Академический Документы

Профессиональный Документы

Культура Документы

Plan de Manteniemiento m53 Mtu

Загружено:

Nippur de LagashОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Plan de Manteniemiento m53 Mtu

Загружено:

Nippur de LagashАвторское право:

Доступные форматы

MTU_ValueService

Technical Documentation

Diesel Engine

8 V 4000 M53R

Application Group 1A

Maintenance Schedule

MS50062/00E

applicable for ...

8V4000M53R

Printed in Germany

2010 Copyright MTU Friedrichshafen GmbH

This Publication is protected by copyright and may not be used in any way whether in whole or in part without the

prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution,

translation, microfilming and storage or processing on electronic systems including data bases and online services.

This handbook is provided for use by maintenance and operating personnel in order to avoid malfunctions or

damage during operation.

Subject to alterations and amendments.

Preface

01

Preface

MTU maintenance concept

Emission regulations prohibit alteration, removal or addition of any mechanical or electronic component or

calibration that could affect the emissions characteristics of the engine. Maintenance, replacement, or repair of

emission control devices and systems can only be performed using MTU approved components or equivalents.

Failure to adhere to these guidelines may be a violation of the Clean Air Act.

MTU Maintenance Schedules ensure the reliability and performance of MTU engines and must be

adhered to during the full life of the engine.

The maintenance system for MTU products is based on a preventive maintenance concept. Preventive maintenance

facilitates advance planning and ensures a high level of equipment availability.

The maintenance schedule is based on the load profile / load factor specified below. Special operating conditions and

technical requirements may require additional maintenance work and/or modification of the maintenance intervals. In

order to be authorized to carry out the individual maintenance jobs, maintenance personnel must have achieved a level

of training and qualification appropriate to the complexity of the task in hand. The various Qualification Levels QL1 to

QL4 reflect the levels of training offered in MTU courses and the contents of the tool kits required:

QL1: Operational monitoring and maintenance which can be carried out during a break in operation without disassembling the engine.

QL2: Component exchange (corrective only).

QL3: Maintenance work which requires partial disassembly of the engine.

QL4: Maintenance work which requires complete disassembly of the engine.

The maintenance schedule matrix normally finishes with extended component maintenance. Following this,

maintenance work is to be continued at the intervals indicated.

The numbers stated in the list of jobs provide a reference to the scope of parts required.

Notes on maintenance

Specifications for fluids and lubricants, guideline values for their maintenance and change intervals and lists of

recommended fluids and lubricants are contained in the MTU Fluids and Lubricants Specifications A001061 and in the

fluids and lubricants specifications produced by the component manufacturers. They are therefore not included in the

maintenance schedule (exception: deviations from the Fluids and Lubricants Specifications). All fluids and lubricants

used must meet MTU specifications and be approved by the relevant component manufacturer.

Amongst other items, the operator/customer must carry out the following additional maintenance work:

Protect components made of rubber or synthetic material from oil. Never treat them with

organic detergents. Wipe with a dry cloth only.

Fuel prefilter:

The maintenance interval depends on how dirty the fuel is. The paper inserts in fuel prefilters

must be changed every two years at the latest (Task 9998).

Battery:

Battery maintenance depends on the level of use and the ambient conditions. The battery

manufacturers instructions must be obeyed.

The relevant manufacturers instructions apply with respect to the maintenance of any components

which do not appear in this maintenance schedule.

This Maintenance Schedule may include components which are not installed on your engine; these may be disregarded.

Out-of-service periods

If the engine is to remain out of service for more than 1 month, carry out engine preservation procedures in accordance

with the Fluids and Lubricants Specifications, MTU Publication No. A001061.

Application Group

TIM ID: 0000000001 001

1A

Continuous operation, unrestricted

Load profile

Load factor

100%

90%

<15%

Corresponding operating time

20%

70%

10%

Max. number of load cycles 1

(<10% to >90%): 2/h

Max. number of load cycles 2

(<10% to >70...90%): 2/h

MS50062/00E

2010-02

MTU

02

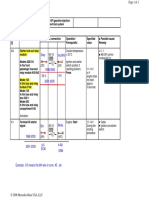

Maintenance schedule matrix

Maintenance schedule matrix

0-10.500 Operating hours

Item

1.000

1.500

2.000

2.500

3.000

3.500

4.000

4.500

5.000

5.500

6.000

6.500

7.000

7.500

8.000

8.500

9.000

9.500

10.000

10.500

Engine operation

Air ducting

Centrifugal oil filter

Valve gear

Fuel filter

2a

Fuel prefilter

2a

Primary fuel filter

2a

Engine mounts

1a

Turbochargers

Coolant filters

3a

Limit

Daily

500

Operating hours [h]

Fuel servicing plant

1a

Fuel servicing plant

2a

Engine oil filter

2a

Air filters

Battery charging generator

Fuel injectors

Combustion chambers

Turbochargers

Component maintenance

Oil replenishment pump

Oil-level regulating pump

Engine mounts

5a

Rubber sleeves

6a

Cylinder heads

HP fuel pumps

Hose lines

6a

Extended component maintenance

18 a

Elastomer coupling (main PTO)

18 a

TIM ID: 0000000002 001

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

Maintenance schedule matrix

03

11.000-21.500 Operating hours

Item

11.500

12.000

12.500

13.000

13.500

14.000

14.500

15.000

15.500

16.000

16.500

17.000

17.500

18.000

18.500

19.000

19.500

20.000

20.500

21.000

21.500

Engine operation

Air ducting

Centrifugal oil filter

Valve gear

Fuel filter

2a

Fuel prefilter

2a

Primary fuel filter

2a

Engine mounts

1a

Turbochargers

Coolant filters

3a

Limit

11.000

Operating hours [h]

Fuel servicing plant

1a

Fuel servicing plant

2a

Engine oil filter

2a

Air filters

Battery charging generator

Fuel injectors

Combustion chambers

Turbochargers

Component maintenance

Oil replenishment pump

Oil-level regulating pump

Engine mounts

5a

Rubber sleeves

6a

Cylinder heads

HP fuel pumps

Hose lines

6a

Extended component maintenance

18 a

Elastomer coupling (main PTO)

18 a

TIM ID: 0000000002 001

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

04

Maintenance schedule matrix

22.000-30.000 Operating hours

Item

22.500

23.000

23.500

24.000

24.500

25.000

25.500

26.000

26.500

27.000

27.500

28.000

28.500

29.000

29.500

30.000

Engine operation

Air ducting

Centrifugal oil filter

Valve gear

Fuel filter

2a

Fuel prefilter

2a

Primary fuel filter

2a

Engine mounts

1a

Turbochargers

Coolant filters

3a

Limit

22.000

Operating hours [h]

Fuel servicing plant

1a

Fuel servicing plant

2a

Engine oil filter

2a

Air filters

Battery charging generator

Fuel injectors

Combustion chambers

Turbochargers

Component maintenance

Oil replenishment pump

Oil-level regulating pump

Engine mounts

5a

Rubber sleeves

6a

Cylinder heads

HP fuel pumps

Hose lines

6a

Extended component maintenance

18 a

Elastomer coupling (main PTO)

18 a

TIM ID: 0000000002 001

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

Maintenance tasks

05

Maintenance tasks

Interval

Qualification

level

[h]

QL1

Limit

Item

Maintenance tasks

Task

1a

Fuel servicing plant

Check alarm function for differential pressure gauge.

W1245

Check pump performance.

W1246

QL1

2a

Fuel servicing plant

Check function of rod electrode.

W1244

QL1

2a

Engine oil filter

Fit new engine oil filters each time the engine oil is changed or, at the

latest, on expiry of the time limit (given in years) .

W1008

QL1

Daily

Engine operation

Check engine oil level .

W0500

Carry out visual inspection of engine for general condition and leaks .

W0501

Inspect intercooler drain system (if fitted) .

W0502

Inspect service indicator of air filter .

W0503

Check the inspection bores of the HP fuel pump .

W0504

Check relief bores of coolant pump(s) .

W0505

Check for abnormal running noises, exhaust gas color and vibration .

W0506

Drain off water and contamination from fuel prefilter (if fitted) .

W0507

Check service indicator of fuel prefilter (if fitted) .

W0508

QL1

500

Air ducting

Inspect air ducting between air filters and turbochargers for leaks

and damage.

W1029

QL1

500

Centrifugal oil filter

Check thickness of oil residue layer. Clean. Fit new sleeve (if fitted) .

W1009

QL1

1000

Valve gear

Check valve clearance .

W1002

QL1

1000

2a

Fuel filter

Fit new fuel filter or new fuel filter insert .

W1001

QL1

1000

2a

Fuel prefilter

Depending on the degree of contamination but at the latest before

expiry of the time limit (in years), fit new filter insert and sealing ring (if

fitted) .

W1494

QL1

1000

2a

Primary fuel filter

Fit new primary fuel filter or primary fuel filter insert (if fitted) .

W1495

QL1

1000

1a

Engine mounts

Carry out visual inspection of engine mounts for general condition .

W1463

2000

Turbochargers

Turbocharger: Clean compressor wheel .

W1076

QL1

3000

Coolant filters

Fit new coolant filters .

W1036

QL1

3000

3a

Air filters

Fit new air filters .

W1005

QL1

5000

Battery charging generator

Battery-charging generator: Check condition of coupling .

W1016

QL1

5000

Fuel injectors

Fit new fuel injectors .

W1006

QL1

5000

Combustion chambers

Inspect cylinder chambers using endoscope .

W1011

QL3

10000

Turbochargers

Overhaul turbochargers.

W1038

Fit new aluminum compressor wheels on secondary turbochargers .

W1493

Before starting maintenance work, carry out test run and record

operating parameters. Then drain coolant and flush cooling systems .

W2012

Inspect rocker arms and valve bridge for wear. Insert an endoscope

through the pushrod bore to visually inspect swing followers and

camshaft running surfaces .

W2001

Clean air ducting .

W2002

Clean intercooler and inspect for leakage .

W2003

Fit new high-pressure fuel sensor .

W2004

QL1

15000

TIM ID: 0000000003 001

QL3

Component maintenance

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

06

Interval

Limit

Item

Maintenance tasks

Task

Check engine coolant thermostat and fit new thermal actuator .

W2006

Inspect centrifugal oil filter for wear (if fitted) .

W2009

Overhaul starter .

W2010

Clean engine coolant cooler (if fitted) and, if possible, inspect it for

leaks .

W2149

Clean engine oil cooler and inspect it for leaks .

W2018

Fit new seals/sealing materials for all disassembled components .

W2062

Overhaul engine coolant pump .

W2110

Overhaul raw-water pump (if fitted) .

W2150

Overhaul bilge pump (if fitted) .

W2112

Check operation of diverter valve .

W2151

[h]

15000

Oil replenishment pump

Check for wear (if fitted) .

W1513

QL3

15000

Oil-level regulating pump

Check for wear (if fitted) .

W1514

QL3

15000

5a

Engine mounts

Check buffer clearance of resilient mounts Check proper seating of

securing screws .

W1026

Check for cracks. Measure cracks if necessary. Measure height of

rubber elements .

W1462

QL3

15000

6a

Rubber sleeves

Replace all rubber sleeves .

W1250

QL3

15000

Cylinder heads

Overhaul cylinder heads. Visually inspect piston crowns and wear

pattern on cylinder liner running surfaces .

W1063

QL3

15000

HP fuel pumps

Fit new HP fuel pumps.

W1058

QL3

30000

6a

Hose lines

Replace all hose lines .

W1251

QL4

30000

18 a

Extended component

maintenance

Completely disassemble the engine.Inspect engine components

as per assembly instructions and repair or fit new components as

required .

W3000

Replace all elastomeric parts and seals with new ones .

W3001

Fit new piston rings .

W3002

Fit new conrod bearings .

W3003

Fit new crankshaft bearings .

W3004

Fit new cylinder liners .

W3005

Fit new fuel delivery pump .

W3010

Fit new actuating cylinders for air flow control flaps .

W3011

Fit new actuator cylinders for exhaust flaps .

W3012

Fit new exhaust flap bearings .

W3013

Fit new camshaft bearings and camshaft thrust bearings .

W3018

Fit new pressure relief valve in high-pressure fuel system .

W3021

Overhaul battery-charging generator .

W3042

Check gear train for cracks, replace bushings, check axles and

replace if necessary .

W3063

Fit new engine oil pump.

W3073

Replace wiring harnesses.

W3083

QL3

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

TIM ID: 0000000003 001

Qualification

level

Maintenance tasks

Maintenance tasks

Qualification

level

QL4

Interval

Limit

07

Item

Maintenance tasks

Task

Fit new rubber elements of engine mounts .

W3100

Replace swing followers and swing-follower shafts .

W3103

Fit new oil replenishment pump (if fitted) .

W3106

Fit new oil-level regulating pump (if fitted) .

W3107

Check vibration damper, fit new one if necessary .

W3108

Fit new elastomer components (if fitted) .

W1544

[h]

30000

18 a

Elastomer coupling (main

PTO)

TIM ID: 0000000003 001

w = weeks

m = months

a = years

MS50062/00E

2010-02

MTU

Вам также может понравиться

- 8v Mtu Engine ManualДокумент1 страница8v Mtu Engine ManualNos Gote25% (8)

- MTU 4000 Maintenance ScheduleДокумент35 страницMTU 4000 Maintenance Schedulenereomad100% (8)

- Audi B8 CAGA Engine WiringДокумент24 страницыAudi B8 CAGA Engine WiringjuanОценок пока нет

- Maintenance ScheduleДокумент22 страницыMaintenance ScheduleDen100% (2)

- Workshop Manual MTU4000R41Документ1 846 страницWorkshop Manual MTU4000R41AnuruddhaSamaradiwakara93% (15)

- Claas Dominator 218 202 Mega II Hydraulics Electrics ServiceДокумент208 страницClaas Dominator 218 202 Mega II Hydraulics Electrics ServiceVlad Ptashnichenko100% (1)

- Maint Sched 12 or 8 V183 TE93Документ4 страницыMaint Sched 12 or 8 V183 TE93dieseldogwillie100% (2)

- Mtu Engine 8v2000m41a Parts Catalog - 531101840-1Документ257 страницMtu Engine 8v2000m41a Parts Catalog - 531101840-1Kevin Burke100% (3)

- E532284 - Funcional Descrition MtuДокумент42 страницыE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- E532284 - Funcional Descrition MtuДокумент42 страницыE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- 203 656 44 Accesorios ElectricosДокумент32 страницы203 656 44 Accesorios ElectricosJESUSCALVILLOОценок пока нет

- Maintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSДокумент25 страницMaintenance Schedule: Diesel Engine V 4000 Mx0 Application Group 1DSNabesterNajam0% (1)

- 12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EДокумент5 страниц12-16V4000 Gx3 3B Maintenance Schedule MS50005 - 00EJuan Carlos Mino Eneque100% (2)

- MTU Marine 16V1163M74 - ATДокумент1 страницаMTU Marine 16V1163M74 - ATghostt123Оценок пока нет

- 12v2000 CR OperatingДокумент170 страниц12v2000 CR OperatingANDREA100% (3)

- V2000M72 - Maintenance ScheduleДокумент29 страницV2000M72 - Maintenance ScheduleFreddy ChenОценок пока нет

- 00a MTU Abreviation ListДокумент12 страниц00a MTU Abreviation ListJuan Rivera100% (2)

- 0406 CD PDFДокумент169 страниц0406 CD PDFEdwin Enrique Osorio100% (2)

- E531827 00E CAN FieldbusДокумент46 страницE531827 00E CAN Fieldbusarcangel_pic100% (1)

- Part Catalog MTU 12V2000 M90Документ250 страницPart Catalog MTU 12V2000 M90Dimas Saputro100% (7)

- Master Mf8600 WSM 03 enДокумент160 страницMaster Mf8600 WSM 03 enSelmirije2100% (2)

- Mantenimiento s2000Документ8 страницMantenimiento s2000FabianОценок пока нет

- MTU Preservations Strategy UpdateДокумент49 страницMTU Preservations Strategy Updatebambang100% (2)

- Мануал L33 - new - MS50199 - 01EДокумент16 страницМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Mtu - Technical Documentation: ServiceДокумент7 страницMtu - Technical Documentation: Servicekarbaran1391Оценок пока нет

- Diesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EДокумент4 страницыDiesel Engines 8V 2000 M70 (BM 531.923) 12V 2000 M70 (BM 535.923) 16V 2000 M70 (BM 536.923) Maintenance Schedule M050540/02EsxturboОценок пока нет

- Maintenance Schedule 6R183 - M050525 - 02EДокумент4 страницыMaintenance Schedule 6R183 - M050525 - 02EdattienОценок пока нет

- MTU Gendrive SalesProgramДокумент55 страницMTU Gendrive SalesProgramEdutamОценок пока нет

- 16 V 4000Документ4 страницы16 V 4000aup0% (1)

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Документ2 страницыDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- Operating Instructions: Diesel Engine 12V2000M91 16V2000M91Документ169 страницOperating Instructions: Diesel Engine 12V2000M91 16V2000M91Bruna Rahd100% (1)

- 1600 Series Parts and OverviewДокумент94 страницы1600 Series Parts and OverviewJorge Eraldo Albarran PoleoОценок пока нет

- Dvigatel Mtu 12v2000g65eДокумент155 страницDvigatel Mtu 12v2000g65eAziz Arrahal100% (1)

- ET 5362003488 - EN 1358 KW EngineДокумент144 страницыET 5362003488 - EN 1358 KW EngineJUAN JOSE VESGA RUEDA100% (2)

- Part Catalog MTU 12V 4000 M73, M73L PDFДокумент813 страницPart Catalog MTU 12V 4000 M73, M73L PDFDimas Saputro100% (2)

- MTU 12V 4000 M60 Engine Maintenance MatrixДокумент3 страницыMTU 12V 4000 M60 Engine Maintenance Matrixchief100% (2)

- Especificaciones Mtu PDFДокумент11 страницEspecificaciones Mtu PDFCeciliagorraОценок пока нет

- Man v28 33d STC Imo Tier II MarineДокумент248 страницMan v28 33d STC Imo Tier II MarineSea Man MktОценок пока нет

- Mtu 16v2000g65 PDFДокумент144 страницыMtu 16v2000g65 PDFPhạm Hoài AnhОценок пока нет

- Maintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BДокумент27 страницMaintenance Schedule: Diesel Engine 16V4000M73 Application Group 1BDimas SaputroОценок пока нет

- MTU 12V4000M53 Spare Parts Catalog PDFДокумент745 страницMTU 12V4000M53 Spare Parts Catalog PDFkhaireddin100% (2)

- Mtu 4000 Water Pump DismantleДокумент93 страницыMtu 4000 Water Pump DismantlesxturboОценок пока нет

- Mtu - Technical Documentation: ServiceДокумент178 страницMtu - Technical Documentation: ServicemultiserviciosjorgegarcesОценок пока нет

- Edel Catalog 2016Документ752 страницыEdel Catalog 2016Mintomo Irawan100% (1)

- 0912 0913 deДокумент218 страниц0912 0913 deRath Asypaden100% (1)

- Operating Instructions: Diesel Engine 12 V 2000 P12 16 V 2000 P12Документ187 страницOperating Instructions: Diesel Engine 12 V 2000 P12 16 V 2000 P12Yasir Jamil100% (1)

- MTU Rail Spec SAM PPAutomДокумент2 страницыMTU Rail Spec SAM PPAutomBJNE01Оценок пока нет

- 01 Introduction Bluevison NG V1 07Документ60 страниц01 Introduction Bluevison NG V1 07Abdul Muksith100% (1)

- MTU White Paper Electronic Engine ManagementДокумент4 страницыMTU White Paper Electronic Engine ManagementDeepak ChachraОценок пока нет

- MarineДокумент210 страницMarinecmendezОценок пока нет

- Workshop Manual CTAGДокумент119 страницWorkshop Manual CTAGPalatzkeОценок пока нет

- Yanmar - 3ym 2ym Service ManualДокумент231 страницаYanmar - 3ym 2ym Service ManualRaul Josing50% (2)

- Manual MTU 12v1600 CompletoДокумент72 страницыManual MTU 12v1600 CompletogmgsolucoesОценок пока нет

- Parts Catalog: EngineДокумент84 страницыParts Catalog: EngineVivek AwasthiОценок пока нет

- MAN Maintenance ScheduleДокумент34 страницыMAN Maintenance ScheduleTesta Bonaventura Vincenzo100% (2)

- MAN Diesel V12 - Maintenance - Schedule - HD - MDДокумент37 страницMAN Diesel V12 - Maintenance - Schedule - HD - MDsledhead47100% (1)

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LДокумент197 страницOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.Оценок пока нет

- Adec 1600Документ84 страницыAdec 1600Sudiono Ajb50% (2)

- Mtu 12v4000 Spec Sheet PDFДокумент6 страницMtu 12v4000 Spec Sheet PDFSomadbsiОценок пока нет

- Mtu 8V4000 M53 & M63Документ2 страницыMtu 8V4000 M53 & M63roberttv374Оценок пока нет

- Operating Instructions 395 SeriesДокумент190 страницOperating Instructions 395 Seriesjamal molana0% (1)

- DDC 12 & 16 V 2000 C&I WS Manual 6se2000 - 02-802 P 1 To 816Документ816 страницDDC 12 & 16 V 2000 C&I WS Manual 6se2000 - 02-802 P 1 To 816Edison Cortes100% (4)

- Maintenance ScheduleДокумент12 страницMaintenance ScheduleVanHoangОценок пока нет

- 3A Maintenance M050733 - 06EДокумент10 страниц3A Maintenance M050733 - 06ELiya Mahagama100% (1)

- График обслуживания дизельного двигателяДокумент41 страницаГрафик обслуживания дизельного двигателяVictorAstakhovОценок пока нет

- Oval Wheel Flowmeter: For Viscous LiquidsДокумент8 страницOval Wheel Flowmeter: For Viscous LiquidsNippur de LagashОценок пока нет

- Caterpillar ADEM III 3126B (1 de 2)Документ1 страницаCaterpillar ADEM III 3126B (1 de 2)Nippur de LagashОценок пока нет

- Operator'S Manual: LH-3000 LH-3000CДокумент44 страницыOperator'S Manual: LH-3000 LH-3000CNippur de LagashОценок пока нет

- Operating Instructions Types: BEVI 2A/2D/3D/4AДокумент11 страницOperating Instructions Types: BEVI 2A/2D/3D/4ANippur de LagashОценок пока нет

- Manual de Operacion DESMI PDFДокумент27 страницManual de Operacion DESMI PDFNippur de LagashОценок пока нет

- fs1550 PDFДокумент65 страницfs1550 PDFNippur de LagashОценок пока нет

- Proportional Valve Group PVG 32Документ76 страницProportional Valve Group PVG 32Nippur de LagashОценок пока нет

- LG 42pj350 Chassis Pd-01a Plasma TV SMДокумент35 страницLG 42pj350 Chassis Pd-01a Plasma TV SMMark A SicilianoОценок пока нет

- AIS ComnavДокумент87 страницAIS ComnavNippur de LagashОценок пока нет

- Man Control PropulsionДокумент32 страницыMan Control PropulsionNippur de Lagash100% (2)

- Coil Electronics ControlДокумент28 страницCoil Electronics ControlNippur de LagashОценок пока нет

- Brother DT6-B926 PDFДокумент49 страницBrother DT6-B926 PDFfernando Diaz GonzalezОценок пока нет

- Theory of Machine LabДокумент2 страницыTheory of Machine LabJaishree ChauhanОценок пока нет

- Starter Lock-Out Relay TestДокумент1 страницаStarter Lock-Out Relay TestПеђа БекићОценок пока нет

- Cause Effect Diag PDFДокумент28 страницCause Effect Diag PDFabderrahmaneОценок пока нет

- SL 718Документ7 страницSL 718Jessey StonerОценок пока нет

- 886 DppNotes Reaction Turbine I DPP 06 Lec 08 GATE Crash CourseДокумент5 страниц886 DppNotes Reaction Turbine I DPP 06 Lec 08 GATE Crash Coursekreddy95054Оценок пока нет

- 4A FE Throttle AdjustmentsДокумент7 страниц4A FE Throttle AdjustmentsPedro Alonzo Mercado ZavalaОценок пока нет

- AL-Nahrain University College of Engineering Mechanical DepartmentДокумент10 страницAL-Nahrain University College of Engineering Mechanical DepartmentAbdullh AhmedОценок пока нет

- Mimatic Driven Toolholders Mazak PDFДокумент100 страницMimatic Driven Toolholders Mazak PDFSergio Gonzalez GuzmanОценок пока нет

- Manual Lathes: The World Turns On Colchester LathesДокумент8 страницManual Lathes: The World Turns On Colchester Lathesfarid said errahmaniОценок пока нет

- 3 04 LT Cooling SystemДокумент25 страниц3 04 LT Cooling Systemstopless_dalian685Оценок пока нет

- Aircraf Atp Index Transmission PDFДокумент1 285 страницAircraf Atp Index Transmission PDFhebert perezОценок пока нет

- KH42-B900 Series: Model CodeДокумент3 страницыKH42-B900 Series: Model Codejose milighettiОценок пока нет

- Madhur Confectioners PVT LTDДокумент2 страницыMadhur Confectioners PVT LTDuniquebearingmpОценок пока нет

- The Innovations Arrived From 1860Документ2 страницыThe Innovations Arrived From 1860NicolasОценок пока нет

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 091252-1049-E1Документ29 страницParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 091252-1049-E1Blayne OsbornОценок пока нет

- SB12 Series Back Pressure/Relief Valves: FeaturesДокумент6 страницSB12 Series Back Pressure/Relief Valves: FeaturesviksursОценок пока нет

- Test Technical English 3-4Документ5 страницTest Technical English 3-4Krzysztof Konczal0% (1)

- Engine Recondition LabДокумент4 страницыEngine Recondition LabSachi MensiОценок пока нет

- Asdooeidk 33201Документ48 страницAsdooeidk 33201Joze MartinezОценок пока нет

- Jost 5th Wheel CatalogДокумент44 страницыJost 5th Wheel CatalogmonokoeОценок пока нет

- V-Rings & V-Seals - Global O-Ring and Seal PDFДокумент7 страницV-Rings & V-Seals - Global O-Ring and Seal PDFMAMI RAKOTOMAHANINAОценок пока нет

- References For VAWT PerformanceДокумент3 страницыReferences For VAWT PerformancePrabhjot Singh SahiОценок пока нет

- Service Drawings QSX15Документ36 страницService Drawings QSX15Muhammad Tasawar Ali Rao100% (4)

- General Standard Part List Cone CrusherДокумент2 страницыGeneral Standard Part List Cone CrushermoddysОценок пока нет

- Motor E15 para Wood MizerДокумент40 страницMotor E15 para Wood MizerCesar Edgardo Lopez PortilloОценок пока нет