Академический Документы

Профессиональный Документы

Культура Документы

Sepax Separator

Загружено:

Mahaveer SinghАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sepax Separator

Загружено:

Mahaveer SinghАвторское право:

Доступные форматы

SEPAX separator

Smart, simple, space

saving design

Key benefits

- High efficiency separation

- Highly effective nibs extraction minimises clogging of

mill grates, thus enabling

long-lasting full mill capacity

- Low operating costs

Low initial costs

- Self-supporting structure

- Standard range drive parts

- One feed point in low position

Flexible and versatile

- Adaptable to:

- All cement grinding ball

mill systems

- Fully or semi air-swept

raw grinding ball mills

- Flash driers

Low maintenance costs

- Optimum wear protection

- Automatic grease lubrication

system

- Easy access for maintenance

The high efficiency separator improves

the mill performance by avoiding over

grinding of the material, and gives the

required product fineness by efficiently

separating the course particles from the

fine particles. Decades of know-how in

high-efficiency separation enables

FLSmidth to supply the most suitable

separator for almost any application.

Low initial costs

The simple and space-saving design

of the SEPAX makes it an economical

investment. The separator is fitted

within a self-supporting shell structure,

and the entire separator unit with cyclones is supported by one ring-shaped

support only. Reducer and motor are

placed in line with the bearing housing,

forming a compact and rigid drive-line

unit. Finally, the SEPAX has one feed

point placed at a low level, minimising

the height of the separator feed

elevator and simplifying the layout.

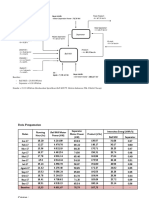

SEPAX separator

1 Air outlet

2 Flexible coupling

3 Motor

4 Reducer

5 Rotor

6 Reject collecting guide

vanes

7 Planetary separator

supported cyclone

5

7

8 Ring-shaped support

9 Fine material outlet

10 Reject outlet cone valve

11 Feed point

12 Pneumatic unloading valve

11

13 Nibs disposal container

10

3

4

2

12

13

Maximum efficiency

The SEPAX is very efficient in operation

and cuts specific energy consumption

to a minimum, while maintaining

maximum output. A highly effective

system for removal of worn grinding

media from the mill discharge material

means less clogging of diaphragms.

This optimises mill performance and

enables long-term, continuous operation.

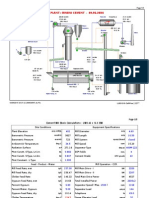

Fines collector

Mill dedusting

Flexible and versatile

The SEPAX is designed to be equipped

with drives ranging from low power

drives for raw grinding to powerful

drives for the finest grinding while still

utilising the full design air flow. This

ensures maximum efficiency regardless

of the end product quality specified.

Nibs

disposal

Mill product

SEPAX system with bag filter

for collection of fines: This

system ensures maximum

product cooling.

Dedusting

The SEPAX can be equipped with separator-supported cyclones or stand-alone

cyclones for the collection of fines.

The feed concept is based on the material being suspended in the vertical air

flow through the riser duct. This makes

the SEPAX highly adaptable to various

raw grinding applications. Consequently,

the separator can be integrated into

the mill venting system, in the case of

fully or semi air-swept mills, or installed

on top of a flash dryer that forms the

riser duct leading up to the SEPAX.

Finished

product

Reject flow

New feed

Finished

product

Reject flow

New feed

SEPAX system for raw

grinding installation

suitably integrated into

the mill vent line.

Mill product

Mill dedusting

Low maintenance costs

The SEPAX is designed to be easily

serviceable. Worn and broken grinding

media are not recycled, which helps to

save maintenance work on the mill

grate plates. The removal of nibs from

the separator feed reduces the wear on

critical separator parts. Easily accessible

and serviceable wear protection is

fitted where appropriate, and the

bearing unit can easily be replaced.

SEPAX system with cyclones

for collection of fines:

Lowest initial and operating

costs. Recuperation of heat

enhances drying of wet slag,

puzzolana or other additives.

Finished

product

Reject flow

New feed

Nibs disposal

Mill product

Wear protection

Densit Wearcast 2000

The material is a 30 mm thick cement

bound composition containing 55%

hard (9 Mohs) grains of corundum

(Al2O3). Densit Wearcast is easy to

install and repair. It has been tested to

outlast basalt by a factor of 1.3 when

exposed to sandblasting at various

inclinations.

Hardox 400

This is a world-known, abrasionresistant, weldable steel plate, which

is throughhardened to more than 360

HB and is recognised for its superior

abrasion resistance properties.

Chromium compound

wear plate

This material is a mild steel plate with a

thickness of 4 to 8 mm, onto which a

4 - 5 mm layer of hardfacing is welded.

The hardfacing consists of primary

chromium carbides in a eutectic matrix

with eutectic chromium carbides.

The hardness of the matrix reaches

600-750 HV, the grains 1400 HV.

The temperature limit is 400 deg C.

High carbon steel

This is a low cost and highly versatile

material which is used in places where

moderate wear occurs.

Mild steel

Revision XX/XX/XXXX al-us

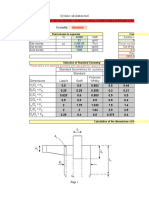

A1

A2

E

Dimensions and characteristics

Size

Air flow

A1

A2

m /s mm mm mm mm mm mm

3

190

7.3

3108

N.A.

5704

N.A.

1900

N.A.

212

10.0

3500

N.A.

6467

N.A.

2120

N.A.

236

13.5

3933

N.A.

7296

N.A.

2360

N.A.

250

15.7

4189

3754

7772

3040

2500

840

265

18.3

4460

4004

8285

3258

2650

900

280

21.1

4736

4262

8792

3492

2800

965

300

25.1

5102

4608

9468

3800

3000

1050

315

28.3

5376

4862

9975

4036

3150

1115

335

32.8

5746

5213

10647

4344

3350

1200

355

37.7

6115

5558

11319

4668

3550

1290

375

42.9

6485

5907

11989

4976

3750

1375

400

49.9

6947

6342

12822

5374

4000

1485

425

57.4

7412

6781

13656

5772

4250

1595

450

65.4

7876

7217

14488

6154

4500

1700

475

73.9

8341

7652

15321

6552

4750

1810

500

83.0

8807

8088

16152

6932

5000

1915

530

94.5

9365

8611

17148

7402

5300

2045

560

106.8

9923

9130

18145

7872

5600

2175

Copyright 2011 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth is a (registered) trademark of FLSmidth A/S. This brochure makes no offers, representations

or warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

Project Centre Denmark

FLSmidth A/S

Vigerslev All 77

DK-2500 Valby

Copenhagen

Tel: +45 3618 1000

Fax: +45 3630 1820

E-mail: info@flsmidth.com

Project Centre USA

FLSmidth Inc.

2040 Avenue C

Bethlehem, PA 18017-2188

Tel: +1 610-264-6011

Fax: +1 610-264-6170

E-mail: info-us@flsmidth.com

Project Centre India

FLSmidth Private Limited

FLSmidth House

34, Egatoor, Kelambakkam

(Rajiv Gandhi Salai, Chennai)

Tamil Nadu 603 103

Tel: +91-44-4748 1000

Fax: +91-44-2747 0301

E-mail: indiainfo@flsmidth.com

www.flsmidth.com

C 02-11 300-4-ENG

Вам также может понравиться

- Preheater Cyclone Dsigns: Tube Dia X EntryДокумент6 страницPreheater Cyclone Dsigns: Tube Dia X EntrynileshОценок пока нет

- Vertical Roller Mill State of The Art Raw GrindingДокумент4 страницыVertical Roller Mill State of The Art Raw GrindingzementheadОценок пока нет

- Rotary Kiln Brick CountДокумент5 страницRotary Kiln Brick CountThaigroup CementОценок пока нет

- Rawmix DesignДокумент3 страницыRawmix DesignavisgopОценок пока нет

- Tromp Curve Example PDFДокумент3 страницыTromp Curve Example PDFThaigroup Cement100% (1)

- Calculating Actual Ball Size and Density Using Archimedes' Principle SpreadsheetДокумент3 страницыCalculating Actual Ball Size and Density Using Archimedes' Principle SpreadsheetIrving Dirzo CarrilloОценок пока нет

- Ball Mill OptimiztionДокумент8 страницBall Mill OptimiztionShakil AhmadОценок пока нет

- Rs 71 Ball Mill Sizng-1Документ4 страницыRs 71 Ball Mill Sizng-1Dilnesa EjiguОценок пока нет

- Neraca Massa dan Energi Ball Mill dan SeparatorДокумент10 страницNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanОценок пока нет

- Cross-Bar CoolerДокумент8 страницCross-Bar CoolernaikОценок пока нет

- Ball Mill GrindingДокумент6 страницBall Mill GrindingShyanu Udeshika WijerathnaОценок пока нет

- Ball Mill Design - CompressДокумент6 страницBall Mill Design - CompressSuresh VedalaОценок пока нет

- Vertical Roller Mill-DatasheetДокумент6 страницVertical Roller Mill-DatasheetAdnan Nawaz100% (2)

- Mill Calculation: Plant: Date: Mill: VisaДокумент2 страницыMill Calculation: Plant: Date: Mill: VisaThaigroup CementОценок пока нет

- Clinker Cooler TypesДокумент17 страницClinker Cooler Typesemad sabri100% (1)

- Modern Cement Grinding Systems ComparedДокумент14 страницModern Cement Grinding Systems ComparedCao Ngoc AnhОценок пока нет

- Cyclone Design Calculation Tool SimplifiedДокумент6 страницCyclone Design Calculation Tool SimplifiedKevin WilliamОценок пока нет

- ABC Cooler Inlet PDFДокумент4 страницыABC Cooler Inlet PDFSushant GuptaОценок пока нет

- Heat Requirement Calculations For ReepДокумент8 страницHeat Requirement Calculations For ReeplkchoudhuryОценок пока нет

- Cement MillДокумент28 страницCement Millsaji kumar100% (2)

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Документ2 страницыVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- Sturt Air ClassifierДокумент6 страницSturt Air ClassifierHenry Vladimir VianchaОценок пока нет

- V SK VSK: Focus On EfficiencyДокумент8 страницV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaОценок пока нет

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYДокумент8 страницQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanОценок пока нет

- ATC Report on Dynamic Separator Gap IssuesДокумент4 страницыATC Report on Dynamic Separator Gap IssuesDilnesa EjiguОценок пока нет

- 4 MPДокумент33 страницы4 MPSyed Shahzaib ShahОценок пока нет

- Cement Grinding - Cement Plant OptimizationДокумент4 страницыCement Grinding - Cement Plant OptimizationHasan KamalОценок пока нет

- KC 1.4 CalcinationДокумент4 страницыKC 1.4 CalcinationCarlos HernanОценок пока нет

- Technical Specification of VSK PDFДокумент28 страницTechnical Specification of VSK PDFmaran.suguОценок пока нет

- Mechanical Operations: Industrial Crushers Ball MillДокумент25 страницMechanical Operations: Industrial Crushers Ball MilljoyОценок пока нет

- MASS BALANCE SUMMARYДокумент51 страницаMASS BALANCE SUMMARYirfan100% (1)

- Ball-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceДокумент7 страницBall-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceMin MCLОценок пока нет

- Tube Mill OptimisationДокумент7 страницTube Mill OptimisationJoko DewotoОценок пока нет

- Alkali Bypass WHRPP Nov - 11 PDFДокумент18 страницAlkali Bypass WHRPP Nov - 11 PDFNinad Bhave100% (1)

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportДокумент2 страницыNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedОценок пока нет

- Circulating Load: in The Crushing and Milling CircuitДокумент17 страницCirculating Load: in The Crushing and Milling Circuitaghilif100% (1)

- Better Grinding Systems with V-Separator and VSK-SeparatorДокумент5 страницBetter Grinding Systems with V-Separator and VSK-SeparatorGerman Gabriel Anaya VegaОценок пока нет

- Literature ReviewДокумент6 страницLiterature ReviewIrfan FadzailahОценок пока нет

- Hardness of Clinker Due To Usage of Pet CokeДокумент1 страницаHardness of Clinker Due To Usage of Pet CokeVijay BhanОценок пока нет

- Annex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasДокумент2 страницыAnnex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasIrfan AhmedОценок пока нет

- Ultratech Report FinalДокумент78 страницUltratech Report FinalrahulОценок пока нет

- Hammer DesaignДокумент21 страницаHammer DesaignZahlul AmriОценок пока нет

- Tromp Curve Calculations and ResultsДокумент3 страницыTromp Curve Calculations and Resultsrecai100% (2)

- Optimize cement kiln grate speed productionДокумент3 страницыOptimize cement kiln grate speed productionrudye kardunОценок пока нет

- Optimum efficiency range for separator performanceДокумент3 страницыOptimum efficiency range for separator performanceShakil AhmadОценок пока нет

- The Effect of Coal Ash On Synthesis and Properties of C3SДокумент6 страницThe Effect of Coal Ash On Synthesis and Properties of C3SNam HuynhОценок пока нет

- Coal Mill Wear Measurement 29.09.2014Документ1 страницаCoal Mill Wear Measurement 29.09.2014Durga PrasadОценок пока нет

- Calculate false air percentage in an HVAC systemДокумент2 страницыCalculate false air percentage in an HVAC systemVijay Bhan100% (1)

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldДокумент1 страницаBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurОценок пока нет

- FivesFCB Brochure Horomill GBДокумент6 страницFivesFCB Brochure Horomill GBpeymanОценок пока нет

- Ball Mill Understanding OptimisationДокумент47 страницBall Mill Understanding OptimisationrecaiОценок пока нет

- Rawmix DesignДокумент2 страницыRawmix DesignBùi Hắc HảiОценок пока нет

- Sepax SeperatorДокумент6 страницSepax Seperatoradanis01100% (1)

- 1568 GB 02Документ7 страниц1568 GB 02Andra EneОценок пока нет

- Roller Mill BrochureДокумент6 страницRoller Mill Brochuregyanendra_vatsa4380Оценок пока нет

- 1592 SEPOL GBДокумент5 страниц1592 SEPOL GBgigihpradanaОценок пока нет

- Competence in CementДокумент24 страницыCompetence in CementJackson VuОценок пока нет

- Sepura Oil Water Separator 4ppДокумент4 страницыSepura Oil Water Separator 4ppmuppetscrapОценок пока нет

- VMT 860 Brochure Issue 2Документ16 страницVMT 860 Brochure Issue 2Florin Paraschivescu100% (1)

- Conturbex: The Worm/screen CentrifugeДокумент12 страницConturbex: The Worm/screen CentrifugeLeonan CaréliОценок пока нет

- StartupIndia ActionPlan 16january2016Документ40 страницStartupIndia ActionPlan 16january2016Kaushik RudraОценок пока нет

- Evaluation of Separator PerformanceДокумент25 страницEvaluation of Separator PerformanceMahaveer SinghОценок пока нет

- 73rd Amendment ActДокумент11 страниц73rd Amendment ActMahaveer SinghОценок пока нет

- Road SignДокумент34 страницыRoad Signonlygehlot6739Оценок пока нет

- Centrifugal FansДокумент50 страницCentrifugal FansMahaveer SinghОценок пока нет

- Welding Definition: by S K MondalДокумент26 страницWelding Definition: by S K MondalSaajal SharmaОценок пока нет

- Pre - FabricationДокумент23 страницыPre - FabricationMahaveer Singh100% (1)

- The MissionДокумент2 страницыThe MissionNagamani KambhamОценок пока нет

- Welding Book PipingДокумент184 страницыWelding Book PipingMahaveer Singh100% (2)

- Photovoltaic Principles (NREL) PDFДокумент71 страницаPhotovoltaic Principles (NREL) PDFED DK KAОценок пока нет

- Casting CompleteДокумент26 страницCasting CompleteRavinder Antil100% (2)

- Reason SkillsДокумент176 страницReason Skillsjnanmol007100% (9)

- Welding Definition: by S K MondalДокумент26 страницWelding Definition: by S K MondalSaajal SharmaОценок пока нет

- Special CastingДокумент18 страницSpecial CastingVivekanand RockОценок пока нет

- Mechanical EngineeringДокумент36 страницMechanical EngineeringSridhar Ramakrishnappa RОценок пока нет

- Road SignДокумент34 страницыRoad Signonlygehlot6739Оценок пока нет

- Heat TransferДокумент72 страницыHeat TransferMontuKumar100% (1)

- Atlas Metals HandbookДокумент45 страницAtlas Metals HandbookJim GrayОценок пока нет

- NC CNC ConventionalДокумент8 страницNC CNC ConventionalNITIN KUMAR SHARMAОценок пока нет

- Binarni BroeviДокумент10 страницBinarni BroevistormceОценок пока нет

- I Too Had A Love Story-Ravinder SinghДокумент112 страницI Too Had A Love Story-Ravinder SinghMahaveer SinghОценок пока нет

- A - Piping Joint HandbookДокумент161 страницаA - Piping Joint HandbookCharles Tauk100% (30)

- Mensuration FormulasДокумент6 страницMensuration FormulasMahaveer SinghОценок пока нет

- Steam TablesДокумент6 страницSteam TablesRichard Olawoyin100% (1)

- Basic Electronic & Transistor Circuits PDFДокумент54 страницыBasic Electronic & Transistor Circuits PDFSandeep GoyalОценок пока нет

- Material ScienceДокумент810 страницMaterial ScienceNikhil Batham67% (3)

- Aws B5 15 2010Документ26 страницAws B5 15 2010Mohamedkheireddine100% (2)

- Casting CompleteДокумент26 страницCasting CompleteRavinder Antil100% (2)

- Hydro TestingДокумент26 страницHydro TestingMahaveer SinghОценок пока нет

- Engineering Material Specification: Printed Copies Are UncontrolledДокумент41 страницаEngineering Material Specification: Printed Copies Are UncontrolledDANIEL DIAZОценок пока нет

- Enhance Pharmaceutical Formulations with SynZeal Research's Bilastine API StandardsДокумент5 страницEnhance Pharmaceutical Formulations with SynZeal Research's Bilastine API StandardssynzealОценок пока нет

- Material Stock Level ReportДокумент9 страницMaterial Stock Level ReportyandiОценок пока нет

- 10) Farming - Conventional and SustainableДокумент76 страниц10) Farming - Conventional and Sustainableeliseobravo572Оценок пока нет

- Vaccine Types: Monovalent vs MultivalentДокумент2 страницыVaccine Types: Monovalent vs MultivalentGrayОценок пока нет

- Biosynthesis of Levan From Sucrose Using A Therm - 2018 - International Journal PDFДокумент9 страницBiosynthesis of Levan From Sucrose Using A Therm - 2018 - International Journal PDFNatalia HataОценок пока нет

- Mechanical Properties of Oil Palm Fibre-Reinforced Polymer Composites: A ReviewДокумент33 страницыMechanical Properties of Oil Palm Fibre-Reinforced Polymer Composites: A ReviewjaviergagocampusanoОценок пока нет

- Herbert Oscar. Final Project TTTДокумент34 страницыHerbert Oscar. Final Project TTTJoe MartinОценок пока нет

- Soybean Motor OilДокумент12 страницSoybean Motor OilJessica FernandesОценок пока нет

- MSDS Acronal 7645Документ14 страницMSDS Acronal 7645Sam MalikОценок пока нет

- Weed Biology and Control-InTech - Vytautas PilipaviÄ IusДокумент134 страницыWeed Biology and Control-InTech - Vytautas PilipaviÄ IusJuliano LorenzettiОценок пока нет

- Sliding Side Door SleevesДокумент20 страницSliding Side Door SleevesSlim.B100% (3)

- MSDS Sentinel HWДокумент4 страницыMSDS Sentinel HWfitrisya luckyОценок пока нет

- SSV Maha Vastu Price List Jan 22Документ8 страницSSV Maha Vastu Price List Jan 22ujwal waguldeОценок пока нет

- Mole Concept XI JEEДокумент23 страницыMole Concept XI JEERoNОценок пока нет

- Waste Management: A Case Study Perspective Analysis: September 2019Документ10 страницWaste Management: A Case Study Perspective Analysis: September 2019rbenseghierОценок пока нет

- RutaceaeДокумент13 страницRutaceaePiyush RathourОценок пока нет

- April 2016 Paper 2 PDFДокумент20 страницApril 2016 Paper 2 PDFLee Jia Bao BerniceОценок пока нет

- Chapter 12. Electricity and Circuits: Very Short Q&AДокумент8 страницChapter 12. Electricity and Circuits: Very Short Q&ASubhojit MitraОценок пока нет

- HT 521 82055 170 ENДокумент5 страницHT 521 82055 170 ENEdward AguillónОценок пока нет

- Analysis of Roller Shaft Pad Steam MachineДокумент14 страницAnalysis of Roller Shaft Pad Steam MachineIJRASETPublicationsОценок пока нет

- A Size Bobbin Cell: Technical DatasheetДокумент2 страницыA Size Bobbin Cell: Technical DatasheetdbmОценок пока нет

- 2021 3285 Moesm1 EsmДокумент33 страницы2021 3285 Moesm1 EsmDanila SaraninОценок пока нет

- Rivet Edge Distance Guide - Key Factors for Aircraft DesignДокумент2 страницыRivet Edge Distance Guide - Key Factors for Aircraft Designnirlep_parikhОценок пока нет

- Valve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Документ2 страницыValve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Tu PhamОценок пока нет

- Arkifloor EHДокумент2 страницыArkifloor EHChristinaОценок пока нет

- AP General Equilibrium Free Response QuestionsДокумент5 страницAP General Equilibrium Free Response QuestionsCynОценок пока нет

- From Gene To Protein - Transcription and TranslationДокумент11 страницFrom Gene To Protein - Transcription and TranslationELOISA N. CASANEОценок пока нет

- Noble 2014Документ13 страницNoble 2014Restu DanikaОценок пока нет

- حسابات صيدلانية ١Документ24 страницыحسابات صيدلانية ١ابراهيم صلاح الدين حامد حمديОценок пока нет