Академический Документы

Профессиональный Документы

Культура Документы

DSP NEXT 15-55 Catalogue

Загружено:

Phanhai KakaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DSP NEXT 15-55 Catalogue

Загружено:

Phanhai KakaАвторское право:

Доступные форматы

OIL FREE SCREW

HITACHI OIL-FREE SCREW COMPRESSOR

SINGLE STAGE15/22/37/55kW

Specifications

Air-Cooled, Fixed Speed Model (1555kW)

ItemUnit

Discharge Pressure

Discharge Air Capacity

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Coolant Pump Motor Output (50/60Hz)

P.D.P

[Dryer] Refrigerator Nominal Output

Refrigerant

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

[]: indicates model with Dryer integrated

DSP-15A[R]5N

DSP-15A[R]6N

Model

DSP-22A[R]5N

DSP-22A[R]6N

DSP-37A[R]5N

DSP-37A[R]6N

DSP-55A[R]5N

DSP-55A[R]6N

0.4

0.7

0.4

0.7

0.4

0.7

0.4

MPa

0.7

5.9

6.4

2.5

3.4

4.0

5.0

8.0

m3/min

2.0

15

22

37

55

kW

4-Pole TEFC Motor

C

Atmospheric Pressure/040 [540]

C

Ambient Temperature +15 or below

Rc1

Rc1-1/2

B

Full Voltage Start

Star-Delta (3 contact)

V-Belt+Gear-Driven

18 (Not filled)

L

12 (Not filled)

0.4

0.9

kW

0.75

kW

0.2/0.3

[10 (Under Pressure)]

[10 (Under Pressure)]

[10 (Under Pressure)]

[10 (Under Pressure)]

C

[0.5]

[1.1]

[1.1]

[1.1]

kW

[R407C]

[R407C]

[R407C]

[R407C]

750 [780]

800 [860]

1,020 [1,170]

1,240 [1,390]

kg

1,8309801,580 [2,2309801,580]

mm

1,4009701,400

63

68

62

63

64

66

68

70

dB(A)

Air-Cooled, V-type Model (2255kW)

[]: indicates model with Dryer integrated

Model

ItemUnit

Discharge Pressure

Discharge Air Capacity

Discharge Pressure

Discharge Air Capacity

PQ

WIDEMODE Discharge Pressure

Discharge Air Capacity

PQ WIDEMODE Range

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Coolant Pump Motor Output (50/60Hz)

P.D.P

[Dryer] Refrigerator Nominal Output

Refrigerant

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

MPa

m3/min

MPa

m3/min

MPa

m3/min

MPa

kW

C

C

B

L

kW

kW

C

kW

kg

mm

dB(A)

DSP-37VA[R]5N

DSP-37VA[R]6N

DSP-22VA[R]5N

DSP-22VA[R]6N

0.7

3.4

0.6

3.7

0.4 [0.5]

4.3 [4.0]

0.40.7 [0.50.7]

0.3

4.6

0.7

5.0

0.6

5.5

0.4 [0.5]

6.4 [6.0]

0.40.7 [0.50.7]

22

DSP-55VA[R]5N

DSP-55VA[R]6N

0.3

6.7

0.7

6.4

0.6

7.0

0.4 [0.5]

8.2 [7.6]

0.40.7 [0.50.7]

37

4-Pole TEFC Motor

Atmospheric Pressure/040 [540]

Ambient Temperature +15 or below

Rc1-1/2

Inverter

V-Belt+Gear-Driven

18 (Not filled)

12 (Not filled)

[10 (Under Pressure)]

[1.1]

[R407C]

850 [910]

1,6509701,400

63

Asia & Oceania

China

Hitachi Industrial Equipment Systems

(China) Co., Ltd.

(Shanghai Branch)

Room1207, Rui Jin Building, No.205

Maoming Road(S) Shanghai 200020

TEL : +86 (21) 5489-2378

FAX : +86 (21) 3356-5070

(Beijing Branch)

Room1420, Beijing Fortune Building,

No.5 Dong San Huan Bei Road,

Chao Yang District, Beijing 100004

TEL : +86 (10) 6590-8180

FAX : +86 (10) 6590-8189

(Guangzhou Branch)

Room3403, Office Tower, CITIC Plaza ,

No.233 Tianhe North Road, Guangzhou

510613

TEL : +86 (20) 3877-0438

FAX : +86 (20) 2735-3820

55

0.9

0.2/0.3

[10 (Under Pressure)]

[10 (Under Pressure)]

[1.1]

[1.1]

[R407C]

[R407C]

1,180 [1,330]

1,080 [1,230]

1,8309801,580 [2,2309801,580]

66

68

68

64

Hitachi Industrial Equipment Systems

(HongKong) co., Limited

6th Floor, North Tower World Finance

Centre, Harbour City, Canton Road,

Tsim Sha Tsui, Kowloon Hong Kong

TEL : +852 2735-9218

FAX : +852 2735-6793

70

[]: indicates model with Dryer integrated

Fixed Speed Model

Model

DSP-37W5N

DSP-37W6N

MPa

m3/min

MPa

m3/min

MPa

m3/min

MPa

kW

C

C

B

L

kW

L/min

C

B

kg

mm

dB(A)

0.3

8.5

0.75

Water-Cooled Model (37/55kW)

ItemUnit

Discharge Pressure

Discharge Air Capacity

Discharge Pressure

Discharge Air Capacity

PQ

WIDEMODE Discharge Pressure

Discharge Air Capacity

PQ WIDEMODE Range

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Cooling Water Flow Rate

Cooling Water Temperature

Cooling Water Pipe Connection

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

SINGLE STAGE15/22/37/55kW

0.7

5.0

V type

DSP-55W5N

DSP-55W6N

0.4

5.9

0.7

6.4

DSP-37VWN

0.4

8.0

NOTE:

1. Capacity is measured according to ISO 1217, Third Edition, Annex C.

2. Sound Levels is the value at 1.5m in front and 1m height in an anechoic room.

It varies in different operating conditions and/or different environment with echo of actual

field installations.

For V-type models, sound level is increased by 2dB at PQ WIDEMODE ON.

3. P.D.P is measured at 30C of intake air temperature and rated discharge pressure.

P.D.P is much worse at 0.4MPa or less of discharge pressure.

P.D.P rises 3C at PQ WIDEMODE ON and 0.6MPa of discharge pressure.

4. Air Capacity of Built-in Dryer model decreases by up to 3% when drain condensates.

5. Discharge air temperature with Dust Proof option or Simple Package Filter option is

ambient temperature + 18C or below.

6. Earth leakage circuit breaker is NOT equipped within. Prepare it in advance.

0.3

6.7

0.7

6.4

0.6

7.0

0.4

8.2

0.40.7

66

64

55

4-Pole TEFC Motor

Atmospheric Pressure/040

Cooling Water Temperature +13 or below

Rc1-1/2

Inverter

V-Belt+Gear-Driven

14 (Not filled)

0.2

80

32 or below

Rc1

1,050

1,150

1,8309801,580

66

64

0.3

8.5

Taiwan Hitachi Asia Pacific Co., Ltd

3th Floor, No. 167, Tun Hwa N. Road,

Hung-Kuo Building, Taipei 10512, Taiwan

TEL : +886 (2) 2718-3666

FAX : +886 (2) 2514-7664

37

37

64

55

4-Pole TEFC Motor

Atmospheric Pressure/040

Cooling Water Temperature +13 or below

Rc1-1/2

Star-Delta (3 contact)

V-Belt+Gear-Driven

14 (Not filled)

0.1

80

32 or below

Rc1

970

1,190

1,8309801,580

66

64

0.7

5.0

0.6

5.5

0.4

6.4

0.40.7

DSP-55VWN

India

Hitachi India Pvt. Ltd.

Units 304-306, 3rd Floor, ABW Elegance

Tower, Jasola District Centre, New Delhi

110 025, India

TEL : +91 (11) 4060-5252

FAX : +91 (11) 4060-5253

Indonesia

PT Hitachi Asia Indonesia

Menara BCA 38th Floor Suite #3804 &

3805 JI. M. H Thamrin No.1, Jakarta

10310, Indonesia

TEL : +62 (21) 2358-6757

FAX : +62 (21) 2358-6755

Malaysia

Hitachi Asia (Malaysia) Sdn. Bhd.

Suite 17.3, Level 17, Menara IMC

(Letter Box No.5) No. 8 Jalan Sultan

Ismail, 50250, Kuala Lumpur

TEL : +60 (3) 2031-8751

FAX : +60 (3) 2031-8758

Philippines

Hitachi Asia Ltd. Philippine Branch

Unit 8, 11th Floor Zuellig Bldg.,

Makati Avenue corner Paseo de Roxas

Makati City, Philippines 1225

TEL : +632 886-9018

FAX : +632 887-3794

Singapore

Hitachi Asia Ltd.

(Industrial Components & Equipment

Group)

No.30, Pioneer Crescent

#10-15, West Park Bizcentral

Singapore 628560

TEL : +65-6305-7400

FAX : +65-6305-7401

Thailand

Russian Federation

Viet Nam

Latin America

Mexico

Hitachi Asia (Thailand) Co., Ltd.

18th Floor, Ramaland Building, 952

Rama IV Road Bangrak, Bangkok 10500

TEL : +66 (2) 632-9292

FAX : +66 (2) 632-9299

Hitachi Asia Ltd.

(Ho Chi Minh City Office)

4th Floor, The Landmark, 5B Ton Duc

Thang Street District 1, Ho Chi Minh City

TEL : +84 (8) 829-9725

FAX : +84 (8) 829-9729

(Ha Noi Office)

Sun Red River Bldg., 5th Floor,

23 Phan Chu Trinh Street

Hoan Kiem District, Hanoi

TEL : +84 (4) 933-3123

FAX : +84 (4) 933-3125

Australia

Hitachi Australia Pty Ltd.

Level 8, 123 Epping Road, Macquarie

Park NSW 2113

TEL : +61 (2) 9888-4100

FAX : +61 (2) 9888-4188

Europe

Germany

Hitachi Europe GmbH

(Industrial Components & Equipment

Group)

Am Seestern 18 (Euro Center)

D-40547 Dsseldorf

TEL : +49 (211) 5283 0

FAX : +49 (211) 5283 649

Hitachi, Ltd. (Moscow Office)

Millenium House, 12, Trubnaya, Moscow

103045

TEL : +7 (095) 787-4022, -4020

FAX : +7 (095) 787-4021

Hitachi Industrial Equipment

Mexico S.A. de C.V.

Avenida Rio Seguro 161, Parque Tecno

Industrial Castro del Rio Tramo

Irapuato-Silao km125, Carretera

Panamericaa C.P.36810, Irapuato, Gto.,

Mexico

TEL : +52 (462) 693-7088, -7089, -7090

FAX : +52 (462) 693-7091

North America

U.S.A.

Hitachi America, Ltd.

(Industrial Components & Equipment

Division)

50 Prospect Avenue, Tarrytown,

New York, 10591-4698

TEL : +1(914) 332-5800

FAX : +1(914) 332-5555

(Charlotte Office)

(Industrial Components & Equipment

Division)

6901 Northpark Blvd., Charlotte, NC 28216

TEL : +1(704) 494-3008

FAX : +1(704) 494-3809

66

7. Pressure is indicated as the gauge pressure.

8. Dimensions do NOT include protruding objects such as piping.

9. Specifications and/or appearances are subject to change without notice.

ISO14001

EC97J1107

D S P - 37 V A R 5 N

Dry

Screw

Package

Nominal

Output (kW)

ISO9001

JQA-QM3443

Hitachi Screw Compressor is manufactured at a factory approved by Environmental Standard

(ISO 14001) and Quality Standard (ISO9001) of International Organization for Standardization.

DSP

Frequency (5:50Hz, 6:60Hz)

R:Built-in Dryer (Without R:without dryer type)

A:Air-cooled, W:Water-cooled

V:V-type (Without V:Fixed Speed type)

E177 1214

OIL FREE SCREW

Hitachi Original Oil-free Screw Technology

Single-Stage Up to 0.7MPa

SINGLE STAGE15/22/37/55kW

Specifications

Instrumental Panel

Air-End

Inverter

Gear Case

Main Motor

Control Panel

Air-Cooled, Fixed Speed Model (1555kW)

ItemUnit

Discharge Pressure

Discharge Air Capacity

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Coolant Pump Motor Output (50/60Hz)

P.D.P

[Dryer] Refrigerator Nominal Output

Refrigerant

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

[]: indicates model with Dryer integrated

DSP-15A[R]5N

DSP-15A[R]6N

Model

DSP-22A[R]5N

DSP-22A[R]6N

DSP-37A[R]5N

DSP-37A[R]6N

DSP-55A[R]5N

DSP-55A[R]6N

0.4

0.7

0.4

0.7

0.4

0.7

0.4

MPa

0.7

5.9

6.4

2.5

3.4

4.0

5.0

8.0

m3/min

2.0

15

22

37

55

kW

4-Pole TEFC Motor

C

Atmospheric Pressure/040 [540]

C

Ambient Temperature +15 or below

Rc1

Rc1-1/2

B

Full Voltage Start

Star-Delta (3 contact)

V-Belt+Gear-Driven

18 (Not filled)

L

12 (Not filled)

0.4

0.9

kW

0.75

kW

0.2/0.3

[10 (Under Pressure)]

[10 (Under Pressure)]

[10 (Under Pressure)]

[10 (Under Pressure)]

C

[0.5]

[1.1]

[1.1]

[1.1]

kW

[R407C]

[R407C]

[R407C]

[R407C]

750 [780]

800 [860]

1,020 [1,170]

1,240 [1,390]

kg

1,8309801,580 [2,2309801,580]

mm

1,4009701,400

63

68

62

63

64

66

68

70

dB(A)

Air-Cooled, V-type Model (2255kW)

[]: indicates model with Dryer integrated

Model

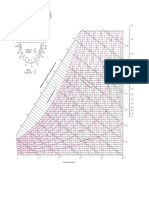

The above picture shows the internal structure

of 55kW Air-Cooled model (V-type).

Premium Air Quality

True Oil-free Air at Class 0 Level

Air purity class of the discharge air from Hitachi Oil-free Screw air compressor (DSP) is proved to be the

highest level Class 0 from the test result which was conducted by the renowned TV institute, in

accordance with ISO8573-1.

ISO-8573-1

ISO8573-1:2010 CLASS 0 TV Certification

TV (The Technische berwachungs Verein), a

Germany based international test service provision

third-party on aspects of technical safety and quality

evaluation, is globally well-reputed on its neutrality

and expertise as well as its strictness in testing.

High Performance Air-End

Stainless Steel Rotor

Particular stainless steel,

which is superior in corrosion

resistance and durability, is

applied for rotor with highly

accurate grinding.

Furthermore, compensated

profile, which is optimized for

thermal expansion during

operation, enables to keep

optimal clearance.

Air-End

High Performance Coating

Hitachi original coating, which can withstand the high temperature of over 300C, protects the rotors from a decrease in performance (efficiency, air purity, etc.).

1

100

50

50

Two-stage

Comparison of

Overhaul Cost (%)

0.7

3.4

0.6

3.7

0.4 [0.5]

4.3 [4.0]

0.40.7 [0.50.7]

0.3

4.6

0.7

5.0

0.6

5.5

0.4 [0.5]

6.4 [6.0]

0.40.7 [0.50.7]

22

0.3

6.7

0.7

6.4

0.6

7.0

0.4 [0.5]

8.2 [7.6]

0.40.7 [0.50.7]

37

4-Pole TEFC Motor

Atmospheric Pressure/040 [540]

Ambient Temperature +15 or below

Rc1-1/2

Inverter

V-Belt+Gear-Driven

18 (Not filled)

12 (Not filled)

Single-stage

Two-stage

Comparison of

Initial Cost (%)

Example of Hitachi 55kW (single-stage) and 45kW (2-stage), without dryer model

Comparison of cost with the same air capacity level

Because there is only one air end for DSP single-stage model,

the initial cost is lower than two-stage model.

The overhaul cost, which covers the most of maintenance cost,

is about half of two-stage for the same reason.

ItemUnit

Discharge Pressure

Discharge Air Capacity

Discharge Pressure

Discharge Air Capacity

PQ

WIDEMODE Discharge Pressure

Discharge Air Capacity

PQ WIDEMODE Range

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Cooling Water Flow Rate

Cooling Water Temperature

Cooling Water Pipe Connection

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

55

[10 (Under Pressure)]

[1.1]

[R407C]

850 [910]

1,6509701,400

63

0.9

0.2/0.3

[10 (Under Pressure)]

[10 (Under Pressure)]

[1.1]

[1.1]

[R407C]

[R407C]

1,180 [1,330]

1,080 [1,230]

1,8309801,580 [2,2309801,580]

66

68

68

64

70

[]: indicates model with Dryer integrated

Fixed Speed Model

DSP-37W5N

DSP-37W6N

MPa

m3/min

MPa

m3/min

MPa

m3/min

MPa

kW

C

C

B

L

kW

L/min

C

B

kg

mm

dB(A)

0.3

8.5

0.75

Model

100

Single-stage

MPa

m3/min

MPa

m3/min

MPa

m3/min

MPa

kW

C

C

B

L

kW

kW

C

kW

kg

mm

dB(A)

DSP-55VA[R]5N

DSP-55VA[R]6N

Water-Cooled Model (37/55kW)

Cut Down Overhaul and Initial Cost

ItemUnit

Discharge Pressure

Discharge Air Capacity

Discharge Pressure

Discharge Air Capacity

PQ

WIDEMODE Discharge Pressure

Discharge Air Capacity

PQ WIDEMODE Range

Nominal Motor Output

Motor Type

Intake Air Pressure/Temperature

Discharge Temperature

Discharge Air Pipe Connection

Starting Method

Driving Method

Oil Quantity

Cooling Fan Motor Output

Coolant Pump Motor Output (50/60Hz)

P.D.P

[Dryer] Refrigerator Nominal Output

Refrigerant

Weight

Dimensions (WDH)

Sound Level (1.5m from front)

DSP-37VA[R]5N

DSP-37VA[R]6N

DSP-22VA[R]5N

DSP-22VA[R]6N

0.7

5.0

V type

DSP-55W5N

DSP-55W6N

0.4

5.9

0.7

6.4

DSP-37VWN

0.4

8.0

NOTE:

1. Capacity is measured according to ISO 1217, Third Edition, Annex C.

2. Sound Levels is the value at 1.5m in front and 1m height in an anechoic room.

It varies in different operating conditions and/or different environment with echo of actual

field installations.

For V-type models, sound level is increased by 2dB at PQ WIDEMODE ON.

3. P.D.P is measured at 30C of intake air temperature and rated discharge pressure.

P.D.P is much worse at 0.4MPa or less of discharge pressure.

P.D.P rises 3C at PQ WIDEMODE ON and 0.6MPa of discharge pressure.

4. Air Capacity of Built-in Dryer model decreases by up to 3% when drain condensates.

5. Discharge air temperature with Dust Proof option or Simple Package Filter option is

ambient temperature + 18C or below.

6. Earth leakage circuit breaker is NOT equipped within. Prepare it in advance.

0.3

6.7

0.7

6.4

0.6

7.0

0.4

8.2

0.40.7

66

64

55

4-Pole TEFC Motor

Atmospheric Pressure/040

Cooling Water Temperature +13 or below

Rc1-1/2

Inverter

V-Belt+Gear-Driven

14 (Not filled)

0.2

80

32 or below

Rc1

1,050

1,150

1,8309801,580

66

64

0.3

8.5

37

37

64

55

4-Pole TEFC Motor

Atmospheric Pressure/040

Cooling Water Temperature +13 or below

Rc1-1/2

Star-Delta (3 contact)

V-Belt+Gear-Driven

14 (Not filled)

0.1

80

32 or below

Rc1

970

1,190

1,8309801,580

66

64

0.7

5.0

0.6

5.5

0.4

6.4

0.40.7

DSP-55VWN

66

7. Pressure is indicated as the gauge pressure.

8. Dimensions do NOT include protruding objects such as piping.

9. Specifications and/or appearances are subject to change without notice.

D S P - 37 V A R 5 N

Dry

Screw

Package

Nominal

Output (kW)

DSP

Frequency (5:50Hz, 6:60Hz)

R:Built-in Dryer (Without R:without dryer type)

A:Air-cooled, W:Water-cooled

V:V-type (Without V:Fixed Speed type)

OIL FREE SCREW

PQ WIDEMODE (V type)

Energy Saving from Various Combinations

Air capacity increases accordingly at PQ WIDEMODE ON.

Inverter

MPa

Gear Case

0.4

0.5

0.6

0.7

For Energy-saving

For Maximum Performance of Compressor

PQ WIDEMODE [OFF]

Model

PQ WIDEMODE [ON]

(%)

4.0

3.7

3.4

Main Motor

Control Panel

37kW

55kW

6.4

8.2

6.0

7.6

5.5

7.0

5.0

6.4

Note: For dryer built-in model, minimum pressure is 0.5Mpa in

the PQ WIDEMODE.

The above picture shows the internal structure

of 55kW Air-Cooled model (V-type).

Conventional

Operation

75

0.7MPa

50

0.6MPa

25

0.5MPa

0

20

40

60

80

100

Air Consumption Ratio (%)

(%)

0.4MPa

1. When the operating pressure is reduced from 0.7MPa to 0.6MPa, the

Max power consumption is automatically reduced to approx. 92% of

0.7MPa.

2. When the pressure is reduced to 0.5MPa, the power consumption

reaches about 85%. When the pressure is reduced to 0.4MPa, the

power consumption reaches about 79%.

If you know your air consumption for sure and wish to achieve EnergySaving, PQ WIDEMODE [OFF] is recommended.

100

Power Consumption Ratio (%)

4.3

(%)

100

Power Consumption Ratio (%)

22kW

Three proposal systems responding to various requirements

Combination V-type with fixed speed type achieves

PQ

WIDEMODE

Energy saving operation without

Energy saving operation with

Energy saving operation by more than

external controller

external controller

one V-type with multi-unit controller

75

0.7MPa

50

0.6MPa

25

0.5MPa

20

40

60

80

100 109 119 128

(%)

0.4MPa

V-M Combination System

Single-V System

Multi-V System

Energy saving operation by one V-type

and maximum two fixed speed type

Energy saving operation by one V-type

and more than one fixed speed type

with multi-unit controller.

Energy saving operation and

averaging V-type operating hour

Air Consumption Ratio (%)

1. When the operating pressure is reduced from 0.7MPa to 0.4MPa, the

power consumption is reduced to approx. 79%.

2. With the excess power from depressurization, you can increase the air

capacity to 128%* of the rated one. At that time, the power consumption reaches 100%.

If you wish to use maximum performance under rated power consumption, PQ WIDEMODE [ON] is recommended.

* In case of 55kW

(55kW 2 units)

Fixed Speed type 55kW with

AUTO operation function

Premium Air Quality

Environment Response

True Oil-free Air at Class 0 Level

Air purity class of the discharge air from Hitachi Oil-free Screw air compressor (DSP) is proved to be the

highest level Class 0 from the test result which was conducted by the renowned TV institute, in

accordance with ISO8573-1.

ISO-8573-1

Oil Mist Remover (OMR) and Auto Drain Valve

installed as Standard Equipment

TV (The Technische berwachungs Verein), a

Germany based international test service provision

third-party on aspects of technical safety and quality

evaluation, is globally well-reputed on its neutrality

and expertise as well as its strictness in testing.

Particular stainless steel,

which is superior in corrosion

resistance and durability, is

applied for rotor with highly

accurate grinding.

Furthermore, compensated

profile, which is optimized for

thermal expansion during

operation, enables to keep

optimal clearance.

Air-End

High Performance Coating

Hitachi original coating, which can withstand the high temperature of over 300C, protects the rotors from a decrease in performance (efficiency, air purity, etc.).

1

Cut Down Overhaul and Initial Cost

100

100

50

50

Single-stage

Two-stage

Comparison of

Overhaul Cost (%)

Air capacity is improved by the

newly-developed high efficiency airend.

Multi-Roller EX +

DSP

-type +

DSP Fixed Speed Models

Fixed

Speed

Model

Capacity Comparison

0.7 MPa Model

0.4 MPa Model

0.3 MPa Model

22kW

3.4

4.0

4.6

37kW

5.0

5.9

6.7

55kW

6.4

8.0

8.5

-type

Comparison of

Initial Cost (%)

Example of Hitachi 55kW (single-stage) and 45kW (2-stage), without dryer model

Comparison of cost with the same air capacity level

Because there is only one air end for DSP single-stage model,

the initial cost is lower than two-stage model.

The overhaul cost, which covers the most of maintenance cost,

is about half of two-stage for the same reason.

In case that the pressure requirement is higher than blower but lower

than standard compressor SPEC,

low pressure SPEC DSP can be your

solution.

Main Production Line

0.7MPa SPEC

Low Pressure Equipment

Powder

0.3MPa SPEC

DSP-55VAN+55AN

Air Consumption Ratio (%)

Air Blow

Fixed

Speed

Model

Multi-Roller EX

Full load lock

Start/Stop

800

600

400

Calculation Condition:

8,000h/year operation

200

0

DSP-55AN

2

400

300

200

100

V

0

100

Approx.

73MWh

Energy-Saving

Effect

200

300

Air Consumption Ratio (%)

Explanation

-type

DSP-55VAN

+DSP-55AN

Control pressure

55AN2: 0.7MPa

55VAN+55AN:0.6MPa

Always running, follow the fluctuation of air

consumption

Fixed speed type or

400

-type

Full load or stop

S indicates Fixed Speed Type.

Application

The compressor described in this catalog utilizes only air as a gas. Never use any gases other than air.

This could result in a fire hazard or damage to the equipment.

Hitachi Compressors are not designed, intended or approved for Breathing Air Applications.

Hitachi assumes no responsibility or liability for compressors used in breathing air applications.

Installation

Install these compressors indoor. Environments susceptible to moisture such as precipitation or vapors should be avoided

this could result in fire hazard, electric shock, rusting, or shortened life of parts.

There should be no explosives, flammable gas (acetylene, propane, etc.), organic solvent, explosive powder, or flame used near the

compressor it may cause fire hazard.

Avoid using the compressor at a place where there is corrosive gas such as ammonia, acid, salt sulfurous acid gas, etc.

this could result in rusting, shortened life, or damage to the equipment.

Applications

Two-stage

Fixed

Speed

Model

Energy-Saving of 73MWh/y can be achieved in case of air consumption at 150%.

Comparison of Annual Power Consumption

in case of Air Consumption at 150%

Single-V (Multi-V)

Example of Multi-Unit Control System

(m3/min)

Single-stage

DSP-55AN2

Air Receiver Tank

V-type 55kW

Expanded Line-Up (Low Pressure)

0.3 MPa model is newly added

Stainless Steel Rotor

Auto Drain Solenoid

Valves for After-cooler

Oil Mist Remover (OMR) and auto drain solenoid valves

are equipped as standard. OMR can collect almost all oil

fumes from the gear casing and recycle them.

Auto drain solenoid valves for condensate of both

inter-cooler and after-cooler minimize air consumption.

ISO8573-1:2010 CLASS 0 TV Certification

High Performance Air-End

Oil Mist Remover

Following Energy-Saving effect can be

achieved due to the V-M Combination

Basic Example of V-M Combination System

Annual Power Consumption (MWh/y)

unit:m3/min

Discharge

Pressure

Proposal for Energy-Saving

PQ WIDEMODE is possible to switch between ON and OFF, responding

to customers requirements.

Capacity in PQ WIDEMODE

Air-End

SINGLE STAGE15/22/37/55kW

-type based Systems

Power Consumption Ratio (%)

Instrumental Panel

Power Consumption Ratio (%)

Hitachi Original Oil-free Screw Technology

Single-Stage Up to 0.7MPa

Usage

Before use, be sure to read the instruction manual thoroughly for correct use of the compressor.

Do not modify the compressor or its components this could result in damage or malfunction.

Powder Transport

Вам также может понравиться

- Printable Spencerian Practice Sheets PDFДокумент5 страницPrintable Spencerian Practice Sheets PDFPhanhai Kaka100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerДокумент1 страница27.Uploads-downloads-DOWN 83915B42C61BD757BG27 Printer RollerPhanhai KakaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesДокумент1 страница32.Uploads-downloads-DOWN - F11B00DF2423BABEBG32 - Engine Testing Room For AutomobilesPhanhai KakaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- FoamДокумент13 страницFoamPhanhai KakaОценок пока нет

- 30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionДокумент2 страницы30.Uploads-downloads-DOWN 1B01F1A4DF91062DBG30 Bridge CorrosionPhanhai KakaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 18.Uploads-downloads-DOWN 5B640AEC998C0EE5Brygram18 Car StorageДокумент1 страница18.Uploads-downloads-DOWN 5B640AEC998C0EE5Brygram18 Car StoragePhanhai KakaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Bowling Alleys: Ffps - Frequently Faced ProblemsДокумент1 страницаBowling Alleys: Ffps - Frequently Faced ProblemsPhanhai KakaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 10.uploads Downloads DOWN 91E4D3FDE6DBC8ACBrygram10 IndoorДокумент1 страница10.uploads Downloads DOWN 91E4D3FDE6DBC8ACBrygram10 IndoorPhanhai KakaОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- T-S ChartДокумент1 страницаT-S ChartPhanhai KakaОценок пока нет

- 17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherДокумент1 страница17.uploads Downloads DOWN D22A32D31D1BBFC8Brygram17 SoleLeatherPhanhai KakaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Leather Storage: Ffps - Frequently Faced ProblemsДокумент2 страницыLeather Storage: Ffps - Frequently Faced ProblemsPhanhai KakaОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Yeast Making: Ffps - Frequently Faced ProblemsДокумент1 страницаYeast Making: Ffps - Frequently Faced ProblemsPhanhai KakaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- PCB Assembly: Ffps - Frequently Faced ProblemsДокумент1 страницаPCB Assembly: Ffps - Frequently Faced ProblemsPhanhai KakaОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- 13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerДокумент1 страница13.uploads Downloads DOWN 9812E97C19F9B525Brygram13 FertilizerPhanhai KakaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- 11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorДокумент1 страница11.uploads Downloads DOWN 7ED44AD7836805A0Brygram11 SemiconductorPhanhai KakaОценок пока нет

- 7.uploads Downloads DOWN 0B6F223BD788BE0EBrygram7 FalconДокумент1 страница7.uploads Downloads DOWN 0B6F223BD788BE0EBrygram7 FalconPhanhai KakaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 8.uploads Downloads DOWN 00F7784227428513Brygram8 PowdercoatДокумент1 страница8.uploads Downloads DOWN 00F7784227428513Brygram8 PowdercoatPhanhai KakaОценок пока нет

- 5.uploads Downloads DOWN 8F012CFC1B79276CBrygram5 ParachuteДокумент1 страница5.uploads Downloads DOWN 8F012CFC1B79276CBrygram5 ParachutePhanhai KakaОценок пока нет

- 3.uploads Downloads DOWN 6103F52B8B4C6314Brygram3 ChoclateДокумент1 страница3.uploads Downloads DOWN 6103F52B8B4C6314Brygram3 ChoclatePhanhai KakaОценок пока нет

- 6.Uploads-downloads-DOWN 37079841C7A76AF8Brygram6 Tyre Creel RoomДокумент1 страница6.Uploads-downloads-DOWN 37079841C7A76AF8Brygram6 Tyre Creel RoomPhanhai KakaОценок пока нет

- Edmt281512 - Fbq-Eve - RZQS, RZQ SeriesДокумент212 страницEdmt281512 - Fbq-Eve - RZQS, RZQ SeriesPhanhai Kaka50% (2)

- 00057Документ31 страница00057Phanhai KakaОценок пока нет

- 4.uploads Downloads DOWN 3E392E620EB170DDBrygram4 IceskatingДокумент1 страница4.uploads Downloads DOWN 3E392E620EB170DDBrygram4 IceskatingPhanhai KakaОценок пока нет

- 12.Uploads-downloads-DOWN 384F58E2EE5DB995Brygram12 Lithium BattДокумент1 страница12.Uploads-downloads-DOWN 384F58E2EE5DB995Brygram12 Lithium BattPhanhai KakaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 2.uploads Downloads DOWN 71F3002C199B073ABrygram2 BiscuitДокумент1 страница2.uploads Downloads DOWN 71F3002C199B073ABrygram2 BiscuitPhanhai KakaОценок пока нет

- Edmt281536 FHQ Davma, RZQS, RZQ SeriesДокумент156 страницEdmt281536 FHQ Davma, RZQS, RZQ SeriesPhanhai KakaОценок пока нет

- Homework 17.Документ2 страницыHomework 17.Chris HeffnerОценок пока нет

- Klima Meat User Manual EngДокумент3 страницыKlima Meat User Manual EngAntonioMartinezОценок пока нет

- Miniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsДокумент2 страницыMiniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsMateusz SynowieckiОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- JOHN - DEERE - 360plus Rotary Harvesting UnitДокумент136 страницJOHN - DEERE - 360plus Rotary Harvesting UnitАлександр CheryОценок пока нет

- Texturing Methods PDFДокумент4 страницыTexturing Methods PDFAnoop KizhakathОценок пока нет

- 6stroke EngineДокумент5 страниц6stroke EngineMitesh KumarОценок пока нет

- 2 - 2011 570 Closed Book Exam (75Qs)Документ15 страниц2 - 2011 570 Closed Book Exam (75Qs)Sunny Thundil100% (3)

- Session 2Документ74 страницыSession 2Syed Shahzad AliОценок пока нет

- Flow Types: - Base of SpillwayДокумент6 страницFlow Types: - Base of Spillwaygizem cenikОценок пока нет

- Outdoor UnitsДокумент47 страницOutdoor UnitsSayeed AnwarОценок пока нет

- Plastic Molding TutorialДокумент32 страницыPlastic Molding TutorialSergio RodriguezОценок пока нет

- PC130-8 Parte 2Документ440 страницPC130-8 Parte 2Renata MansanoОценок пока нет

- CHAPTER 2 - Part 1 Air Conditioning System PDFДокумент77 страницCHAPTER 2 - Part 1 Air Conditioning System PDFazmie100% (1)

- Big Block Chevy Info - Grumpys Performance GarageДокумент104 страницыBig Block Chevy Info - Grumpys Performance GarageAsad Khan100% (1)

- Service Bulletin: Troubleshooting DTC P1456 and P1457Документ4 страницыService Bulletin: Troubleshooting DTC P1456 and P1457Vic3501Оценок пока нет

- Biddle - VRVДокумент31 страницаBiddle - VRVutzu_yooОценок пока нет

- JCB JS145W+JS160WTechnical DataДокумент36 страницJCB JS145W+JS160WTechnical DataMoataz SamiОценок пока нет

- FE700 Installation Manual Echo SounderДокумент58 страницFE700 Installation Manual Echo SounderNidhin.c.prakashОценок пока нет

- ch5 Limit Switches PDFДокумент208 страницch5 Limit Switches PDFkhaled tahaОценок пока нет

- Sunfolding Pneumatics White Paper 2020 07Документ8 страницSunfolding Pneumatics White Paper 2020 07Hilmi Dhiya UlhaqОценок пока нет

- 1327 751 102b - AS-Tronic Truck & Bus Repair Manual (10-, 12 - and 16-Speed Version Without ZF-Intarder Repair Level 3)Документ122 страницы1327 751 102b - AS-Tronic Truck & Bus Repair Manual (10-, 12 - and 16-Speed Version Without ZF-Intarder Repair Level 3)Сергей Миненко100% (8)

- Fast Metal Removal SolutionsДокумент124 страницыFast Metal Removal SolutionsvrjrОценок пока нет

- Valvula DesaireadoraДокумент4 страницыValvula DesaireadoracccОценок пока нет

- Gears PresentationДокумент33 страницыGears PresentationNaveen YadavОценок пока нет

- 5.3 Code, Standard and RegulationДокумент7 страниц5.3 Code, Standard and Regulationandrieysyah2525Оценок пока нет

- Format - CISДокумент8 страницFormat - CISgopichandallakaОценок пока нет

- WC67-160 3200 Bending Machine From JIUYING LydiaДокумент9 страницWC67-160 3200 Bending Machine From JIUYING LydiaSantiago LeivaОценок пока нет

- Design Calculation-Inia-Pergola 1Документ10 страницDesign Calculation-Inia-Pergola 1Glastal EngineersОценок пока нет

- Liebherr Hs DimensionsДокумент12 страницLiebherr Hs DimensionsLiebherrОценок пока нет

- A Creep Life Assessment Method For Boiler Pipes Using Small Punch Creep TestДокумент6 страницA Creep Life Assessment Method For Boiler Pipes Using Small Punch Creep TestAndrea CalderaОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)