Академический Документы

Профессиональный Документы

Культура Документы

Piping-Mechanical Design Drawings

Загружено:

amnoorulamanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piping-Mechanical Design Drawings

Загружено:

amnoorulamanАвторское право:

Доступные форматы

Section 4

Piping/Mechanical Design Drawings

GENERAL

The primary drawings that a Piping/Mechanical Field Engineer will use in the course of completing

a field assignment are:

Piping and Instrument Diagram (P&ID)

Piping Isometric

Plot Plans

Piping Class Sheets

Piping Support Details and Hanger Drawings

Vendor Drawings and Manuals

Instrument and Tubing Drawings

Standard Instrument Details

Steam Heat Tracing Drawings

These drawings along with project installation specifications provide quality guidelines for properly

completing the assigned system.

Piping and Instrument Diagram

The single most important drawing for the installation of piping systems is the Piping and

Instrument Diagram (P&ID). It provides the base design description of the required pipe routing

and sizing, flow direction and slope, instrumentation and controls, insulation, heat tracing, and

equipment and/or instrument references. This provides a road map to finding other drawings,

vendor data, and piping information to properly complete the installation. The P&ID does not

however provide dimensional data or physical locations of any commodities.

The Piping Line List and the Instrument Index are issued documents which often provide this

information.

PIPING ISOMETRIC AND PLOT PLAN DRAWINGS

Piping Isometric and Plot Plan drawings provide plant references and physical dimensioning that

are not on the P&ID. Along with dimensioning and locating the pipe itself, the drawings also show

the physical installation guides, including:

Hanger location references to plant coordinates and piping commodities

Specific installation details and/or requirements

Material requirements for both the shop and/or field

Correct valve orientation

Existing equipment outlines

© 1996 Bechtel Corp. Piping/Mechanical Handbook 4-1

Section 4 Piping/Mechanical Design Drawings

Pull or dismantling space

Piping class

Pressure test requirements

Spools

Welds (including welded attachments)

Valves

Hangers

Specialty items with unique tag numbers

For bulk piping systems, Engineering supplies a detailed Bill of Material for each drawing listing

the required material including material description, quantities, stock code numbers, flange

gasket, and flange bolting. Other information that engineering provides includes coating and

slope requirements for the detailed piping system, connecting equipment nozzle numbers, tap

orientations, stress relief and NDE requirements for piping welds, and standard details for vents

and drains.

PIPING CLASS SHEETS

Piping class sheets specify the material and code requirements for designated piping system

pressure and temperature ratings. A sample Piping Class Sheet is shown in Attachment 4-1.

HANGER DRAWINGS

Hanger drawings provide a detailed drawing of the pipe support, and include the following:

Detailed bill of materials

Building location and elevation reference

Piping dimensional reference for installation location

Welding requirements

Line reference numbers

Design loads (on some projects, hanger loads are determined from standard load tables

and/or charts based on pipe size, span, and support member size)

VENDOR DRAWINGS AND MANUALS

Drawings supplied by vendors will vary by manufacturer but generally provide:

Outline drawings

Material types

Parts listing

Weights and Centers of Gravity

Field test requirements

4-2 Piping/Mechanical Handbook 1996:Rev.2

Piping/Mechanical Design Drawings Section 4

Operating pressures and temperatures and data (e.g. pump curves)

Start-up, operating, and maintenance procedures

INSTRUMENT AND TUBING DRAWINGS

Design Engineering provides a standard set of drawings for the Mechanical Field Engineer to use

in the installation process. The Piping/Mechanical Field Engineer will match the instrument

category and service fluid and instruct the craft in which detail should be used. The standard

usually will show routing, vents and drains, manifolds, bill of material and stock codes.

HEAT TRACING DRAWINGS

Heat tracing drawings provide the Mechanical Field Engineer with:

Heat tracing category

Plant location

Piping isometric and line number

Manifold locations with specific tap numbers for tie-in of both steam and condensate tubing.

1996:Rev.2 Piping/Mechanical Handbook 4-3

Section 4 Piping/Mechanical Design Drawings

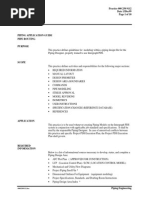

SAMPLE PIPING CLASS SHEET

ATTACHMENT 4-1

Class (XXX)

ASME B31.1 Power Piping Code

o

Primary Rating 150 LB @ 600 F

Pipe: 26" and larger Seamless ASTM A-672, Gr. B70 SCH. (later

if required).

12" thru 24" Seamless ASTM A-106, Gr. B STD. WALL

1

2 /2" to 10" SCH. 40

2" and smaller SCH. 80

Fittings: 26" and larger ASTM A234 GR. WPBW seam weld, butt

weld, wall thickness to match pipe

1

2 /2" thru 24" ASTM A234 GR WPB or WPBW seamless

or seamweld, butt weld, wall to match pipe

2" and smaller ASTM A-105 3000# socket weld SCH. 80

Flanges: ASTM A-105, bored to match pipe.

26" and larger 150# welding neck R.F.

1

2 /2" thru 24" 150# slip-on, R.F.

2" and smaller 150# socket weld, R.F.

Plate: ASTM A515 GR. 70

Bolting: Bolts Stud bolts, ASTM A-193 GR. B7

Nuts Heavy hex, ASTM A-194, GR 2H

Gaskets: All Sizes SEE NOTE 2

ASBESTOS FREE SPIRAL WOUND

Valves: SEE PS-22

Joints: Welded except at flange equipment connections. Field weld end

preparation and weld end transition (ref. PS-06)

Notes: 1. This piping shall not be used where service temperature exceeds

o

775 F.

2. Flexitallic Style CG with Flexite-Super filler or equal for design

o

temperature not exceeding 1000 F. Metal Strip used shall be

stainless steel TP304.

3. Pipe minimum walls (pipe schedules) are based on design

o

conditions of 200 PSIG @ 400 F.

4-4 Piping/Mechanical Handbook 1996:Rev.2

Вам также может понравиться

- ASME/ANSI B16 Standards For Pipes and FittingsДокумент14 страницASME/ANSI B16 Standards For Pipes and FittingsEquilibrium EngineersОценок пока нет

- Basics On Piping LayoutДокумент11 страницBasics On Piping Layoutpuru55980Оценок пока нет

- Hose & Fittings SPECIFICATIONДокумент3 страницыHose & Fittings SPECIFICATIONPonnivalavanОценок пока нет

- Be An Expert in Piping Design & LayoutДокумент40 страницBe An Expert in Piping Design & LayoutSathish100% (3)

- Pipe Hanger Design-05Документ82 страницыPipe Hanger Design-05kjsvonb100% (4)

- Piping Input and OutputДокумент7 страницPiping Input and OutputpraneshОценок пока нет

- Acoustic Pipe Supports for Temperatures up to 200°CДокумент6 страницAcoustic Pipe Supports for Temperatures up to 200°Cnamdq-1Оценок пока нет

- Flare Line Stress AnalysisДокумент7 страницFlare Line Stress AnalysisdhurjatibhuteshОценок пока нет

- Quy Trinh PipeStress Amp SupportДокумент24 страницыQuy Trinh PipeStress Amp SupportVuong BuiОценок пока нет

- Pipe RoutДокумент10 страницPipe Routghkashyap1Оценок пока нет

- Pipe DesignДокумент48 страницPipe Designdineshkumar1234Оценок пока нет

- Expansion Loop DesignДокумент61 страницаExpansion Loop DesignTauqueerAhmadОценок пока нет

- Online Piping and Caesar Course SyllabusДокумент10 страницOnline Piping and Caesar Course Syllabusm 418Оценок пока нет

- Flange Pressure ChartДокумент1 страницаFlange Pressure ChartValiullah SarpanchОценок пока нет

- Piperack Guide2 (7 May, 02)Документ61 страницаPiperack Guide2 (7 May, 02)adnan_kasaloОценок пока нет

- Piping DesignДокумент9 страницPiping Designjmclaug502Оценок пока нет

- Pipes Should Be Properly SupportedДокумент3 страницыPipes Should Be Properly SupportedGomathyselviОценок пока нет

- BN-DG-C01K Plant Layout PumpsДокумент16 страницBN-DG-C01K Plant Layout Pumpshalder_kalyan9216Оценок пока нет

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignДокумент81 страницаC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- CEASAR and PDMS SoftwareДокумент10 страницCEASAR and PDMS Softwarehayatmdazhar100% (1)

- PIPE RACK Design and Layout Guide for RefineriesДокумент50 страницPIPE RACK Design and Layout Guide for Refineries124swadeshiОценок пока нет

- Overview Part 1 PDFДокумент65 страницOverview Part 1 PDFKim NamjoonОценок пока нет

- Pipe Support BasisДокумент4 страницыPipe Support BasisBabyface888Оценок пока нет

- Presentation On: Internal Attachments - ABSORBERДокумент14 страницPresentation On: Internal Attachments - ABSORBERmuraliОценок пока нет

- Pipe Stress Amp SupportДокумент24 страницыPipe Stress Amp Supportaap1Оценок пока нет

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deДокумент21 страницаChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilОценок пока нет

- How To Draw Piping IsometricsДокумент18 страницHow To Draw Piping IsometricsEmavwodia Solomon100% (1)

- Piping Engineering.nДокумент6 страницPiping Engineering.nAjay KumarОценок пока нет

- Secondary Pipe Support Devices: Secondary Pipe Support DevicesДокумент34 страницыSecondary Pipe Support Devices: Secondary Pipe Support DeviceszebmechОценок пока нет

- FRP Pipes & Fitting PDFДокумент10 страницFRP Pipes & Fitting PDFAbbasОценок пока нет

- Piping Design (Revised)Документ22 страницыPiping Design (Revised)Yash PatelОценок пока нет

- Piping DesignДокумент33 страницыPiping DesignUsha Kiran P100% (1)

- Pipe Drafting and Design-Halaman-136-155Документ20 страницPipe Drafting and Design-Halaman-136-155Tiar AgustiantoОценок пока нет

- Develop Plot Plans for Piping ProjectsДокумент9 страницDevelop Plot Plans for Piping ProjectsTom0% (1)

- Design Practice General PipeДокумент8 страницDesign Practice General PipedevОценок пока нет

- Pipe Support Design GuidelinesДокумент9 страницPipe Support Design GuidelineskarunaОценок пока нет

- Typical Questions For Piping Engineers Knowledge Testing With AnswersДокумент5 страницTypical Questions For Piping Engineers Knowledge Testing With AnswersAnonymous rjs9SOrОценок пока нет

- Pipe Thickness Calculation GuideДокумент10 страницPipe Thickness Calculation GuideVinay SharmaОценок пока нет

- Electrode Consumption PDFДокумент1 страницаElectrode Consumption PDFharold_bhieОценок пока нет

- Pipe Rack and Rack Piping Design GuideДокумент23 страницыPipe Rack and Rack Piping Design GuideAlessandro1975Оценок пока нет

- Piping/Mechanical Design DrawingsДокумент3 страницыPiping/Mechanical Design Drawingscherif yahyaouiОценок пока нет

- Pipe Support Reference 8-29-14Документ108 страницPipe Support Reference 8-29-14HITESHОценок пока нет

- Pipe Supports Std.Документ98 страницPipe Supports Std.Victor Hugo Carrasco Fuentes100% (1)

- Section 23 11 25 Facility Gas PipingДокумент10 страницSection 23 11 25 Facility Gas PipingNiong DavidОценок пока нет

- Steam and Condensate Piping Design BasicsДокумент21 страницаSteam and Condensate Piping Design BasicsVIVEKZI0Оценок пока нет

- MechanicalДокумент173 страницыMechanicalKerx EndranoОценок пока нет

- Codes Standards For YANBU ProjectДокумент7 страницCodes Standards For YANBU ProjectBehçet Serdal CanbazОценок пока нет

- Stainless Steel Pipe and Fittings SpecificationДокумент10 страницStainless Steel Pipe and Fittings SpecificationCassy AbulenciaОценок пока нет

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalДокумент643 страницы6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85Оценок пока нет

- PmsДокумент3 страницыPmsKurian JoseОценок пока нет

- Piping Material Specification GuideДокумент60 страницPiping Material Specification GuideNeeraj Bora100% (10)

- Pipe and Pipe FittingsДокумент21 страницаPipe and Pipe FittingsAdamОценок пока нет

- Piping BasisДокумент32 страницыPiping Basislowermine100% (2)

- ASME B16 Standards For Pipes and FittingsДокумент7 страницASME B16 Standards For Pipes and FittingsEHT pipeОценок пока нет

- Corporate Piping SpecДокумент56 страницCorporate Piping Specamanojp100% (2)

- ASME Standard List of Piping and FittingsДокумент7 страницASME Standard List of Piping and Fittingsjuantamad02Оценок пока нет

- Piping Isometric ChecklistДокумент21 страницаPiping Isometric ChecklistNguyen Anh Tung50% (2)

- Piping Material Specification 2010014 00 l0 Gs 001Документ215 страницPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- Pipe Sizes and MaterialsДокумент4 страницыPipe Sizes and Materialsamnoorulaman100% (4)

- Field Piping GuidelinesДокумент3 страницыField Piping GuidelinesamnoorulamanОценок пока нет

- Underground and Embedded Piping SystemsДокумент7 страницUnderground and Embedded Piping Systemsamnoorulaman100% (2)

- Insulation and Heat TracingДокумент5 страницInsulation and Heat Tracingamnoorulaman100% (1)

- Piping Class - AD30Документ2 страницыPiping Class - AD30Дмитрий РыбаковОценок пока нет

- Engineering Interview Questions and MCQs on Fluid MechanicsДокумент20 страницEngineering Interview Questions and MCQs on Fluid MechanicspiluОценок пока нет

- Print Head Doctor 15 - Print Head DoctorДокумент4 страницыPrint Head Doctor 15 - Print Head DoctorNo PromisesОценок пока нет

- Calculating CAPEX for a CO2 Capture SystemДокумент4 страницыCalculating CAPEX for a CO2 Capture SystemEldeniz AxundОценок пока нет

- Comparing Gibbs and Equilibrium Reactors in HYSYSДокумент11 страницComparing Gibbs and Equilibrium Reactors in HYSYSATUL SONAWANEОценок пока нет

- Description of Ammonia Manufacturing ProcessesДокумент4 страницыDescription of Ammonia Manufacturing ProcessesSameer PandeyОценок пока нет

- Methods For Calculation of Evaporation From Swimming Pools and Other Water SurfacesДокумент16 страницMethods For Calculation of Evaporation From Swimming Pools and Other Water SurfacesBogdan BrieОценок пока нет

- As Built ReportДокумент1 страницаAs Built ReportWakil AhmadОценок пока нет

- Operating Instructions Automatic Air Inlet ValveДокумент4 страницыOperating Instructions Automatic Air Inlet ValveelecbaОценок пока нет

- ch16 Lecture 8e GOODДокумент105 страницch16 Lecture 8e GOODJana Mae Catot AcabalОценок пока нет

- Multistage Multioutlet PumpДокумент11 страницMultistage Multioutlet Pumpmajortay100% (1)

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSДокумент2 страницыSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289Оценок пока нет

- StrengthandFracture PDFДокумент108 страницStrengthandFracture PDFMarcoОценок пока нет

- Valve Sizing Report for Carbon Dioxide ProcessДокумент3 страницыValve Sizing Report for Carbon Dioxide ProcessYawar QureshiОценок пока нет

- Decomposition of 1,3,5-Trioxane at 700-800 KДокумент3 страницыDecomposition of 1,3,5-Trioxane at 700-800 KPilar MayaОценок пока нет

- Air Blowing: Method Statement FORДокумент6 страницAir Blowing: Method Statement FORrvsreddysenaОценок пока нет

- Real-World-Modeling PDFДокумент12 страницReal-World-Modeling PDFGATOMICOОценок пока нет

- Dry Reforming of MethaneДокумент9 страницDry Reforming of MethaneVikrant Agrawal0% (1)

- G11re Toc TZ1Документ14 страницG11re Toc TZ1Mohammad BaqerОценок пока нет

- 692J Manual Technical Complete For Printing 06.30.2021Документ469 страниц692J Manual Technical Complete For Printing 06.30.2021Justin WestОценок пока нет

- The Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosДокумент12 страницThe Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosVishal100% (1)

- MEE2005 Heat Transfer Lab ManualДокумент114 страницMEE2005 Heat Transfer Lab ManualAslam AzeezОценок пока нет

- Chemical Kinetics Exercise SolutionsДокумент98 страницChemical Kinetics Exercise SolutionsKivilia EduventuresОценок пока нет

- Piping Pressure Drop CalculationДокумент8 страницPiping Pressure Drop CalculationSurya Kiran KОценок пока нет

- Elements or Appurtenances of The Stilling BasinsДокумент21 страницаElements or Appurtenances of The Stilling BasinsAhmad PshtiwanОценок пока нет

- Reg. No: Year/Dept: IV/CIVIL Date: .08.2018 Reg. No: Year/Dept: IV/CIVIL Date: .08.2018Документ1 страницаReg. No: Year/Dept: IV/CIVIL Date: .08.2018 Reg. No: Year/Dept: IV/CIVIL Date: .08.2018ganesh15Оценок пока нет

- HT3eChap11 103Документ31 страницаHT3eChap11 103msdhiman2003Оценок пока нет

- Heat Transfer: Spring 2021Документ12 страницHeat Transfer: Spring 2021Chaudhrysaad UllahОценок пока нет

- 40QBG QBU CatalogДокумент4 страницы40QBG QBU CatalogKhun WunОценок пока нет

- Material Take OffДокумент5 страницMaterial Take OffArindom KunduОценок пока нет