Академический Документы

Профессиональный Документы

Культура Документы

PTI 2010 HooverDamBypassBridge

Загружено:

Rodrigo Lameiras0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров15 страницpti

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документpti

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров15 страницPTI 2010 HooverDamBypassBridge

Загружено:

Rodrigo Lameiraspti

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 15

Hoover Dam Bypass Bridge:

Temporary Stay Cables

Considerations for Design, Testing,

Installation and Inspection

by

Michael Schwager, P.E.

Schwager Davis, Inc.

Presented at

2010 PTI Technical Conference

Fort Worth, Texas

Project Description

1,060 foot span cast in place concrete segmental twin

arch bridge with precast segmental columns

SDIs Scope of Work

Fabricate, furnish and install post-tensioned rock

anchors in the arch skew backs

SDIs Scope of Work

Fabricate, furnish and install post-tensioned rock

anchors in the stay anchor blocks

SDIs Scope of Work

Furnish post-tensioning materials, equipment and

technical assistance for precast columns, temporary

towers and bent caps

SDIs Scope of Work

Furnish temporary stay cable system and provided

technical assistance and inspection services

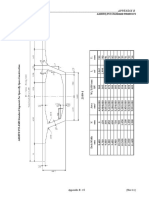

Contract Stay Cable Layout

Backstay Cable Geometry

Access for installation & Stressing

Revised Stay Cable Layout

Removed Lower Cables

Brought all Cables to tower top

Re-routed Backstay Cables

Lowered Forestay Connection

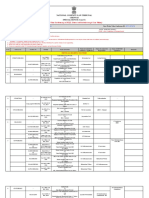

Stay Cable Design Considerations

More critical in many ways than permanent stay cables

Permanent stay cables

Long term Fatigue

Corrosion

Temporary stay cables

Large load variations (wedge bite)

Angle change due to sag from load variation

Temporary construction obstacles

Constructability

Additional Testing

Strand fatigue and wedge testing

Cyclical loading with high angle change

(2 Million cycles)

Critical Anchorage Testing

Swaged anchor with adjustable ring nut

Post-Blocking equipment

Strand Installation equipment

Load Transfer Strand to Anchorage

Machined Anchor Heads / Wedge Design

Post-Blocking Device

Installation Challenges

Forestay Lower Anchorage

Dampeners

Hoover Dam Bypass Bridge

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Concrete in The Stress Meter B Ac Load Cell Isolator Surrounding ConcreteДокумент9 страницConcrete in The Stress Meter B Ac Load Cell Isolator Surrounding ConcreteRodrigo LameirasОценок пока нет

- FR Prcs 9 Final 00027Документ4 страницыFR Prcs 9 Final 00027Rodrigo LameirasОценок пока нет

- CE7016 CourseOutline-1Документ2 страницыCE7016 CourseOutline-1Rodrigo LameirasОценок пока нет

- Ipacs - Report - Thermal Properties of Concrete PDFДокумент23 страницыIpacs - Report - Thermal Properties of Concrete PDFRodrigo LameirasОценок пока нет

- Report Be96-38432001 97-4Документ8 страницReport Be96-38432001 97-4Rodrigo LameirasОценок пока нет

- Composite Structures: Julien Michels, Christoph Czaderski, Raafat El-Hacha, Rolf Brönnimann, Masoud MotavalliДокумент10 страницComposite Structures: Julien Michels, Christoph Czaderski, Raafat El-Hacha, Rolf Brönnimann, Masoud MotavalliRodrigo LameirasОценок пока нет

- FR Prcs 9 Final 00022Документ4 страницыFR Prcs 9 Final 00022Rodrigo LameirasОценок пока нет

- Knoppik PHD ThesisДокумент174 страницыKnoppik PHD ThesisRodrigo LameirasОценок пока нет

- Seismic Retrofit of Shear-Critical R.C. Beams Using CFRP: FRPRCS-9 Sydney, AustraliaДокумент4 страницыSeismic Retrofit of Shear-Critical R.C. Beams Using CFRP: FRPRCS-9 Sydney, AustraliaRodrigo LameirasОценок пока нет

- Michels Et Al SMAR2013Документ9 страницMichels Et Al SMAR2013Rodrigo LameirasОценок пока нет

- Pci Bridge Design ManualДокумент2 страницыPci Bridge Design ManualRodrigo LameirasОценок пока нет

- PTI 2012 Conference SegmentalBridgeДокумент24 страницыPTI 2012 Conference SegmentalBridgeRodrigo Lameiras100% (1)

- 4 PTI EDC 130 Prestress LossesДокумент27 страниц4 PTI EDC 130 Prestress Lossesshinji_naviОценок пока нет

- 140204-3-PTI EDC-130-Flexure-55Документ55 страниц140204-3-PTI EDC-130-Flexure-55Rodrigo LameirasОценок пока нет

- Design of Post-Tensioned Industrial SlabsДокумент39 страницDesign of Post-Tensioned Industrial SlabsRodrigo LameirasОценок пока нет

- PTI 2009 Mexpressa BridgeExternal RoofДокумент92 страницыPTI 2009 Mexpressa BridgeExternal RoofRodrigo LameirasОценок пока нет

- PCI Zone6 Curved Spliced GirdersДокумент20 страницPCI Zone6 Curved Spliced GirdersRodrigo LameirasОценок пока нет

- 2013 FRPRCS-11 2013 Lameiras Et Al FULLPAPER ReviewedДокумент10 страниц2013 FRPRCS-11 2013 Lameiras Et Al FULLPAPER ReviewedRodrigo LameirasОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Java Examination: Multiple Choice QuestionsДокумент7 страницJava Examination: Multiple Choice QuestionsAnand ls nairОценок пока нет

- GPS Submittal PDFДокумент32 страницыGPS Submittal PDFshankar05Оценок пока нет

- Understanding Commercial and Government EntityДокумент5 страницUnderstanding Commercial and Government EntitystackedaerospaceОценок пока нет

- Group-1 1BM19EC020 044 045 052Документ15 страницGroup-1 1BM19EC020 044 045 052Vineet AОценок пока нет

- (Winter 2021) : CS231A: Computer Vision, From 3D Reconstruction To Recognition Homework #0 Due: Sunday, January 17Документ2 страницы(Winter 2021) : CS231A: Computer Vision, From 3D Reconstruction To Recognition Homework #0 Due: Sunday, January 17Nono Nono100% (1)

- Business Result Advanced PDF - Google SearchДокумент2 страницыBusiness Result Advanced PDF - Google SearchVimal Rajan0% (2)

- Decision Trees Classification: Mustafa JarrarДокумент46 страницDecision Trees Classification: Mustafa Jarrarrferreira85Оценок пока нет

- ARO Pump ManualДокумент8 страницARO Pump Manualrazaq athabОценок пока нет

- IEEE STDF 519 2014Документ29 страницIEEE STDF 519 2014paoloesquivel100% (1)

- VLF Tan Delta TestingДокумент5 страницVLF Tan Delta TestingArif KhanОценок пока нет

- Transmission Removal and Installation at PDFДокумент3 страницыTransmission Removal and Installation at PDFUgratara AutoОценок пока нет

- DDV V-S Su Ub B: Compact High Power SubwooferДокумент4 страницыDDV V-S Su Ub B: Compact High Power SubwooferGobitobiОценок пока нет

- NIE Ethan NovekДокумент1 страницаNIE Ethan NovekHartford CourantОценок пока нет

- Radovan Damjanović Srbsko Srbski Rečnik: Download NowДокумент9 страницRadovan Damjanović Srbsko Srbski Rečnik: Download NowTinamou0001Оценок пока нет

- From April 15 To The End of June 2004Документ2 страницыFrom April 15 To The End of June 2004HUO MENGWENОценок пока нет

- Angel Felker Mos Word CertificateДокумент1 страницаAngel Felker Mos Word Certificateapi-327897521Оценок пока нет

- Aug. 13, 2020 Activity 1 by LJ Diane TuazonДокумент2 страницыAug. 13, 2020 Activity 1 by LJ Diane TuazonLj Diane TuazonОценок пока нет

- Shortcut AutocadДокумент3 страницыShortcut AutocadDjoko Dwi IrwantoОценок пока нет

- MT 720 Transfer of A Documentary CreditДокумент3 страницыMT 720 Transfer of A Documentary CreditA. T. M. Anisur Rabbani100% (1)

- Exercise 32 MEP Training Syllabus (1.1)Документ2 страницыExercise 32 MEP Training Syllabus (1.1)Ali SalmanОценок пока нет

- JellДокумент1 страницаJellMuhammad DanuОценок пока нет

- Ajp MP 2Документ15 страницAjp MP 2LalitОценок пока нет

- AMR Voice Quality Improvement Based On PLVA (RAN19.1 - 01)Документ24 страницыAMR Voice Quality Improvement Based On PLVA (RAN19.1 - 01)anthonyОценок пока нет

- National Company Law Tribunal Chennai Special Bench (Court I)Документ7 страницNational Company Law Tribunal Chennai Special Bench (Court I)Parimal KashyapОценок пока нет

- 2 Maps TypesДокумент22 страницы2 Maps TypesSiphumeze TitiОценок пока нет

- Risk Assesment - MobilisationДокумент7 страницRisk Assesment - Mobilisationشاز إياسОценок пока нет

- 2023 New Value Report RippleДокумент62 страницы2023 New Value Report RippleThorbenОценок пока нет

- Digital Marketing MaterialДокумент16 страницDigital Marketing MaterialRABIAОценок пока нет

- Superhuman: Human Enhancement and AdvancementДокумент3 страницыSuperhuman: Human Enhancement and AdvancementShyamol BoseОценок пока нет

- Alphabet Series Tricks - PDF: Intervals LikeДокумент7 страницAlphabet Series Tricks - PDF: Intervals LikeAbhishek A. NadgireОценок пока нет