Академический Документы

Профессиональный Документы

Культура Документы

lg15 Calver2012

Загружено:

api-311256138Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

lg15 Calver2012

Загружено:

api-311256138Авторское право:

Доступные форматы

1 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

LabGuide 15

Calibration Verification

This LabGuide pertains to QSE Equipment and the Analytic Phase of the Path of Workflow.

INTRODUCTION

On January 24, 2003, the Centers for Medicare and Medicaid Services (CMS) published

updated laboratory regulations that became effective April 24, 2003. These updated CLIA

requirements included revised standards for calibration verification of nonwaived

(moderate and high complexity) test systems.

For analytes that require calibration, laboratories must continue to perform calibration as

specified in the manufacturers instructions. In addition, laboratories must also perform

calibration verification at least every six months, using at least three levels of materials

that are within the reportable range of the test. COLA accreditation criteria help ensure

that COLA laboratories comply with the CLIA requirements for calibration verification.

Calibration sets the

instrument to give an

accurate result for each

analyte.

This LabGuide begins by defining calibration and calibration verification, and explaining

the difference between the two related processes. It continues by providing detailed

information about calibration verification to help you understand the process and meet

the CLIA and COLA requirements.

CALIBRATION

Calibration is the process of testing and adjusting the instrument or test system readout

in order to establish a correlation between the instruments measurement of the

substance being tested (the analyte) and the actual concentration of that substance. In

other words, calibration sets the instrument to give an accurate result for each analyte.

Calibration Frequency

The laboratory is responsible for performing calibration for each analyte at the frequency

specified by the manufacturer of the test. Calibration may also be required when

calibration verification does not give acceptable results. If calibration for your test system

is less stable than the manufacturers recommended frequency, then more frequent

calibration and/or additional calibration materials may be required, as determined by

your laboratory.

Calibration Exceptions

Calibration is not required for:

Manual procedures that do not involve an instrument; and

Microscopic procedures.

These tests use visual interpretations rather than instrument measurements, so there is

nothing to calibrate.

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

2 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

The following are examples of manual procedures:

Microbiology cultures;

Tilt-tube prothrombin times; and

ABO group and D (Rho) typing.

The following are examples of microscopic procedures:

Urine sediment examination;

KOH and pinworm preparations; and

Manual WBC differentials.

The following are examples of other tests that do not require calibration:

Most prothrombin time devices;

Point-of-care or unit-use devices that are factory calibrated and do not permit

user calibration, or those where calibration is performed internally by the

instrument.

Note: Calibration VERIFICATION is required for nonwaived devices of these types.

Calibration Materials

The test systems instructions describe the process for performing calibration, as well as

the number, type, and concentration of calibration materials to use for each analyte.

Calibration materials (calibrators) are solutions that contain a known amount of the

analyte being measured. Some calibrators contain, and can be used to calibrate, more

than one analyte. Previously, the term standards was used when referring to

calibration materials.

Calibration Summary

Calibration sets the instrument to give an accurate result for the analyte being tested.

It is performed

At the frequency specified by the manufacturer of the test, or more frequently if

determined necessary by the laboratory;

Using the number, type, and concentration of calibration materials specified by the

manufacturer; and

When calibration verification does not give acceptable results.

Calibration verification

may be required even

if calibration is not.

LINEARITY

Before the final CLIA regulations were published in 2003, laboratories were required to

perform linearity studies every six months for quantitative high complexity tests. These

studies involved:

Replicate testing of five samples spanning the reportable range;

Determining a mean for each sample; and

Plotting the points to produce a linear curve.

Linearity studies, as such, are no longer required by CLIA, but they are considered good

laboratory practice. Calibration verification has basically replaced the process of linearity

studies.

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

3 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

REPORTABLE RANGE

Reportable range is the range of results for an analyte, from minimum to maximum,

that the test system can accurately measure. Determining reportable range and other

requirements for verification of performance specifications is covered in detail in

LabGuide 13.

CALIBRATION VERIFICATION

Calibration verification entails testing materials with known concentrations of the

analyte in the same manner as patient specimens. At least three specimens that span

the reportable range of the test are tested as unknowns. They must be tested in the

normal patient test mode, not the calibration mode. Compare the result values to the

known values of the materials. If the values obtained are acceptable, calibration of the

analyte is verified. If not, a new calibration may be required.

In other words, calibration verification checks the instruments calibration for the

analyte to verify that calibration is still valid. A successful calibration verification

confirms that the test system is providing accurate results for the analyte throughout

the reportable range of the test.

Calibration Verification Frequency

Calibration verification

checks the calibration

to verify that it is still

valid.

The laboratory is responsible for performing calibration verification, for each analyte

measured by the test system, every six months. It is required more frequently if:

Specified in the manufacturers test system instructions; or if

The lab has determined (when establishing or verifying performance

specifications) that the calibration for this test system or analyte should be

checked more frequently.

The laboratory must also perform calibration verification when:

There is a change in the reagent lot number, reagent formulation, or reagent

manufacturer used for the test;

Note: A lab is not required to perform calibration verification after lot number

changes if they have documented several instances where the calibration

verification was acceptable after a lot number change.

There is major preventive maintenance or replacement of critical parts; and

Control materials do not perform as expected.

Calibration Verification Exceptions

The requirement for calibration verification is automatically met if the test systems

calibration procedure for the analyte uses three or more levels of calibration material

AND:

Includes a low, mid-point, and high value; and

Is performed at least once every six months.

If an acceptable calibration is performed at least every six months for an analyte, then

calibration verification does not have to be performed for that analyte. Calibration at

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

4 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

least every six months satisfies the requirement for calibration verification.

The calibration verification requirements for automated hematology cell counters (CBC

instruments) that utilize the impedance method are met if the laboratory:

Follows the manufacturers instructions for instrument operation;

Tests at least two levels of control materials each day of testing; and

Obtains acceptable results for the daily controls.

Calibration Verification Materials

To perform calibration verification, materials of known concentration are tested in the

same manner as patient specimens. There are several different materials of known

concentration that can be used for calibration verification:

Commercially available calibration materials or linearity sets;

Acceptability limits are established by the manufacturer.

Proficiency testing samples with known results;

CLIA-defined acceptability limits are listed in the PT summary.

Control materials with known results; (You must use a different lot number for

calibration verification than you use for your routine quality control.)

Acceptability limits are established by the manufacturer.

Patient specimens with known results;

Acceptability limits are established by your laboratory. Use limits that are

reasonable for the analyte, i.e., 2SD, or a set amount or percentage.

Proficiency Testing limits are a good guide.

Since calibration verification is used to check if the test system is providing accurate

results across the reportable range of the test, it is important to use calibration

verification materials for each analyte that include at least:

A low value at or near the lower limit of the instruments reportable range;

A mid-point value; and

A high value at or near the upper limit of the instruments reportable range.

Use materials of

known concentration

to perform calibration

verification. These

materials have several

sources.

Even though many commercially available calibration verification materials contain

more than one analyte, you may still need to use more than one set of calibration

verification materials in order to perform calibration verification for all of the analytes

on all the test systems used in your laboratory.

Calibration Verification Performance

To perform calibration verification:

1. Document the date, the analyte, and the calibration verification materials used.

2. Run at least three levels of materials, in the same manner and test mode that

patient specimens are tested, and record the results. One repetition for each

level is adequate, but additional repetitions will supply more data that the

laboratory may find useful.

3. Compare the results obtained to the acceptable limits.

4. Document the results and indicate if the results are acceptable.

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

5 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

Calibration Verification Example

The following is an example calibration verification to help demonstrate how to evaluate

the data.

Analyte: Total Cholesterol

Instrument: ChemXYZ

Calibration Verification Material Used: XYZ Brand Commercial Calibrators

Source of Acceptable limits: Manufacturer limits

Known Value of Material

Low 20

Mid 150

High 300

Acceptable limits

18 22

135 165

270 330

Obtained result

20

152

269

Result acceptable?

Yes

Yes

No

Comments:

Recalibration may be required. Will use troubleshooting checklist first.

Since the results for the low sample and the midpoint sample fall within the range of

acceptable limits, these points are acceptable. Since the high value sample result is below

the acceptable limits, this point is unacceptable.

Corrective action is

needed whenever

calibration verification

fails.

A successful calibration verification requires acceptable results for all materials tested.

This data means the calibration verification for this analyte failed, which means that the

instrument calibration for this analyte may no longer be valid and corrective action is

needed.

When Calibration Verification Fails

If your calibration verification fails (results for one or more levels of materials are not

acceptable) for any analyte, you may need to recalibrate the instrument for that analyte.

A troubleshooting checklist is provided at the end of this LabGuide to help uncover

potential problems that require corrective action. Proceed through the troubleshooting

checklist and attach the completed form to your calibration verification worksheet.

If calibration verification fails on a test system that is factory-calibrated by the

manufacturer and cannot be recalibrated by the laboratory, then contact the

manufacturer for advice on what steps to take next.

Corrective Action

The troubleshooting checklist may uncover a problem that you can correct (e.g., replacing

expired material). If so, calibration verification can simply be repeated once the

correction has been made.

The checklist may also uncover a problem that indicates a new calibration (recalibration)

is necessary. If so, recalibrate by following the manufacturers instructions for calibration.

Corrective action is needed even if the troubleshooting checklist does not uncover the

cause of the problem. Recalibrate the instrument for the analyte by following the

manufacturer's instructions for calibration.

Document the calibration and indicate that it was performed in response to an

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

6 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

unsuccessful calibration verification. Run all levels of controls after calibrating the

instrument and document the results.

If the instrument still does not perform as expected, call the manufacturer for further

troubleshooting advice.

Documentation

Document all actions taken when performing calibration verification, and those taken

during an investigation of calibration verification failure. All corrective actions taken and

those taken during follow-up of corrective actions should be documented also.

Retain this documentation for at least two years. The retention period may be longer

depending on other Federal, State, local, and organizational regulations and

requirements.

Calibration Verification Summary

The CLIA regulations published in 2003 specify requirements for calibration verification of

nonwaived testing. The COLA criteria for calibration verification are derived from these

requirements.

Calibration verification checks the test systems calibration at a point in time to determine

if it is still providing accurate results for the analyte throughout the reportable range.

Perform calibration verification for each analyte at least once every six months, or

whenever certain situations occur.

Perform calibration verification using materials of known concentrations.

Document all actions

taken and retain this

documentation for at

least two years.

Properly document all calibration verification actions and any corrective actions taken.

Retain records of all calibration verification activities for at least two years.

REFERENCES

CLIA Regulations, Subpart K, 493.1255, Standard: Calibration and calibration verification

procedures; http://wwwn.cdc.gov/clia/regs/subpart_k.aspx#493.1255

CMS Brochure #3 Calibration and Calibration Verification;

http://www.cms.gov/Regulations-and-Guidance/Legislation/CLIA/Downloads/6065bk.pdf

COLA Criteria for Quality Laboratory Performance, Evaluation Grouping: Calibration.

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

7 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

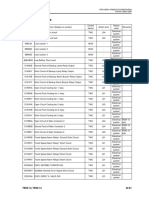

CALIBRATION VERIFICATION

WORKSHEET AND DOCUMENTATION FORM

Date

Analyte

Instrument

Serial #

Reagent/strip/cassette Lot #

Expiration Date

Calibration Materials Used

Source of Acceptable Limits

Low Level

Mid Level

High Level

Mid Level

High Level

Lot Number

Expiration Date

Expected Result

Acceptable Limits

Calibration Verification Results

Low Level

Repetition #1

Repetition #2

Repetition #3

Mean

Results acceptable?

Comments and/or Corrective Actions

Performed by

Reviewed by

Date

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

8 LG 15

Comments? Feedback? Questions?

Email us at info@cola.org or call us at 800 981-9883

CALIBRATION VERIFICATION TROUBLESHOOTING CHECKLIST

Date

Analyte

Instrument

Serial #

1. Check the analytes Quality Control (QC) results.

Are there any patterns seen in the control results?

Are all values below the mean?

Are all values above the mean?

Are there any noticeable shifts or trends over time?

Are accuracy and precision acceptable?

Comments

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

2. Check the calibration verification materials.

Are the materials appropriate and in-date?

Have the acceptable limits been properly determined?

Comments

Yes

Yes

No

No

3. Check the reagents.

Have the reagents changed in any way? (Include a check for discoloration, cloudiness, and contamination.)

Is there a new lot number in use?

Has the reagent manufacturer changed?

Has the reagent formulation changed? (Check the package insert.)

Are reagents in-date?

Comments

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

4. Check instrument maintenance. Review all maintenance logs (daily, weekly, monthly, quarterly, annually, etc.)

Are there any missing maintenance actions, any problems, or any changes?

Yes

Comments

No

5. Check the environment.

Has the instrument been moved recently?

Have there been any changes to the instruments environment or surroundings?

Comments

Yes

Yes

No

No

6. Check instrument service records.

Has the instrument been serviced recently?

Have there been any software or hardware upgrades or changes?

Comments

Yes

Yes

No

No

7. Check instrument operation.

Are there new instrument operators?

Are all operators following established procedures for instrument operation?

Has the test procedure / technique been modified recently?

Comments

Yes

Yes

Yes

No

No

No

8. Check a comparative method.

Is there another laboratory that could test the calibration verification materials so results can be compared? Yes

Comments

No

9. Is recalibration indicated for the analyte?

Yes

No

9881 Broken Land Parkway | Columbia, MD 20146 | 800-981-9883

www.COLA.org | www.COLAcentral.org | www.LabUniversity.org

COLA is a physician-directed organization whose purpose is to promote excellence in laboratory medicine and

patient care through a program of voluntary education, consultation, and accreditation

COLA

Original: 05/2007

Revised: 08/20/2012

Next Scheduled

Review: 08/22/2014

Вам также может понравиться

- Handout-Cal CalverДокумент8 страницHandout-Cal Calverapi-311256138Оценок пока нет

- Please Do Not Write Your Answers in REDДокумент13 страницPlease Do Not Write Your Answers in REDapi-311256138Оценок пока нет

- Rubricassign6 2 9272015Документ1 страницаRubricassign6 2 9272015api-311256138Оценок пока нет

- Gottsponerfinal Piesppt03222015Документ17 страницGottsponerfinal Piesppt03222015api-311256138Оценок пока нет

- Rubric 209272015Документ2 страницыRubric 209272015api-311256138Оценок пока нет

- Technicalbulletin2015 3 IqcpendoftransitionДокумент2 страницыTechnicalbulletin2015 3 Iqcpendoftransitionapi-311256138Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- IGS-NT Troubleshooting Guide 05-2013Документ43 страницыIGS-NT Troubleshooting Guide 05-2013dlgt63100% (2)

- Engine Misfires, Runs Rough or Is Unstable CAT 320DДокумент4 страницыEngine Misfires, Runs Rough or Is Unstable CAT 320DfalahОценок пока нет

- Electrical Site Engineer - ResumeДокумент1 страницаElectrical Site Engineer - Resumevignesh vikkyОценок пока нет

- Printed Circuit Board Maintenance - Repair - and Testing GuideДокумент194 страницыPrinted Circuit Board Maintenance - Repair - and Testing GuideSebastião Jorge dos SantosОценок пока нет

- 9.manual Tecnico B105Документ114 страниц9.manual Tecnico B105Karen Tatiana Bolivar67% (6)

- ITCAM Agent For SAP Applications V7.1.1.1 Troubleshooting GuideДокумент64 страницыITCAM Agent For SAP Applications V7.1.1.1 Troubleshooting GuiderameshctlatpОценок пока нет

- X-Ray System TroubleshootingДокумент46 страницX-Ray System TroubleshootingCompuWan PolancoОценок пока нет

- Champ Ii Scale With Cd11: Operating and Installation InstructionsДокумент11 страницChamp Ii Scale With Cd11: Operating and Installation InstructionsseabellОценок пока нет

- 10259130-EN-20150615 Operating ManualДокумент610 страниц10259130-EN-20150615 Operating ManualCezar HauОценок пока нет

- Error Code Komatsu FB25-12Документ6 страницError Code Komatsu FB25-12Aighn NartОценок пока нет

- Optical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorДокумент4 страницыOptical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorAhmad IbrahemОценок пока нет

- ADM TroubleshootДокумент19 страницADM TroubleshootCiprian FuiaОценок пока нет

- Cisco SCE 2000 4xGBE Installation and Configuration Guide 3.1Документ142 страницыCisco SCE 2000 4xGBE Installation and Configuration Guide 3.1Dimitar MojsovskiОценок пока нет

- Wagner Paint Crew ManualДокумент26 страницWagner Paint Crew ManualJames Wiley DeckОценок пока нет

- Service Manual: EPSON Stylus Photo RX585/RX595/RX610Документ131 страницаService Manual: EPSON Stylus Photo RX585/RX595/RX610Carlos ChiaraОценок пока нет

- HSVF Trouble Manual (Ver-0) 20111223 PDFДокумент32 страницыHSVF Trouble Manual (Ver-0) 20111223 PDFReynold Suarez100% (7)

- Fuel SistemДокумент55 страницFuel SistemRodolfo AlbertoОценок пока нет

- SM Pc78uu-6 Pc78us-6 1025-1-45Документ45 страницSM Pc78uu-6 Pc78us-6 1025-1-45Daman Huri60% (5)

- Consumer Electronics Servicing CG - 2 PDFДокумент25 страницConsumer Electronics Servicing CG - 2 PDFPedro Diaz86% (7)

- Codes That Inhibit Operation of Aftertreatment SystemДокумент4 страницыCodes That Inhibit Operation of Aftertreatment SystemCatalinUrsuОценок пока нет

- AT-05197 - HYSYS - Study Guide - 2 PDFДокумент8 страницAT-05197 - HYSYS - Study Guide - 2 PDFahmedОценок пока нет

- Mechanic Electric Vehicle - CTS1.0 - NSQF-5Документ58 страницMechanic Electric Vehicle - CTS1.0 - NSQF-5Rohit KutlehriaОценок пока нет

- Birds Repair PDFДокумент13 страницBirds Repair PDFEl SleskoОценок пока нет

- Pre Job BriefingДокумент5 страницPre Job Briefingliveconnectionz2820% (1)

- MTTS V1-V3 Infant Warmer. 001 User and Service ManualДокумент13 страницMTTS V1-V3 Infant Warmer. 001 User and Service ManualAdemar PereiraОценок пока нет

- Sap Basis General Problems & SolutionДокумент17 страницSap Basis General Problems & SolutionAnimesh SinhaОценок пока нет

- Pehj0184 00Документ2 страницыPehj0184 00Madhana GopalОценок пока нет

- (SM) D155ax 3Документ1 180 страниц(SM) D155ax 3rts-ural100% (3)

- CloudEngine 6800&5800 V100R003C00 Troubleshooting Guide 01Документ167 страницCloudEngine 6800&5800 V100R003C00 Troubleshooting Guide 01MenganoFulanoОценок пока нет

- 2.1) Instruction Manual (Sau8810) For Alarm Monitoring System - 6N-2521-102Документ50 страниц2.1) Instruction Manual (Sau8810) For Alarm Monitoring System - 6N-2521-102D ArsenОценок пока нет