Академический Документы

Профессиональный Документы

Культура Документы

Control Account

Загружено:

Miguel Ruiz TatajeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Control Account

Загружено:

Miguel Ruiz TatajeАвторское право:

Доступные форматы

FLUID POWER

HYDROCONTROL ENGINEERING TEAM

CONTROL ACCOUNT

here has been dramatic development in the world of proportional hydraulics in the past few

years. Yet not that long ago,

proportional electronic components were used exclusively by

only the largest manufacturers, and

even then only for the most technically

advanced market technologies or topof-the-range machines. Today, however,

the situation is very different.

Nowadays, low-technology markets

are ready to accept complex hydraulic

systems, with European machine manufacturers tending to apply proportional

control technology to medium- and

lower-range machines anyway.

The reasons behind this trend lie

first of all in the increasingly common

presence of electronic controls on the

machines. Electronic control systems

not only facilitate proportional

hydraulic parts installation but also aim

at totally controlling them, to enable

special functions and act as filters

between the operator and the controls,

which consequently enhances safety.

The global movement towards

improving machine ergonomics and

comfort should also be added to this,

which inevitably leads to removing all

hydraulic parts particularly control

valves from the operators workstation

and relying more and more on electric

remote controls.

Ergonomics, control and safety are

the driving forces behind proportional

hydraulics diffusion, as well as the goals

most sought after by every machine

Despite the benefits, new concepts in proportional hydraulics

have not been accessible to all until fairly recently, with lowtechnology machines preferring simplified and cheaper systems

manufacturer. It is, however, common

thinking that proportional systems

must be inevitably expensive and that

their cost/efficiency ratio should be

carefully evaluated.

Among other things, this belief is the

result of the fact that, until now, proportional electrohydraulic controls have

only been implemented on top-level

control valves, and load-sensing control

valves in particular. Therefore, the higher

control system costs had to be added to

the higher cost of the control valve itself.

Hydrocontrols answer

Hydrocontrol has been working to

respond to all of these considerations.

In particular, a practical solution has

been researched to improve the accessibility of proportional systems.

Hydrocontrol is today able to offer,

instead of a single product, a complete

development program aimed at increasing the use of proportional control

valves with cost-containment in mind

at the same time.

Hydrocontrol is well known all over

the world for its quality levels, technological innovation and massive product

range. Most of the biggest OEMs have

acknowledged its capabilities, which

include the most advanced design,

calculation, simulation and prototyping

skills to supplying the most suitable

solutions to a variety of requirements.

The company can nowadays rely on

its new resources and know-how and

has consequently increased its product

range, especially as far as proportional

products are concerned.

The new range has been added to an

already popular control valve. The HCMV99 is a load-sensing control valve

compensated in all its sections with

proportional electrohydraulic control,

which has been produced for a few years

and is popular among OEMs. Its construction solidity and sturdiness, original structure (patented) and control

fine-tuning and accuracy have made it

successful in a variety of fields.

New possibilities for existing products

To respond to the increasing demand

for competitively priced proportional

control units, increasingly used in simpler machines too, Hydrocontrol has

now developed a proportional electrohydraulic kit that can be used in all the

open-centre range control valves.

FLUID POWER

PREVIOUS PAGE: Despite its straightforward

design, the new HC-NVD2 guarantees

excellent control accuracy

FIGURE 1 (LEFT): The HC-MV99

electroproportional load-sensing valve

FIGURE 2 (BELOW): Electroproportional kit for

standard monoblock and stackable valves

FIGURE 3 (BOTTOM): Section of the patented

valve HC-NVD2

FIGURE 4 (RIGHT, CENTRE): Electronic devices

to complete Hydrocontrols proportional

hydraulics program

FIGURE 4 (FAR RIGHT): The HC-NVD2 valve is a

new concept in proportional hydraulics

This means that all of the existing

Hydrocontrol products (i.e. all the

monoblock and stackable control

valves, in all their flow rate versions

from 50-250 l/min) can now be

operated by a proportional electric

control system, via a special kit with two

pressure-reducing solenoid valves and

a feedback mechanical system. The

mechanical control-loop system

guarantees accurate spoolpositioning control with virtually no hysteresis at all.

This proportional kit is even

more interesting when you consider

that, in order to install it, control valve

modification is not required, and the

installation procedure only takes a few

minutes. This makes it easy to upgrade

all of the control valves previously sold

to the market and facilitates the job of

proportional concept. The key features

of the new HC-NVD2 product are control and simplicity. The new products

goal is to guarantee the same control

accuracy as the most sophisticated loadsensing systems, while maintaining the

characteristic design straightforwardness

of traditional open-centre control valves.

HC-NVD2s main strength is its design simplicity, which makes

it cost-efficient and exceptionally improves its reliability

all those who have to make existing

machines (especially truck cranes) suitable for radio controlling.

A new concept for a revolutionary product

However, the real strong point of the

new Hydrocontrol proportional control

program is a brand new control valve

the HC-NVD2. This is the result of a

truly innovating drive; of the desire to

start from square one and redesign the

This result was successfully achieved

by using patented new technology,

which based on the principle of

mechanical-hydraulic feedback guarantees perfect flow control and simultaneity of the various movements,

independently from load conditions.

This control valve, which mechanically and during manual control

behaves just like a traditional opencentre control valve when electrically

operated by the proportional coils has

control features exactly matching those

of the most sophisticated control systems.

The main strength of the product,

however, is its design simplicity, which

makes it cost-efficient and, at the same

time, exceptionally improves its reliability. It does not include any electronic

parts or sensors either, which can be easily damaged when exposed to sudden

temperature changes, mechanical vibration and external agents. In addition, it

does not include any extra compensating spools, and there are no long

hydraulic signals that might be sensitive

to contamination.

The internal components are kept

to a minimum so, consequently, the

possible causes of malfunction are

proportionally minimised too. Last, but

by no means least, its compact dimensions and neat design make it ideally

suitable for installation on medium- to

small-sized machines.

FLUID POWER

Compensator on working sections

Control devices to complete the program

A valve manufacturer in the area of proportional control products is expected

to present a range of accessories to go

with its control valves as well. For this

reason, Hydrocontrol has added a wide

range of control devices to its existing

program. In addition to its control

valves, two electronic remote controls

are also offered.

HC-MAS is a single-axis remote

control available with either voltage or

power outputs (with PWM proportional

valve, direct-control system). The easily

accessible adjustment trimmers enable

simple and immediate basic control

parameters to be set. HC-JS, meanwhile,

is the new, twin-axis remote control, also

available with voltage or power outputs,

and fully programmable for accurate

control-parameter selection.

These remote controls are available

with different handgrips and additional

on/off controls, while an extra proportional axis can be added via an adjusting

potentiometer roller.

Finally, several types of electronic

boards are available to complete this rich

product range. These are available for

PWM current control for a single

hydraulic section (two PWM outputs), for

two hydraulic sections (four PWM outputs) and for eight hydraulic sections (16

PWM outputs). Digital technology is

applied to some of these boards to

improve their programming and softwarepersonalisation features, implement

auxiliary functions and manage a higher

number of inputs and outputs.

In all respects, Hydrocontrol is an ideal

partner for the development of a proportional control system a partner able to

supply OEMs with not only all the standard components required in proportional

applications, but also highly innovative

products to combine cost-containment

with top performance and established

and renowned quality levels. iVT

The Engineering Team at Hydrocontrol has a

combined experience of 20 years, and is based at

the companys Bologna-based facilities in Italy

Вам также может понравиться

- BacharachДокумент2 страницыBacharachMiguel Ruiz TatajeОценок пока нет

- Power Train Service Manual Wagner Scooptrams: Inspection and MaintenanceДокумент3 страницыPower Train Service Manual Wagner Scooptrams: Inspection and MaintenanceMiguel Ruiz TatajeОценок пока нет

- Camión MT 444Документ3 страницыCamión MT 444José R. CastroОценок пока нет

- Wagner Scooptrams Operator's Manual Preventive Maintenance: Master Switch Wheels and TiresДокумент2 страницыWagner Scooptrams Operator's Manual Preventive Maintenance: Master Switch Wheels and TiresMiguel Ruiz TatajeОценок пока нет

- 3 - Comparativo AB - Jan.2014Документ1 страница3 - Comparativo AB - Jan.2014Miguel Ruiz TatajeОценок пока нет

- Specifications: Wagner Scooptrams Operator's Manual Preventive MaintenanceДокумент1 страницаSpecifications: Wagner Scooptrams Operator's Manual Preventive MaintenanceMiguel Ruiz TatajeОценок пока нет

- Wagner Scooptrams Operator's Manual Preventive Maintenance: ControlsДокумент1 страницаWagner Scooptrams Operator's Manual Preventive Maintenance: ControlsMiguel Ruiz TatajeОценок пока нет

- Tire DesmountingДокумент10 страницTire DesmountingMiguel Ruiz TatajeОценок пока нет

- MSDS R134aДокумент8 страницMSDS R134aMiguel Ruiz TatajeОценок пока нет

- MSDS R-22Документ7 страницMSDS R-22Miguel Ruiz TatajeОценок пока нет

- STSMДокумент278 страницSTSMMiguel Ruiz TatajeОценок пока нет

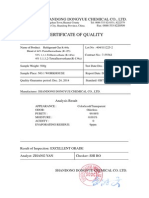

- Certificado de Calidad R-404A (55582)Документ1 страницаCertificado de Calidad R-404A (55582)Miguel Ruiz TatajeОценок пока нет

- Certificado de Calidad R-134 (55566)Документ1 страницаCertificado de Calidad R-134 (55566)Miguel Ruiz TatajeОценок пока нет

- Certificado de Calidad R-22 (55735)Документ1 страницаCertificado de Calidad R-22 (55735)Miguel Ruiz TatajeОценок пока нет

- Heat BalanceДокумент18 страницHeat Balancehafidhrahadiyan2Оценок пока нет

- Error Code For BeeДокумент4 страницыError Code For BeeMiguel Ruiz TatajeОценок пока нет

- Ejc 130DДокумент4 страницыEjc 130DMiguel Ruiz Tataje100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- SQA&TДокумент9 страницSQA&TSharat RamОценок пока нет

- TS 103 190 - V1.1.1 - Digital Audio Compression (AC-4) Standard PDFДокумент295 страницTS 103 190 - V1.1.1 - Digital Audio Compression (AC-4) Standard PDFHien Ly cong minhОценок пока нет

- Transmissions Corse MorseДокумент87 страницTransmissions Corse MorseVatsa MolanoОценок пока нет

- Distillation of Cutback Asphaltic D402 08Документ5 страницDistillation of Cutback Asphaltic D402 08Pedro AlvelaisОценок пока нет

- 2012 Volvo v60 80571 PDFДокумент400 страниц2012 Volvo v60 80571 PDFcosmin1987Оценок пока нет

- Techline La36 Atex Actuator User Manual EngДокумент88 страницTechline La36 Atex Actuator User Manual EngBeto LimaОценок пока нет

- NC Perfect Part Brochure 2011 WebДокумент12 страницNC Perfect Part Brochure 2011 WebMetrology Software Products Ltd (MSP)Оценок пока нет

- PLC Anupam Samanta 2010JE0976Документ64 страницыPLC Anupam Samanta 2010JE0976Anupam SamantaОценок пока нет

- SuiteB Implementer G-11Suite B Implementer's Guide To NIST SP 800-56A3808Документ33 страницыSuiteB Implementer G-11Suite B Implementer's Guide To NIST SP 800-56A3808jeffgr1776Оценок пока нет

- Telematrix PhoneДокумент55 страницTelematrix PhoneKris IribeОценок пока нет

- UI5 TrainingДокумент101 страницаUI5 TrainingSumit Abhishek0% (1)

- T3S 250 MA200 Im 1200..2400 3p F F: General InformationДокумент2 страницыT3S 250 MA200 Im 1200..2400 3p F F: General InformationYonas Dwiananta YuwonoОценок пока нет

- Branz Advisory Trower PartitionsДокумент6 страницBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- S7700 and S9700 V200R008C00 Configuration Guide - Ethernet SwitchingДокумент1 277 страницS7700 and S9700 V200R008C00 Configuration Guide - Ethernet SwitchingRahat MehmoodОценок пока нет

- Language, Dialects, and VarietiesДокумент5 страницLanguage, Dialects, and VarietiesMina ShinyОценок пока нет

- Mando Moga XP5 X PlusДокумент10 страницMando Moga XP5 X PlusVicente Manuel Vidal ValdesОценок пока нет

- 1393F-Eaton 9170plus WebДокумент86 страниц1393F-Eaton 9170plus Webdavidcevs89Оценок пока нет

- Gsxe Rotary Control Valve With Electric Actuation: Product Manual 26689 (Revision T, 3/2019)Документ44 страницыGsxe Rotary Control Valve With Electric Actuation: Product Manual 26689 (Revision T, 3/2019)Léandre Ettekri NdriОценок пока нет

- TDX Manual enДокумент28 страницTDX Manual enJack Duff100% (2)

- OM-CP - DATA LOOGER AND SOFTWARE OPERATING MANUAL v2.07.1Документ129 страницOM-CP - DATA LOOGER AND SOFTWARE OPERATING MANUAL v2.07.1Tania GonzalezОценок пока нет

- Meraki Product Manual Cloud ControllerДокумент124 страницыMeraki Product Manual Cloud ControllerJefferson Arandas Prado100% (1)

- QP 06 Calibration of IMTEДокумент3 страницыQP 06 Calibration of IMTEShanmuga PrakashОценок пока нет

- BWare English Brochure en-LRДокумент4 страницыBWare English Brochure en-LRJorge Palma LaraОценок пока нет

- Rack ManualДокумент29 страницRack ManualrasgeetsinghОценок пока нет

- Password Recovery Procedure For The Cisco 3600 and 3800 Series Routers - CiscoДокумент9 страницPassword Recovery Procedure For The Cisco 3600 and 3800 Series Routers - CiscoDani Kirky YlaganОценок пока нет

- pmg317 t20bДокумент284 страницыpmg317 t20bRolando Falla0% (1)

- Tags Description - Meaning - DefinitionДокумент23 страницыTags Description - Meaning - DefinitionArun MohanarajОценок пока нет

- API 560 InspectionДокумент4 страницыAPI 560 InspectionaszlizaОценок пока нет

- Check List of SAS-Substation Automation SystemДокумент5 страницCheck List of SAS-Substation Automation SystemSanthosh Kumar VinayagamОценок пока нет

- E78-900M22S Usermanual EN v1.3Документ28 страницE78-900M22S Usermanual EN v1.3navivoc270Оценок пока нет