Академический Документы

Профессиональный Документы

Культура Документы

RC Pile Cap Design (ACI318)

Загружено:

topukuetАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RC Pile Cap Design (ACI318)

Загружено:

topukuetАвторское право:

Доступные форматы

Borhanul hasan Tapu

Project

Job Ref.

Section

Sheet no./rev.

Bangladesh Institute of Technology

Khulna

Bangladesh

Calc. by

Date

TH

4/11/2016

Chk'd by

Date

App'd by

Date

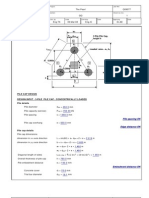

PILE CAP DESIGN (ACI318-11)

TEDDS calculation version 1.1.07

tcap

eemb

sid

e_

dia

g

w2

P1

Ly

hcol

bcol

s

w1

0.866s

0.288s

P3

dpile

e

P2

e

Lx

Pile details

Number of piles;

N=3

Pile diameter;

dpile = 20.0 in

Pile capacity (service);

Pcap = 120.0 kips

Pile spacing provided;

s = 60.0 in

Minimum pile spacing required;

smin = max (36 in, (dpile + 24 in)) = 44.0 in

PASS - Provided spacing is not less than minimum required

Edge distance of pile from pile cap edge;

e = 11.0 in

Minimum edge distance required;

emin = 11 in

PASS - Provided edge distance is not less than minimum required

Pile cap details

Concrete cover;

cc = 3.0 in

Length of pile cap along X axis;

Lx = s + dpile + 2 e = 8.5 ft

Length of pile cap along Y axis;

Ly = sin(60) s + dpile+ 2 e = 7.8 ft

Overall pile cap thickness;

tcap = 40.0 in

w1 = dpile + 2 e = 3.50 ft

w2 = dpile + 2 e = 3.50 ft

Diagonal length of sides;

Lside_diag = ((Ly - w1)2 + ((Lx - w2) / 2)2) = 5.000 ft

Pile embedment distance;

eemb = 6.0 in

Minimum pile embedment distance;

ec_min = 6 in

PASS - Provided embedment distance is not less than minimum required

Column details

Column width along X axis;

bcol = 24.0 in

Column width along Y axis;

hcol = 18.0 in

Borhanul hasan Tapu

Project

Job Ref.

Section

Sheet no./rev.

Bangladesh Institute of Technology

Khulna

Calc. by

Date

TH

4/11/2016

Yield strength of tension reinforcement;

fy = 60 ksi

Concrete strength;

fc = 4 ksi

Concrete density;

c = 150 lb/ft3

Bangladesh

Chk'd by

Date

App'd by

Date

Material properties

Reinforcement details (ACI 318, cl. 7.12, cl. 10.5)

Diameter number of steel bar along X axis;

Dx_bar_num = 6

Diameter of steel bar along X axis;

Dx_bar = 0.75 in

Depth of cap above bottom reinforcement (X axis); dx = tcap eemb -cc - Dx_bar / 2 = 30.6 in

Total number of steel bars along X axis;

Nx_bar = 22

Spacing of steel bars along X axis;

sx_bar = (Ly 2 cc - Dx_bar) / (Nx_bar - 1) = 4.2 in

Area of steel provided along X axis;

Ast_x = Nx_bar 0.25 Dx_bar2 = 9.7 in2

Gross cross sectional area of cap along Y axis;

Ag_y = Ly tcap = 3758.5 in2

C/S area of cap above bottom reinf. along Y axis;

Ab_y = Ly d = 2842.3 in2

Minimum area of steel required along X axis;

Ast_min_x = max (0.0018Ag_y, 200Ab_y1psi /fy, 3(fc1psi)Ab_y/fy)

Ast_min_x = 9.5 in2

PASS - Provided area of steel along X axis is greater than minimum required

Loading details

Strength reduction factor (flexure);

f = 0.90

Strength reduction factor (shear);

v = 0.75

Strength reduction factor (tied-arch);

t = 0.75

Column axial dead load;

Pdl = 150.0 kips

Area of pile cap;

Acap = Lx Ly - sin(60) Lside_diag2/2 = 55.731 ft2

Weight of pile cap;

Pwt = (Acap tcap - 3 dpile eemb / 4) c = 27.4 kips

Surcharge pressure on pile cap;

sur = 3.000 ksf

Surcharge load;

Psur = sur (Acap - hcol bcol) = 158.2 kips

Column axial live load;

Pll = 20.0 kips

Total column load (unfactored);

Pn = Pdl + Pll = 170.0 kips

The service load per pile is;

Pn_pile = (Pn + Pwt + Psur) / 3 = 118.5 kips

PASS - Pile capacity is sufficient

Total column load (factored);

Pu = 1.2 Pdl + 1.6 Pll = 212.0 kips

The ultimate load per pile is;

Pu_pile = (Pu + 1.2 (Pwt + Psur)) / 3 = 144.9 kips

Pile cap forces tied arch method

Distance between centroid of column and pile;

dcl_pl = ((s / 2)2 + (0.288 s)2) = 34.621 in

xcl_pl = (dcl_pl2 + d2) = 45.975 in

= atan(dcl_pl / d) = 48.855 deg

= acos(((d2 + (0.288 s)2)) / xcl_pl) = 40.733 deg

Compression within pile cap;

Cmax = Pu_pile / cos() = 220.212 kips

Tension within pile cap;

T = Cmax sin() / 2 = 71.848 kips

Compression checks for pile cap

Strength reduction factor (struct plain concrete);

u = 0.55

Strength reduction factor (bearing on concrete);

b = 0.65

Check diagonal comp. as an unreinforced column, using a core equivalent to 2 pile diameters (ACI 318-05, cl. 22.5.2)

Bearing capacity of core equivalent to 2 pile dia;

Pc = u 0.60 fc ((2 dpile)2) / 4 = 1451.4 kips

Borhanul hasan Tapu

Project

Job Ref.

Section

Sheet no./rev.

Bangladesh Institute of Technology

Khulna

Bangladesh

Calc. by

Date

TH

4/11/2016

Chk'd by

Date

App'd by

Date

PASS - Compression within cap is less than diagonal compression

Check bearing capacity of pile cap over piles (ACI 318, cl. 22.5.5)

Area of pile cap;

Acap = 8025.230 in2

Cross sectional area of pile;

Apile = dpile2 / 4 = 314.16 in2

Bearing capacity of cap above pile ;

Pbrg_pile = u 0.85 fc Apile min (2, (Acap / Apile)) = 1028.1 kips

PASS - Bearing capacity pile cap over pile is sufficient

Check bearing capacity of pile cap under column; (ACI 318, cl. 10.14)

Cross sectional area of column;

Acol = bcol hcol = 432.00 in2

Bearing capacity of cap below column;

Pbrg_col = b 0.85 fc Acol min (2, (Acap / Acol)) = 1670.8 kips

PASS - Bearing capacity pile cap under column is sufficient

Area of steel check for moment resistance

Distance from pile to face of column;

xface = max (0.577 s min (bcol , hcol) / 2, 0 in) = 25.6 in

Pressure due to weight and surcharge;

qu = 1.2 (sur + Pwt / Acap) = 4.2 ksf

Width at column face;

bw = 71.6 in

Ultimate moment at column face;

Muy = Pu_pilexface - quw2xface2/2+20.577 xface3/3) = 260.2 kip_ft

Net moment at column face;

Mny = Muy / v= 347.0 kip_ft

Rreq_y = Mny / (fc d2) / Lx = 0.012746

Lever arm factor;

Jy = (0.25 - Rreq_y / (0.85 2)) + 0.5 = 0.9924

Area of steel required to resist moment;

Ast_req_Mx = Mny / (fy Jy d) = 2.3 in2

Ast_req_T = T / (t fy) = 1.6 in2

Area of tension steel required for tied-arch behavior;

Area of steel required along X axis;

Ast_req_x = max (Ast_req_Mx, Ast_req_T) = 2.3 in2

PASS - Provided area of steel along X axis is sufficient

Each set of bar should be placed in the direction of axis connecting centers of piles (tringular pattern)

Stress block depth factor;

= 0.85

Depth of equivalent rectangular stress block;

a = Ast_x fy / (0.85 fc Lx) = 1.92 in

Balanced neutral axis depth(X axis);

c = a / 1 = 2.261 in

Strain in steel (X axis);

ty= 0.003 ((d c) / c) = 0.03714

Pass - Ductility is sufficient at ultimate strength

Necessary shear checks

Beam action at distance 'd' in the section parallel to X axis is not applicable

Beam action at column face in the section parallel to X axis must be checked

Beam action at distance 'd' in the section parallel to Y axis is not applicable

Beam action at column face in the section parallel to Y axis must be checked

Punching of single pile is not applicable

Punching of pile at corner must be checked

Punching of overlapping piles is not applicable

Punching shear at d / 2 from column face is not applicable

Punching shear at column face must be checked

Beam action at face of column

Distance from face of column to edge of cap;

xo = max ((Ly - e - dpile / 2 - 0.288 s - hcol / 2), 0 in) = 46.7 in

bx = min ((w2 + 2 (e + dpile / 2) tan(30)), (2 w12)) = 59.40 in

Shear at face of column parallel to X axis;

Vact_face = Pu_pile = 144.9 kips

VMrat1 = Muy / (Vact_face d) = 0.7

Borhanul hasan Tapu

Project

Job Ref.

Section

Sheet no./rev.

Bangladesh Institute of Technology

Khulna

Bangladesh

Calc. by

Date

TH

4/11/2016

Chk'd by

Date

App'd by

Date

w = Ast_x / (Ly d) = 0.003419

f1 = (d / xface) (3.5 - 2.5 VMrat1) = 2.0

f2 = 1.9 1 psi (fc / (1 psi)) = 0.1 ksi

f3 = 2500 w 1 psi / VMrat1 = 0.0 ksi

Vc1 = f1 (f2 + f3) Lx d = 779.0 kips

Vc2 = min (Vc1, 10 1 psi (fc / (1 psi)) Lx d) = 779.0 kips

Vc = max (Vc2, 2 1 psi (fc / (1 psi)) Lx d) = 779.0 kips

Vs = 0 kips

Shear resist. at face of column parallel to X axis;

Vr_face = v (Vc + Vs) = 584.2 kips

PASS - Pile cap is safe in beam action at face of column

Punching of single pile at corner check

Perimeter of area at d / 2 from pile at corner;

bo = (dpile + d) / 4 + 2 (e + dpile / 2) = 81.47 in

Shear resistance of concrete;

Vc = 4 1 psi (fc / 1 psi) bo d = 583.173 kips

Shear resistance of steel;

Vs = 0 kips

Ultimate shear resistance;

Vr_corner = v (Vc + Vs) = 437.379 kips

Shear acting;

Vact_ corner = Pu_pile = 144.9 kips

PASS - Resistance to pile punching at corner is sufficient

Punching shear check at face of column

Length of shear perimeter d / 2 from column face;

bo = 2 (bcol + d + hcol + d) = 205.000 in

Length of shear perimeter at column face;

bs = 2 (bcol + hcol) = 84.000 in

w = 22.620 in

Vact_pun_face = Pu + (Psur + Pwt) (s min (Ly, s)) / Lx2 = 276.210 kips

Vc1 = (d / w) (bo / bs) 2 1 psi (fc / 1 psi) bs d = 981.242 kips

Vc2 = min (Vc1, 32 1 psi (fc / 1 psi) bs d) = 981.242 kips

Vc = max (Vc2, 4 1 psi (fc / 1 psi) bo d) = 1467.484 kips

Vs = 0 kips

Vr_ pun_face = v (Vc + Vs) = 1100.613 kips

PASS - Pile cap is safe in punching shear at face of column

Development length of tension steel (ACI 318, cl. 12.5)

All bars must be provided with standard 180 end hooks.

ldh_1 = (0.02 efy 1 psi-1 dev (fc / 1 psi))) Dx_bar = 15.213 in

Modification factor;

mod1 = 0.7

Required development length of hook;

ldh_req = max (ldh_1 mod1, 6 in, 8 Dx_bar) = 10.649 in

Provided development length;

ldh_prov = e cc + dpile / 2 = 18.00 in

PASS - Hook development length is sufficient

Вам также может понравиться

- Pile CAP Design Example + 2 PilesДокумент3 страницыPile CAP Design Example + 2 PilesTharanga Pradeep100% (1)

- Pile Cap Design 1Документ6 страницPile Cap Design 1kjpatel2100% (2)

- 2 Piles Cap Design bs8110Документ3 страницы2 Piles Cap Design bs8110Faizal ImranОценок пока нет

- Hilti Calculation ExamplesДокумент10 страницHilti Calculation ExamplesNgoc TruongОценок пока нет

- RIV ACI 2-Pile CapДокумент12 страницRIV ACI 2-Pile CapMitra RampersadОценок пока нет

- Design for Pile Cap Calculation SheetДокумент3 страницыDesign for Pile Cap Calculation Sheetbhaskardharani50% (2)

- Pile Cap Design at AbutmentДокумент4 страницыPile Cap Design at AbutmentAzwani Abdullah100% (1)

- Design of Pile CapДокумент3 страницыDesign of Pile CapVasilescu Cristian93% (15)

- Ring Wall Foundation Design CalculationsДокумент6 страницRing Wall Foundation Design Calculationsraghav abudhabiОценок пока нет

- Aci 318-14/350-06 Design Spreadsheet - Reinforcement SelectionДокумент13 страницAci 318-14/350-06 Design Spreadsheet - Reinforcement Selectionislam saadОценок пока нет

- Design of Sleeper Pedestal Reinforcement in CulvertДокумент2 страницыDesign of Sleeper Pedestal Reinforcement in Culvertmunishant10% (1)

- Masonry Design ExamplesДокумент13 страницMasonry Design ExamplesRoger FonsecaОценок пока нет

- Base Plate Design Excel DesignДокумент120 страницBase Plate Design Excel DesignOmPrakash33% (3)

- Composite Column DesignДокумент3 страницыComposite Column DesignEngDbt50% (2)

- Composite Floor Deck DesignДокумент4 страницыComposite Floor Deck DesignsaipodinОценок пока нет

- ACI 350-06 ExampleДокумент1 страницаACI 350-06 ExampleAhmed Ben Hmida100% (1)

- Design of Pile Cap Excel SheetДокумент4 страницыDesign of Pile Cap Excel SheetKaushal Raut100% (1)

- ACI 350 ExampleДокумент1 страницаACI 350 ExamplesitehabОценок пока нет

- Pile Cap For 1 PilesДокумент5 страницPile Cap For 1 Pileshemantkle2u80% (5)

- 600MM Pile Cap DesignДокумент2 страницы600MM Pile Cap DesignVishal Nanavare0% (1)

- Joint Shear Aci CalculationДокумент2 страницыJoint Shear Aci CalculationAnonymous xcFcOgMi0% (1)

- 1030 - Embedded Plate Design - 4 - S7.00Документ9 страниц1030 - Embedded Plate Design - 4 - S7.00rajedmaglinte100% (2)

- Pile Cap ACI - EC2-20161217Документ27 страницPile Cap ACI - EC2-20161217mongkol_1001100% (1)

- Base Plate BiaxilДокумент26 страницBase Plate BiaxilvijaystructuralОценок пока нет

- Pile Cap Design (4-Piles)Документ4 страницыPile Cap Design (4-Piles)Uttam Kumar GhoshОценок пока нет

- Aci 350 BeamДокумент6 страницAci 350 BeammegunОценок пока нет

- Bridge Deep Foundations Design GuideДокумент116 страницBridge Deep Foundations Design Guiderutgers_v100% (2)

- Rectangular Concrete Beam Analysis - Design Per ACI 318-99Документ20 страницRectangular Concrete Beam Analysis - Design Per ACI 318-99Anonymous w5SJiLs100% (1)

- MBMA-96load Combinations PDFДокумент2 страницыMBMA-96load Combinations PDFsonofalexander100% (1)

- CRSI-PILECAP (Full Version)Документ228 страницCRSI-PILECAP (Full Version)xhq08Оценок пока нет

- Design of reinforced concrete corbels for shear and moment resistanceДокумент2 страницыDesign of reinforced concrete corbels for shear and moment resistancemoseslugtu632475% (4)

- RC Pile Cap Design ACI318 PDFДокумент4 страницыRC Pile Cap Design ACI318 PDFMAHTAB HOSSAINОценок пока нет

- Water Tank Design (Aci 318-05)Документ8 страницWater Tank Design (Aci 318-05)arnoldОценок пока нет

- Wood & ArmerДокумент1 страницаWood & ArmerYam BalaoingОценок пока нет

- Modeling of Diaphragms in STAAD ProДокумент13 страницModeling of Diaphragms in STAAD Proclarkorbe50% (2)

- Design of Chequered Plates BS QCS PDFДокумент1 страницаDesign of Chequered Plates BS QCS PDFEddySyahputraBenSyahrenОценок пока нет

- Pile Cap For 2 PilesДокумент5 страницPile Cap For 2 Pileshemantkle2uОценок пока нет

- Plain Concrete FootingДокумент4 страницыPlain Concrete Footingjoshua humirangОценок пока нет

- Vertical Vessel Foundation Design GuideДокумент22 страницыVertical Vessel Foundation Design Guideslabsandfootings100% (1)

- ACI Column SheetДокумент51 страницаACI Column SheetRajveer SinghОценок пока нет

- 3.0crack Width Check (Aci)Документ48 страниц3.0crack Width Check (Aci)klynchelle100% (1)

- Wind Load As Per ASCE-7-10Документ17 страницWind Load As Per ASCE-7-10Tri huỳnhОценок пока нет

- Block FoundationДокумент3 страницыBlock Foundationdsananda67% (3)

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Документ21 страницаACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014coreteamОценок пока нет

- Pile Cap Design Calculations With CSI SAFEДокумент7 страницPile Cap Design Calculations With CSI SAFEMiguel J.Оценок пока нет

- Design of WingwallДокумент29 страницDesign of WingwallMar MartillanoОценок пока нет

- Shear Wall With Boundary ElementДокумент4 страницыShear Wall With Boundary ElementArnel DodongОценок пока нет

- Large Moment ExampleДокумент5 страницLarge Moment ExampleAmro Ahmad AliОценок пока нет

- EMBEDMENT CALCULATIONДокумент5 страницEMBEDMENT CALCULATIONMWKELIOLAОценок пока нет

- RC Column Design (ACI318-05)Документ5 страницRC Column Design (ACI318-05)Rizwan MirzaОценок пока нет

- Col NДокумент7 страницCol NMohammed SumerОценок пока нет

- Circ BaseДокумент8 страницCirc BaseMario Sajulga Dela Cuadra100% (1)

- Pad Footing Analysis and Design (Bs8110-1:1997)Документ6 страницPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Оценок пока нет

- AISC-Extended Shear Plate ConnectionДокумент7 страницAISC-Extended Shear Plate ConnectionMuthukumaran SivalingamОценок пока нет

- Framed beam connection design detailsДокумент11 страницFramed beam connection design detailsmhel_almoОценок пока нет

- Uplift With Moment CalculationДокумент4 страницыUplift With Moment CalculationdennykvgОценок пока нет

- Column Base Plate DesignДокумент5 страницColumn Base Plate Design_jessecaОценок пока нет

- Technical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataДокумент30 страницTechnical Calculation of Segmental PC I Beam For Bridge SPAN (CTC) L I. DataAnisha MayaОценок пока нет

- DS-08 - Strip Raft With BeamДокумент21 страницаDS-08 - Strip Raft With BeamKutty MansoorОценок пока нет

- Footing DesignДокумент1 страницаFooting DesigntopukuetОценок пока нет

- Credit and CommerceДокумент3 страницыCredit and CommercetopukuetОценок пока нет

- SAFE Steel CalculationДокумент1 страницаSAFE Steel CalculationtopukuetОценок пока нет

- Water Tank DesignДокумент1 страницаWater Tank DesigntopukuetОценок пока нет

- Water TankДокумент1 страницаWater TanktopukuetОценок пока нет

- SAP2000 Steel CalculationДокумент1 страницаSAP2000 Steel CalculationtopukuetОценок пока нет

- RCC Pver Head TNK Design. HFGHF HNVGHNVNVB Thyfgthftd D Rdtdrfyd e YryhtyhrhybДокумент1 страницаRCC Pver Head TNK Design. HFGHF HNVGHNVNVB Thyfgthftd D Rdtdrfyd e YryhtyhrhybtopukuetОценок пока нет

- Hydro StaticДокумент1 страницаHydro StatictopukuetОценок пока нет

- Hibbler FrameДокумент1 страницаHibbler FrametopukuetОценок пока нет

- Pilecap LeterДокумент1 страницаPilecap LetertopukuetОценок пока нет

- Design DesignДокумент1 страницаDesign DesigntopukuetОценок пока нет

- Standard Level For Various Electrical AppliancesДокумент1 страницаStandard Level For Various Electrical AppliancestopukuetОценок пока нет

- Pilecap LeterДокумент1 страницаPilecap LetertopukuetОценок пока нет

- SAP2000 Water Pressure LoadingДокумент7 страницSAP2000 Water Pressure Loadingdasd322100% (1)

- Pile No. & Column DesignДокумент7 страницPile No. & Column DesigntopukuetОценок пока нет

- Photo ShopДокумент1 страницаPhoto ShoptopukuetОценок пока нет

- Disturbed SoilДокумент1 страницаDisturbed SoiltopukuetОценок пока нет

- SAP2000 V 15Документ1 страницаSAP2000 V 15topukuetОценок пока нет

- Cone Slump Test ProcedureДокумент1 страницаCone Slump Test ProceduretopukuetОценок пока нет

- Flat SlabДокумент1 страницаFlat SlabtopukuetОценок пока нет

- Etabs LearningДокумент1 страницаEtabs LearningtopukuetОценок пока нет

- Load TransferДокумент1 страницаLoad TransfertopukuetОценок пока нет

- HouseДокумент1 страницаHousetopukuetОценок пока нет

- RC SectionДокумент1 страницаRC SectiontopukuetОценок пока нет

- Photoshop TutorialДокумент1 страницаPhotoshop TutorialtopukuetОценок пока нет

- Bangladesh National Building Code BNBNДокумент1 страницаBangladesh National Building Code BNBNtopukuetОценок пока нет

- Load distribution analysisДокумент9 страницLoad distribution analysisBala Subramanian100% (5)

- Load TransferДокумент1 страницаLoad TransfertopukuetОценок пока нет

- Load TransferДокумент1 страницаLoad TransfertopukuetОценок пока нет

- Modave2005 PDFДокумент298 страницModave2005 PDFpolickОценок пока нет

- A Multi-Sphere Scheme For 2D and 3D PackingДокумент5 страницA Multi-Sphere Scheme For 2D and 3D PackingArs Santosh KumarОценок пока нет

- Applied Physics - P. K. PalanisamyДокумент63 страницыApplied Physics - P. K. PalanisamyPhanitha veeranki0% (1)

- Chuyên Anh Quảng Bình 23-24Документ6 страницChuyên Anh Quảng Bình 23-24Ngân ĐặngОценок пока нет

- 6" Encapsulated Submersible Motors: Application DataДокумент2 страницы6" Encapsulated Submersible Motors: Application DataBenicio Joaquín Ferrero BrebesОценок пока нет

- Exp 4 BiochemДокумент5 страницExp 4 BiochemLê ThắngОценок пока нет

- Fracture Energy of Concrete BeamsДокумент37 страницFracture Energy of Concrete Beamsphyrexio100% (1)

- The Plumb Pudding ModelДокумент1 страницаThe Plumb Pudding ModelMatt246Оценок пока нет

- Experiment 1 Determination of Flash PointДокумент7 страницExperiment 1 Determination of Flash Pointismat irfanОценок пока нет

- Design of Keys and CouplingsДокумент31 страницаDesign of Keys and CouplingsAbdul RehmanОценок пока нет

- Generalization of Smoluchowski's Diffusion EquationДокумент4 страницыGeneralization of Smoluchowski's Diffusion EquationDanieleRinaldoОценок пока нет

- Pre-Socratic Philosophers' BeliefsДокумент3 страницыPre-Socratic Philosophers' Beliefsliscob15Оценок пока нет

- Practical Design Approaches for Pressure Vessels and Heat ExchangersДокумент10 страницPractical Design Approaches for Pressure Vessels and Heat ExchangersballisnothingОценок пока нет

- ME 352 - Machine Design I Name of Student: - Fall Semester 2019 Lab Section NumberДокумент5 страницME 352 - Machine Design I Name of Student: - Fall Semester 2019 Lab Section NumberirqoviОценок пока нет

- 1.1.1 The Microscope in Cell StudiesДокумент16 страниц1.1.1 The Microscope in Cell StudiesRudra Sai Sreeman Reddy MulaОценок пока нет

- NM Intro 1Документ27 страницNM Intro 1Nurul AsyilahОценок пока нет

- Unit 2 - Week 1: Assignment-1Документ6 страницUnit 2 - Week 1: Assignment-1suneethaОценок пока нет

- Midterm-Flight Dynamics and ControlДокумент17 страницMidterm-Flight Dynamics and ControljameelahmadОценок пока нет

- Nature Comm - 41467 - 2018 - 4699 - MOESM1 - ESMДокумент14 страницNature Comm - 41467 - 2018 - 4699 - MOESM1 - ESMdupuytrenОценок пока нет

- Revision Questions in Physics 101Документ13 страницRevision Questions in Physics 101lozzzzzОценок пока нет

- Chapter 2 Arithmetic SequenceДокумент113 страницChapter 2 Arithmetic SequenceCaren VilloriaОценок пока нет

- 1 - Well Log Evaluation - IntroductionДокумент29 страниц1 - Well Log Evaluation - IntroductionKyosuke HilmiОценок пока нет

- Partial Loading Optimal Control - Steam Turbine EffДокумент6 страницPartial Loading Optimal Control - Steam Turbine EffLTE002Оценок пока нет

- 日机伺服 NCS-FI - FS 使用手冊-1 (英) PDFДокумент154 страницы日机伺服 NCS-FI - FS 使用手冊-1 (英) PDFandhikabpОценок пока нет

- Business Statistics, 5 Ed.: by Ken BlackДокумент34 страницыBusiness Statistics, 5 Ed.: by Ken BlackRushabh VoraОценок пока нет

- University of Baghdad Collage of Engineering Department Petroleum Lab ReportДокумент4 страницыUniversity of Baghdad Collage of Engineering Department Petroleum Lab Reportعلي خالد كاظم عبودОценок пока нет

- Lessons in Electric Circuits - Volume IДокумент555 страницLessons in Electric Circuits - Volume IArdit KarajОценок пока нет

- Tcschsyll 2018-19 Scheme PDFДокумент121 страницаTcschsyll 2018-19 Scheme PDFchetanОценок пока нет

- Howden Axial Fans HC Centrifugal Fans PDFДокумент116 страницHowden Axial Fans HC Centrifugal Fans PDFSurya Kiran KОценок пока нет

- Median Grade Fa 07Документ25 страницMedian Grade Fa 07Sohan JainОценок пока нет