Академический Документы

Профессиональный Документы

Культура Документы

ASME IX Interpretation-Part9

Загружено:

kevin herryАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ASME IX Interpretation-Part9

Загружено:

kevin herryАвторское право:

Доступные форматы

1/36

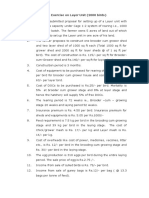

GO TO ASME.ORG HOME >

Interpretation Detail Print to PDF

Please limit your selection on the search results screen to 10 interpretations.

Standard Designation:

BPV Section IX

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Section IX, QW-407.4, Postweld Heat Treatment

Record Number:

BC91-614

Date Issued:

Interpretation Number :

02/28/1992

IX-92-33

Question(s) and Reply(ies): Question: Can a PQR conducted on a 2 in. thick base metal with notch

toughness required and PWHT above the upper transformation temperature

be used to support a WPS on a in. thick base metal with all other essential

variables, including notch toughness, unchanged?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-200.2(b) and QW-300.2; Manufacturer's and Contractor's

Responsibility

12/20/1991

BC91-415

IX-92-25

Question(s) and Reply(ies): Question (1): According to QW-200.2(b), may a manufacturer or contractor

provide guidelines for a procedure qualification, and a WPS, and a welder

to a test lab, then audit on random basis and certify the procedure?

Reply (1): No.

Question (2): According to QW-300.2, may a manufacturer or contractor

provide acceptance and rejection criteria, a WPS, and a welder performance

for a qualification test to a test lab then audit on a random basis and accept

responsibility for the performance qualification test?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-306; Combination of Welding Process

Record Number:

BC91-470

Date Issued:

Interpretation Number :

12/20/1991

IX-92-26

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

2/36

Question(s) and Reply(ies): Question: When a welder has been qualified using a single welding process

and later takes a test using a combination of welding processes, which

includes the previously qualified process, and does not pass, does this affect

the earlier qualification?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section II, Part C, SA 5.4 - Table 4

Record Number:

BC91-471

Date Issued:

Interpretation Number :

12/20/1991

IX-92-27

Question(s) and Reply(ies): Question: Should the footnotes a, b, and c of Table 4 read as follows: a) See

Section 10 and 14.2 b) See Section 11.1 and 14.3 c) See Section 11.2 and

Figs. I and 3?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-281.2(f); Corrosion-Resistant Weld Metal Overlay Essential Variables

12/20/1991

BC91-472

IX-92-28

Question(s) and Reply(ies): Question: May a corrosion-resistant weld metal overlay procedure

qualification test joint 2 in. in thickness that was postweld heat treated

(PWHT) for 2 hr (1 hr per in.) qualify a PWHT of a 5 in. thick material for

5 hr (1 hr per in.)?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-151.3 and QW-462.1, Tension Tests and Test Specimens

Record Number:

BC91-473

Date Issued:

Interpretation Number :

02/28/1992

IX-92-29

Question(s) and Reply(ies): Question (1): For plate coupon, welded by one process and procedure, may

either reduced-section specimens conforming to the requirements given in

QW-462.1(a) or turned specimens conforming to the requirements given in

QW-462.1(d) be used for tension test specimens?

Reply (1): Yes.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

3/36

Question (2): For a 2 in. plate test coupon welded with one process and

procedure, may two turned 0.505 tensile specimens conforming to QW462.1(d) be used for each tension test?

Reply (2): Yes.

Question (3): In performing tension tests on a 2 in. test coupon welded with

one process and procedure using turned specimens conforming to QW462.1(d) and spaced in accordance with QW-151.3(b), is it acceptable if

portions of weld deposit are not included in the tension tests?

Reply (3): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200.1, General Welding Procedure Qualifications

Record Number:

BC91-587

Date Issued:

Interpretation Number :

02/28/1992

IX-92-30

Question(s) and Reply(ies): Question: Does QW-200.1(c) require that there be a history of changes such

as margin notes or other record documenting what specific changes were

made in the essential, nonessential, or supplemental variables each time a

WPS is revised?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-310, Qualification of Test Coupons

Record Number:

BC91-613

Date Issued:

Interpretation Number :

02/28/1992

IX-92-31

Question(s) and Reply(ies): Question: May a welder repair the root pass from the root side of a Welder

Performance test coupon and be qualified to weld without backing?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-351, General Welding Variables for Welders

Record Number:

BC91-631

Date Issued:

Interpretation Number :

Question(s) and Reply(ies):

02/28/1992

IX-92-32

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

4/36

Question: When using a single test coupon for welder performance

qualifications, is it necessary to determine the deposited weld metal

thickness for each process the welder uses to weld the single test coupon?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-451, Groove-Weld Procedure Qualification Thickness

Limits and Test Specimens

02/28/1992

BC91-586

IX-92-34

Question(s) and Reply(ies): Question (1): Tables QW-451.1 and QW-451.2 state limits for base metal

and deposited weld metal thickness. Where QW-250 lists variables

applicable to thickness, do these variables supersede the limits of QW-451.1

and QW-451.2?

Reply (1): Yes.

Question (2): Tables QW-451.1 .and QW-451.2 do not give a minimum

deposited weld metal thickness. When the variable QW-403.6 states a

minimum base metal thickness, does this minimum also apply to deposited

weld metal?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-452.1, Transverse Bend Test for Performance Qualification

Thickness Limits and Test Specimens

02/28/1992

BC91-277

IX-92-35

Question(s) and Reply(ies): Question: Even though QW-484 does not provide space for documenting

conformance of the test coupon groove with the requirements of QW-452.1,

Notes 8 or 9, does a signed Record of Welder/Welding Operator

Performance Qualification form indicate that these requirements have been

met?

Reply: Yes.

Note: However, at the present moment, QW-484 is under consideration for

possible revision.

Standard Designation:

Edition/Addenda:

BPV Section IX

Para./Fig./Table No:

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

5/36

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

Section IX, QW-452.1, Transverse Bend Test for Performance Qualification

Thickness Limits and Test Specimens

02/28/1992

BC91-616

IX-92-36

Question(s) and Reply(ies): Interpretation IX-83-90 states:

"Question (1): Can a double-beveled plate, 1 in. thick with each beveled

groove being in., be welded by a welder qualified to weld a weld metal

deposit of 0.864 in.?

Reply (1): No.

Question (2): Can the same joint as above be welded by two individual

welders, each with a deposited weld metal qualification of 0.864 in.,

provided each welder does not exceed 0.864 in.?

Reply (2): Yes."

Question: Can a double-beveled plate, 1 in. thick with each beveled

groove being in., be welded by two individual welders, one on each side

of the plate and each with a deposited weld metal qualification of 0.864 in.,

provided each welder does not exceed 0.864 in.?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-151 and QW-451, Tension Test Specimens and GrooveWeld Procedure Qualification Thickness Limits and Test Specimens

02/28/1992

BC92-097

IX-92-37

Question(s) and Reply(ies): Question (1): Do paragraphs QW-151.1, QW-151.2, QW-151.3, and QW151.4 define the number of tension test specimens required for each tension

test as specified in QW-451.1 and QW-451.2?

Reply (1): Yes.

Question (2): Do Tables QW-451.1 and QW-451.2 specify the minimum

required number of tension and guided bend tests needed for various groove

welded coupons, regardless of diameter when pipe or tube is used?

Reply (2): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

BPV Section IX

Section IX, QW-200, General Welding Procedure Qualifications

05/28/1992

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

6/36

Record Number:

Interpretation Number :

BC91-630

IX-92-38

Question(s) and Reply(ies): Background: A welder was monitored while performing production welding

and was found to be welding above the amperage range listed on the WPS

for a specific electrode diameter (SMAW process).

Question: Does Section IX require the WPS to be amended or requalified,

as applicable, when a variable is not followed such as welding above or

below the established amperage or voltage range listed on the WPS?

Reply: The disposition of nonconformances is not within the scope of

Section IX.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-300.3, Simultaneous Qualification of Welders

Record Number:

BC92-121

Date Issued:

Interpretation Number :

05/28/1992

IX-92-39

Question(s) and Reply(ies): Background: Three contractors desire to use the same WPS and

simultaneously qualify welders in accordance with QW-300. Each

contractor has a pre-existing PQR covering the scope of the WPS. Each

contractor's name and corresponding PQR number is entered on the WPS

and separate signature blocks are provided for each contractor. This method

of weld procedure and welder performance qualification and operational

controls is described in the QC system for each contractor.

Question (1): May the WPS described be used to simultaneously qualify

welders?

Reply (1): Yes.

Question (2): May the WPS described be used for production welding by all

three contractors?

Reply (2): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-409.1, Electrical Characteristics

Record Number:

BC92-110

Date Issued:

Interpretation Number :

05/28/1992

IX-92-40

Question(s) and Reply(ies): Question (1): When notch toughness tests are a requirement, and option

QW-409.1(a) is chosen as a means of determining heat input, must the

actual voltage, amperage, and travel speed used be recorded on the PQR?

Reply (1): Yes.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

7/36

Question (2): When notch toughness tests are a requirement, and option

QW-409.1(b), bead size, is chosen as a means of determining heat input,

must the actual bead width and height deposited to ascertain "Volume of

Weld Metal" deposited be recorded on the PQR?

Reply (2): Yes.

Question (3): May either of the above methods be substituted for the other,

when writing a WPS that has notch toughness requirements, by estimating

the values of the "other" method [i.e., using option (a) (with estimated

amps, volts, and travel speed) when option (b) (actual Volume of Weld

Metal) was used when the test coupon was welded]?

Reply (3): No.

Question (4): When notch toughness tests are a requirement, and option

QW-409.1(b), bead size, is chosen as a means of determining heat input,

can any electrode diameter be used as long as the volume of deposited weld

metal, which is recorded on the PQR, is not exceeded?

Reply (4): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-461.9, Performance Qualifications - Position and Diameter

Limitations

05/28/1992

BC92-035

IX-92-41

Question(s) and Reply(ies): Question: Are welders qualified on plate in 2G, 3G, and 4G positions

qualified to weld on pipe less than 24 in. OD in the 5G position?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200.4(a), Combination of Welding Processes

Record Number:

BC92-011

Date Issued:

Interpretation Number :

09/30/1992

IX-92-42

Question(s) and Reply(ies): Question: May a single set of weld metal impact test specimens be used to

qualify two or more processes or procedures?

Reply: Yes, provided weld metal from each process or procedure is

included in each specimen.

Standard Designation:

Edition/Addenda:

BPV Section IX

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

8/36

Para./Fig./Table No:

Subject Description:

Section IX, QW-492, Definition of Machine Welding

Record Number:

BC92-100

Date Issued:

Interpretation Number :

09/30/1992

IX-92-43

Question(s) and Reply(ies): Question: Is a GMAW spot welding process in which all variables are

preset, except for placement of the nozzle against the material and

activation of the trigger by the operator, considered machine welding?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-251.4 and QW-280, Special Processes

Record Number:

BC92-168

Date Issued:

Interpretation Number :

09/30/1992

IX-92-44

Question(s) and Reply(ies): Question (1): According to the 1990 Addenda of Section IX, are there any

supplementary essential or nonessential variables required to be addressed

in a WPS for the special processes described in QW-280?

Reply (1): No.

Question (2): According to the 1991 Addenda of Section IX, are there any

supplementary essential or nonessential variables required to be addressed

in a WPS for the special processes described in QW-251.4?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-303.2 and QW-452.4, Fillet Welds

Record Number:

BC92-238

Date Issued:

Interpretation Number :

09/30/1992

IX-92-45

Question(s) and Reply(ies): Question: When Section IX requires separate performance qualification for

fillet welds on small diameter pipe, does the same requirement apply to

longitudinal fillet welds (such as the attachment of gussets in the

longitudinal direction)?

Reply: No.

Standard Designation:

Edition/Addenda:

BPV Section IX

Para./Fig./Table No:

Subject Description:

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

9/36

Date Issued:

Record Number:

Interpretation Number :

Section IX, QW-303.3 and QW-461.9, Special Positions for Performance

Qualification

09/30/1992

BC92-265

IX-92-46

Question(s) and Reply(ies): Question: Is a welder who is qualified to weld groove welds in a special

orientation also qualified to weld in the 1G position?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-322.2, Renewal of Qualification

Record Number:

BC92-266

Date Issued:

Interpretation Number :

09/30/1992

IX-92-47

Question(s) and Reply(ies): Question: May the renewal of welder and welding operator performance

qualification be done on production work?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-407.2, Postweld Heat Treatment

Record Number:

BC93-586

Date Issued:

Interpretation Number :

11/22/1993

IX-92-84

Question(s) and Reply(ies): Background: A PQR was welded on a 2 in. thick P-No. 1, Gr. 2 material

and post weld heat treated at 1150"F for six hours (3 hrs/in.) with

supplementary essential variable requirements.

Question: Will this PQR support a WPS for a production weld in 2 in. thick

P-No. 1, Gr. 2 material that is PWHT at 1150F for 2 hours (1 hr/in.)?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-201, Manufacturer's or Contractor's Responsibility

Record Number:

BC95-482

Date Issued:

Interpretation Number :

Question(s) and Reply(ies):

03/19/1996

IX-95-27

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

10/36

Question: May a subcontractor use a WPS supported by a PQR which was

qualified by the contracting company and subsequently supplied to the

subcontractor?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-403.10, Short Circuiting Mode

Record Number:

BC96-002

Date Issued:

Interpretation Number :

03/19/1996

IX-95-28

Question(s) and Reply(ies): Question: Are the base metal thickness restrictions for the GMAW process

short circuiting mode stated in QW-403.10 and QW-404.32 also applicable

to fillet weld tests, either in procedure qualifications (QW-451.3, QW451.4) or in performance qualifications (QW-452.4, QW-452.5, and QW452.6)?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-466, Test Jigs

Record Number:

BC92-267

Date Issued:

Interpretation Number :

09/30/1992

IX-92-48

Question(s) and Reply(ies): Question: In determining the appropriate test jig dimensions of QW-466 to

use for bend tests, is it permissible to use the dimensions corresponding to

P-No. 35 material when the filler metal is a F-No. 36, even though the base

material is other than a P-No. 35 material?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-466, Test Jigs

Record Number:

BC92-268

Date Issued:

Interpretation Number :

09/30/1992

IX-92-49

Question(s) and Reply(ies): Question: In qualifying a welding procedure which utilizes a F-No. 36 filler

of ER CuAl-A1 (SFA 5.7) for corrosion resistant weld metal overlay of a

P-No. 1 carbon steel material, is the required mandrel diameter for side

bend testing 4t as determined from column A of QW-466.1, QW-466.2 or

QW-466.3?

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

11/36

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-403.6, Base Metals

Record Number:

BC92-217

Date Issued:

Interpretation Number :

09/30/1992

IX-92-50

Question(s) and Reply(ies): Question: If Heat Affected Zone (HAZ) notch toughness requirements are

applicable, does QW-403.6, base metal thickness requirements, apply?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-451.3 and QW-462.4, Fillet Weld Test SpecimensProcedure, and QW-452.4, Performance Qualification Thickness Limits and

Test Specimens

09/30/1992

BC92-276

IX-92-51

Question(s) and Reply(ies): Question: If a welder performs a procedure qualification per QW-462.4(d)

using 2 in. NPS pipe and passes, is he qualified for all diameters as outlined

in QW-451.3?

Reply: No, per QW-452.4 he is qualified down to 1 in. O.D.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-462.5, Corrosion-Resistant Overlay Cladding/Hard-Facing

Overlay, Chemical Analysis Specimen

12/14/1992

BC92-252

IX-92-52

Question(s) and Reply(ies): Question: May only one chemical analysis specimen be removed from the

vertical portion of a 6G positioned hard facing welded PQR coupon when

the weld travel direction is reversed every other weld pass resulting in weld

beads deposited in vertical-upward and vertical-downward direction?

Reply: Yes, provided a chemical analysis represents each vertical travel

direction.

Standard Designation:

Edition/Addenda:

BPV Section IX

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

12/36

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

Section IX, QW-452.1, Groove Weld Procedure Qualifications Thickness

Limits and Test Specimens

12/14/1992

BC92-254

IX-92-53

Question(s) and Reply(ies): Question: A welder has qualified on 3 in. O.D. in. wall pipe in the 1G

position. He has also qualified on 1 in. O.D. 1/8 in. wall pipe in the 6G

position. Is he qualified to weld 1 in. O.D. in. wall in all positions?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-214.3, Corrosion-Resistant Weld Metal Overlay

Record Number:

BC92-305

Date Issued:

Interpretation Number :

12/14/1992

IX-92-54

Question(s) and Reply(ies): Question: Prior to the 1991 Addenda, did QW-214.3 address the number of

chemical analysis tests required for Corrosion Resistant Weld Metal

Overlay utilizing the GTAW Machine Welding Process in the 5G or 6G

position?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-103.2, Records

Record Number:

BC92-307

Date Issued:

Interpretation Number :

12/14/1992

IX-92-55

Question(s) and Reply(ies): Question: Is it acceptable to satisfy the requirements of QW-103.2 for

record maintenance, certification, and accessibility by means of an

electronic storage medium, e.g., computer database?

Reply: Section IX does not address the media in which records are required

to be maintained.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-451.3, Fillet Weld Tests

Record Number:

BC92-308

Date Issued:

12/14/1992

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

13/36

Interpretation Number :

IX-92-56

Question(s) and Reply(ies): Question: A welder performs a fillet weld procedure qualification in

accordance with QW-451.3, which fails; therefore, neither the procedure

nor the welder are qualified. Is it permissible for the welder to then perform

a successful groove weld procedure qualification test and be qualified for

grooves and fillets?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, 1989 Edition A91 Addenda, QW-253, QW-256, and QW-406.3,

Maximum Interpass Temperature

12/14/1992

BC92-354

IX-92-57

Question(s) and Reply(ies): Question: According to the 1991 Addenda of Section IX, is it permissible to

revise a WPS by increasing interpass temperature to more than 100F above

that recorded on the supporting PQR when supplementary essential

variables do not apply without requalification?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-364, Friction Welding

Record Number:

BC92-357

Date Issued:

Interpretation Number :

12/14/1992

IX-92-58

Question(s) and Reply(ies): Question: For performance qualification, is a friction weld operator required

to requalify for each seat size and base metal combination to be qualified to

operate the machine?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-306, Combination of Welding Processes, QW-452.1 and

QW-452.3, Performance Qualification Thickness Limits and Test

Specimens

02/22/1993

BC92-206

IX-92-59

Question(s) and Reply(ies): Background: The combination of welding processes and pipe diameters

listed below were used for performance qualification:

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

14/36

(1) 2 in. Sch. 80 (.218) pipe with open butt using GTAW process. (2) 2 in.

Sch. 160 (.343) pipe with consumable insert and fill pass using the GTAW

process and the remainder welded with SMAW process. (3) 6 in. XXS

(.864) using SMAW process with backing.

Question: Using the combinations listed in the Background, in accordance

with QW-306, Note 2 of QW-452.1 to determine maximum thickness

qualified, and QW-452.3 for minimum diameter qualification, is the welder

qualified to weld on unlimited thickness and diameters above 1 in., using

either an open butt joint or a consumable insert with the root layer deposited

with the GTAW process and the remainder deposited with the SMAW

process?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-214, Corrosion-Resistant Weld Metal Overlay

Record Number:

BC92-421

Date Issued:

Interpretation Number :

02/22/1993

IX-92-60

Question(s) and Reply(ies): Question: When corrosion-resistant weld metal overlay is deposited in a

base material groove to a depth that is not included in the design

calculations must the deposit be tested as a groove weld?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section II, Part C, SFA 5.13, Specification for Solid Surfacing Welding

Rods and Electrodes

02/22/1993

BC92-422

IX-92-61

Question(s) and Reply(ies): Question: May powdered filler metal be classified under Section II, Part C,

SFA 5.13?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-408.2, Shielding Gas

Record Number:

BC92-425

Date Issued:

Interpretation Number :

02/22/1993

IX-92-62

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

15/36

Question(s) and Reply(ies): Question (1): When changing shielding gases of a specific mixture, is it

permissible to adjust the nominal percentage(s) of the minor component(s)

by +/- 20% without requalifying the procedure?

Reply (1): No.

Question (2): In addition, when the absolute value of +/- 20% times the

nominal percentage of a minor component is less than 1%, would it be

permissible to make a +/- 1% adjustment to the gas mixture?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-153.1, Tensile Strength

Record Number:

BC92-452

Date Issued:

Interpretation Number :

02/22/1993

IX-92-63

Question(s) and Reply(ies): Question: A welding procedure qualification test coupon is welded using

P-No. 23, SB-209, alloy 6061 aluminum base material in the ("o") temper.

After welding the test coupon, it is subjected to a "T-6" heat treatment. To

establish acceptability of tensile tests per QW-153.1, may the tensile

requirements of QW-422 for SB-209, alloy 6061 (T4 and T6 tempers in the

welded condition) be used?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-322, Expiration and Renewal of Qualification

Record Number:

BC92-464

Date Issued:

Interpretation Number :

05/26/1993

IX-92-64

Question(s) and Reply(ies): Background: A welding operator is in. the process of renewing his/her

qualification using machine GTAW welding equipment. During the process

the machine malfunctions and burns through the root pass of the test

coupon. No operator error is noted. Following the malfunction, the test

coupon is repaired using a manual GTAW process. After the repair the

machine welding equipment is used to complete the rest of the test coupon.

Question: May a welding operator performance test coupon being welded

for qualification or renewal be repaired prior to testing using a manual

welding procedure?

Reply: No.

Standard Designation:

Edition/Addenda:

BPV Section IX

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

16/36

Para./Fig./Table No:

Subject Description:

Section IX, QW-423.1, Alternate Base Metals for Welder Qualification

Record Number:

BC93-148

Date Issued:

Interpretation Number :

05/26/1993

IX-92-65

Question(s) and Reply(ies): Question: In QW-423.1, is P-No. 42 included in P-No. 4X?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-201, Manufacturer's or Contractor's Responsibility

Record Number:

BC93-377

Date Issued:

Interpretation Number :

05/26/1993

IX-92-66

Question(s) and Reply(ies): Background: Company A and Company B merge divisions to form a new

Company, C.

Question (1): May the new Company, C, use PQRs and WPSs developed

previously by Company A and Company B?

Reply (1): Yes, provided operational control is in accordance with QW-201.

Question (2): May the new Company, C, use the central materials

laboratory of Company A to develop WPSs and PQRs?

Reply (2): Yes, provided operational control is in accordance with QW-201.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-201, Manufacturer's or Contractor's Responsibility

Record Number:

BC93-391

Date Issued:

Interpretation Number :

05/26/1993

IX-92-67

Question(s) and Reply(ies): Question: In a contract involving piping construction work, our company

subcontracted the piping prefabrication work to a subcontractor. This

subcontractor is managed by our company but has a different name. The

subcontractor proceeded to qualify welding procedures which were

conducted in the presence and with the approval of our company's welding

engineer who monitored the welding of the test coupons and signed

approval on the PQRs. The Quality Control System of the subcontractor and

our company fully describe the operational control of procedure

qualifications. Was our client right in rejecting the use by our company of

the subcontractor qualified welding procedures for the erection work of the

prefabricated piping?

Reply: This is a contractual issue, which ASME does not address.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

17/36

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-306, Combination of Welding Processes, and QW-451,

Groove Weld Procedure Qualification Thickness Limits and Test

Specimens

06/30/1993

BC92-011A

IX-92-68

Question(s) and Reply(ies): Question: In using a single set of test specimens to qualify two or more

processes or procedures, does Section IX specify a minimum weld deposit

thickness to be included in each test specimen from each of the processes or

procedures?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-409.1, Electrical Characteristics

Record Number:

BC92-011B, BC92-228, BC92-353

Date Issued:

Interpretation Number :

06/30/1993

IX-92-69

Question(s) and Reply(ies): Question: Is it the intent of QW-409.1 that the heat input, to be recorded on

the PQR, be calculated based on the parameters used at the location where

the impact specimens were removed?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-403.5, Base Metals

Record Number:

BC92-450

Date Issued:

Interpretation Number :

09/22/1993

IX-92-70

Question(s) and Reply(ies): Question (1): When a procedure qualification with supplemental notch

toughness requirement is conducted with one P-Number material having

multiple certifications in different Group Numbers, are WPSs qualified for

all combinations of the Group Numbers?

Reply (1): Yes.

Question (2): In the above question, does one set of HAZ impact specimens,

when required, satisfy the requirements of Section IX?

Reply (2): Yes.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

18/36

Question (3): When a procedure qualification with supplemental notch

toughness requirements is conducted with two materials of different

P-Numbers each having multiple certifications in different Group Numbers,

are WPSs qualified for all combination of the multiple certified Group

Numbers of the first P-Number material to the multiple certified Group

Numbers of the second P-Number material?

Reply (3): Yes.

Question (4): In the above question, does one set of HAZ impact specimens

from each P-Number material, when required, satisfy the requirements of

Section IX?

Reply (4): Yes.

Question (5): In Question (3), are materials from the multiple certified

Group Numbers qualified for welding a P-Number material to itself?

Reply (5): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-302.4, Visual Examination

Record Number:

BC93-365

Date Issued:

Interpretation Number :

09/22/1993

IX-92-71

Question(s) and Reply(ies): Question: Are welders or welding operators qualified in accordance with

Section IX prior to the 1992 addenda, for which the results of visual

examination required by QW-302.4 were not documented on the WPQ,

required to requalify in order that visual examination results may be

documented?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-381(c), Corrosion Resistant Weld Metal Overlay, QW-453

and QW-461.9, Performance Qualification

09/22/1993

BC93-392

IX-92-72

Question(s) and Reply(ies): Question (1): May welder qualifications for corrosion-resistant overlays per

QW-381 and QW-453 be made on plate, when qualifying for welding on

pipe/tubes parallel to the axis of the pipe/ tubes?

Reply (1): Yes.

Question (2)(a): Should the side bends required in QW-453 consist of the

base metal plus overlay thickness, after surface conditioning per Note 4 of

QW-453?

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

19/36

Question (2)(b): When the overlay test specimens are less than 3/8 in. thick,

may the side bend specimen width be the test specimen thickness?

Question (2)(c): May the edges of the overlay be outside of the bent area as

long as at least a 1-1/2 in. width of overlay and HAZ are completely within

the bend?

Reply (2)(a): Yes.

Reply (2)(b): Yes.

Reply (2)(c): Yes.

Question (3): May QW-461.9 Groove-Pipe be used for the position essential

variable rules for welder qualifications on corrosion-resistant overlap?

Reply (3): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-321.3, Welder Qualification After Further Training or

Practice

09/22/1993

BC93-468

IX-92-73

Question(s) and Reply(ies): Background: A welder performance qualification test plate fails to meet the

radiographic requirements for qualification. After further training a new

performance qualification test plate is welded.

Question: May the new test plate be evaluated by bend testing?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QB-402.1, Base Metals

Record Number:

BC93-474

Date Issued:

Interpretation Number :

09/22/1993

IX-92-74

Question(s) and Reply(ies): Question: When brazing material used for a procedure qualification test is

not listed in QB-422 or Appendix C, but is similar to P-No. 107 or S-No.

107 materials listed in QB-422 or Appendix C, may this material be

considered as a P-No. 107 or S-No. 107 material in accordance with QB402.1?

Reply: No.

Standard Designation:

Edition/Addenda:

BPV Section IX

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

20/36

Para./Fig./Table No:

Subject Description:

Section IX, QW-200.4(b), Combination of Welding Procedures

Record Number:

BC93-490

Date Issued:

Interpretation Number :

09/22/1993

IX-92-75

Question(s) and Reply(ies): Question: When writing multi-process welding procedures per QW-200.4

(a), where the tube wall thickness is less than 1 in., using a separate

qualification for the root deposit only, must the root deposit qualification

coupon be 1/2 in. minimum thickness as stated in QW-200.4(b)?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-462, Test Specimens

Record Number:

BC93-515

Date Issued:

Interpretation Number :

09/22/1993

IX-92-76

Question(s) and Reply(ies): Question: QW-462 defines W as "specimen width, 3/4 in." Is 3/4 in. a

minimum or maximum dimension requirement for preparing a reduced

section tensile specimen?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-200.4, Combination of Welding Procedures, and QW451.4, Fillet Welds Qualified by Groove Weld Tests

09/22/1993

BC93-518

IX-92-77

Question(s) and Reply(ies): Background: A butt welding procedure qualification was completed on a

pipe with E6010 electrode (F-No. 3) for the root pass and E7018 electrode

(F-No. 4) for the remaining process. Question (1): Will the above procedure

qualification alone support a WPS to make a fillet weld with E-7018

electrodes (F-No.4) for all the passes for all fillet sizes on all base metal

thicknesses when all the other essential variables under QW-253, SMAW

process, are the same?

Reply (1): Yes.

Question (2): Will the above procedure qualification alone support a WPS

to make a butt weld with E-7018 electrodes (F-No. 4) for all the passes

including the root pass within the limits of qualification of QW-451.1 and

within the limits of the essential variables under QW-253, SMAW process?

Reply (2): Yes.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

21/36

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200.2(b), Welding Procedure Qualifications

Record Number:

BC93-561

Date Issued:

Interpretation Number :

09/22/1993

IX-92-78

Question(s) and Reply(ies): Question (1): May a company subcontract weld procedure development and

qualification including certification of the PQR without a company

representative present to witness the welding, testing, and certification?

Reply (1): No.

Question (2): May a company subcontract weld procedure development and

qualification including certification of the PQR with a company

representative present to witness the welding, testing, and certification?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX - 1989 Edition, Addenda 91; QW-151.1, Tension Tests, Reduced

Section-Plate, and QW-462.1(a), Test Specimens

09/22/1993

BC93-583

IX-92-79

Question(s) and Reply(ies): Question (1): Is it permissible to reduce a plate test coupon thickness

beyond removing the reinforcement to allow for parallel surfaces?

Reply (1): Yes.

Question (2): What percentage of the thickness is permissible to be removed

for procedure qualification?

Reply (2): The minimum necessary to obtain parallel surfaces.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-103, Responsibility, and QW-201, Manufacturer's or

Contractor's Responsibility

09/22/1993

BC93-584

IX-92-80

Question(s) and Reply(ies): Question: When a company changes names during the course of time must

all the historical documents such as PQRs and WPQs be revised to show

this new name?

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

22/36

Reply: No, provided there is documented traceability from the new

company name to the WPSs and PQRs qualified under the old company

name.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-103.1 and QW-201, Manufacturer's or Contractor's

Responsibility

10/18/1993

BC92-306

IX-92-81

Question(s) and Reply(ies): Question (1): According to Section IX, para. QW-201, is it permissible for a

manufacturer or contractor to have the welding of the test weldments

performed by another organization?

Reply (1): No.

Question (2): According to para. QW-201, is it permissible to subcontract

the work preparation of test metal for welding and subsequent work on

preparation of test specimens from the completed weldment, performance

of nondestructive examination, and mechanical test, provided that the

manufacturer or contractor accepts the responsibility for any such work?

Reply (2): Yes.

Question (3): If the manufacturer or contractor writes the WPS and the

welder used to produce weldments to be tested for qualification of

procedures are under full supervision and control of a representative of the

manufacturer or contractor during the production of these test weldments,

may the welder be an employee of another organization?

Reply (3): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, Code Case 2141, Electrodes and Fluxes for Submerged Arc

Welding, SFA 5.17 and SFA 5.23

11/22/1993

BC93-434

IX-92-82

Question(s) and Reply(ies): Question (1): Does the "Manufacturer's Data Report" in the Section IX

Code Case 2141 mean the following: (a) Manufacturer's Data Report

required in PG-112 of SC I; (b) Data Report required in NCA-3770 of

Section III; (c) Data Report required in UG-120 of Section VIII, Div. 2; or

(d) Manufacturer's Data Reports required in AS-300 of Section VIII, Div.

2?

Reply (1): A Manufacturer's Data Report form is any data report form that

is required in an ASME Code Book.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

23/36

Question (2): Is it required to described this Code Case number on

procurement and/or manufacturer's specifications and certified material test

report of welding consumables?

Reply (2): Section IX does not address procurement and manufacturer's

specifications.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QB-415, Brazing Variables

Record Number:

BC93-527

Date Issued:

Interpretation Number :

11/22/1993

IX-92-83

Question(s) and Reply(ies): Question (1): Does ASME Section IX permit braze welding qualifications

using the rules of Part QW, Welding?

Reply (1): Yes.

Question (2): May a fabricator qualify hard-facing using the brazing

variables listed in QB-415?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QB-121 and QB-123, Brazing Test Positions

Record Number:

BC93-655

Date Issued:

Interpretation Number :

11/22/1993

IX-92-85

Question(s) and Reply(ies): Question: If the test material is oriented at 15 deg. above horizontal (i.e., 75

deg. down from vertical) and the brazing filler metal flows upward by

capillary action through the joint, would the brazer then be qualified for

both the flat-flow and vertical-upflow positions?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-100.3, Welding General Requirements

Record Number:

BC93-658

Date Issued:

Interpretation Number :

11/22/1993

IX-92-86

Question(s) and Reply(ies): Question: May a hard-facing procedure qualification test that was

performed in 1990 on a 1 in. thick test coupon and is used to support a

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

24/36

welding procedure specification written in 1993 be used to deposit a hardfacing overlay on base material 1 in. to unlimited thickness?

Reply: Yes. QW-100.3 allows welding procedure specification (WPS) to be

supported by procedure qualifications accomplished subsequent to 1962

without amending the WPS to include any variables required by later

Editions and Addenda.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-403.6, Base Metals and QW-409.1, Electrical

Characteristics

02/14/1994

BC93-151

IX-92-87

Question(s) and Reply(ies): Background: Two PQRs have been qualified to support a WPS with notch

toughness requirements and having a qualified base metal thickness range

from 5/16 in. to 2 in. inclusive. One PQR was qualified on 1 in. thick

material with a maximum heat input of 85,000 J/in. The second was

qualified on 5/16 in. thick material with a maximum heat input of 45,000

J/in. All other essential and supplementary essential variables are the same.

Question (1): Is this WPS qualified for using 85,000 J/in. max. heat input on

thicknesses 5/16 in. to 2 in.?

Reply (1): No.

Question (2): Is the heat input value of 85,000 J/in. applicable to base metal

thicknesses between 5/8 in. to 2 in. and the heat input value of 45,000 J/in.

applicable to base metal thicknesses between 5/16 in. and 5/8 in.?

Reply (2): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-409.1 and QW-409.8, Electrical Characteristics

Record Number:

BC93-593

Date Issued:

Interpretation Number :

02/14/1994

IX-92-88

Question(s) and Reply(ies): Question: Section IX, QW-409.8 and QW-409.1, require that the volts and

amps be specified in the WPS. Does Section IX require voltage to be

measured at a specific location in the welding circuit or the current to be

measured using a specific type of meter (RMS, averaging or other type)?

Reply: No.

Standard Designation:

Edition/Addenda:

BPV Section IX

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

25/36

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

Section IX, QW-452.1, Groove Weld Procedure Qualification Thickness

Limits and Test Specimens and QW-452.3, Groove Weld Diameter Limits

02/14/1994

BC93-653

IX-92-89

Question(s) and Reply(ies): Question: A welder has qualified on 3 in. O.D. 1/2 in. wall pipe in the 1G

position and has also qualified on 1 in. O.D. 1/8 in. wall pipe in the 1G

position. Is the welder qualified to weld 1 in. O.D. 3/8 in. wall in the 1G

position?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-461.9; Performance Qualification Position and Diameter

Limitations

02/14/1994

BC93-753

IX-92-90

Question(s) and Reply(ies): Question: A welder has passed two separate tests; one on 5/8 in. O.D. by

0.049 in. thick pipe welded in the 6G position using GTAW process, and

another on 1/2 in. thick plate welded in the 1G position using GTAW

process. Do these two tests in combination qualify the welder to weld pipe

of unlimited diameter in all positions up to 1 in. thick using GTAW?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-300, General Welding Performance Qualifications

Record Number:

BC93-755

Date Issued:

Interpretation Number :

02/14/1994

IX-92-91

Question(s) and Reply(ies): Question: Does Section IX prohibit making editorial corrections to welder

and welding operator performance qualification records?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

BPV Section IX

Section IX, QW-201, Manufacturer's or Contractor's Responsibility,

Clarification Request to Interpretation IX-92-07 Date Issued Oct. 7, 1991,

File BC91-156

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

26/36

Date Issued:

05/20/1994

Interpretation Number :

IX-92-92

Record Number:

BC93-678

Question(s) and Reply(ies): Question (1): Is the term "Organization" as stated in QW-201 and

"Company A" in Interpretation IX-92-07 one and the same?

Reply (1): No.

Background: Two companies are contracted by a client company to

undertake pipe work installation on its facility. All stages of the Welding

Procedure Qualification Processes for the two contracted companies are

witnessed by the client companies representative and the documentation

duly stamped and signed as accepted by the client.

Question (2): May these procedures be used by the client company?

Reply (2): No.

Question (3): Does the client company have to requalify these procedures in

order to perform in-house maintenance at a later date using all the same

essential and nonessential variables with its own qualified welders?

Reply (3): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QB-402.1, Brazing Data and Appendix C - Nonmandatory

S-Numbers

05/20/1994

BC93-752

IX-92-93

Question(s) and Reply(ies): Question (1): Does the brazing procedure qualification test with a base

metal assigned one S-Number, or S-Number plus Group-Number, qualify

for all other base metals in the same S-Number grouping?

Reply (1): Yes.

Question (2): Does the brazing procedure qualification test with dissimilar

metals using one metal listed in one S-Number to one specific metal not

listed in one S or P-Number qualify for the brazing of all other base metals

in the same S-Number to themselves and to the specific base metal without

S or P-Number?

Reply (2): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section II, Part C, SFA-5.8

Record Number:

BC93-754

Date Issued:

05/20/1994

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

27/36

Interpretation Number :

IX-92-94

Question(s) and Reply(ies): Question: May AWS Classification BAg-34 be considered SFA-5.8 filler

metal even though it does not appear in the 1992 ASME Boiler and Pressure

Vessel Code Section II, Part C (including the 1992 Addenda)?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200, General Welding Procedure Qualifications

Record Number:

BC94-008

Date Issued:

Interpretation Number :

05/20/1994

IX-92-95

Question(s) and Reply(ies): Question: May a single WPS be qualified both with PWHT and without

PWHT (two PQRs), thereby allowing the WPS to be used with or without

PWHT?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-300, General Welding Performance Qualifications

Record Number:

BC94-102

Date Issued:

Interpretation Number :

05/20/1994

IX-92-96

Question(s) and Reply(ies): Background: A welder is qualified on a NPS 2 Sch. 40 pipe test coupon

using GTAW 1.6 mm deposited weld metal and SMAW 2.4 mm deposited

weld metal.

Question (1): Is the SMAW portion of the performance qualification

considered welding with backing?

Reply (1): Yes.

Question (2): Is the welder qualified to weld NPS 4 single welded groove

weld without backing using the SMAW process only?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200.4(a), Combination of Welding Procedures

Record Number:

BC94-167

Date Issued:

Interpretation Number :

05/20/1994

IX-92-97

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

28/36

Question(s) and Reply(ies): Question: According to QW-200.4(a), when a qualified WPS for a

combination process is available, must a new WPS be generated if only one

of the processes is to be used in production, provided all requirements of

Section IX for the process used are met?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, Appendix C, Nonmandatory S-Numbers

Record Number:

BC94-236

Date Issued:

Interpretation Number :

05/20/1994

IX-92-98

Question(s) and Reply(ies): Question: May steel produced to ASTM A-108 Grade 1018, UNS G10180,

be considered S-1 material?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-432.6, F-Numbers and Section II, Part C, SFA-5.29, 1992

Addenda

06/10/1994

BC93-762 and BC93-769

IX-92-99

Question(s) and Reply(ies): Question: May AWS 5.24 ER Zr4 be considered as an F-No. 61 filler

metal?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-200.1(b), General Welding Procedure Qualifications and

QW-402.4, Joints

09/21/1994

BC94-104

IX-95-01

Question(s) and Reply(ies): Question: If a WPS states that the GTAW process shall be used on root and

second pass of open root or metal backed groove joints and the SMAW

process shall be used on the remainder of the groove joint, is it necessary to

state that the SMAW portion of the WPS must be performed with backing

(i.e., the GTAW process)?

Reply: No.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

29/36

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-462, Test Specimens

Record Number:

BC94-181

Date Issued:

Interpretation Number :

09/21/1994

IX-95-02

Question(s) and Reply(ies): Question: What are the minimum and maximum tolerances for specimens

shown in QW-462, where the figures show "approximate" dimensions?

Reply: As stated in the Foreword, "The Code does not fully address

tolerances. When dimensions, sizes, or other parameters are not specified

with tolerances, the values of these parameters are considered nominal and

allowable tolerance or local variances may be considered acceptable when

based on engineering judgment and standard practices as determined by the

designer."

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-202.2(b), Groove and Fillet Weld Tests and QW-202.3(b),

Weld Repair and Buildup Tests

09/21/1994

BC94-235

IX-95-03

Question(s) and Reply(ies): Background: Procedure Qualification was performed by making a full

penetration weld on 1 in. thick plate. Paragraph QW-202.2(b) states that

qualification on 1 in. or thicker base metal qualifies for making partial

penetration welds on base metals with no upper limit of base metal

thickness. No minimum thickness of base metal is addressed.

Question (1): Does qualification of 1 in. thick base metal qualify for

making partial penetration groove welds on base metals which are less than

3/16 in. thick?

Reply (1): No. See para. QW-451.1 for minimum base metal thicknesses.

Background: Procedure qualification was performed by making a full

penetration weld on 1 in. thick plate. Paragraph QW-202.3(b) states that

qualification on 1 in. thick or thicker base metal qualifies for making weld

repairs or weld build-ups on base metals of unlimited thickness.

Question (2): Does qualification on 1 in. base metal qualify for making

weld repairs or weld build-ups on base metals which are less than 3/16 in.

thick?

Reply (2): No. See para. QW-451.1 for minimum base metal thicknesses.

Standard Designation:

Edition/Addenda:

BPV Section IX

Para./Fig./Table No:

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

30/36

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

Section IX, QW-452.3, Groove Weld Diameter Limits and Submerged Arc

Wire Flux Combination

09/21/1994

BC94-296

IX-95-04

Question(s) and Reply(ies): Question (1): According to para. QW-452.3 is the inside diameter an

essential variable for performance qualification?

Reply (1): No.

Background: A WPS for SAW process was qualified with a wire flux

combination classified as F6P0-EL8, using one trade name for flux. This

WPS was in use for several years. Now the flux manufacturer has changed

the classification to F7P2-EL8 without changing the trade name of flux. The

flux trade name is mentioned on the WPS and PQR along with the former

AWS classification.

Question (2): Is it required to requalify this WPS due to the change in the

AWS class of the wire flux combination by the flux manufacturer without

changing its Trade Name?

Reply (2): Yes. See para. QW-404.9(a).

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-422, P-Numbers

Record Number:

BC94-365

Date Issued:

Interpretation Number :

09/21/1994

IX-95-05

Question(s) and Reply(ies): Question: May SB-564 UNS N08825 be considered as P-No. 45, since it

has identical properties to SB-425 UNS N08825 that is assigned P-No. 45 in

QW-422?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-153.1, Tension Tests

Record Number:

BC94-542

Date Issued:

Interpretation Number :

09/21/1994

IX-95-06

Question(s) and Reply(ies): Question: If a tensile specimen breaks in the weld metal, below the weld

metal's minimum specified tensile requirement, but not below the minimum

tensile strength specified for the base metal, is the PQR considered

acceptable?

Reply: Yes.

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

31/36

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-420.2, S-Numbers

Record Number:

BC94-522

Date Issued:

Interpretation Number :

03/17/1995

IX-95-07

Question(s) and Reply(ies): Question: When qualifying a welding procedure using S1 group 2 for API

5LX60 pipe joining to MSS SP-75 or ASTM A860 WPHY-65 fittings, or

when joining WPHY-60 fittings to each other, is it permissible to use the

corresponding S-Number for the fitting as the same grade of high strength

pipe when the physical properties are similar?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-462.4(a), Fillet Weld Procedure

Record Number:

BC94-543

Date Issued:

Interpretation Number :

03/17/1995

IX-95-08

Question(s) and Reply(ies): Question (1): When T2 is greater than 3/4 in. in Fig. QW-462.4(a), what is

the maximum size fillet weld required?

Reply (1): 3/4 in.

Question (2): In QW-462.4(a), what does "size of fillet = thickness of T2"

mean?

Reply (2): The length of each fillet leg(s) shall be nominally equal to the

thickness of T2.

Question (3): Is there a tolerance for the fillet leg size?

Reply (3): No. As stated in the 1992 Addenda to the Foreword, when

tolerances are not specified, dimensions are considered nominal and

allowable tolerances or local variances may be considered acceptable when

based on engineering judgement and standard practices as determined by

the designer.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-153, Acceptance Criteria--Tension Tests

Record Number:

BC94-570

Date Issued:

Interpretation Number :

Question(s) and Reply(ies):

03/17/1995

IX-95-09

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

32/36

Question: When welds between base metals of different minimum specified

tensile strengths are being tested and tensile failure occurs in either of the

base metals, does the reference to base metal within QW-153.1(d) mean the

base metal with the lower minimum specified tensile strength?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-200.4, Combination of Welding Procedures

Record Number:

BC94-662

Date Issued:

Interpretation Number :

03/17/1995

IX-95-10

Question(s) and Reply(ies): Question: May a single process WPS be qualified by a combination process

PQR where no essential variables for the process are changed?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-408, Gas

Record Number:

BC95-002

Date Issued:

Interpretation Number :

03/17/1995

IX-95-11

Question(s) and Reply(ies): Question: Is it required to indicate the purity level by percent composition

or descriptive terms of a single shielding gas on the WPS and on the PQR?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-202.4, Dissimilar Base Metal Thicknesses

Record Number:

BC95-027

Date Issued:

Interpretation Number :

03/17/1995

IX-95-12

Question(s) and Reply(ies): Question: Does QW-202.4 include butt joints and corner joints when

joining dissimilar base metal thicknesses when prepared with a groove?

Reply: Yes.

Standard Designation:

Edition/Addenda:

BPV Section IX

Para./Fig./Table No:

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

33/36

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

Section IX, 1989 Addenda, QW-203, Limits of Qualified Positions for

Procedures Section II Part C, 1989 Addenda, SFA 5.1 and 5.5

06/15/1995

BC94-035

IX-95-13

Question(s) and Reply(ies): Question: Do the requirements for classification of filler metals in

accordance with ASME Section II Part C apply to the qualification of

welding and brazing procedures in accordance with Section IX?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-300.3, Welding Performance Qualifications

Record Number:

BC95-040

Date Issued:

Interpretation Number :

06/15/1995

IX-95-14

Question(s) and Reply(ies): Question: Are there any circumstances under which a non-employee person

or organization can represent one or more participating organizations during

welding of the test coupon in accordance with the requirements of QW300.3?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-160, Guided-Bend Tests and QW-466 Note (b)- Test Jigs

Record Number:

BC95-094

Date Issued:

Interpretation Number :

06/15/1995

IX-95-15

Question(s) and Reply(ies): Question: Is it acceptable to measure the percent elongation of the tensile

specimens in lieu of bend specimens to measure the ductility for welding

procedure qualification acceptance?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-255, Welding Variables Procedure Specifications for

FCAW and QW- 408.2, Gas

06/15/1995

BC95-095

IX-95-16

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

34/36

Question(s) and Reply(ies): Question: May a FCAW welding procedure qualified without shielding gas,

be used with a shielding gas without requalification?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-302.4, Visual Examination

Record Number:

BC95-035

Date Issued:

Interpretation Number :

10/19/1995

IX-95-17

Question(s) and Reply(ies): Question (1): For the fillet weld coupon in welder performance

qualification, does the macro examination required per QW-452.5 exempt

the visual examination required per QW-302.4?

Reply (1): No.

Question (2): Does the visual examination of the fillet weld test coupon

required per QW-302.4 refer to the final weld face side only?

Reply (2): Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-409.8, Electrical Characteristics

Record Number:

BC95-220

Date Issued:

Interpretation Number :

10/19/1995

IX-95-18

Question(s) and Reply(ies): Question: Does Section IX require that a separate amperage range be

specified for each filler metal size listed in the WPS?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Date Issued:

Record Number:

Interpretation Number :

BPV Section IX

Section IX, QW-300.3, Welding Performance Qualifications and QW-322.1

(b), Expiration of Welder Qualification

10/19/1995

BC95-221

IX-95-19

Question(s) and Reply(ies): Background: A welder simultaneously qualifies for ten different contractors

in accordance with QW-300.3. QW-300.3 requires the contractor that

rejects a welder to notify the other contractors who participated in the

simultaneous test that the welder's qualification has been revoked. One of

the contractors subsequently revokes the welder's qualification for specific

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

35/36

reason in accordance with QW-322.1(b). Question (1): Are the other nine

contractors who qualified the welder simultaneously required to revoke the

welder's qualification per QW-322.1(b)?

Reply (1): No.

Question (2): When a participating contractor revokes a welder's

qualification for specific reason, does QW-300.3 require the other

participating contractors to retest the welder or welding operator?

Reply (2): No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-300, Welding Performance Qualification

Record Number:

BC95-302

Date Issued:

Interpretation Number :

10/19/1995

IX-95-20

Question(s) and Reply(ies): Question: If the manufacturer or contractor writes the WPS and the welder

used to produce the weldments to be tested for qualification of procedures is

under the full supervision and control of the manufacturer or contractor

during the production of these test weldments, may the welder be a

contracted employee, provided the Quality Control system or Quality

Assurance Program of the manufacturer or contractor describes the control

of contracted welders?

Reply: Yes.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

BPV Section IX

Subject Description:

Section IX, QW-403.5, Base Metals

Record Number:

BC95-318

Date Issued:

Interpretation Number :

10/19/1995

IX-95-21

Question(s) and Reply(ies): Background: A PQR is qualified in accordance with Section IX, with

supplementary essential variables, using a material from British Standard

1501-224-490A-LT50.

Question: May this PQR be used to support a WPS utilizing a P-Number 1,

Group Number 2 material with supplementary essential variables?

Reply: No.

Standard Designation:

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

BPV Section IX

Section IX, QW-424, Base Metals Used for Procedure Qualification

https://cstools.asme.org/Interpretation/InterpretationDetail.cfm

2016/5/4

36/36

Date Issued:

12/28/1995

Interpretation Number :

IX-95-22