Академический Документы

Профессиональный Документы

Культура Документы

Energy Saving of Chiller

Загружено:

احمد الجزار20070 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров14 страницenergy saving of chiller

Оригинальное название

energy saving of chiller

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документenergy saving of chiller

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

32 просмотров14 страницEnergy Saving of Chiller

Загружено:

احمد الجزار2007energy saving of chiller

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

Energy and Bulngs 1192016) 308-322

‘Contents list a

lable at ScienceDirect

Energy and Buildings

journal homepage: www-clsevier.com/locate/enbuild

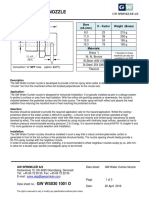

Detailed analysis on part load ratio characteristics and cooling energy

saving of chiller staging in an office building

Qu

Byeong Mo Seo®, Kwang Ho Lee?"

+ conduate Sho Hanbt National Univers, Daejeon, South Roe

"Departmen Architectural ngnering, Hanba Nana User agen, uth Korea

ARTICLE INFO ABSTRACT

‘Accepted 25 Naren 2016

‘Commercial Buldings account for significant portions of the total bullding energy i Korea and thus

vasietyofreseach on tie chiller operation was arred out thusfar. However most of thezesearches were

carried out on the chile itself Le, the part load ratio characteristics ané the corresponding electricity

energy consumption pattern were not analyze in the existing studs. In this std. the part load ratio

and the operating characteristics of vapor compression chiller were analyzed within an offic building

‘equipped with the conventional variable ar volume system. In alition. the enezgy consumption among

‘ferent chiller staging schemes was conyparatively analyzed Asa vest, significa portions of total

‘operating hous, cooling load and energy consumption turned ou tobe inthe pat load ratio range of 0

‘through 50 and thus the energy consumption was significantly affected by the chile COP (Coefcent

Commercial baling

eaten ot petrmance of Performance) at lw pat load conditions, indicating thatthe chiller operation atthe pat loa i an

teres important factor in comsmerllbuldings In adtion, wing sequential chiler aging scheme can

"ive annual cooling energy usage by more than 10.2% compared to opesting 3 snge chiles. For further

‘eductioninconing energy, applying the sequential contro ehiler staging uring the intermediate eason

and appving the uniform contol clr staging algorithm during the cooling season is considered to be

{the optrtal contro algorithm fr maximum efficiency of eile.

{© 2016 Elsevier BV. Al rights reserved

1. Introduction of greenhouse gases and approximately 87% of energy source used

LL. Background

There isa growing concern on the global warming recently and

issues regarding energy and environments such as climate changes

due to the global warming, new & renewable energy which could

replace fossil fuel, and increase in energy consumption due to pop-

ulation growth have become main topics in the every area and

everyday lle of society. Korea based on export-oriented indus-

trial structure is one of the top ten major producers of greenhouse

ses facingincreasing pressure for the reduction of greenhouse gas

emission from the global community, and since Korea is included

in the mandatory target countries for the reduction of green-

house gas emissions from 2020, so if we are unable to take proper

‘measures, national Key industries may decline rapidly. Current,

approximately 92% of total energy used in the country is produced

‘Hough fossil fuel which is the biggest factor for the production

“onrespending autor

matladars lest hanbat cr (RH. Lee

(0578-7748) 2016 sever BV. Al rights reserve.

comes from imports |,Als0,the consumption of fossil fuelsis done

‘mostly in cities, and carbon dioxide generated from the combus-

tion of fossil fuels is mostly from the energy usage in urban spaces.

Therefore, while the main target of the government's greenhouse

sas reduction measures in the past was the industrial sector that

consumed energy in volume, recently there isa growing emphasis

on the needs to prepare measures in city unit (2.

Currently, the energy consumption in our country consists

of approximately 55% for industries, 24% for buildings, and 21%

for transportation. CO, generation rate due to buildings which

account for most energy consumption in city space is announced

as approximately 23% of total CO, generation in the country

oniy in consideration of generation rate from energy consumption

Fequied for maintaining buildings, ut iftotal energy consumption

required for producing, transporting subsidiary building materi-

als and construction work is considered, i is estimated to reach

approximately 38% [2. Also, the cost used for energy consumption

among the lifecycle cost ratio ofa buildings approximately 34% of

{otal costs 4), and approximately 23% of total energy used in office

buildings is consumed as cooling energy [5

Most domestic studies cartied out prior to 2000s were con-

‘centrated in the architectural methods, bu inthe recent tend of

studies, studies on various saving measures forthe building energy

‘conservation are required so that various studies regarding exhaust

heat recovery, high efficiency device and commissioning are being

carried out actively (3), However, studies regarding the overestima-

tion of heat source equipment which is considered as an endemic

problem are inadequate, and also the overestimation af heat source

‘equipment may lead to increase in initial investment and mainte-

nance expense, and installation space as well 3s increase in cooling

and heating energy consumption according to the characteristics

‘of part load, According to relevant research trends. Lee et al. [5

‘determined the overestimation evel of capacity of heat source sys~

‘tem through the reference material and actual case investigations

and analyzed the annual operational performance according to the

part load characteristics of office building through the simulation,

‘obtaining the result that in case of applying the staging of heat

source equipment differentially spiting chillers to 5:5 and boil-

cers t0 7:3 had the highest energy saving rate in comparison to the

‘ease of no staging, and Park and Jung (7| analyzed the economic

Feasibility of alternative heat source systems based on the air con-

ditioning system n office building according tothe different staging,

control, Many domestic studies regarding energy saving according,

tothe staging of heat source equipment have been carried ou, but

study regarding the analysis of mast efficient load distribution con-

trol algorithm to supply heat source to each heat source equipment

is significantly limited,

Incase of international studies outside Korea, Abou-Ziyan et al

investigated the effect of different load-sharing operation strate-

‘ies on the aggregate performance for existing multiple-chiler

system under different partial oads and environmental conditions.

The various tested load-sharing operation strategies obtain aggre-

«gate performance from 1.06 to 1.41 for the full day and the best

load-sharing operation strategy was better than conventional by

22-33%, I was also stated that the load shating strategy is influ

‘enced by many parameters such as the condition ofthe chillers and,

‘compressors, the piping arrangement, and the heat loss from the

chilled water piping where these parameters may overwhelm the

individual chiller performance, and thus the need for maintenance

‘can be predicted and the standby chiller may be eliminated (15

Sun etal [15] proposed an optimal strategy for operating chillers

in steps in response to the changing building cooling loads, The

Gordon and Ng's thermodynamic model correlates the chiller COP

(Coefficient of Performance) with the temperature monitored at

‘the evaporator and condenser sides [17), Chan and Yu [18] ana-

lyzed how the chiller component interact with each other and

discussed the use of floating condensing temperature control to

improve chiller performance.

Therefore, the purpose of this study is to analyze the annual

‘operational performance of chiller according tothe part load char

acteristics related to cooling energy which accounts for the largest

portion of energy consumption in office buildings through the

‘dynamic simulation of building energy. tn addition, by utilizing

chiller staging technique, energy usage through the comparative

analysisof annual operational performance oftwo load distribution

control algorithms including sequential control which distributes

load in consecutive order and uniform [9] control which distributes

load evenly among load distribution control algorithms of Ener-

_gyPlus which have not been considered in previous studies were

‘compared: and the optimal cooling load distribution control algo-

richn in case of applying chiller staging scheme for office buildings

was presented,

rable

12, Scope

This study aims to reduce the consumption of cooling energy

in office buildings, and the scope of contents is classified into two

aspects. First, the enesgy consumption of chillers with no chiller

Staging is estimated to analyze the annual energy consumption

according to the performance of chillers, characteristics of part

load and energy required for each section. Second, by analyzing

the annual energy consumption according to the performance of

chillers under different load distribution control algorithms the

‘optimal load distribution control algorithm in case of applying,

chiller staging technique is presented, Fig. | shows the overall flow

of this study,

2. Methods

2.1, Simulation software

For the simulation program used in this study, EnergyPlus v6.0

‘which could analyze the cooling and heating load of a building and

verify the thermal environments mathematically was selected | 10)

EnergyPlus uses the heat balance method which is recommended

bby American Society of Heating, Refrigerating. and Air Condition-

ing Engineers (ASHRAE) for calculating the building load |11|- Also,

‘in case of EnergyPlus, it has been verified through ASHRAE 140

sguidelines, which is the most representative dynamic simulation

tales [12), and it has a big advantage to simulate the systematic

connection between each component by executing Zone, Surface,

‘ir Heat Balance, System and Plant modeling, which are the main

‘components of building energy simulation integrally step by step

ateach time. The detailed contents regarding the development and

verification ofthe program have been described many times in the

precedent studies [13),

22, Description of simulate office

For the EnergyPlus simulation model, large scale office building

prototype model of ASHRAF 90.1 provided in EnergyPlus was used

forthe analysis The building was 731m long and 48m wide, andthe

internal heat generating elements entered to the simulation were

shown in Table I

23, Simulation condition

{As the modeling applied for such study, the analysis was car-

ried out through the ASHRAE Standard 90.1 based large scale office

‘building prototype model provided in EnergyPlus. For the repre-

senting period selected for analysis, May 3nd August 14 which bad

‘the highest load during the intermediate season (March, April, May,

September and October) when both cooling and heating equip

ment were used complexiy and the summer season (June, July and

‘August) when only the cooling equipment was used were selected.

asthe representing days since the office building was cooling-based

Duilding, and forthe operation time of chiller, the period from am,

to6 pam. was selected asthe operation time according t the sched-

ule of office building. For the weather data. the weather data of

Incheon area provided internally in EnergyPlus was used.The fol-

lowing Table 2 shows basic input conditions used inthe study, and

Sen KH. Le nergy ont ngs 119 (2016) 308-822 an

Theoretical consideration

{| Background of study and objective setup

© Consideration of previous studies

|| Setting of study method and range

Chiller control algorithm in case of applying

operating number split

+ Sequential + Unitorm

EnergyPlus Simulation

|| Use of large scale office building (EnergyPlus v6.0)

' Application of weather data provided by EnergyPlus

setting of Simulation Input value

| Selection of representative days and analysis of tem

perature pattern

Case Modeling

+ caren | = 1chiller

+ casez | 2 chillers, Sequential

+ cases | — 2 chillers, Uniform

Case of Simulation Anal

Performance Analysis | Analysis of part load ratio, performance coefficient and

er chiter electric consumption of representative days

Whours by section of

- + Analysis of cumulative opera

ee nna part load ratio

eo + Analysis of electric consumption by section of annual

Case Study year

Deena

Sumiary of HVAC system cntguaion 1520,

partload ratio,

+ Comparison of electric consumption by case, month and

‘Comparison of cumulative operating hours by ease and

by annual part load ratio section

+ Comparison of electric consumption by case and by

section of annual part load ratio

SP

Coe cia)

FEA Study ow bart,

hile Capacity

Tenrusveo

73tm) 48m

side sree Tea8-08m sm?

ables

Performance curve input at

‘Table 3 is as follows. From §:00 until 18:00 the system controls

‘the internal air temperature to a cooling and heating temperature

set point of 24°C and 21°C, respectively. During the night time

‘the system is switched off. The infiltration was assumed equal

to 020003331 (sm) (low per exterior surface area). The mini-

‘mum outdoor air flow rate was set to be 0.782L(s/a?) (flow pet

‘1085 area) and was provided from $:00 until 18:00. Each zone is,

served by conventional VAV (Variable Air Volume) box. Inthe cool-

ing mode, the airflow is adjusted to meet the cooling load with

the discharge air temperature fixed at the AHU Supply Air Tem-

perature (SAT) set-point. In the heating mode, the hot water low

through the reheat coil and the resultant discharge air tempera-

ture are adjusted with the airflow fixed at the minirmum airflow.

‘The building is served by a single variable-speed central station ait

handling uni(AHU) including an economizer, chilled water cooling

coll, hot water heating coil and supply fan, The AHU fanis controlled

‘with a static pressure reset strategy. The central plant consists of

«2 centtifugal chiller with variable-speed pumps and a two-speed.

‘cooling tower. A gas fied boiler provides hot water to all heating

cals

3. Chiller modeling

3.1 Performance curves

In order to analyze annual energy consumption using Energy-

Plus according to the performance of chiller, characteristics of patt

load and required energy per the part oad ratio section, coeficients

regarding the following 3 performance curves should be entered

inadvance. Therefore, coefficients required forthe calculation for-

mula were calculated through actual measurement data of catalog

provided by a company in US. and the description on the calcula-

tion formula of each performance curve and the entered coetficient

value are as shown in Table 4 [14

3.1.1. Cooling capacity function of temperature curve

performance curve)

ChillerCapFTemp = a+b (Tew.t) + €(Tew.t)” +4 (Toone)

(tane)* +4 (Font) (Tete)

were

ChillercapFTemp=cooling capacity factor, equal to 1 at refer-

Tewsleaving chilled water temperature, C

Tec wenteing condense uid temperatre

3.12. Energy input to cooling output ratio function of

temperature curve)

ChillerEIRFTemp = a~b (Tew.t) + €(Tewt) "+4 (Teond.e)

nde) +£ (Tew) (Teonee)

where,

ChillerEIRFTemp energy input to cooling output factor, equal

to Lat eference conditions

Tow = leaving chilled water temperature, C

Trang “entering condenser fuid temperature, C

3.13. Energy input to cooling output ratio function of part ioad

ratio curve 14)

(Chiller EIRFPLR = a+ (PLR) + (PLR)

where,

CChillerEIRFPLR~ energy input to cooling output factor, equal to

1 at reference conditions

PLR part-load-ratio= (cooling load){chillr’s available cooling

capacity)

32, Load distribution algorithm

‘ig. 2 shows the behavior method of load distribution control

algorithm in EnergyPlus. [14] Each behavior method of load dis

‘wibution conttol algorithm is as follows. Optimal operates each,

plece of equipment at its optimal past load ratio and will oper=

ate the last component between its minimum and maximum part

load ratio in order to meet the loop demand. Sequential uses each,

piece of equipment to its maximum part load ratio and will oper=

ate the last required piece of equipment between its minimum

land maximum part load ratio in order to meet the loop demand,

Uniform evenly distributes the loop demand amongst all avail

able components on the equipment list for a given load range (9),

However, according to the part load ratio input value of chillers

‘which were applied to this study, there is no difference in the min-

imum and maximum part load ratio input values in comparison

to the optimum part load ratio and minimum unloading ratio val-

‘ues which become input variables of optimal control algorithm, so

‘optimal control algorithm and sequential control algorithm behave

equally as explained above. Therefore, since the analysis of load

distribution contol algorithm according to changes of part load

ratio input had a different objective than the presentation of opti-

‘mal load distribution control algorithm in case of applying chiller

staging technique which is the objective of this study, the analy-

sis of optimal control algorithm among three control algorithms

was excluded, and the minimum part load ratio input was fixed

and cases were classified into 3 cases as shown in Table 5, In

CCase-I which is the base case, one chiller with the capacity of

‘B50 EW was applied, and in Case.2, the capacity of chiller in the

base case was split to 425KW respectively at a ratio of 5:5, and

‘the sequential [oad method was selected for the load distribu-

tion. and the priority order of equipment is in order of Chiller!

and Chiller2. The Uniform control method that the capacity of

{wo chillers is divided into 425KW respectively and chiller! and,

CChiller2 handle the same load is adopted in Case-3 just as Case 2,

and due (0 the characteristics of load control algorithm, chillers

dare operated at the same time in Case-3 regardless of priority of

equipment.

Identity available equipment

Select Scheme

os ead teaeleeatioercal

Toad equipment

Toad equipment] Load equipment ) | Ceadequipment

tooptinalPLR | | tocapactyin Uniformly to

‘equip ist order capacty

‘Sim Equiprvent

‘non-uniformly to

‘Sim Equipment

“Sim Equipment

tn ago 1420),

Tables

Tiel Easier GeoTew ‘pean poy Toad Dsbationagoriim

4, Results analysis

4.1, Analysis of outdoor air temperature

Fig, 3 shows the annual outdoor air temperature of Incheon

Metropolitan City. Incheon is located at latitude of 37.48° and a

Tongitude of 126.55°, and for the weather data of Incheon, the

weather data provided in EnergyPlus was used. The analysis result

showed that the annual average outdoor air temperature was

11.8°C, minimum temperature was -9.7°C on December 15 and

the temperature was 32.6°C on July 23. Also, March, April, May,

September and October were selected asthe intermediate season

Which was the period to use both cooling and heating and June,

July and August were selected as the cooling season mainly based

‘on cooling, and inorder to carry aut the analysis on the period touse

chillers, May 3 and August 11 having average temperature pattern

and load were selected as the representative days of intermediate

season and summer season respectively.

42. Load of chillers on the representative days and changes in

‘urdaor air temperature

In this study. May 3 and August 11. which record the repre

sentative average temperature values of intermediate season and

cooling season were selected as the representative day of each sea-

som respectively and a close analysis was cartied out. The following,

Fig. 4 shows the cooling load of AHU cooling coil and outdoor tem-

perature on the representative days. The temperature distribution

of 15.3-23.1 "Cis shown on the representative day ofthe interme-

diate season, and the temperature distribution of 25.1-322°C is

shown on the representative day ofthe summer season. Fortheload

pattern on the representative day, the distribution of 0-300 KW in

«ase ofthe intermediate season ané the distribution of 0-550 KW in

case ofthe summer season are shown, and we can see that the pat-

terms which are almost similar withthe office schedule are shown,

We can confirm that there is no oceursence of cooling load from

19:00 to 4:00 which is not the main building usage time because

challers are not operated and cooling load occurs from 5:00 to 18:00

which is the main building usage time. Also, on the contrary to the

intermediate season, we can confirm that load increases rapidly

from 5:00 to 7-00 onthe representative days during summer season

regardless of office schedule. Ths is to reduce the indoor temper-

ature to the indoor setting temperature (24°C) while removing

accumulated heat in the building while the system is turned off

faring nighttime,

43. Part load ratio variations

‘The following Figs 5 and 6 show the part load ratio at the repre-

sentative days in each case tn case of Case 3s similar with Case.1

soitis only shown in Fig. 5 For the distribution from 05:00 to 18:00

‘which isthe operating hours chillers, Case.1, 3 showed adistribu-

tion of 10-34x, chiller! in Case_2 showed a distribution of 10-68%

and Chiller2 showed a distribution of O% in case of intermediate

season, Incase of summer season, Case.1 showed a distribution of

44-61%, Chiller in Case.2 showed a distribution of 83-97% and

Chiller2 showed a distribution of 0-26%, Chllert and Chiller2 in

Case.3 showed a distribution of 41-61% which was same with

Case-1. The part load ratio of Case.1 and Case-3 was maintained

at 10% from 5:00 to 9:00 constantly during the intermediate sea-

son, and this is because the minimum part load ratio was 10%. We

can see that even if actual load applied tothe chiller was less than

aa 1M Se KE Le very and lng 1192018) 308-322

Fe 3. Outdoor ar temperature of Incheon City |)

=i Intermediate Season Outdoor Ar seb Cooling Seon Outdoor Ar

2 ntermesiae Seaton Cooling Rate —# cooling seston Coting ate

Outdoor Air Dry Bulb [°C]

22348 6 7 @ 9 101142 43 14 35 16 17 18 19 2011-223 24

Hour

Fig. 4. AU cooling cl cooling ate and outeor air temperature varatins 82).

—teintermediate Seaton Cooling Seaton

5

Pat Lad Ratio U6)

sh R EGER REE

Hour

Fig 5 Part lad eto (C3 3,319

10%, the part load ratio of chiller was fixed to 10% which was the load increases rapidly due to the effect of incoming solar radiation

‘minimum part load ratio. Between 14:00 and 15:00 when cooling and indoor heating elements, the maximum value is recorded, and.

EM Ses, KH Le nergy end Buns 119 (2016) 309-822 a

Intermediate Season Chiler 1

—wcoolng Season chiler 1

Part Load Ratio [%]

sR 289888

inermadiate Season Chiller 2

+ Cooling Season Ciler 2

eooeo

1g 6. Part oad aio case?

then the value gradually decreases so that PLR is maintained at 0

from 19:00 to 04:00 when chillers are not operated

In case of summer season, a similar distribution with the load

pattern in Fig. 4 i shown, and the highest PLR is shown as 617% at

(05:00 when the operation of chillers begins in order to achieve the

indoor setting temperatute, and then decreases gradually until it

becomes the minimum value as 44% at 7:00 and then increases to

near 60% again at between 14:00 and 15:00 due to the eflect of

‘incoming solar radiation and indoor heating elements, After that,

PLR decreases gradually and becomes 0% at 19:00 when the oper”

ation of chillers stops. The part load ratio of Case.2 shown in Fig. 5

‘was maintained at 10% from 5:00 to 7:00 constantly in case of

Chiller} during the intermediate season, and this is because 10%

which was the minimum part load ratio was maintained as men-

tioned above, The maximuim value is recorded between 14:00 and

15:00 when cooling load increases rapidly due to the effect of

incoming solae radiation and indoor heating elements, and then

the value gradually decreases. Chiller2 is not operated during the

intermediate season so 0% is maintained. In case of Chiller, PLR

{s maintained at 97% during the summer season except for 07:00

and 18:00, and in case of chiller2, PLR occurs dusing the operating

hhours except for 07:00 and 18:00

The total capacity of chiller in all three cases is 8SOKW and

the maximum load on the representative day of cooling season is

'S50kW occurred at 05:00 equally. In Case.1, the chiller handles

'550.W with the capacity of 850KW, so PLR is recorded at 61%,

land in Case-3, two chillers with the capacity of 42SkW handle

evenly distributed load at the same time, so each chiller handles

275KW and PLR is recorded at 61% same as Case.t. In Case.

the fact of two chillers with the capacity of 425KW is same with

CCase-3, bt load is distributed and handled in consecutive order in

‘order fo Chillerl and chiller2, so Chller2 is not operated during,

the intermediate season. During summer season, when load which

cannot be handled by Chiller! occurs as shown in Tig. 6, Chiller2

is operated, handling the load. Case-1 and Case-3 show the same

pattern even though there isa difference in the number and capac-

ty of chillers and Case-2 shows a different pattern from Case.1 and

Case-3 because the load is handled with the total capacity of one

chillerin Case-1 and the uniform control algorithm distributes load

evenly when it occurs in Case.3 as explained above. On the other

hhand, when load occurs in Case.2, the sequential control algorithm

handles the load with 2 chillers in consecutive order according £0

the priority

44. COP variations during representative days

The following Figs. ? and 8 show COP atthe representative days

in each case. In ease of Case-3 is similar with Case-t, soit is only

shownin ig. 7-For the distribution from 08-00 to 18:00 whichis the

operating hours of chillers, Case-1 and Case-3 showed a distribu-

tion of 1.7-55, Chiller in Case 2 showed a distribution of 17-66

and Chiller? showed a distribution of in case of intermediate sea-

son, In case of summer season, Case.| and 3 show a distribution

ff 5.6-6.1, Chiller! in Case.2 shows a distribution of 5.3-5.7 and

Chiller2 shows a distribution of 0,5-2 8.COP of Case.1 and 3 shown

in Fig, 7is maintained constantly at approximately 17 from 05:00

to 09:00 during the intermediate season, and this is because the

operation amount is decided according to the minimum part load

ratio as explained above, Betiveen 14:00 and 15:00 when cooling

load becomes highest during the day due tothe effect of incoming

solar radiation and indoor heating elements, the value i recorded

at 55, and then the value gradually decreases so that COP is main-

tained at 0 from 19:00 to 04:00 when chillers are not operated.

In case of summer season, COP of Chiller is fixed at 6.0 on aver-

age throughout the day except for 5.7 at 07:00 and 5.6 at 18:00.

In Fig. 8, COP of Chller1 in Case.2is maintained at approximately

117 constantly from 05:00 to 07:00 during the intermediate sea-

son, inereases rapidly to 64 until 13:00 and 6.6 at 16:00, and then

decreases gradually, and Chiller2 is not operated. In case of sum-

‘mer season, COP of Chiller is fixed at 5.4 on average throughout

the day except for 5.6 at 07:00 and 5.7 at 18:00. COP of Chiller2

is recorded 3.1 at 05:00 when the operation of chillers begins, and

then gradually deceases and becomes 0 at 07:00, Between 14:00

and 15:00 when coolingload becomeshighest duringthe day due to

the effect of incoming solar radiation and indoor heating elements

itis recorded at 38, and then the value gradually decreases.

‘There iso significant difference in COP value a 15:00 between

the intermediate season and summer season in Case.1 and Case 3

because two chillers are operated equally under all load conditions

incase of Case-3 and the part load ratio which each chiller is oper-

ated is the same with Case.1. As the grounds for this, the load at

(07:00 on the representative day of summer season in two cases

1M Seo KH Le Brey an ukings 1192018) 308-322

arintermediate Season -t-Cooling Season

ig. 7, COP varavone (C4131

Ineo Sexson hier

terme Seaton cher?

Hour

shown in Fig, 4 is 381)0W, PLR and COP in Fig. 5 is 44% and 56

respectively, and the load at 15:00 on the representative day of

intermediate season is 301 kW, and PLR and COP are 34% and 5.5

respectively. On the other hand, the reason why the COP curve of

the representative day in Case_2 shows a pattern different from

‘other cases isthe difference inthe part load ratio which each chiller

is operated, n case of intermediate season, only Chillert with the

‘capacity of 425 KW which is a half in comparison to Case.1 and 3

is operated. Therefore, Case.1 and 3 have the average value of 3.06

‘during the operation hours of chillers on the representative days of

intermediate season, but Case.2 has a significantly higher value of,

461

45. Chiller electric consumption during representative days

‘The following Figs. 9 ancl 10 show the electric consumption of,

chiller at the representative days in each case. In case of Case.3

and Case 1 are same patterns, o tis only shown in ig. 9. For the

distribution from 05:00 to 18:00 which is the operating houts of

chiller, Case.1 showed a distribution of 16.3-54.7 kWh, Chiller

in Case_2 showed a distribution of 164-463kWh and Chiller?

showed a distribution of 0 KWh, and Chiller1 and Chiller? in Case.3

showed the same distribution of 8 2-27 4 kWh incase of intermedi

ate season. In ase of summer season, Case.1 showed a distribution

‘of 65.5-89.9kWh, Chiller in Case2 showed a distribution of

{53.1-79.1 kWh, Chiller2 showed a distribution of 0-33.1 kWh, and

Chiller and Chiller2 in Case.3 showed the same distribution of

32.2-45.2 kWh. The electric consumption of chillers in Case-1 and

3 shown in Fig. 9 occurs at 05:00 when the operation of chillers

Degin and then decreases slightly at 06:00 in case of intermedi-

ate season. A rapidly rising curve of electric consumption is shown,

‘between 06:00 and 09:00 as time goes on, and then aconstantelec-

{ric consumption is shown until 18:00, During summer season, a

similar curve of electric consumption with the load pattern on the

representative day of summer season shown in Fig 4is shown, The

clectric consumption of chillers in Case.2 shown in Fig. 10 shows

a different pattern from Case. and Case_3. In case of Chiller! dur-

ing intermediate season, the electric consumption accurs at 05:00

‘when the operation of chiller begins and then decreases slightly

at 06:00. Then, the electric consumption increases until 08:00, and

then aconstant electric consumption is maintained until 10:00, and

the electric consumption is recorded at 46.3 kWh between 14:00,

Sen KH Le nergy ont ung 119 (2016) 309-822 ar

tenement eat

25 o2

Fecre Consumption a]

“cooing Season

Fie clr elect consuption (Case 1.2) (18

‘seiner Season Chile

cooing Season Chiler

tere oneuption (i)

8

our

+ Intermaait Senan Cir 2

Fi 10. Chiles tere consumption (ate 2,

and 15:00 when cooling load becomes highestduring the day due to

the effect of incoming solar radiation and indoor heating elements,

and then the value gradually decreases. Chiller? is nat operated so

that OkWh of electric consumption is shown throughout the inter-

‘mediate season, During summer season, Chillert shows a relevant

low electric consumption at 07:00 and 18:00 during the operation.

time from 05:00 to 18:00 in comparison to other times on the con-

trary to COP pattern, and Chiller2 records an electric consumption

(33.0 kWh at 05:00 and stops operation at 07:00 when fewer loads

‘occur. Also, a constant electric consumption of 27.9 kWh is shown,

between 10:00 and 16:00.

‘The pattern of electric consumption shown in Figs. 9 and 10

are closely related to the part load ratio (Figs. 5 and 6), COP

(igs. 7 and 8) and the load of chiller (Fig. 4). The graph of electric

consumption during the intermediate season and summer season

sn Case.1 and Case.3 shows a similar pattern just as PLR and COP

graphs above, and Case_2 showsa significant difference from Case.1

and Case.3 due to the effect of chiller number control algorithm.

46. Detailed analysis on annual data

‘The following Figs. 11, 12 and 13 and Table 6 are graphs and

table showing annual cumulative operation hours, annual cumula-

tive cooling coil rate and annual total chiller electric consumption

for each PLR (10 part load ratios). In case of Case-1 where only

tone chiller is operated. che section of over PLR 0% an below 10%

{0 a §

2 w -

& I é

. =

Part Load Ratio [61

Fig. 15, Cumulative operation outs, etry enh FER (Case 3) [20

electric consumption. This is because load which chillers should and low part load ratio, The section of PLR over 10% and below 20%

handle is significantly low and electric consumption is also low (10 = PLR<20) had a higher electric consumption in comparison to

accordingly even though COP is low due to many operating hours the cumulative operating hours and cooling load because chillers

1 Sen KH Le /Enerzy on uiings 1192018)

Tables

‘Gmulative hour of Operation hile Bcc

‘Cumslave hour of Operon AEilerHecnie. Total Coting Call

hours at Consumption ensumpten Consumption | Rate

Opecation|in)_ ews hw hw

are turned on and off according tothe minimum partload ratio set-

ting, so the electric consumption atthe section of PLR at 10% which

is the set value occurs higher in comparison to the load. Also, we

can see that the operating hours, electric consumption and load

decrease significantly from the section of PLR over 50% and below

60x (50 = PLR <60), and electric consumption at the section of PLR

ver 0% and below 50x (50 = PLR <60) aecounts for 74% of annual

chillerelectric consumption. Ifthe part load ratio which chillers are

‘operated is low, COP will decrease and the electric consumption

will ncrease, and this result proves the need ofthe chiller staging

contralto operate more than 2 chillers rather than to operate only

chiller 33 Case.t

The annual total lectric consumption in Case2 was

24028,.9kWh at the section of PLR over 50x and below 60%

(50-=PLR<60) and 10,755.2kWh at the section of PLR over 80%

and below 90% (80 = PLR

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Eclips Orfice ValveДокумент4 страницыEclips Orfice Valveاحمد الجزار2007Оценок пока нет

- Highrise Smoke Removal System StandardДокумент3 страницыHighrise Smoke Removal System Standardاحمد الجزار2007Оценок пока нет

- Fixture Unit CalculatorДокумент14 страницFixture Unit Calculatorاحمد الجزار2007Оценок пока нет

- 3 Ton Workinside Container OfferДокумент3 страницы3 Ton Workinside Container Offerاحمد الجزار2007Оценок пока нет

- Pump CurvesДокумент4 страницыPump Curvesاحمد الجزار2007Оценок пока нет

- Stairwell PressurisationДокумент2 страницыStairwell PressurisationsudeeshkumarsОценок пока нет

- LPG CalДокумент1 страницаLPG Calاحمد الجزار2007Оценок пока нет

- Jet Fan ManualДокумент2 страницыJet Fan Manualاحمد الجزار2007Оценок пока нет

- Heat Treatable Steel Grades and Chemical AnalysisДокумент1 страницаHeat Treatable Steel Grades and Chemical Analysisاحمد الجزار2007Оценок пока нет

- Medical Gas SystemsДокумент81 страницаMedical Gas Systemszampacaanas100% (2)

- Bsen 737-1Документ18 страницBsen 737-1احمد الجزار2007Оценок пока нет

- BS en 737-2-1998Документ30 страницBS en 737-2-1998احمد الجزار2007Оценок пока нет

- FirePro Aerosol SystemДокумент16 страницFirePro Aerosol Systemاحمد الجزار2007Оценок пока нет

- FirePro Xtinguish V1.03Документ99 страницFirePro Xtinguish V1.03احمد الجزار2007100% (1)

- Stake EffectДокумент113 страницStake Effectاحمد الجزار2007Оценок пока нет

- CMAA 70 SpecificationДокумент18 страницCMAA 70 SpecificationPranoy Barua71% (7)

- Water Use Power GenerationДокумент66 страницWater Use Power Generationاحمد الجزار2007Оценок пока нет

- Part of Nfpa 20 Handbook 2016Документ12 страницPart of Nfpa 20 Handbook 2016احمد الجزار200750% (2)

- FirePro Aerosol SystemДокумент16 страницFirePro Aerosol Systemاحمد الجزار2007Оценок пока нет

- EXA Design Manual IndustrialДокумент70 страницEXA Design Manual Industrialاحمد الجزار2007Оценок пока нет

- CoolingTower DT GBДокумент16 страницCoolingTower DT GBاحمد الجزار2007Оценок пока нет

- BS en 14384-2005Документ27 страницBS en 14384-2005احمد الجزار2007Оценок пока нет

- Water Curtain (20.04.16)Документ3 страницыWater Curtain (20.04.16)احمد الجزار2007Оценок пока нет

- Fire Protection at High Ceiling Clearance FacilitiesДокумент13 страницFire Protection at High Ceiling Clearance Facilitiesاحمد الجزار2007Оценок пока нет

- Affect of Total DT in Chilled Water SystemДокумент8 страницAffect of Total DT in Chilled Water Systemاحمد الجزار2007Оценок пока нет

- Septic Tank - Swimmimng PoolДокумент24 страницыSeptic Tank - Swimmimng Poolاحمد الجزار2007Оценок пока нет

- Compressed Air Piping Design DataДокумент36 страницCompressed Air Piping Design Dataاحمد الجزار2007Оценок пока нет

- Affect of Total DT in Chilled Water SystemДокумент8 страницAffect of Total DT in Chilled Water Systemاحمد الجزار2007Оценок пока нет

- Chiller Plant Distribution NetworkДокумент6 страницChiller Plant Distribution Networkاحمد الجزار2007Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)