Академический Документы

Профессиональный Документы

Культура Документы

A59

Загружено:

Guillermo Vasquez0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров4 страницыThis document provides summaries for 26 articles related to modeling and optimization of grinding and flotation processes in mineral processing. The articles cover topics like prediction of power draw in grinding circuits, cleaner energy approaches, ball mill modeling, breakage mechanisms in tumbling mills, measurement of grinding media wear, modeling the influence of slurry on power draw, froth-based modeling of batch flotation, optimization of reagent dosages, and effect of ions on sphalerite flotation.

Исходное описание:

titulos de procesamientos de minerales

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides summaries for 26 articles related to modeling and optimization of grinding and flotation processes in mineral processing. The articles cover topics like prediction of power draw in grinding circuits, cleaner energy approaches, ball mill modeling, breakage mechanisms in tumbling mills, measurement of grinding media wear, modeling the influence of slurry on power draw, froth-based modeling of batch flotation, optimization of reagent dosages, and effect of ions on sphalerite flotation.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров4 страницыA59

Загружено:

Guillermo VasquezThis document provides summaries for 26 articles related to modeling and optimization of grinding and flotation processes in mineral processing. The articles cover topics like prediction of power draw in grinding circuits, cleaner energy approaches, ball mill modeling, breakage mechanisms in tumbling mills, measurement of grinding media wear, modeling the influence of slurry on power draw, froth-based modeling of batch flotation, optimization of reagent dosages, and effect of ions on sphalerite flotation.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

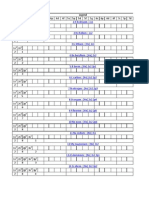

A59.

90 Comparison of Prediction Models for Power Draw in

Grinding and Flotation

Processes in a Gold Treatment Plant.

Author(s): Shu Dong, et al.

Source: Journal of Chemical Engineering of Japan (2016) 49(2): 204210.

A59.138 Cleaner energy for cleaner production: modelling,

simulation, optimisation

and waste management.

Author(s): Yong, J.Y., Kleme, J.J., Varbanov, P.S. and Huisingh, D.

Source: Journal of Cleaner Production (2016). 111 (Part A): 1-16.

A59.140 Development of a novel methodology to determine

mill power draw.

Author(s): Bbosa, L. S., Govender, I., and Mainza, A.

Source: International Journal of Mineral Processing (2016). 149: 94103.

A59.142 Comminution mechanisms, particle shape evolution

and collision

energy partitioning in tumbling mills.

Author(s): Cleary, P., and Morrison, R.

Source: Minerals Engineering (2016). 86: 75-95.

A59.149 A closer look at increasing HPGR efficiency through

reductions in edge effect.

Author(s): Knorr, B., Herman, V., and Whalen, D.

Source: Minerals and Metallurgical Processing Journal (2016). 33(1),

1-6.

A59.153 A discussion on the measurement of grinding media

wear.

Author(s): Massola, C.P.

Source: Journal of Materials Research and Technology (2016). 7

pages.

A59.155 Modelling the influence on power draw of the slurry

phase in

Autogenous (AG), Semi-autogenous (SAG) and ball mills.

Author(s): Morrell, S.

Source: Minerals Engineering (2016). 89:148-156.

A59.161 A specific energy-based ball mill model: From batch

grinding to

continuous operation.

Author(s): Shi, F., and Xie, W.

Source: Minerals Engineering (2016). 86, 66-74.

A59.168 An application of breakage mechanics for predicting

energysize

reduction relationships in comminution.

Author(s): Zhang, C., Nguyen, G. D., and Kodikara, J.

Source: Powder Technology (2016). 287: 121-130.

A59.170 Ore impact breakage characterisation using mixed

particles in wide size range.

Author(s): Zuo, W. and Shi, F.

Source: Minerals Engineering (2016) 86: 96-103.

A59.176 Critical copper concentration in sphalerite flotation:

Effect of

temperature and collector.

Author(s): Albrecht, T., Addai-Mensah, J. and Fornasiero, D.

Source: International Journal of Mineral Processing (2016) 146:15-22.

A59.177 Removal of sulfate ions by dissolved air flotation

(DAF) following

precipitation and flocculation.

Author(s): Amaral Filho, J., Azevedo, A., Etchepare, R., and Rubio, J.

Source: International Journal of Mineral Processing (2016). 149: 1-8.

A59.178 A Study on the Modified Flotation Parameters and

Selectivity Index in Copper Flotation.

Author(s): Azizi, A.

Source: Particulate Science and Technology (2015).

A59.181 A novel approach for flotation recovery of copper and

molybdenite from a copper-arsenic ore.

Author(s): Cao, Z.-F., Qiu, P., Zhong, H. et al.

Source: Metallurgical Research and Technology (2016). 113(1): 103.

A59.182 Review of the flotation of molybdenite. Part I:

Surface properties and floatability.

Author(s): Castro, S., Lopez-Valdivieso, A. and Laskowski, J.

Source: International Journal of Mineral Processing. (2016). 148: 4858.

A59.182 Review of the flotation of molybdenite. Part I:

Surface properties and floatability.

Author(s): Castro, S., Lopez-Valdivieso, A. and Laskowski, J.

Source: International Journal of Mineral Processing. (2016). 148: 4858.

A59.186 Adsorption of sulfide ions on cerussite surfaces and

implications for flotation.

Author(s): Feng, Q., Wen, S., Zhao, W., et al.

Source: Applied Surface Science (2016) 360 (Part A): 365-372.

A59.187 Modeling of Flotation Process -An Overview of

Different Approaches

Author(s): Gharai, M. and R. Venugopal

Source: Mineral Processing and Extractive Metallurgy Review (2016)

37(2): 120133

A59.188 Application of Statistical and Intelligent Techniques

for Modeling of Metallurgical Performance of a Batch Flotation

Process.

Author(s): Jahedsaravani, A., Marhaban, M. and Massinaei, M.

Source: Chemical Engineering Communications (2016). 203(2): 151160.

A59.189 Froth-based modeling and control of a batch flotation

process.

Author(s): Jahedsaravani, A., Marhaban, M., Massinaei, M. et al.

Source: International Journal of Mineral Processing (2016). 146: 9096.

A59.192 Effect of flotation froth properties on froth rheology.

Author(s): Li, C., Runge, K., Shi, F., and Farrokhpay, S.

Source: Powder Technology (2016). 294: 55-65.

A59.198 Optimization Of Air-Injection Spargers For Column

Flotation

Applications.

Author(s): Mankosa, M., Wasmund, E., Ramirez, V. and Luttrell, G.

Source: SME Annual Meeting (2016), 16-149, 6 pages.

A59.199 The mechanism of pyrite depression at acidic pH by

lignosulfonatebased biopolymers with different molecular

compositions.

Author(s): Mu, Y., Peng, Y., and Lauten, R.A.

Source: Minerals Engineering (2016). 92: 37-46.

A59.203 Flotation column performance optimisation based on

imperialist

competitive algorithm.

Author(s): Nakhaei, F., Irannajad, M. and Yousefikhoshbakht, M.

Source: International Journal of Mining and Mineral Engineering

(2016). 7(1): 117.

A59.204 Real-time optimization for a laboratory-scale

flotation column.

Author(s): Navia, D., Villegas, D., Cornejo, I., and de Prada, C.

Source: Computers and Chemical Engineering (2016). 86: 62-74.

A59.212 Predictive control of the bubble size distribution in a

two-phase pilot flotation column.

Author(s): Riquelme, A., Desbiens, A., del Villar, R. and Maldonado,

M.

Source: Minerals Engineering (2016). 89: 71-76.

A59.217 Reagent dosages control based on bubble size

characteristics for

flotation process.

Author(s): Binfang Cao; Yongfang Xie, Chunhua Yang et al.

Source: IET Control Theory & Applications. (2016) IEEE,

A59.219 The Adsorption of Cu Species onto Pyrite Surface and

Its Effect on Pyrite Flotation.

Author(s): Yang, B., Tong, X., Deng, Z. and Lv, X.

Source: Journal of Chemistry (2016).

A59.221 Experimental Study on New Process of High

Efficiency Flotation of Copper Molybdenum Ore with Low

Grade:

Author(s): Ye, Z., Huang, H. and Cao, X.

Source: Mine Engineering. (2015) 3(4): 179-187

A59.222 Particle entrainment model for industrial flotation

cells

Author(s): Yianatos, J. and F. Contreras

Source: Powder Technology (2016) 197(3): 260-267

A59.223 Recognition of flotation working conditions through

froth image

statistical modeling for performance monitoring.

Author(s): Zhang, J., Tang, Z., Liu, J. et al.

Source: Minerals Engineering (2016). 86: 116-129.

A59.225 Combined fuzzy based feedforward and bubble size

distribution based feedback control for reagent dosage in

copper roughing process.

Author(s): Zhu, J., Gui, W., Liu, J., Xu, H. and Yang, C.

Source: Journal of Process Control (2016). 39: 50-63.

A59.226 Complexing collecting agent for selective flotation of

chalcopyrite.

Author(s): Zimbovsky, I., Ivanova, T., Chanturia, V. and Chanturia, E.

Source: Journal of Mining Science (2015). 51(3): 568-572.

A59.316 The effect of calcium, magnesium, and sulphate ions

on the surface properties of copper activated sphalerite.

Author(s): Ejtemaei, M., Plackowski, C. and Nguyen, A.V.

Source: Minerals Engineering (2016). 89: 42-51.

Вам также может понравиться

- Daftar Pustaka GasifikasiДокумент3 страницыDaftar Pustaka Gasifikasisetianto wibisonoОценок пока нет

- Das 2010Документ26 страницDas 2010IqraОценок пока нет

- Daftar Pustaka: REZA HENDY DJOERKAEFF, Prof. Ir. Wahyudi Budi Sediawan, S.U., PH.DДокумент4 страницыDaftar Pustaka: REZA HENDY DJOERKAEFF, Prof. Ir. Wahyudi Budi Sediawan, S.U., PH.DAngga SaputraОценок пока нет

- Parametric Optimization of MIG Welding On 316L Austenitic Stainless Steel by Grey-Based Taguchi MethodДокумент11 страницParametric Optimization of MIG Welding On 316L Austenitic Stainless Steel by Grey-Based Taguchi MethodNarendra KalerОценок пока нет

- 1-s2.0-S0301479717307521-Main - PDF Eliminacin de Metales Por NanofiltracionДокумент6 страниц1-s2.0-S0301479717307521-Main - PDF Eliminacin de Metales Por NanofiltracionJaime CazaОценок пока нет

- HSC Chemistry Literature References PDFДокумент57 страницHSC Chemistry Literature References PDFMhd Nuh HudawiОценок пока нет

- PHD Thesis Catalogue Year Student Thesis Title at 20/08/2012Документ8 страницPHD Thesis Catalogue Year Student Thesis Title at 20/08/2012Deepak AnandanОценок пока нет

- Samuel FrimpongДокумент14 страницSamuel Frimpongdunlut pelemОценок пока нет

- Referencia BibliograficaДокумент4 страницыReferencia BibliograficaDaniel Oliveira de FariasОценок пока нет

- B Hitesh Paper 2Документ17 страницB Hitesh Paper 2Hitesh RoyalОценок пока нет

- SpringerДокумент10 страницSpringerBalamurugan KarnanОценок пока нет

- Jiang 2018Документ9 страницJiang 2018Dr. Khan MuhammadОценок пока нет

- Janak NCITM PDFДокумент4 страницыJanak NCITM PDFjanakОценок пока нет

- Explaining Relationships Among Various Coal Analyses With Coal Grindability Index by Random ForestДокумент7 страницExplaining Relationships Among Various Coal Analyses With Coal Grindability Index by Random ForestAlan KinataОценок пока нет

- Khurram Shahzad, PH.DДокумент7 страницKhurram Shahzad, PH.DTalha MughalОценок пока нет

- New Microsoft Word DocumentДокумент53 страницыNew Microsoft Word DocumentSourav SarkarОценок пока нет

- Daftar Pustaka FixДокумент2 страницыDaftar Pustaka FixSetyo MasОценок пока нет

- Publicações Com DEAДокумент648 страницPublicações Com DEAAnonymous b0cKPzDMqfОценок пока нет

- Development of A New Supplementary Cementitious Material From The PDFДокумент10 страницDevelopment of A New Supplementary Cementitious Material From The PDFBrian FuentesОценок пока нет

- 10.1016@j.matpr.2019.11.257AA2024 andAA6061 ANOVAДокумент5 страниц10.1016@j.matpr.2019.11.257AA2024 andAA6061 ANOVAV.v. TaguisОценок пока нет

- Exploring Ventilation Efficiency in Poultry BuildingsДокумент6 страницExploring Ventilation Efficiency in Poultry BuildingsgepsizultaОценок пока нет

- 13 PJGM 13 de 13Документ3 страницы13 PJGM 13 de 13gladekarpinskiОценок пока нет

- ReferencesДокумент4 страницыReferencesned starkОценок пока нет

- Daftar Pustaka BagusДокумент3 страницыDaftar Pustaka BagusarizalОценок пока нет

- Annexes AДокумент5 страницAnnexes AHayet BoudjemaaОценок пока нет

- BiblioДокумент10 страницBiblioAlisonSanchez7Оценок пока нет

- Casting Alloy Design and ModificationДокумент3 страницыCasting Alloy Design and ModificationffazlaliОценок пока нет

- Engineering Science and Technology, An International JournalДокумент7 страницEngineering Science and Technology, An International JournalGonzalo Paredes ContrerasОценок пока нет

- Mathematical Modeling For Radial Overcut On Electrical Discharge Machining of Incoloy 800 by Response Surface MethodologyДокумент10 страницMathematical Modeling For Radial Overcut On Electrical Discharge Machining of Incoloy 800 by Response Surface MethodologySai SrinivasОценок пока нет

- BibliographyДокумент4 страницыBibliographyFathОценок пока нет

- Gating and RiseringДокумент12 страницGating and RiseringCarlos Ortega JonesОценок пока нет

- Characterization of Metal Aerosols in PM10 From Urban, Industrial, and Asian Dust SourcesДокумент13 страницCharacterization of Metal Aerosols in PM10 From Urban, Industrial, and Asian Dust SourcesANAS OTMANIОценок пока нет

- Yao 2019Документ11 страницYao 2019talk storeОценок пока нет

- ReferencesДокумент6 страницReferencesMuhammad FaisalОценок пока нет

- Academic Qualifications: Responsibilities at IIT MadrasДокумент5 страницAcademic Qualifications: Responsibilities at IIT MadrasdkannanapkОценок пока нет

- List of Publications I. Paper Published in JournalsДокумент1 страницаList of Publications I. Paper Published in JournalsDilipОценок пока нет

- Reference Format IOP Conference SeriesДокумент2 страницыReference Format IOP Conference SeriesSaznizam Sazmee SinohОценок пока нет

- Determination of Optimum Machining Parameters For Face Milling Process of Ti6A14V Metal Matrix CompositeДокумент13 страницDetermination of Optimum Machining Parameters For Face Milling Process of Ti6A14V Metal Matrix CompositeMainak PalОценок пока нет

- Daftar PustakaДокумент2 страницыDaftar PustakaSyafrizal FauzyОценок пока нет

- 2016-References CitedДокумент4 страницы2016-References Citedsrikant_revurОценок пока нет

- Powder Characterisation Techniques and Effects of Powder Characteristics On Part Properties in Powder-Bed Fusion ProcessesДокумент28 страницPowder Characterisation Techniques and Effects of Powder Characteristics On Part Properties in Powder-Bed Fusion ProcessesRaj RajeshОценок пока нет

- Experimental Study On The Influence ofДокумент12 страницExperimental Study On The Influence ofAnon PuayuanОценок пока нет

- L.D College of EngineeringДокумент16 страницL.D College of Engineeringsarvaiya akshayОценок пока нет

- LBW OptimizationДокумент11 страницLBW Optimizationfathi.alfazaniОценок пока нет

- Daftar PustakaДокумент4 страницыDaftar PustakaI Gde Dharma AtmajaОценок пока нет

- 预测铜价格通过应用强大的人工智能技术Документ11 страниц预测铜价格通过应用强大的人工智能技术赵一霏Оценок пока нет

- ReferencesДокумент10 страницReferencesPalash SwarnakarОценок пока нет

- Influence Cutting Parameters On The Surface Quality andДокумент15 страницInfluence Cutting Parameters On The Surface Quality andLincoln BrandãoОценок пока нет

- Mohdyusuf2021 Tribological Behaviour of 316L Stainless Steel Additively Manufactured byДокумент11 страницMohdyusuf2021 Tribological Behaviour of 316L Stainless Steel Additively Manufactured byVivekananda SubramaniОценок пока нет

- Feature Extraction and Selection From Acoustic Emission Signals With An Application in Grinding Wheel Condition MonitoringДокумент11 страницFeature Extraction and Selection From Acoustic Emission Signals With An Application in Grinding Wheel Condition MonitoringSeraph LinОценок пока нет

- Wear Characterization and Modelling of MN Steel Liners Used in Rock CrushersДокумент3 страницыWear Characterization and Modelling of MN Steel Liners Used in Rock CrushersRahul SinhaОценок пока нет

- Daftar Pustaka: Chemical Physics, 7, Pp. 1103-1112. Doi: 10.1063/1.1750380Документ10 страницDaftar Pustaka: Chemical Physics, 7, Pp. 1103-1112. Doi: 10.1063/1.1750380kirdipОценок пока нет

- Theoretical Modeling and Experimental VerificationДокумент8 страницTheoretical Modeling and Experimental Verificationrroma_1983Оценок пока нет

- Design and Optimization of Automotive Multi-Leaf Spring by Finite Element MethodДокумент10 страницDesign and Optimization of Automotive Multi-Leaf Spring by Finite Element MethodShaik Darban RayanОценок пока нет

- Analysis and Optimization of Gating System For Commutator End BracketДокумент17 страницAnalysis and Optimization of Gating System For Commutator End BracketManjunath ReddyОценок пока нет

- 09JSTVol252Apr2017 JST-0634-2016R1 pg497-506 2Документ11 страниц09JSTVol252Apr2017 JST-0634-2016R1 pg497-506 2Rajiv RanjanОценок пока нет

- Mechanical Properties and ApplicationДокумент2 страницыMechanical Properties and ApplicationaramikaelatanОценок пока нет

- The Mechanics of Machining Ultrafine-Grained Grade 2 TiДокумент2 страницыThe Mechanics of Machining Ultrafine-Grained Grade 2 TiMike LiebermannОценок пока нет

- Effect of Air Abrasion On The Marginal Configuration of Titanium Crowns After CastingДокумент5 страницEffect of Air Abrasion On The Marginal Configuration of Titanium Crowns After CastingNengsi YusufОценок пока нет

- Advances in Thermal Spraying: Proceedings of the Eleventh International Thermal Spraying Conference, Montreal, Canada September 8-12, 1986От EverandAdvances in Thermal Spraying: Proceedings of the Eleventh International Thermal Spraying Conference, Montreal, Canada September 8-12, 1986Оценок пока нет

- IGCSE Chemistry NotesДокумент40 страницIGCSE Chemistry Notestasha100% (5)

- Aptitude TestДокумент3 страницыAptitude TestEmmanuelОценок пока нет

- Astm D5600Документ4 страницыAstm D5600Abu WildanОценок пока нет

- SDYC 2011 Academic BookletДокумент124 страницыSDYC 2011 Academic BookletsuhangdageekОценок пока нет

- Welding Technology WFC 112a-1Документ74 страницыWelding Technology WFC 112a-1ibrahim mustaphaОценок пока нет

- Engineering MaterialsДокумент7 страницEngineering MaterialsVinoth MalaikaniОценок пока нет

- Kalviseithi 11th STD Chemistry School Guides SampleДокумент119 страницKalviseithi 11th STD Chemistry School Guides SampleslogeshwariОценок пока нет

- IB Chemistry SL ReviewДокумент120 страницIB Chemistry SL ReviewShamwow_12389% (9)

- AluminumДокумент5 страницAluminumBlueOneGaussОценок пока нет

- Arc Welding Types MP IIДокумент40 страницArc Welding Types MP IISyedUbaidRehman100% (1)

- Methods of PurificationДокумент5 страницMethods of PurificationFatema KhatunОценок пока нет

- Class 12th Chemistry Chapter 1 (The Solid State) Important Unsolved Questions PDFДокумент7 страницClass 12th Chemistry Chapter 1 (The Solid State) Important Unsolved Questions PDFTreesa TomОценок пока нет

- Red Book Book 3 Commercial Installation GuideДокумент232 страницыRed Book Book 3 Commercial Installation GuideDarren Bkaer67% (3)

- Name - Bee Bee Iqra Department - Msc. Chemistry: Sem - 2 SemesterДокумент15 страницName - Bee Bee Iqra Department - Msc. Chemistry: Sem - 2 SemesterAna PattinsonОценок пока нет

- Engineering Materials Data SheetДокумент6 страницEngineering Materials Data Sheetrajarao1234Оценок пока нет

- Nickel and Its AlloysДокумент164 страницыNickel and Its Alloysgacm98100% (2)

- Patuan David Parulian BatubaraДокумент3 страницыPatuan David Parulian BatubaraReigina Zhazha AnastaciaОценок пока нет

- Electronegativities of The Elements (Pauling Scale) : General Trends in ElectronegativityДокумент1 страницаElectronegativities of The Elements (Pauling Scale) : General Trends in ElectronegativityS Linaili RahmahОценок пока нет

- Question 2 MEPДокумент23 страницыQuestion 2 MEPlazyreaderr67% (3)

- Casting MaterialsДокумент42 страницыCasting MaterialsTirta BudiawanОценок пока нет

- Electron ConfigurationДокумент24 страницыElectron Configurationarunasagar_2011Оценок пока нет

- FE 2200 Spark Resistant Fan ConstructionДокумент2 страницыFE 2200 Spark Resistant Fan ConstructionAvery OppegardОценок пока нет

- FilosilicatosДокумент111 страницFilosilicatosÁlvaroAresApazaVascuenceОценок пока нет

- D - Block ElementДокумент2 страницыD - Block ElementShovon BiswasОценок пока нет

- APCO Silent Check PDFДокумент8 страницAPCO Silent Check PDFtanvir04169Оценок пока нет

- MJC 2011 H2 Chem Paper 2 NO ANSWERSДокумент21 страницаMJC 2011 H2 Chem Paper 2 NO ANSWERSonnoezОценок пока нет

- An Inquiry Into The Reko Diq Mine ScandalДокумент37 страницAn Inquiry Into The Reko Diq Mine ScandalKamran Tahir100% (1)

- Duplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasДокумент40 страницDuplex Coatings, TSA, ZN Sprayed Coating, Sealer, Duplex, Ships, Oil&gasXiaohua Chen100% (1)

- Lab 3 ReportДокумент5 страницLab 3 ReportPaula HoОценок пока нет

- KITZ Bronze Brass Valves E-101-11Документ0 страницKITZ Bronze Brass Valves E-101-11uyab1989Оценок пока нет