE RECOMMENDATIONS OF ACI 315R

"MANUAL OF ENGINEERING AND PLACING DRAWINGS FOR REINFORCED

CONCRETE STRUCTURES" AND CRSI "MANUAL OF STANDARD PRACTICE".

MIXING, TRANSPORTING, AND PLACING OF CONCRETE SHALL CONFORM TO

ACI 301.

NOTE NOT USED.

A.

GROUT FOR BASE PLATES SHALL BE NONSHRINKABLE, NONMETALLIC

CONFORMING TO ASTM C827, AND SHALL HAVE A SPECIFIED COMPRESSIVE

STRENGTH AT 28 DAYS OF 5000 PSI. PREGROUTING OF BASE PLATES WILL NOT

BE PERMITTED.

04.05

05.15

05.17

FLY ASH MAY BE USED AS A POZZOLAN TO REPLACE A PORTION OF THE

PORTLAND CEMENT IN A CONCRETE MIX, SUBJECT TO THE APPROVAL OF THE

GENERAL CONTRACTOR AND THE STRUCTURAL ENGINEER. FLY ASH, WHEN USED,

SHALL CONFORM TO ASTM C618, TYPE C OR F. CONCRETE MIXES USING FLY ASH

SHALL BE PROPORTIONED TO ACCOUNT FOR THE PROPERTIES OF THE SPECIFIC

FLY ASH USED AND TO ACCOUNT FOR THE SPECIFIC PROPERTIES OF THE FLY

ASH CONCRETE THUS RESULTING. THE RATIO OF THE AMOUNT OF THE FLY ASH

TO THE TOTAL AMOUNT OF FLY ASH AND CEMENT IN THE MIX SHALL NOT EXCEED

25 PERCENT.

04.11

04.12

04.14

04.15

04.16

03.04

03.05

03.06

03.07

03.08

CONNECTION BOLTS FOR STRUCTURAL STEEL MEMBERS SHALL BE HIGH

STRENGTH BOLTS WHICH MEET OR EXCEED THE REQUIREMENTS OF ASTM A325,

TYPE N, X, OR SC CLASS A. BOLTS SHALL BE DESIGNED AS BEARING TYPE

BOLTS, EXCEPT AS NOTED. BOLTS SHALL BE INSTALLED IN ACCORDANCE WITH

THE "SNUG TIGHT" CONDITION AS OUTLINED IN THE "RCSC'S SPECIFICATION FOR

STRUCTURAL JOINTS USING ASTM A325 OR A490 BOLTS". BOLTS SHALL HAVE A

HARDENED WASHER PLACED UNDER THE ELEMENT TO BE TIGHTENED.

CONNECTIONS WITH OVERSIZES ROUND HOLES AND CONNECTIONS WITH HOLES

SLOTTED IN THE DIRECTION OF LOAD, AND CONNECTIONS NOTED ON THE

DRAWINGS TO BE "SLIP CRITICAL" (SC CLASS A) BOLTS, AND SHALL BE

DESIGNED AS SUCH. BOLTS FOR SLIP-CRITICAL CONNECTIONS SHALL BE

TIGHTENED BY THE USE OF THE TURN-OF-THE-NUT METHOD OR THE USE OF

LOAD-INDICATING TYPE BOLTS, OR LOAD-INDICATING WASHERS, INSTALLED IN

ACCORDANCE WITH THE MANUFACTURER'S RECOMMENDATIONS.

CONTRACTOR SHALL FABRICATE AND ERECT STEEL IN ACCORDANCE WITH

OSHA'S SAFETY REQUIREMENTS, INCLUDING 29 CFR PART 1926 SAFETY

STANDARDS FOR STEEL ERECTION.

TYPICAL BEAM CONNECTION DETAILS ARE DETAILED ON THE DRAWINGS. FOR

NON-COMPOSITE BEAMS, THE END REACTION OF THE CONNECTED BEAM SHALL

BE DETERMINED FROM AISC "MANUAL OF STEEL CONSTRUCTION - ALLOWABLE

STRESS DESIGN," NINTH EDITION, PART 2 "ALLOWABLE LOADS ON BEAMS",

UNLESS A DESIGN REACTION IS INDICATED ON THE PLANS. IN NO CASE SHALL

THE END REACTION BE TAKEN AS LESS THAN 12.0 KIPS. IF ALTERNATE BEAM

CONNECTION DESIGNS ARE USED AND FOR ALL OTHER CONNECTIONS NOT

DETAILED ON THE DRAWINGS, THE FABRICATOR SHALL HAVE A REGISTERED

PROFESSIONAL ENGINEER PREPARE THE CONNECTION DESIGNS IN

ACCORDANCE WITH AISC "MANUAL OF STEEL CONSTRUCTION - VOLUME II

CONNECTIONS" AND "HOLLOW STRUCTURAL SECTIONS-CONNECTIONS MANUAL."

SUCH DESIGNS SHALL BE SUBMITTED PRIOR TO PREPARATION OF THE SHOP

DRAWINGS AND SHALL BEAR THE SEAL OF THIS RESPONSIBLE PROFESSIONAL

ENGINEER.

PRIOR TO DETAILING CONNECTIONS FOR STRUCTURAL STEEL, THE STEEL

FABRICATOR SHALL SUBMIT FOR APPROVAL REPRESENTATIVE DETAILS AND

CALCULATIONS FOR EACH TYPE OF STRUCTURAL STEEL CONNECTION TO BE

UTILIZED. AFTER APPROVAL, THE CONNECTIONS MAY BE INCORPORATED INTO

THE SHOP DRAWINGS, ALONG WITH A TABLE OF DESIGN CAPACITIES FOR THE

RANGE OF CONNECTIONS TO BE USED.

WELDING SHALL CONFORM TO THE AMERICAN WELDING SOCIETY STANDARD

D1.1. ELECTRODES FOR SHOP AND FIELD WELDS SHALL CONFORM TO AWS

A5.1 OR AWS A5.5, CLASS E70XX, LOW HYDROGEN.

03.10

ALL FILLET WELDS SHALL BE MINIMUM AS REQUIRED BY AISC TABLE J2.4, BUT

NOT LESS THAN 3/16". UNLESS OTHERWISE NOTED WELDS SHALL BE WELDED

ALL AROUND ON ALL ACCESSIBLE SIDES.

03.11

ALL FULL PENETRATION WELDS AT MOMENT CONNECTIONS SHALL BE TESTED

AND CERTIFIED BY AN INDEPENDENT TESTING LAB USING NON-DESTRUCTIVE

TESTING METHOD. CERTIFICATIONS SHALL BE SUBMITTED PRIOR TO COVERING

CONNECTIONS WITH ARCHITECTURAL FINISHES.

03.12

SPLICING OF STRUCTURAL STEEL MEMBERS WHERE NOT DETAILED ON THE

CONTRACT DOCUMENTS IS PROHIBITED WITHOUT THE PRIOR APPROVAL OF THE

STRUCTURAL ENGINEER AS TO LOCATION, TYPE OF SPLICE AND CONNECTION TO

BE MADE.

REINFORCEMENT DESIGNATED AS "CONTINUOUS" SHALL HAVE A CLASS B LAP

SPLICE UNLESS NOTED OTHERWISE. REINFORCEMENT BAR SPLICES IN GRADE

BEAMS SHALL BE LOCATED AT THE CENTERLINE OF SUPPORTS FOR BOTTOM

BARS AND AT MIDSPAN FOR TOP BARS. PROVIDE STANDARD ACI HOOKS FOR TOP

AND BOTTOM BARS AT DISCONTINUOUS ENDS OF ALL GRADE BEAMS.

03.13

03.14

PENETRATIONS SHALL NOT BE CUT IN STRUCTURAL STEEL MEMBERS UNLESS SO

INDICATED IN THE DRAWINGS OR AS REVIEWED BY THE ENGINEER.

HORIZONTAL FOOTING AND HORIZONTAL WALL REINFORCEMENT SHALL BE

CONTINUOUS AND SHALL HAVE 90-DEGREE BENDS AND EXTENSIONS, OR CORNER

BARS OF EQUIVALENT SIZE LAPPED WITH CLASS B LAP SPLICES, AT CORNERS

AND INTERSECTIONS.

03.15

BEAMS SHALL BE CAMBERED UPWARD WHERE SHOWN ON THE CONTRACT

DOCUMENTS. WHERE NO UPWARD CAMBER IS INDICATED, ANY MILL CAMBER

SHALL BE DETAILED UPWARD IN THE BEAMS.

HORIZONTAL JOINTS WILL NOT BE PERMITTED IN CONCRETE CONSTRUCTION

EXCEPT AS SHOWN ON THE CONTRACT DOCUMENTS. VERTICAL JOINTS SHALL

OCCUR AT CENTER OF SPANS AT LOCATIONS REVIEWED BY THE STRUCTURAL

ENGINEER.

CONSTRUCTION JOINTS BETWEEN PIERS AND PIER CAPS, FOOTINGS AND WALLS

OR COLUMNS, OR WALLS, COLUMNS, BEAMS AND THE FLOOR SYSTEM THEY

SUPPORT SHALL BE PREPARED BY ROUGHENING THE CONTACT SURFACE TO A

FULL AMPLITUDE OF APPROXIMATELY 1/4 INCH LEAVING THE CONTACT SURFACE

CLEAN AND FREE OF LAITANCE.

PROVIDE (2) NO. 4 REINFORCEMENT BARS X 4'-0" AT REENTRANT CORNERS OF

SLAB ON GRADE AT POUR STRIPS AND COLUMN BLOCKOUTS. PLACE BARS

CENTERED IN THE SLAB AND DIAGONAL TO THE CORNER WITH 1" CLEARANCE

FROM THE SLAB AT THE CORNER.

CONDUIT, PIPES, AND SLEEVES EMBEDDED IN CONCRETE SHALL CONFORM TO

THE REQUIREMENTS OF ACI 318, CHAPTER 6.3.

03.16

02.03

THE CONTRACTOR SHALL NOTIFY STRUCTURAL ENGINEER OF ANY MISFABRICATED

STRUCTURAL STEEL PRIOR TO ERECTION OF SAME.

WHERE INDICATED ON THE DRAWINGS, STRUCTURAL STEEL MEMBERS,

FABRICATIONS, AND WELDED ASSEMBLIES SHALL BE GALVANIZED AFTER

FABRICATION BY HOT DIP PROCESS IN ACCORDANCE WITH ASTM A123. WEIGHT

OF ZINC COATING SHALL CONFORM TO THE REQUIREMENTS SPECIFIED UNDER

"WEIGHT OF COATING" IN ASTM A123 OR ASTM A386, AS APPLICABLE. THE

AFFECTED PORTIONS OF FIELD WELDED GALVANIZED ASSEMBLIES SHALL BE

FIELD PAINTED WITH ZINC RICH CORROSION RESISTANT PAINT.

STRUCTURAL STEEL MEMBERS TO RECEIVE FIREPROOFING SHALL NOT BE

PRIMED NOR PAINTED. FIREPROOFING MATERIAL THICKNESS SHALL BE

INCREASED AS REQUIRED FOR STEEL MEMBERS NOT CONFORMING TO THE

MINIMUM SIZES INDICATED IN THE U.L. FIRE RESISTANCE DIRECTORY VOLUME 1 AND FOR STEEL MEMBERS DETERMINED UNRESTRAINED.

03.18

ERECTION OF THE STRUCTURAL FRAME SHALL NOT PROCEED MORE THAN FOUR

LEVELS ABOVE A LEVEL CONTAINING A COMPLETED CONCRETE SLAB.

03.19

ARCHITECTURALLY EXPOSED STRUCTURAL STEEL MEMBERS AND CONNECTIONS

SHALL CONFORM WITH THE REQUIREMENTS OF THE AISC "CODE OF STANDARD

PRACTICE FOR STEEL BUILDINGS AND BRIDGES" FOR ARCHITECTURALLY

EXPOSED STRUCTURAL STEEL (AESS), SECTION 10, UNLESS MORE STRINGENT

REQUIRMENTS ARE SHOWN OR SPECIFIED ELSEWHERE.

THE CONTRACTOR SHALL SUBMIT FOR THE REVIEW A MIX DESIGN FOR THE

PROPOSED CONCRETE. MIX DESIGNS SHALL BE IN ACCORDANCE WITH ACI 318

CHAPTER 5 AND SHOW WEIGHT PROPORTIONS FOR ALL COMPONENTS OF THE

MIX. THE CONTRACTOR SHALL NOT VARY FROM THE MIX DESIGN WITHOUT THE

APPROVAL OF STRUCTURAL ENGINEER

THE FIRE PROTECTION RATING FOR THIS PROJECT IS BASED UPON THE USE

OF NORMAL WEIGHT AGGREGATE CONCRETE MADE WITH CARBONATE

AGGREGATES. CARBONATE AGGREGATES CONSIST MAINLY OF CALCIUM OR

MAGNESIUM CARBONATE, E.G., LIMESTONE OR DOLOMITE, AND CONTAIN 40

PERCENT OR LESS QUARTZ, CHERT AND FLINT.

02.04

02.05

02.06

02.07

02.08

FOUNDATION CONDITIONS NOTED DURING CONSTRUCTION, WHICH DIFFER

FROM THOSE DESCRIBED IN THE GEOTECHNICAL REPORT SHALL BE

REPORTED TO THE ARCHITECT, STRUCTURAL ENGINEER AND GEOTECHNICAL

ENGINEER BEFORE FURTHER CONSTRUCTION IS ATTEMPTED.

02.09

WALLS RETAINING BACKFILL HAVE BEEN DESIGNED FOR IN SERVICE LOADS

ONLY. THE CONTRACTOR SHALL PROVIDE TEMPORARY SHORING DURING

CONSTRUCTION. THE SHORING SHALL NOT BE REMOVED UNTIL THE

SUPPORTING ELEMENTS ARE IN PLACE, THE CONCRETE IN THE WALLS AND

SUPPORTING ELEMENTS HAS ATTAINED THE SPECIFIED 28 DAY COMPRESSIVE

STRENGTH (FC') AND COMPACTION OF THE BACKFILL HAS BEEN COMPLETED.

02.10

DURING CONSTRUCTION, THE CONTRACTOR SHALL PROVIDE TEMPORARY

SHORING OF WALLS WHICH ARE ULTIMATELY SUPPORTED TOP AND BOTTOM.

SUCH SHORING SHALL NOT BE REMOVED UNTIL THE SUPPORTING ELEMENTS

ARE IN PLACE, THE CONCRETE IN THE WALLS AND SUPPORTING ELEMENTS

HAS ATTAINED THE SPECIFIED 28 DAY COMPRESSIVE STRENGTH (FC') AND

COMPACTION OF THE BACKFILL AGAINST THE WALL HAS BEEN COMPLETED.

02.11

A GRAVITY DRAINAGE SYSTEM IS REQUIRED TO PREVENT THE BUILD-UP OF

HYDROSTATIC PRESSURE BEHIND THE WALLS.

02.12

GENERAL CONTRACTOR SHALL NOTIFY THE ARCHITECT AND STRUCTURAL

ENGINEER, 24 HOURS PRIOR TO PLACEMENT OF CONCRETE IN THE FOOTINGS.

02.13

REINFORCEMENT PLACEMENT SEQUENCE FOR FOOTINGS IS NOTED ONLY FOR

MAJOR REINFORCEMENT BAR LAYERS. IN SPREAD FOOTINGS AND MATS THE

CONTRACTOR SHALL SEQUENCE ALL OTHER BAR PLACEMENTS AS REQUIRED

TO CONFORM TO THE CONTRACT DOCUMENTS.

02.14

02.15

02.17

BASIC WIND SPEED

ENCLOSURE

BUILDING CATEGORY

WIND EXPOSURE

INTERNAL PRESSURE COEFFICIENT

70 PCF

90 PCF

TEMPORARY STEEL CASING MAY BE REQUIRED DURING THE INSTALLATION OF

DRILLED PIERS (SEE GEOTECHNICAL REPORT). THE CONTRACTOR SHALL

PROVIDE A UNIT PRICE FOR THE USE OF STEEL CASING AS A SEPARATE ITEM

IN THE CONTRACT.

SUBGRADE UNDER SLABS ON FILL SHALL HAVE A MAXIMUM PLASTICITY INDEX

OF 15 AND SHALL BE PREPARED, PLACED AND COMPACTED IN STRICT

ACCORDANCE WITH THE RECOMMENDATIONS CONTAINED IN THE

GEOTECHNICAL REPORT.

SLABS ON GRADE SHALL HAVE CONSTRUCTION JOINTS OR CRACK CONTROL

JOINTS AT EACH COLUMN LINE IN EACH DIRECTION. ADDITIONAL CRACK

CONTROL JOINTS SHALL BE PROVIDED, SUCH THAT THE SPACING OF THE

JOINTS DOES NOT EXCEED 36 TIMES THE SLAB THICKNESS, AND THE RESULTING

ASPECT RATIO OF THE DIMENSIONS OF SLAB AREA DOES NOT EXCEED 1.5 TO 1.

CRACK CONTROL JOINTS SHALL BE MADE USING A "SOFT-CUT" CONCRETE SAW AS

SOON AS THE SLAB WILL SUPPORT THE WEIGHT OF THE SAW AND OPERATOR

WITHOUT DISTRUBING THE FINAL FINISH. REFER TO STANDARD FOUNDATION

DETAILS FOR INFORMATION ON CONTROL JOINTS, CONSTRUCTION JOINTS,

REINFORCEMENT DETAILS AND JOINT SEALANT DETAILS. FOR SLABS

REINFORCED WITH REINFORCING BARS OR WELDED WIRE FABRIC SUPPLIED

IN FLAT SHEETS PROVIDE STANDARD CORROSION RESISTANT HIGH-CHAIRS

WITH SAND BEARING PLATES TO MAINTAIN THE REINFORCEMENT AT OR ABOVE

THE MID-DEPTH OF THE SLAB.

GRADE BEAMS SHALL BE CAST ON 8 INCH DEEP x BEAM WIDTH CORRUGATED

CARDBOARD CARTON FORMS. CARTON FORMS SHALL BE SUREVOID WAX

COATED VERTICAL CELL RECTANGULAR BOXES (OR EQUIVALENT).

TRAPEZOIDAL VOID BOXES SHALL NOT BE USED. DIAGONAL CELL BOXES

SHALL NOT BE USED. BOXES SHALL NOT BE WRAPPED IN POLYETHYLENE. SOIL

RETAINERS SHALL BE USED ON EACH SIDE OF THE GRADE BEAM TO PREVENT SOIL

FROM SLOUGHING OFF INTO THE VOID. RETAINERS SHALL BE PLASTIC

MOTZBLOCK OR OTHER MATERIAL PROVIDED TO THE STRUCTURAL ENGINEER.

DEC 09, 2015 ISSUE FOR SITE ROUGH GRADING / GARAGE

FONDATION PERMIT

01-18-2016 FOUNDATION REVISIONS

120 MPH

ENCLOSED

III

B

0.18

BASIC WIND SPEED IS 3-SECOND GUST SPEED AT A REFERENCE ELEVATION

OF 33 FEET ABOVE THE GROUND.

01.05

ALL EXTERIOR COMPONENT AND CLADDING MATERIALS SHALL BE DESIGNED TO

WITHSTAND THE WIND PRESSURES SPECIFIED IN COMPONENTS AND CLADDING

LOAD TABLE, THIS SHEET.

01.06

ALL EXTERIOR PARAPET COMPONENT AND CLADDING MATERIALS SHALL BE

DESIGNED TO WITHSTAND THE WIND PRESSURES SPECIFIED IN PARAPET

COMPONENTS AND CLADDING LOAD TABLE, THIS SHEET.

01.07

THE GROUND SNOW LOAD 'Pg' FOR THIS AREA IS 5 PSF OR LESS.

01.08

THE STRUCTURE HAS BEEN DESIGNED TO WITHSTAND THE SEISMIC FORCES

SPECIFIED IN CHAPTER 16, SECTION 1613, OF THE INTERNATIONAL BUILDING

CODE, USING THE FOLLOWING PARAMETERS:

SEISMIC IMPORTANCE FACTOR

Ss

S1

SITE CLASS

SDS

SD1

OCCUPANCY CATEGORY

SEISMIC DESIGN CATEGORY

1.25

0.074g

0.040g

D

0.079g

0.065g

III

A

01.09

STRUCTURAL MEMBERS HAVE BEEN LOCATED AND DESIGNED TO

ACCOMMODATE THE MECHANICAL EQUIPMENT AND OPENINGS SPECIFIED BY

THE MECHANICAL CONSULTANT. ANY SUBSTITUTIONS RESULTING IN

REVISIONS TO THE STRUCTURE SHALL BE THE RESPONSIBILITY OF THE

CONTRACTOR TO COORDINATE WITH STRUCTURAL ENGINEER.

01.10

THE LIVE LOADS ARE NOT REDUCED IN PASSENGER CAR GARAGES EXCEPT

THE LIVE LOADS FOR MEMBERS SUPPORTING TWO OR MORE FLOORS ARE

REDUCED UP TO A MAXIMUM OF 20 PERCENT.

01.11

THE PARKING DECK FLOOR SYSTEM HAS BEEN DESIGNED TO WITHSTAND A

CONCENTRATED WHEEL LOAD OF 3000 POUNDS PLACED UPON ANY SPACE 20

SQUARE INCHES, IN ACCORDANCE WITH SECTION 1607 OF THE BUILDING

CODE.

01.12

GARAGE GUARDRAILS HAVE BEEN DESIGNED TO WITHSTAND A SERVICE LOAD

FORCE OF 6000 POUNDS APPLIED HORIZONTALLY AT 1'-6" ABOVE THE PARKING

LEVEL, IN COMPLIANCE WITH SECTION 1607.7.3 OF THE INTERNATIONAL

BUILDING CODE. THE FORCE MAY BE DISTRIBUTED OVER A 1 FT SQUARE

AREA.

01.13

THE STRUCTURE HAS BEEN DESIGNED FOR THE IN-SERVICE LOADS ONLY. THE

METHODS, PROCEDURES, AND SEQUENCES OF CONSTRUCTION ARE THE

RESPONSIBILITY OF THE CONTRACTOR. SUPPORTING FORMWORK FOR THE

CONCRETE CONSTRUCTION SHALL NOT BE REMOVED BEFORE THE CONCRETE

HAS GAINED SUFFICIENT STRENGTH TO SAFELY STRESS THE POSTTENSIONING TENDONS IN BOTH DIRECTIONS AND THE STRUCTURE HAS GAINED

SUFFICIENT STRENGTH TO SAFELY SUPPORT THE DEAD AND SUPERIMPOSED

LOADS WHICH WOULD BE SUBSEQUENTLY APPLIED. THE CONTRACTOR SHALL

TAKE ALLNECESSARY PRECAUTIONS TO MAINTAIN AND INSURE THE INTEGRITY

OF THE TRUCTURE AT ALL STAGES OF CONSTRUCTION.

SLAB ON GRADE SHALL BE UNDERLAID BY A MAXIMUM OF 2 INCHES OF SAND.

PRIOR TO PLACING THE SAND, THE FLOOR SUBGRADE SHALL BE PROPERLY

COMPACTED, PROOFROLLED, FREE OF STANDING WATER, MUD AND FROZEN

SOIL. BEFORE PLACEMENT OF THE CONCRETE, A VAPOR BARRIER SHALL BE

PLACED ON TOP OF THE GRANULAR MATERIAL.

VAPOR BARRIER SHALL CONFORM TO ASTM E1745, CLASS C OR BETTER AND

SHALL HAVE A MAXIMUM VAPOR PERMEANCE OF 0.04 PERMS WHEN TESTED IN

ACCORDANCE WITH ASTM E96. VAPOR BARRIER SHALL BE NO LESS THAN

10 MILS THICK IN ACCORDANCE WITH ACI 301.1R-96.

20 PSF

80 PSF

125 PSF

125 PSF

AS REQUIRED

40 PSF

ACTUAL WTS

AS PER SECTION 1609.1.1 OF THE INTERNATIONAL BUILDING CODE, THE

STRUCTURE HAS BEEN DESIGNED TO WITHSTAND THE WIND PRESSURES

SPECIFIED IN CHAPTER 6 OF ASCE 7, USING THE FOLLOWING INFORMATION:

WALLS RETAINING BACKFILL HAVE BEEN DESIGNED FOR THE FOLLOWING

LATERAL EARTH PRESSURES:

DRILLED PIERS SHALL BE EXCAVATED, CLEANED, REINFORCED AND

CONCRETE PLACED ON THE SAME DAY. DRILLED PIERS WITH LESS THAN 2'-0"

CLEAR BETWEEN BELLS OR SHAFTS SHALL BE EXCAVATED AND CONCRETE

PLACED A MINIMUM OF 24 HOURS APART. IF PIERS CAN NOT BE FORMED

WITHOUT CAVING OF THE SOIL, THE ARCHITECT, STRUCTURAL ENGINEER AND

GEOTECHNICAL ENGINEER SHALL BE NOTIFIED BEFORE FURTHER

CONSTRUCTION IS ATTEMPTED.

LIVE LOADS

ROOF

OFFICE

MECHANICAL SPACE

LIGHT STORAGE

MECHANICAL & PIPING LOADS

PARKING

MECHANICAL EQUIPMENT AND PADS

01.04

10,000 PSF

CANTILEVER RETAINING WALLS

WALLS SUPPORTED TOP AND BOTTOM

10 PSF

10 PSF

FIRE SPRINKLER PIPING SUPPORTED BY THE STRUCTURAL SYSTEM IS TO BE

DISTRIBUTED SO THAT THE WEIGHT OF THE WATER-FILLED PIPE DIVIDED BY

THE TRIBUTARY AREA OF THE SUPPORTING MEMBER DOES NOT EXCEED

5 POUNDS PER SQUARE FOOT, AND THE LOAD IMPARTED TO ANY ONE

STRUCTURAL MEMBER DOES NOT EXCEED 50 POUNDS PER LINEAR FOOT.

EACH STRUCTURAL SUPPORT OF THE PIPING SHALL BE DESIGNED TO SUPPORT

A LOAD EQUAL TO THE WEIGHT OF THE WATER-FILLED PIPE PLUS 250 POUNDS.

THE FOUNDATION FOR THE STRUCTURE HAS BEEN DESIGNED FOR THE

FOLLOWING ALLOWABLE SOIL BEARING PRESSURES AT A DEPTH OF 50 FT

BELOW EXISTING GRADE:

TOTAL LOAD

SUPERIMPOSED DEAD LOADS

CEILING + MECHANICAL

BUILT-UP ROOF

01.03

4,500 PSF

DRILLED AND UNDERREAMED PIERS

02.18

THE COMPRESSIVE STRENGTH OF CONCRETE IN POST-TENSIONED SLAB

SYSTEM AT TIME OF TRANSFER (FCI') SHALL BE CAPABLE OF DEVELOPING

ULTIMATE TENDON ANCHORAGE STRENGTH.

THE FOUNDATION FOR THE STRUCTURE HAS BEEN DESIGNED FOR THE

FOLLOWING ALLOWABLE SOIL BEARING PRESSURES AT A DEPTH OF 25 FT

BELOW EXISTING GRADE:

TOTAL LOAD

02.16

03.17

STRUCTURE HAS BEEN DESIGNED BASED ON A MAXIMUM POTENTIAL VERTICAL

RISE (PVR) OF 1 INCH. PER THE PROJECT GEOTECHNICAL REPORT, THE SLABS

ON GRADE WILL REQUIRE A MINIMUM OF 8 FT OF SELECT NON-EXPANSIVE

MATERIAL BELOW THE SLAB EXTENDING THROUGHOUT THE BUILDING LIMITS

AND UNDER THE ADJOINING FLATWORK. REFER TO THE GEOTECHNICAL REPORT

FOR ADDITIONAL REQUIREMENTS.

DRILLED AND UNDERREAMED PIERS

STRUCTURAL STEEL DETAILING, FABRICATION AND ERECTION SHALL CONFORM

TO THE AISC "SPECIFICATION FOR STRUCTURAL STEEL BUILDINGS" AND THE

MARCH 2000 VERSION OF THE AISC "CODE OF STANDARD PRACTICE FOR STEEL

BUILDINGS AND BRIDGES".

03.09

GRADE 60

GRADE 75

02.02

01.14

01.15

01.16

ELEVATOR SHAFT AND SUPPORT BEAMS HAVE BEEN DESIGNED AND DETAILED

BASED ON A(N) KONE ECOSPACE 3500 LB CAPACITY ELEVATOR. THE ELEVATOR

CONTRACTOR SHALL BE RESPONSIBLE FOR THE CONNECTION OF THE MACHINE

BEAMS AND/OR SECONDARY BEAMS TO THE STRUCTURE. SHOP DRAWINGS FOR

THE ELEVATORS SHOWING CONNECTION DETAILS, LOCATION AND MAGNITUDE OF

LOADS APPLIED TO THE STRUCTURE, ETC. SHALL BE SUBMITTED TO STRUCTURAL

ENGINEER FOR VERIFICATION OF DESIGN ASSUMPTIONS.

THE GENERAL CONTRACTOR AND SUBCONTRACTORS SHALL DETERMINE THE

SCOPE OF THE STRUCTURAL WORK FROM THE CONTRACT DOCUMENTS TAKEN AS

A WHOLE. THE STRUCTURAL DRAWINGS SHALL NOT BE CONSIDERED

SEPARATELY FOR PURPOSES OF BIDDING THE STRUCTURAL WORK. DUE

CONSIDERATION SHALL BE GIVEN TO OTHER STRUCTURAL WORK OR WORK

RELATED TO THE STRUCTURE, INCLUDING NECESSARY COORDINATION

DESCRIBED OR IMPLIED BY THE ARCHITECTURAL AND MECHANICAL DRAWINGS.

METHODS, PROCEDURES, AND SEQUENCES OF CONSTRUCTION ARE THE

RESPONSIBILITY OF THE CONTRACTOR. THE CONTRACTOR SHALL TAKE ALL

NECESSARY PRECAUTIONS TO MAINTAIN AND INSURE THE INTEGRITY OF THE

STRUCTURE AT ALL STAGES OF CONSTRUCTION.

01.17

THE REPRODUCTIVE USE OF THE STRUCTURAL CONTRACT DOCUMENTS OR

ELECTRONIC FILES AS STRUCTURAL SHOP DRAWING DOCUMENTS BY THE

CONTRACTOR OR SUB-CONTRACTORS IS AT THEIR OWN RISK. STRUCTURAL

ENGINEER ASSUMES NO LIABILITY AS THE RESULT OF THE REPRODUCTIVE USE

OF THE STRUCTURAL CONTRACT DOCUMENTS FOR SHOP DRAWINGS.

01.18

SCALES NOTED ON THE DRAWINGS ARE FOR GENERAL INFORMATION ONLY. NO

DIMENSIONAL INFORMATION SHALL BE OBTAINED BY DIRECT SCALING OF THE

DRAWINGS.

01.29

THE GENERAL CONTRACTOR IS RESPONSIBLE FOR COORDINATION OF ALL

RESULTING REVISIONS TO THE STRUCTURAL SYSTEM AS A RESULT OF

ACCEPTANCE OF CONTRACTOR PROPOSED ALTERNATIVES OR SUBSTITUTIONS.

01.20

PRINCIPAL OPENINGS IN THE STRUCTURE ARE INDICATED ON THE CONTRACT

DOCUMENTS. REFER TO THE ARCHITECTURAL, MECHANICAL, ELECTRICAL, AND

PLUMBING DRAWINGS FOR SLEEVES, CURBS, INSERTS, ETC. NOT HEREIN

INDICATED. OPENINGS IN SLABS WITH A MAXIMUM SIDE DIMENSION OR DIAMETER

OF 12 INCHES OR LESS SHALL NOT REQUIRE ADDITIONAL FRAMING OR

REINFORCEMENT, UNLESS NOTED OTHERWISE.THE LOCATION OF SLEEVES OR

OPENINGS IN STRUCTURAL MEMBERS SHALL BE SUBMITTED TO THE STRUCTURAL

ENGINEER FOR REVIEW.

GENERAL PROGRESS OF WORK.

1001 Fannin Street, Suite 4040 | Houston, Texas 77002 USA

Phone 713.622.1180 | Fax 713.622.7021

www.morris-hz.com

Project Team

STONEHENGE HOLDINGS LLC

OWNER

MORRIS

ARCHITECT

HUITT-ZOLLARS, INC.

CIVIL ENGINEER

ENSIGHT HAYNES WHALEY, LLC

STRUCTURAL ENGINEER

BLUM CONSUTLING ENGINEER, INC.

MEP ENGINEER

THE OFFICE OF JAMES BURNETT

LANDSCAPE CONSULTANT

FERGUSON CONSULTING, INC.

TECHNOLOGY / SECURITY CONSULTANT

DESIGN LOAD (psf)

ZONE

0-10 sq ft

>100 sq ft

12.1, -29.6

10, -27.1

12.1, -49.5

10, -32.1

12.1, -74.8

10, -32.1

2 (O.H.)

-47.2

-44.7

3 (O.H.)

-74.8

-24.6

ZONE

0-10 sq ft

>500 sq ft

22.6, -22.6

15.1, -17.6

22.6, -25.1

15.1, -25.1

SHOP DRAWINGS SHALL NOT SHOW MATERIALS FOR MORE THAN ONE LEVEL OF

THE SAME PLAN.

3000 PSI

4000 PSI

4000 PSI

4000 PSI

4000 PSI

3500 PSI

4000 PSI

SEE SCHEDULE

SEE SCHEDULE

5000 PSI

3750 PSI

PARAPET DESIGN LOAD (psf)

INTERIOR ZONE

h

0-30

40

50

60

CORNER ZONE

FRONT SURFACE

BACK SURFACE

FRONT SURFACE

BACK SURFACE

0-10 sf

>500 sf

0-10 sf

>500 sf

0-10 sf

>500 sf

0-10 sf

>500 sf

+22.0

+15.4

+22.0

+15.4

+22.0

+15.4

+22.0

+15.4

-19.8

-15.4

-39.5

-24.1

-39.5

-22.0

-61.5

-24.1

+23.8

+16.7

+23.8

+16.7

+23.8

+16.7

+23.8

+16.7

-21.4

-16.7

-42.9

-26.2

-42.9

-23.8

-66.7

-26.2

+25.4

+17.8

+25.4

+17.8

+25.4

+17.8

+25.4

+17.8

-22.9

-17.8

-45.7

-27.9

-45.7

-25.4

-71.1

-27.9

+26.8

+18.7

+26.8

+18.7

+26.8

+18.7

+26.8

+18.7

-24.1

-18.7

-48.2

-29.4

-48.2

-26.8

-74.9

-29.4

(BUILDING CATEGORY III, EXPOSURE B, V = 120 MPH, GABLE/HIP ROOF <7 DEGREES)

COMPONENTS & CLADDING WIND LOAD - PARAPETS

01-18-2016

Project Name

TEXAS A&M CAIN HALL SITE

4

REDEVELOPMENT - VOLUME 4

500 GENE STALLINGS BOULEVARD,

COLLEGE STATION, TEXAS 77840

06.03

DRILLED PIERS

PIER CAPS

PLINTHS

FOOTINGS

GRADE BEAMS

SLABS ON GRADE

WALLS

COLUMNS

SHEAR WALLS

POST TENSIONED SLAB SYSTEMS

MINIMUM AT TRANSFER (FCI')

MASONRY UNITS SHALL BE GRADE N, TYPE I LIGHT WEIGHT OR MEDIUM WEIGHT

HOLLOW CONCRETE UNITS MEETING FIRE RATING REQUIREMENTS AND

CONFORMING TO THE REQUIREMENTS OF ASTM C90. MASONRY UNITS SHALL

HAVE A MINIMUM COMPRESSIVE STRENGTH OF 1900 PSI ON THE NET AREA AT 28

DAYS, BUT NOT LESS THAN THE REQUIRED STRENGTH TO PRODUCE THE MINIMUM

MASONRY STRENGTH (F'M). MASONRY UNITS SHALL NOT BE INSTALLED PRIOR TO

ATTAINING THE REQUIRED 28 DAY STRENGTH.

h = 57 ft

a = 15 ft

JANUARY 18, 2016

Project Number

R303928.03

Drawing Name

NOTES

a

06.02

Description

1.

(0-10 sq ft) EXAMPLE DENOTES EFFECTIVE WIND AREA.

2.

+ AND - SIGNS SIGNIFY PRESSURES ACTING TOWARD OR AWAY

FROM THE SUFACES, RESPECTIVELY.

3.

WIND PRESSURES MAY BE INTERPOLATED FOR EFFECTIVE WIND

AREAS BETWEEN THE SPECIFIED RANGES.

4.

(O.H.) REFERS TO ROOF OVERHANG.

GENERAL

STRUCTURAL NOTES

Scale:

(BUILDING CATEGORY III, EXPOSURE B, V = 120 MPH, GABLE/HIP ROOF <7 DEGREES)

COMPONENTS & CLADDING WIND LOAD

12" = 1'-0"

Drawing Number

S-0.00

Вам также может понравиться

- Structural Steel and Reinforcing Steel Inspection and Testing RequirementsДокумент20 страницStructural Steel and Reinforcing Steel Inspection and Testing RequirementsRommel Abenoja100% (2)

- APartment and Restuarant SINGLE FILEДокумент4 страницыAPartment and Restuarant SINGLE FILEAkela RichardОценок пока нет

- 07 - General NotesДокумент1 страница07 - General NotesDave LicerioОценок пока нет

- Pre - Engineered BuildingsДокумент19 страницPre - Engineered BuildingsPratikKhatmodeОценок пока нет

- 08 JOSE Structural Design Practice in Phillippines PDFДокумент53 страницы08 JOSE Structural Design Practice in Phillippines PDFDiana celestialОценок пока нет

- A-5.01 Typical Lift DetailsДокумент1 страницаA-5.01 Typical Lift DetailsamitОценок пока нет

- Drawings and specifications for proposed 40-storey condominium buildingДокумент1 страницаDrawings and specifications for proposed 40-storey condominium buildingGarduque AngreysОценок пока нет

- Design Consultancy FeeДокумент3 страницыDesign Consultancy FeeSaima Akhtar SyedОценок пока нет

- Earthquake Resistant Design ConceptsДокумент55 страницEarthquake Resistant Design ConceptsKatherine Shayne Yee100% (1)

- Certificate of StabilityДокумент1 страницаCertificate of StabilitySreedharanPNОценок пока нет

- Extrude Solutions Company Profile October 2009Документ11 страницExtrude Solutions Company Profile October 2009Ernest Christian NanolaОценок пока нет

- Metal Deck PDFДокумент1 страницаMetal Deck PDFabet hilarioОценок пока нет

- Ac 001 List of DrawingsДокумент1 страницаAc 001 List of Drawingswael hassanОценок пока нет

- Working DrawingsДокумент7 страницWorking DrawingsJanak NepalОценок пока нет

- TV UnitДокумент1 страницаTV UnitNavin NaОценок пока нет

- Technical SpecificationsДокумент8 страницTechnical SpecificationsAngel AbrajanoОценок пока нет

- Structural General NotesДокумент1 страницаStructural General Notesjuan camiloОценок пока нет

- Summary Sheet (Annexure F1 & F2)Документ5 страницSummary Sheet (Annexure F1 & F2)Ajay Malik100% (1)

- Toilet Details R1 A2Документ1 страницаToilet Details R1 A2Irshad KhanОценок пока нет

- Beginner's Guide To Structural AnalysisДокумент20 страницBeginner's Guide To Structural Analysisricosanojuan100% (1)

- Steel Members DesignДокумент26 страницSteel Members DesignApple Grace S. ValenciaОценок пока нет

- LIFTS SYSTEM HISTORY AND COMPONENTSДокумент47 страницLIFTS SYSTEM HISTORY AND COMPONENTSWyncie CariñoОценок пока нет

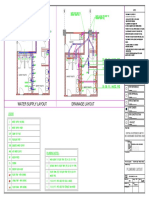

- Water and Drainage Layout for Building Interior DesignДокумент1 страницаWater and Drainage Layout for Building Interior DesignKriya SinghОценок пока нет

- Occupancy CategoryДокумент1 страницаOccupancy CategoryTracyval CadaОценок пока нет

- Column & Footing Details Block-1 & Block-2Документ1 страницаColumn & Footing Details Block-1 & Block-2Sandeep VarmaОценок пока нет

- DCPR 2034 Note I Regulations 1-29Документ26 страницDCPR 2034 Note I Regulations 1-29Saurin Khanolkar100% (1)

- Residential Proposed Three-Storey: Engr. Mayson R. FesalbonДокумент1 страницаResidential Proposed Three-Storey: Engr. Mayson R. FesalbonMarc Arjo MontelibanoОценок пока нет

- Wdrive BoostersДокумент72 страницыWdrive BoostersAnonymous 7lcVBaOPNgОценок пока нет

- Its 2008 IRR: Revised Rules and StandardsДокумент32 страницыIts 2008 IRR: Revised Rules and StandardsErika RafaelОценок пока нет

- Tensile Membrane StructuresДокумент16 страницTensile Membrane StructuressriОценок пока нет

- Centex Gas Station:Starbucks ProposalДокумент2 страницыCentex Gas Station:Starbucks ProposalnewsroomОценок пока нет

- General Detail-General Detail FullДокумент1 страницаGeneral Detail-General Detail FullHaque BossAnwarОценок пока нет

- Waffle SlabДокумент3 страницыWaffle Slabnarotham_medi4108100% (2)

- Substrate: QV1 Mechanical Fastening System Using Visible RivetsДокумент12 страницSubstrate: QV1 Mechanical Fastening System Using Visible RivetssebkahnОценок пока нет

- Basement 1 Floor Plan Basement 2 Floor Plan: High Rise Office and Commercial BuildingДокумент1 страницаBasement 1 Floor Plan Basement 2 Floor Plan: High Rise Office and Commercial BuildingLeidy Evangelista FujitaОценок пока нет

- Tibetan Canadian Cultural Center Tender Package: Coolearth Architecture IncДокумент70 страницTibetan Canadian Cultural Center Tender Package: Coolearth Architecture IncM IQbalОценок пока нет

- Plumbing Layout Layout1Документ1 страницаPlumbing Layout Layout1Ej ApeloОценок пока нет

- FM-CPM22-01 CSHP Application Form - Simplified - REV 0 - MAY 19 2020Документ1 страницаFM-CPM22-01 CSHP Application Form - Simplified - REV 0 - MAY 19 2020Benedict NisperosОценок пока нет

- New Civil Structural Permit FormДокумент2 страницыNew Civil Structural Permit FormRodolfo NidoyОценок пока нет

- Long Span Structure PDFДокумент123 страницыLong Span Structure PDFSammy NguyenОценок пока нет

- Roof Apex and Side Elevation Diagrams for 2 Storey ResidenceДокумент1 страницаRoof Apex and Side Elevation Diagrams for 2 Storey ResidenceJoanne Managuit BangoyОценок пока нет

- Client Architect Agreement Caa-2009 PDFДокумент13 страницClient Architect Agreement Caa-2009 PDFjustnewbieОценок пока нет

- Specification of 1BHK Bungalow: StructureДокумент2 страницыSpecification of 1BHK Bungalow: StructureJayson MalaaОценок пока нет

- General and Technical Specification Section 1.0-GeneralДокумент3 страницыGeneral and Technical Specification Section 1.0-GeneralTarhata KalimОценок пока нет

- Walmart Site PlanДокумент1 страницаWalmart Site PlanProsper SpeaksОценок пока нет

- Is 13920 1993Документ24 страницыIs 13920 1993structuralengineersОценок пока нет

- Case Study Oasis TowersДокумент1 страницаCase Study Oasis TowersSameera BommisettyОценок пока нет

- Bom Specs EsteДокумент7 страницBom Specs EsteNikolai GongoraОценок пока нет

- Metric Handbook Planning AND Design Data: Edited by David AdlerДокумент17 страницMetric Handbook Planning AND Design Data: Edited by David AdlerEng Venance MasanjaОценок пока нет

- ALUMINIUM JOINERY DETAILS-R0dwg-ModelДокумент1 страницаALUMINIUM JOINERY DETAILS-R0dwg-ModelVijjy Vijaya KumarОценок пока нет

- High-Rise Building: Structural System & ServicesДокумент72 страницыHigh-Rise Building: Structural System & ServicesSukirt VermaОценок пока нет

- Precast Concrete SlabДокумент55 страницPrecast Concrete SlabKimberly LoОценок пока нет

- Maqueta Mariel PDFДокумент17 страницMaqueta Mariel PDFRichardОценок пока нет

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Документ1 страницаConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASОценок пока нет

- Jain Ariditha-1Документ26 страницJain Ariditha-1preethiОценок пока нет

- Space Frame Structures ExplainedДокумент40 страницSpace Frame Structures ExplainedB-05 ISHA PATELОценок пока нет

- Structural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesДокумент17 страницStructural analysis of multi-storey steel frames exposed to travelling fires and traditional design firesAlem LoajnerОценок пока нет

- General Notes & SpecificationsДокумент6 страницGeneral Notes & SpecificationsDon Santos100% (1)

- General Notes 2Документ5 страницGeneral Notes 2Amer GonzalesОценок пока нет

- Slab Design Span 7mДокумент12 страницSlab Design Span 7mKrish ChandОценок пока нет

- GE 441 Course Syllabus-2008Документ2 страницыGE 441 Course Syllabus-2008Godino ChristianОценок пока нет

- Chelsey EPPДокумент3 страницыChelsey EPPGodino ChristianОценок пока нет

- Additional NotesДокумент7 страницAdditional NotesGodino ChristianОценок пока нет

- No Sugar ChallengeДокумент1 страницаNo Sugar ChallengeGodino ChristianОценок пока нет

- Decelaration Lane DesignДокумент3 страницыDecelaration Lane DesignGodino ChristianОценок пока нет

- Global Mapper TutorialДокумент14 страницGlobal Mapper TutorialGodino ChristianОценок пока нет

- Civil Engineering Drawing Sheets and DetailsДокумент1 страницаCivil Engineering Drawing Sheets and DetailsGodino ChristianОценок пока нет

- Corrugated Metal Roof Sheets and Accessories ListingДокумент1 страницаCorrugated Metal Roof Sheets and Accessories ListingGodino ChristianОценок пока нет

- Chelsey Assignment 1Документ2 страницыChelsey Assignment 1Godino ChristianОценок пока нет

- Summit County Site Plan Check ListДокумент1 страницаSummit County Site Plan Check ListGodino ChristianОценок пока нет

- Celebrating Oscar's 4th BirthdayДокумент1 страницаCelebrating Oscar's 4th BirthdayGodino ChristianОценок пока нет

- Topo of Land - Each Contour Is 2 Ft.Документ1 страницаTopo of Land - Each Contour Is 2 Ft.Godino ChristianОценок пока нет

- Lot Information: Golden Bear Loop WestДокумент1 страницаLot Information: Golden Bear Loop WestGodino ChristianОценок пока нет

- Sample SmartviewДокумент1 страницаSample SmartviewGodino ChristianОценок пока нет

- Lot Information: Golden Bear Loop WestДокумент1 страницаLot Information: Golden Bear Loop WestGodino ChristianОценок пока нет

- Grade I Ilang Ilang 2020-2021Документ1 страницаGrade I Ilang Ilang 2020-2021Godino ChristianОценок пока нет

- Base PlanДокумент1 страницаBase PlanGodino ChristianОценок пока нет

- Chelsey Assignment 1Документ2 страницыChelsey Assignment 1Godino ChristianОценок пока нет

- PHYSICAL WEATHERING - FrancesДокумент5 страницPHYSICAL WEATHERING - FrancesGodino ChristianОценок пока нет

- Grade I Ilang Ilang 2020-2021Документ1 страницаGrade I Ilang Ilang 2020-2021Godino ChristianОценок пока нет

- Nanay 2Документ3 страницыNanay 2Godino ChristianОценок пока нет

- Alang Drainage - CIVIL3D - Final-CS1Документ1 страницаAlang Drainage - CIVIL3D - Final-CS1Godino ChristianОценок пока нет

- Chelsey Assignment2Документ4 страницыChelsey Assignment2Godino ChristianОценок пока нет

- Nanay 2Документ3 страницыNanay 2Godino ChristianОценок пока нет

- Regional Manager NIA Region 3, Tambubong, San Rafael, BulaacanДокумент1 страницаRegional Manager NIA Region 3, Tambubong, San Rafael, BulaacanGodino ChristianОценок пока нет

- Chelsey Assignment 3Документ2 страницыChelsey Assignment 3Godino ChristianОценок пока нет

- Vaccine - Ate FormДокумент2 страницыVaccine - Ate FormGodino ChristianОценок пока нет

- Alang Drainage - CIVIL3D - Final-C-2Документ1 страницаAlang Drainage - CIVIL3D - Final-C-2Godino ChristianОценок пока нет

- John Paul Application TraineeДокумент2 страницыJohn Paul Application TraineeGodino ChristianОценок пока нет

- PCCP Minimum StandardДокумент3 страницыPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- Hilti Shear ConnectorsДокумент52 страницыHilti Shear Connectorssuman_civilОценок пока нет

- RCC Lab ReportДокумент18 страницRCC Lab ReportShuvanjan Dahal50% (4)

- 435R-95 Control of Deflection in Concrete StructuresДокумент89 страниц435R-95 Control of Deflection in Concrete StructuresIbrahim MОценок пока нет

- Structural Steel Solution: Beams - Columns - Angles - ChannelsДокумент24 страницыStructural Steel Solution: Beams - Columns - Angles - ChannelsPradeepОценок пока нет

- Internal Road - With RateДокумент34 страницыInternal Road - With RateROAD KINGОценок пока нет

- Assignment 1 SolutionДокумент48 страницAssignment 1 SolutionBibhuti B. BhardwajОценок пока нет

- CE-324 Soil Mechanics-II Chapter: Pile FoundationsДокумент93 страницыCE-324 Soil Mechanics-II Chapter: Pile FoundationsAli BajwaОценок пока нет

- Damp-proofing methods to prevent moisture damageДокумент68 страницDamp-proofing methods to prevent moisture damageMARUFОценок пока нет

- Concrete Grade EquivalentДокумент3 страницыConcrete Grade EquivalentHoang Duc LocОценок пока нет

- Bubble Deck Slab REPORTДокумент29 страницBubble Deck Slab REPORTMangesh ShindeОценок пока нет

- M23-50 15complete PDFДокумент1 306 страницM23-50 15complete PDFIbnuyusoff77Оценок пока нет

- Chapter 6 STEELДокумент20 страницChapter 6 STEELhannah cedОценок пока нет

- Civil HPCДокумент14 страницCivil HPCVivek Raj GuptaОценок пока нет

- NL4 Notes Concrete RepairДокумент18 страницNL4 Notes Concrete Repairjeffyeung2015Оценок пока нет

- Cables and Arches: Tension Forces and Structural AnalysisДокумент24 страницыCables and Arches: Tension Forces and Structural AnalysisOne Less than TwiceОценок пока нет

- Monitoring Steel Girder Stability PDFДокумент12 страницMonitoring Steel Girder Stability PDFYaselaОценок пока нет

- Helicoidal StairДокумент5 страницHelicoidal StairGandhi HammoudОценок пока нет

- SLAB DESIGN CALCULATIONSДокумент6 страницSLAB DESIGN CALCULATIONSsharathkn50% (2)

- 009-wms For Wood Partition WorkДокумент6 страниц009-wms For Wood Partition WorkRaman BhadouriaОценок пока нет

- Feasibility Study Drawings of China-Maldives Friendship BridgeДокумент95 страницFeasibility Study Drawings of China-Maldives Friendship Bridgeani4576100% (1)

- Analysis of continuous prestressed concrete beamsДокумент14 страницAnalysis of continuous prestressed concrete beamsChinnu JacobОценок пока нет

- Profiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Документ2 страницыProfiled Steel Sheets: Sacrificial Siiuttering (Form Deck)Sarmishtha DeОценок пока нет

- Code of Practice for Underground Winding SystemsДокумент58 страницCode of Practice for Underground Winding SystemsSteve PennОценок пока нет

- Investigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeДокумент12 страницInvestigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeIJRASETPublicationsОценок пока нет

- Rigid Pavement: Joints & ReinforcementДокумент7 страницRigid Pavement: Joints & ReinforcementTeCkMunОценок пока нет

- Alberta Transportation Integral AbutmentДокумент13 страницAlberta Transportation Integral AbutmentMehdi.MostОценок пока нет

- RCC RulesДокумент18 страницRCC RulessitaramgvsОценок пока нет

- Circular Water Tank Design and Reinforcement LayoutДокумент28 страницCircular Water Tank Design and Reinforcement LayoutLachu M. SharmaОценок пока нет

- Concrete Mix Design m75Документ2 страницыConcrete Mix Design m75nil sutar100% (1)

- Government Polytechnic Civil Engineering Building Cracks Investigation and Repair ReportДокумент10 страницGovernment Polytechnic Civil Engineering Building Cracks Investigation and Repair ReportJoshi MayurОценок пока нет