Академический Документы

Профессиональный Документы

Культура Документы

Basarkar

Загружено:

jacs127Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Basarkar

Загружено:

jacs127Авторское право:

Доступные форматы

WorkshopProgramDFI2013Conference,IITBombay

WELCOMEALL

WorkshopProgramDFI2013Conference,IITBombay

Rock Socketing using Reverse

Circulation Rig under operation at

Karwar, India

Piling with 180kN.m Torque Hydraulic

rigs

Piling with Tripod rigs at Gangtok,,

Sikkim, India

ROCKSOCKETEDPILES CURRENTINDIANPRACTICE

Dr.SunilS.Basarkar

ITDCementationIndialimited

PRESENTATIONOUTLINE

Conceptofrockanddefiningthem

Relevantquestionsonrocksocketing

Behaviour ofrocksocketedpiles

Designapproachesforrocksocketedpiles

Fieldterminationcriteriaforsocketedpiles

Rocksocketingtechniques Indiacontext

ConcludingRemarks

References

DFI2013India,IITBombay

CONCEPTOFROCK&DEFININGTHEM

DFI2013India,IITBombay

SOCKETEDPILES

SocketedPiles:

Aportionofpileshaftthatpenetratesintoarock

formationunderneaththeoverburden(IS:14593)

Thesepilesderiveresistancefromsideshearand

endbearingatthesocketportion

Thesepileshavelessdisplacementcomparedto

pilesinsandandclays

Advantages:

Usedwhennostrongbearingmaterialisavailableatshallow

depths&structuralloadisheavy

Haveveryhighcapacity especiallywhenSideshear&End

Bearingareaccountedpragmatically

Withsuitabledesign&constructionmethods,theygivevery

highUpliftcapacity

DFI2013India,IITBombay

CONCEPTOFROCKANDDEFININGROCK

RockDefinition

ToanEngineer,Rocksignifiesfirm,coherentorconsolidatedsubstances

thatcannotbenormallyexcavatedbymanualmeansalone(Jumikis,

1979)

Indesigningofsocketedpiles,engineersassumerockashomogeneous

andisotropicmedium

However,mostrocksarenotsound.Hencetheyareneither

homogeneousnorisotropic

Insitufeaturesofrockslikejointingpattern,fracturesstronglygovern

thebehaviour ofsocketedpiles,particularlyoflargediameter

DFI2013India,IITBombay

CONCEPTOFROCKANDDEFININGROCK

Tables2.ISCodeClassificationofRock

Table: Strength of Intact Rock Material (MPa) (IS: 13365 (Part 1) 1998.

-------------------------------------------------------------------------------------------------------------------------------Description

Compressive Strength

Point Load Strength

Rating

-------------------------------------------------------------------------------------------------------------------------------Exceptionally Strong

>250

>8

15

Very Strong

100-250

4-8

12

Strong

50-100

2-4

7

Average

25-50

1-2

4

Weak

10-25

Use of UCS preferred

2

Very Weak

2-10

-do1

Extremely weak

<2

-do0

-------------------------------------------------------------------------------------------------------------------------------Table: Terms for Strength of Rock Material (IS: 4464-1985)

-------------------------------------------------------------------------------------------------------------------------------Term

Compressive Strength (kg/cm2)

-------------------------------------------------------------------------------------------------------------------------------Very Weak

<12.50

Weak

12.50-50.0

Moderately weak

50 to 125

Moderately Strong

125 to 500

Strong

500 to 1000

Very Strong

1000 to 2000

Extremely Strong

>2000

--------------------------------------------------------------------------------------------------------------------------------

DFI2013India,IITBombay

CONCEPTOFROCKANDDEFININGROCK

Tables2.ISCodeGuidelinesonRock

Table: Rock Quality in Terms of Weathering Grades of Rock Mass (IS: 4464 1985)

Terms

Fresh

Slightly

Weathered

Moderately

weathered

Highly weathered

Completely

Weathered

Residual Soil

Description

No visible sign of rock material weathering; perhaps slight

Discoloration on major discontinuity surfaces

Discoloration indicates weathering of rock material and

discontinuity surfaces. Weathering may discolour all the rock

material

Less than half of the rock material is decomposed or

disintegrated to a soil. Fresh or discoloured rock is present

either as a continuous framework or as core stones.

More than half of the rock material is decomposed or

disintegrated to a soil. Fresh or discoloured rock is present

either as a discontinuous framework or as core stones.

All rock material is decomposed and/or disintegrated to soil.

The original mass structure is still largely intact.

All rock material is converted to soil. The mass structure and

material Fabric is destroyed. There is a large change in

volume, but the soil has not been significantly transported.

Grade

I

Interpretation

CR: >60%

II

CR: 40 60%

III

CR: 25 40%

IV

CR: 11 25%

CR: 0 10%

VI

CR=0; but N>50

DFI2013India,IITBombay

CONCEPTOFROCKANDDEFININGROCK

Tables2.ISCodeGuidelinesonRock

Rock Quality Designation (RQD) of Rock (IS: 13365 (Part 1) 1998.

Rock Quality Designation

( RQD )

Diagnostic Description of

Rock

Exceeding 90%

Excellent

90 % - 75 %

Good

75 % - 50 %

Fair

50 % - 25 %

Poor

Less Than 25 %

Very Poor

Rock Quality Designation : Sum of Length of Core Pieces greater than 100mm /

Length of Run

Table: Net Safe Bearing Pressure Based on RMR

-------------------------------------------------------------------------------------------------------------------------------Classification No.

I

II

III

IV

V

-------------------------------------------------------------------------------------------------------------------------------Description of Rock

Very Good

Good

Fair

Poor

Very Poor

RMR

100-81

80-61

60-41

40-21

20-0

qns (t/m2)

600-448

440-288

280-151

145-90-58

55-45-40

--------------------------------------------------------------------------------------------------------------------------------

DFI2013India,IITBombay

10

CONCEPTOFROCKANDDEFININGROCK

Upto Nvalueof60,StratamaybedefinedasSoil.Beyond

60orRefusal,StratamaybeconsideredasWeatheredor

Weakrock.

MEDIUM

WEAK

VERY WEAK

WEAK

1.4

VERYWEAK

0.5

1.0

WEAK

2.0

MOD WEAK

MODSTRONG

STRONG

10

40

4

MODWEAK

MODSTRONG

5.0

10

20

STRONG

VERY

STRONG

Kulhawy (1991)

EXTREAMLY

STRONG

Cole&Stroud

(1977)

STRONG

50

100

ProposedRevision

ToBS5930

200

500

UCS(MPa)

ClassificationofRockMaterialStrength (Kulhawy &Phoon,1993;Cole&Stroud,

1977)

DFI2013India,IITBombay

11

CONCEPTOFROCKANDDEFININGROCK

Shear

Strength

2

KN/m

40000

Approx.

N Value

Strength/

Consistency

*

Strong

Grade

Breakability

Difficult to break

against solid object

with hammer

Penetration

Cannot be

scratched with

knife

Scratch

Moderately

strong

Broken against

Solid object with

hammer

Can just be

scratched with

knife

Broken in hand by

hitting with hammer

Scratched with

knife. Can just be

scratched with

thumb-nail

Broken by leaning

on sample with

hammer

No penetration with

knife

Broken by hand

Penetration to abt.

2mm with knife

Easily broken by

hand

Penetration to abt.

5mm with knife

20000

Cole&StroudChart

600

10000

8000

6000

400

Manyconsultantsfeelthat

GradeC,D,EandFmaterial

cannotbeconsideredas

socket

4000

Moderately

weak

2000

200

Scratched with

thumb-nail

Weak

1000

800

100

600

80

Hard or

very weak

400

GradeCandabovewould

giveaveryhighendbearing

60

Very stiff

40

Penetrated by thumbnail to about 15mm

with knife

200

Stiff

Indented by thumb

Firm

Penetrated by thumb

with effort

soft

Easily penetrated

by thumb

100

20

80

IS:2911(Part1/Sec.2)2010

usesCole&StroudChartfor

Piledesign

60

10

40

8

6

20

4

10

2

N.B.

Very soft

* Geol. Soc. Working Party Report (1970) and CP 2004 (1972) except that the designation 'hard' for

soil materials has been given a separate identity which is analogous to very weak for materials

classifiable as rock.

Grades and shear strengths for rocks refer to intact specimen. The N value, however, is an in-situ

test and includes some effect of discontinuities. For cohesive soils the correlation between N

values and in-situ strength assumed is that given by Stroud (1974) for clays of low plasticity.

Fig. 2.4. Scale of Strengths and N Values for Weak Rocks and Soils

(Cole and Stroud, 1977).

DFI2013India,IITBombay

12

RELEVANTQUESTIONSONROCKSOCKETING

DFI2013India,IITBombay

13

RELEVANTQUESTIONSONROCKSOCKETING

HowdoyoudifferentiateWeatheredrock,WeakandHardrock?

Howmuchsocketingisrequired?

Whataretherockparametersthataffectthecapacityofrocksocketed

piles?

Isroughnessfactorofsocket,andmethodofrockdrillingquantifiedduring

capacityanalysis?

Howtoaddressfieldterminationforsocketedpiles?

IstherecommongroundofunderstandinginIndiabetweentheContractors,

DesignersandtheClientsonthematterofsocketingrequirements?

AreLoadtestsonrocksocketsreallyusedforsocketdepthoptimization?

Arethepaymentsforpileboringinvariousrockcategoriesstandardized?

WhatisaLargeDiameterandaSmallDiameterPile?

DFI2013India,IITBombay

14

BEHAVIOUROFROCKSOCKETEDPILES

DFI2013India,IITBombay

15

BEHAVIOUROFROCKSOCKETEDPILES

Linear/ElasticPhase:

Shearstrainsareelastic.

Majorloadsarecarriedinsidewallshear.

Pileexhibitselasticbehaviour underthisstage.

NonLinearPhase:

Slipstartsattherockconcreteinterface.

Increasingportionofloadtransferredtothepile

base.

Rockconcretebondisbroken,andconstant

frictionalresistanceisdeveloped.

Thestructuralpileexhibitselasticbehaviour even

underthisphaseunderhighpileloaden

DFI2013India,IITBombay

16

BEHAVIOUROFROCKSOCKETEDPILES

Fullsideshearmobilizedat

relativelysmallpile

movements

Load

Qu

Largemovementsrequired

tomobilizeBaseResistance

QB

QS

Pilemovement

Behaviour ofSocketedPiles

DFI2013India,IITBombay

17

BEHAVIOUROFROCKSOCKETEDPILES

FactorsAffectingLoadCapacityofSocketedPile:

Socketgeometry.

Modulusofrockatthesideandthepilebase.

Strengthofrockatthesideandthepilebase.

Socketwallcondition&roughness.

Conditionatbottomofsocket.

Layeringofrock,presenceofclayseams.

Creeps.

DFI2013India,IITBombay

18

DESIGNAPPROACHESFORROCKSOCKETEDPILES

DFI2013India,IITBombay

19

ROCKSOCKETEDPILES:DESIGNAPPROACHESININDIA

ElasticMethod

UsingRockStrengthofsocketmaterial

UsingprovisionsofIS:145931998

UsingIRC782000,Amendment54,dated28th May2009.

UsingIS:2911(Part1/Section2)2010

DFI2013India,IITBombay

20

ROCKSOCKETEDPILES:DESIGNAPPROACHES

ElasticAnalysis

ChartsbasedonoriginalFE

analysisofMattes&Poulos

(1969)

ExtendedbyPells &Turner

(1979)toaccommodate

practicalrangeofmodulus

ratioKandL/Dratioof

socket

PresentschartsforElastic

Settlements,andLoad

distributionalongpile.

Settlement of rock-sockets

with clean base

(Pells & Turner, 1979)

Load distribution in a socket

with a clean base

(Pells & Turner, 1979)

DFI2013India,IITBombay

10

21

ROCKSOCKETEDPILES:DESIGNAPPROACHES

ElasticAnalysis(Example,continued)

ElasticAnalysis(Example)

For12mmdisplacement,w,Load,Q=

Forpiledia.D=1m;Socketdepth,L=2.0m

L/D=2

w.Er.D/(2.Ip)=28845300N

Pileconcretegrade:M30

or2884.5MT

Avg.UCSofsocketmaterial,r:20MPa

Ep=5000.Sqrt(30) =27386.1MPa

Er=215.Sqrt(r) =961.51MPa

Ep/Er =28.48

ForL/D=2,&Ep/Er =28.48,

InfluencefactorfromChart,Ip=0.2

Safeload,2884.5/1.5=1923.00MT

Notes:1.Elasticsolutionstobeusedonlyas

guideline

2.AFactorofsafetyof3tobefurtherused

foraccountingnonlinearity,heterogeneity,

andvariationinworkmanship

DFI2013India,IITBombay

22

ROCKSOCKETEDPILES:DESIGNAPPROACHES

UsingRockStrengthofsocket

UCSofsocketmaterialisusedasabasis

CoreRecovery&RQDofrockmassmaybeusedtoarriveatfield

UCS

Sideshearandbaseresistanceofsocketempiricallyrelatedto

theUCSvalue

Example,

Max.Sideshear,fmax=0.4(c)0.5

Max.Baseresistance,qmax =3.0(c)0.5

(Zhang&Einstein,1999)

(Zhang&Einstein,1999)

Afactorofsafetyof3maybeusedforsafesideshearand2.5for

safebaseresistance

Exercisecaution,whilearrivingatsafecapacity.Capacitytobe

confirmedbyfieldloadtests

DFI2013India,IITBombay

11

23

ROCKSOCKETEDPILES:DESIGNAPPROACHES

IS:14593 1998

Thecodeattemptstogiveguidelineforsocketedpileofdiameter 1500mm

SuggestedMinimumSocketlengthaspertable:

SuggestedMinimumSocketLength

RockType

ls

Soundrelativelyhomogeneousrock

includinggranite,gneiss

1to2D

Moderatelyweathered,closelyjointed

includingschist,slate

2to3D

Softrocks,sedimentaryrocksincluding

hardshale,sandstones,siltstone,

mudstone

3to 4D

NOTEDisthediameterofpile.

DFI2013India,IITBombay

24

ROCKSOCKETEDPILES:DESIGNAPPROACHES

IS:14593 1998

BetteroptionfordesignisusingUCSvalues

SafePileLoad

Where,

qc

Nd

Ap

D

Is

Nj

=

=

=

=

=

=

=

=

=

safeloadcapacityofpile,inMT;

uniaxialcompressivestrengthofrock,T/ ;

depthfactor=O.8O.2ls/D,l 2;

areaofpiletoe,

/4;

diameterofpile,inm;

socketlengthintotherock,inm;

rocksocketslideresistancereductionfactor(Fig.1);

rocksocketcorrectionfactor(Fig.2);and

valuesasperFig.2ofIS12070areapplicable,

DFI2013India,IITBombay

12

25

ROCKSOCKETEDPILES:DESIGNAPPROACHES

IS:14593 1998

DFI2013India,IITBombay

26

ROCKSOCKETEDPILES:DESIGNAPPROACHES

UsingIRC782000(latestamendment)

SpecifiestwomethodsforsocketedpilesandstatedinAppendix5ofIRC78(Clause

709.3.1)

AppliedwhencoresofrockcanbetakenandUCSestablishedbylaboratorytests

Where,

Qall

Re

Raf

Ksp

=

=

=

=

=

Ultimatesocketedpilecapacityinrock;

Allowablepilecapacity;

Ultimatebaseresistance;

Ultimatesideshear;

Empiricalcorrectionaspertablebelow;

Ksp maybelinearlyinterpolated

(CR+RQD)/2

Ksp

30%

0.3

100%

1.2

DFI2013India,IITBombay

13

27

ROCKSOCKETEDPILES:DESIGNAPPROACHES

UsingIRC782000(latestamendment)

CR

CoreRecovery(%)

RQD

Rockqualitydesignation(%)

qc

AverageUCSofrockcorebelowpile

df

Depthfactor=(1+0.4lsoc/D) 1.2

As

Socketedsurfacearea

Cus

Ultimateshearstrengthofsocketmaterialalongsocketlength

0.225

3.0MPa forM35pileconcrete

(3.0x

)forothergradepileconcrete

DFI2013India,IITBombay

28

ROCKSOCKETEDPILES:DESIGNAPPROACHES

UsingIRC782000(latestamendment) METHOD2

ApplicablewherestrataishighlyfragmentedwithverylowRQD&CRvalue,or

whereUCS<10MPa

UsesextrapolatedSPTvaluesasperTable

ShearStrength

ModeratelyWeak

Weak

VeryWeak

ApproximateNValue

300 200

200 100

100 60

Cohesion(MPa)

3.3 1.9

1.9 0.7

0.7 0.4

Where,

Nc

=

=

=

Averageultimateshearstrengthbelowpilebase

Ultimateshearstrengthalongsocket

9

DFI2013India,IITBombay

14

29

ROCKSOCKETEDPILES:DESIGNAPPROACHES

IS:2911(Part1/Section2)2010

AppendixB7&B8addressedtopilesinRock

B8Addressestosocketedpiledesigninweathered/SoftRock

UsesColeandStroud(1977)Chart

DecipheringproperNvalueofrockiskeyfactor

/

/F

Where,

F=3,

=0.9(Recommended)

ForN 60,stratumistreatedasweatheredrockratherthansoil

DFI2013India,IITBombay

30

FIELDTERMINATIONCRITERIAFORSOCKETEDPILES

DFI2013India,IITBombay

15

31

FIELDTERMNATIONCRITERIAFORSOCKETEDPILES

Appliedfortwocases:

PilingbyPercussionmethod(Chiseling)

PilingbyHydraulicrigswithTorquemeasurement

CHISELENERGYCRITERIA

E=(W.H.n)/A.d

E=ChiselenergyinT.m/m2/cmpenetration

W=ChiselweightinT

H=DropofChiselinm

n=Reductionfactorusuallyrangingfrom0.6to0.8.

A=CSAreaofpile(m2)

d=Averagechiselpenetrationperblow(Takenas

averageofnumberofblowsoveraperiodof

30minutes).

DFI2013India,IITBombay

32

FIELDTERMNATIONCRITERIAFORSOCKETEDPILES

GUIDELINESOFENERGYCRITERIA

Energyvalue,Eof40.0T.m/m2/cmcorrespondstostratumhaving

SPT=50.

ForarockrequiringaboutE=225T.m/m2/cm,

Datye (1990)suggestsrockpilefrictionof15T/m2 andEndBearing

Resistanceof450T/m2

FoundationstratumisassumedtostartwhenEnergy,Eof75

T.m/m2/cmpenetration

DFI2013India,IITBombay

16

33

FIELDTERMNATIONCRITERIAFORSOCKETEDPILES

TERMINATIONCRITERIAFORHYDRAULICRIGS

ConceptofPilePenetrationRatio(PPR),inT.m/m2/cmpenetrationis

used

PilePenetrationRatio(PPR)forRotarypiles=2NT.t

AP

t=timeinminutes

A=C.S.areaofpileinm2

P=penetrationincm

N=RPMofhydraulicmotor

T=TorqueinTm

Tcanbeknownfrom,equation

HPofhydraulicmotor,HP=2NT

4.5

HPistakenas30to40%ofratedHPoftherig.(forT=180kN.m,HP=

325)

DFI2013India,IITBombay

34

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

DFI2013India,IITBombay

17

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

35

A Heavy Duty Rig with Rock Auger,

Akola, near Mumbai, India

Piling through sandy overburden at

Noida, with 180kN.m torque rigs

DFI2013India,IITBombay

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

Boring & Socketing under constraints

Lo-drill rig in operation at Gangtok,

Sikkim, India

36

Boring through overburden soil at Noida,

near Delhi, India

DFI2013India,IITBombay

18

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

37

Piling works with Tripod rigs using

Chiseling method at Gangtok, Sikkim

DFI2013India,IITBombay

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

38

Rock Auger : Ready for use at Akola,

Central India

Rock Bucket: ready for use at Akola,

Central India

DFI2013India,IITBombay

19

ROCKSOCKETINGTECHNIQUES INDIANCONTEXT

Rock Auger

39

Cleaning Bucket

DFI2013India,IITBombay

40

CONCLUDINGREMARKS

DFI2013India,IITBombay

20

41

CONCLUDINGREMARKS

Rockasamaterialisadebatedareaandfrictioniscommonin

Contracts

DesignapproachesinIndiaareconservative,andthereisarare

agreementonthesocketingrequirements

Designapproachesforrocksocketedpilesareyettogainconfidence

duetovariability

ModernRigsandtoolsforsocketinghavebeenintroducedinIndia,but

stilltoestablishitsfootholdintermsofcostrecovery

TerminationcriteriawithPercussionmethodsarewellestablished

Terminationcriteriaforhydraulicrotaryrigsisyettogainwide

acceptance,andisstillamatterofresearch

DFI2013India,IITBombay

42

REFERENCES

DFI2013India,IITBombay

21

REFERENCES

43

Basarkar,S.S.(2004).AnalyticalandExperimentalStudiesonRockSocketedPilesin

MumbaiRegion,IITBombay,2004.

Datye,K.R.(1990).BoredpilinginBombayregion.Proc.IndianGeotechnical

Conference(IGC)1990,Bombay,571588.

Deere,D.U.,andMiller,R.P.(1966).EngineeringClassificationandIndexPropertiesof

IntactRock.TechnicalReportNo.AFWLTR65116,AirForceWeaponsLaboratory,

KirtlandAirForceBase,NewMexico.

IRC:782000. StandardSpecificationsandCodeofPracticeforRoadBridges.SectionVII

Foundations&Substructures(2ndRevision),Amendmentno.54,dated28/5/2009.

IS:2911(Part1/Section2). Design&ConstructionofPileFoundations CodeofPractice

Part1ConcretePiles,Section2,BoredCastInsituConcretePiles.

IS4464:1985(Revised2004). CodeOfPracticeForPresentationOfDrillingInformation

andCoreDescriptionInFoundationInvestigation.

IS133651(1998). Quantitativeclassificationsystemofrockmass Guidelines,Part1:

RMRforpredictingofengineeringproperties

IS:14593:1998. Design&ConstructionofBoredCastinSituPilesFoundedonRocks

Guidelines.

DFI2013India,IITBombay

REFERENCES

44

Jumikis,A.(1979).RockMechanics.TransTechPublications.

Kulhawy,F.H.(1978).Geomechanical modelforrockfoundationsettlement.Jr.of

Geotech.Engnr.Div.,Proc.ASCE,Vol.104(GT2),211227.

Mattes,N.S.andPoulos,H.G.(1969).Settlementofsinglecompressiblepile.Jr.ofSoil

Mech.andFound.Div.,ASCE,95(1),189207.

analysis

Pells,P.J.N.andTurner,R.M.(1979).Elasticsolutionsforthedesignand

ofrocksocketedpiles.Can.Geotech.Jr.,16,481487.

Rowe,R.K.andArmitage,H.H.(1987).Adesignmethodfordrilledpiersinsoftrock.

Can.Geotech.Jr.,24,126142.

Zhang,L.andEinstein,H.H.(1998).Endbearingcapacityofdrilledshaftsin rock.Jr.

ofGeotech.andGeoenvr.Engnr.,ASCE,Vol.124(7),574584.

DFI2013India,IITBombay

22

45

THANKYOU

23

Вам также может понравиться

- O CellsДокумент7 страницO Cellsjacs127Оценок пока нет

- Abrahamson and SilvaДокумент31 страницаAbrahamson and Silvajacs127Оценок пока нет

- 14) Webinar Content - Stone Columns For Improving Weak GroundsДокумент110 страниц14) Webinar Content - Stone Columns For Improving Weak GroundsEswara PrasadОценок пока нет

- 03 McVay FinalДокумент47 страниц03 McVay Finaljacs127Оценок пока нет

- O-Cells in QatarДокумент4 страницыO-Cells in Qatarjacs127Оценок пока нет

- Ocell Test in IndaiДокумент3 страницыOcell Test in IndaiSushanta TakhellambamОценок пока нет

- RIM-cell Testing in Australia (Perth)Документ2 страницыRIM-cell Testing in Australia (Perth)jacs127Оценок пока нет

- Hussien 2016Документ54 страницыHussien 2016jacs127Оценок пока нет

- E 146Документ7 страницE 146jacs127Оценок пока нет

- Https WWW - Irctc.co - in Eticketing PrintsdfTicketДокумент2 страницыHttps WWW - Irctc.co - in Eticketing PrintsdfTicketJayamkondanОценок пока нет

- Challenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban EnvironmentsДокумент17 страницChallenges to Quality Control in Bored Cast-In-Situ Piling in Growing Urban Environmentsjacs127Оценок пока нет

- AICTE Tentetive 2017-18Документ9 страницAICTE Tentetive 2017-18jacs127Оценок пока нет

- A Unified Procedure For Earth Pressure CalculationsДокумент5 страницA Unified Procedure For Earth Pressure Calculationsjacs127Оценок пока нет

- Anderson 2001Документ6 страницAnderson 2001jacs127Оценок пока нет

- ISGTI BrochureДокумент2 страницыISGTI Brochurejacs127Оценок пока нет

- Industry Academia Brochure 18-11-2017Документ2 страницыIndustry Academia Brochure 18-11-2017jacs127Оценок пока нет

- Code of Practice For Oil Storage Installations 1992Документ22 страницыCode of Practice For Oil Storage Installations 1992Hassan SleemОценок пока нет

- Mesotech MS1000 PDFДокумент2 страницыMesotech MS1000 PDFArnoldo López MéndezОценок пока нет

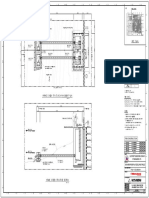

- Haripur River Water Intake GA, SectionДокумент1 страницаHaripur River Water Intake GA, Sectionjacs127Оценок пока нет

- Indigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQДокумент4 страницыIndigo TKT of MR Jaykumar Shukla 18 Oct Ccu Del BDQjacs127Оценок пока нет

- Shaking Table Tests and Stability Analysis of Steep Nailed SlopesДокумент16 страницShaking Table Tests and Stability Analysis of Steep Nailed Slopesjacs127Оценок пока нет

- Code of Practice For Oil Storage Installations 1992Документ22 страницыCode of Practice For Oil Storage Installations 1992Hassan SleemОценок пока нет

- Brown 1969Документ6 страницBrown 1969jacs127Оценок пока нет

- BRC Ju Jcs Bhavin 22102017Документ2 страницыBRC Ju Jcs Bhavin 22102017jacs127Оценок пока нет

- Mou With DD Ws DR Do Bio DigesterДокумент15 страницMou With DD Ws DR Do Bio Digesterjacs127Оценок пока нет

- Chapter 2Документ42 страницыChapter 2Manoj SinghОценок пока нет

- Vopak BHДокумент1 страницаVopak BHjacs127Оценок пока нет

- Co-Ordinates in UTM and Degree MinuteДокумент2 страницыCo-Ordinates in UTM and Degree Minutejacs127Оценок пока нет

- Stability of Steel Oil Storage Tanks Duncan OrazioДокумент20 страницStability of Steel Oil Storage Tanks Duncan Oraziojacs127Оценок пока нет

- Bio DigesterBrochureДокумент2 страницыBio DigesterBrochurejacs127Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Module 1 - Basics of Soil Mechanics Finished (Compatibility Mode)Документ145 страницModule 1 - Basics of Soil Mechanics Finished (Compatibility Mode)Sahil Jawa100% (1)

- Geology Report 1Документ166 страницGeology Report 1Camille T. PajarillagaОценок пока нет

- Geography Pamphlet Grade 10-12Документ82 страницыGeography Pamphlet Grade 10-12Kingdavid Waitolo91% (11)

- MST Lesson 6 - Soil and Land ResourcesДокумент39 страницMST Lesson 6 - Soil and Land ResourcesPolОценок пока нет

- EOSC 310 NotesДокумент42 страницыEOSC 310 NotesDanОценок пока нет

- O Level GeographyДокумент32 страницыO Level GeographyMemuna Ilahi29% (7)

- AG20103 Soil Technology Class OverviewДокумент34 страницыAG20103 Soil Technology Class OverviewMayank PriayadarshiОценок пока нет

- Science7 Q4 M2 V4-For-LearnersДокумент41 страницаScience7 Q4 M2 V4-For-LearnersJoan Maris LaurenteОценок пока нет

- Introduction to Construction Materials and TestingДокумент5 страницIntroduction to Construction Materials and TestingSophia deniseОценок пока нет

- Terminology of Soil Fertility, Fertilizer and Organics (PDFDrive)Документ116 страницTerminology of Soil Fertility, Fertilizer and Organics (PDFDrive)Heera KardongОценок пока нет

- CVE - 131 - 1 - Lecture 1Документ24 страницыCVE - 131 - 1 - Lecture 1ZxeroОценок пока нет

- Small Crack Under Cyclic and Static LoadingДокумент8 страницSmall Crack Under Cyclic and Static LoadingNebiyu Samuel NebaОценок пока нет

- Soil & AgricultureДокумент18 страницSoil & AgricultureMurtuza JafriОценок пока нет

- Southern de Oro Philippines College: Fourth Periodical Test in Science and Health 5Документ11 страницSouthern de Oro Philippines College: Fourth Periodical Test in Science and Health 5Maria sheila BalistaОценок пока нет

- Appropriate terminology for karst-like landformsДокумент5 страницAppropriate terminology for karst-like landformsCaegeoОценок пока нет

- Geology Notes 2Документ6 страницGeology Notes 2Lily QuiОценок пока нет

- Tech UdlДокумент34 страницыTech Udlapi-264885171Оценок пока нет

- Questionaire 2Документ9 страницQuestionaire 2Dain AliceОценок пока нет

- Impact Strength Vs Fracture ToughnessДокумент2 страницыImpact Strength Vs Fracture ToughnessEdwardОценок пока нет

- CE 331 Introductiom To Geotechnical Engineering - 2Документ64 страницыCE 331 Introductiom To Geotechnical Engineering - 2HAB FFSОценок пока нет

- Unit 3 Earth Surface Processes: StructureДокумент10 страницUnit 3 Earth Surface Processes: StructureSree Mallikarjuna Sevaa SadanОценок пока нет

- 3.0 Types and Causes of Deterioration in ConcreteДокумент3 страницы3.0 Types and Causes of Deterioration in ConcreteMuhammad Muhsin JamaluddinОценок пока нет

- Abalo - Notes in Science (1st Sem)Документ19 страницAbalo - Notes in Science (1st Sem)Rachel Hanh AbaloОценок пока нет

- Earth and Life Science 4th WeekДокумент11 страницEarth and Life Science 4th WeekElleKaye Mercado100% (1)

- Rock mass characterization system overviewДокумент40 страницRock mass characterization system overviewhessian123100% (2)

- Module #25 NotesДокумент38 страницModule #25 NoteskimjimОценок пока нет

- Variability in Weathering: ClimateДокумент5 страницVariability in Weathering: ClimateRoxann BardagoОценок пока нет

- 483 - Sos 211 Lecture NoteДокумент64 страницы483 - Sos 211 Lecture NoteFarai Faustos100% (1)

- Maths Interview ListeningДокумент12 страницMaths Interview ListeningNga Nguyen VuОценок пока нет

- Text Book of Soil Science R.K. MehraДокумент504 страницыText Book of Soil Science R.K. MehraPraveen Kumar100% (6)