Академический Документы

Профессиональный Документы

Культура Документы

Handi Instr Twob

Загружено:

notjustsomeoneАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Handi Instr Twob

Загружено:

notjustsomeoneАвторское право:

Доступные форматы

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 1

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Warning and Disclaimer: Make sure that the firearm is unloaded before going further. Also, be aware

that if you modify firearms from factory stock, you are likely voiding your warranty. If you can't afford to

try this project as a learning experience, DON'T ATTEMPT IT. Important: NEVER, EVER HAVE LIVE

AMMO of the caliber of the firearm you are working on IN THE SAME ROOM. Only inert "Dummy" rounds,

"Action Proving rounds or "Snap-Caps" should be allowed in your work area. Be SAFE, not sorry.

AND MOST IMPORTANT OF ALL IF YOU ARENT WILLING TO BEAR ALL THE LIABILITY AND

RESPONSIBILITY OF CHECKING FOR SAFETY AND PROPER FUNCTION AFTER ANY TRIGGER

WORK, DONT ATTEMPT IT. YOU ALONE ARE LIABLE FOR ANY INJURY OR DAMAGE.

Part II - Lightening the trigger pull and reassembly.

Overview:

There is no magic to lightening the trigger pull weight on the Handi-Rifle. To bring the pull weight down to

an acceptable 3.25 - 2.75 lbs all you have to do is a complete light polish and lubrication of the internals.

Basically you are just overcoming the effects of friction on the rough finish of some factory parts. Only a small

amount of smoothing on any one part is required to achieve an overall effect that is much better than the

factory pull. It is essential that you dont just grind away at the internal parts; take care and read these

instructions through completely before you begin. If done at the factory this handwork would add a quite a

few dollars to the cost of these firearms and truthfully, for a majority of the intended market, the heavier trigger

isnt an issue. However many shooters who discover how handy the Handi-Rifle is want to take performance

to the level of a truly great hunting or target gun with a lighter trigger pull.

Heres a tip:

This next step is not necessary and can be skipped without affecting your results at all. I did it because I was

going to do a bunch of Handi triggers and I wanted a better fixture for disassembly. I ordered two transfer

punches from MSC Industrial for about two dollars each. Transfer punches are prick punches that come in exact

sizes, in this case 3/32 and 3/16 like the two pin sizes used in the Handi action. I clamped my frame (padded)

against a piece of 1/4 thick by 2 tall aluminum stock I bought at the hardware store. Then I ran the transfer

punches through the frame and rapped them with my hammer to make exactly located marks to drill my slightly

oversized holes (7/64 and 7/32). Sand the holes and the rest of the aluminum smooth when finished.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 2

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

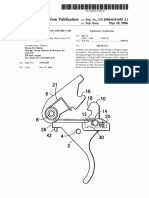

First, assemble your hammer, trigger and lifter/striker assembly on their 3/16 splined pins on the outside of

the right side your frame. To obtain contrast for photography, I did the same using my aluminum fixture. The

first photo below shows the parts in the hammer down postion - the second shows them at the full cock

position. Moving them gently to avoid scratching your frame side, work your parts in the same way and pay

close attention to how they bear on each other. These are the areas you must polish to ease friction in the

trigger, hammer and action parts.

All pin holes, pins and bearing surfaces must be smoothed while taking care not to enlarge pin holes or

reduce the pins they ride on by more than one or two thousandths of an inch. Any more than that and

undesirable play and slop will creep into the trigger pull. The areas highlighted below in yellow will require

polishing; the exact tools and methods best used will be shown in the pages that follow.

A Arrows indicate an area to polish that is out of view - in this case the

slot in the barrel catch that the lifter is sitting in.

B This arrow indicates the hole area in the lifter that you cant see.

C Arrow indicates the flat sides of the extension, including the back side

that you cant see. I only had to polish this part on one of the three

Handis I worked, but do inspect it for rough spots.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 3

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Polish all three 3/16 splined pins. Polish the pins by locking the splined end in a hand drill and spinning

them in LIGHTLY held 600 grit wet sandpaper. Work the sandpaper back and forth so it doesnt stay in

one spot. Note the two shiny rub marks from roughness of factory parts on the unpolished pin in my hand

in the first photo below. This roughness is what we want to eliminate throughout the action.

Gauge your pins with calipers before polishing. Even if they dont get as shiny as the one in the photo,

stop when you have removed a max .002 of material.

600 grit wet sandpaper wrapped around the 5/32 punch does nicely to polish the insides of holes on the

hammer, trigger, lifter, extension and catch. Use a popsicle stick and sandpaper to smooth any rough

spots in the slot inside the disassembled barrel catch. Remember that you are lightly smoothing, not

enlarging the holes.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

When the pins and holes are polished, reference

the diagram from page 3 and remember the

surfaces that bore on each other when you

assembled those parts outside your frame. Polish

these surfaces with your Dremel using a round felt

polishing wheel and a fine metal polish. I used the

Flitz polish shown. DONT POLISH HOOK OF

THE HAMMER WITH THE DREMEL. BE VERY

CAREFUL TO JUST LIGHTLY POLISH THE SEAR

BY DREMEL, THEYLL BOTH BE POLISHED

WITH A STONE IN THE NEXT STEP.

Polishing gets those felt Dremel wheels

black fast, but they last a LONG time. Spin

in a rag to remove build-up, then apply

fresh polish.

Note how rough this surface of the

hammer is. The surface Im pointing to

only bears on the sear section of the

trigger while cocking, but once you stone

the sear smooth, why would you want it

to rub over and over on a rough surface?

Pg. 4

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

This surface of the lifter that the hammer

bears on when pushing it to the fire

position must be polished to a slick finish.

Polish this area of the sear the hammer

rides on while cocking slick with the

Dremel. Dont go past the area on the tip

indicated by the yellow line.

Also notice how bright and smooth that

section is after polishing. Im polishing the

hammer tip that pushes the lifter up here.

It needs a real slick finish as well. Work

around the tip and polish the top before

finishing.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 5

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

If your pull was less than four pounds before disassembly, the steps on this page regarding stoning

the hammer and sear should NOT be done until you reassemble and check pull weight. You cant

go back if you take the pull down too light without buying a new hammer and trigger/sear. So if your

weight was less than four pounds, go on to the lubrication and reassembly instructions, check that

pull weight and, if it is still too high, come back and JUDICIOUSLY go through these stoning steps.

Also, correctly stoning angles on the tiny areas of sears and hammers is an artform unto itself that

gunsmiths study for years. A little goes a long way, so proceed with caution.

The angles you are going to stone on the sear and hammer

are fairly easy, but you are only going to SMOOTH the

surfaces at the angles shown, not re-cut them. And a lot will

depend

figure

onon

your

your

specific

specific

hammer

hammer

and

and

trigger.

trigger.

Use

Use

a magnifier

a magnifier

and inspect them. The hammer hook Iatscanned

right is not

at right

a perfect

was

90 degrees

not

a perfectwhen

90 degrees,

enlarged.

butI stoned

two I worked

the hammer

were. Ilocked

still stoned

upside-down

this

one like the

in arest,

padded

locked

vise

in with

a padded

the square

vise with

stone

thepressed

square

against

stone

pressed

the faceagainst

of the ithook.

like it was

Give90

20degrees.

strokes or

Then

so atI angled

the

angle

the

stone

indicated

and gave

by the

20 short

strokes

yellow

or soline.

at the

If you

breaking

dont feel

angle

you

have the skill

indicated

by the

to keep

short your

yellow

strokes

line. Ifeven

you dont

at thisfeel

angle

youacross

have

the skill

whole

to surface

keep your

face

strokes

- DONT

even

tryat

it. these angles across the

whole surface face - DONT try it.The two surfaces I

smoothed on the trigger sear tip are detailed below.

Dont forget to keep your stone saturated with

honing oil! And keep those strokes consistent

and parallel to the surface angle.

I would only stone the hammer hook as indicated above and give the sear about 10 to 20 light strokes

at the 90 angle shown below, then reassemble and check pull weight. If still too heavy give the sear

section about 20 more light strokes on your oiled stone. Make sure to keep the whole surface you are

stoning in contact at the correct angle for the complete stroke to avoid rounding off the corners of the

engagement surface. Light strokes means almost no downward pressure on the part at all.

90

The photo at right

shows how to hold

the trigger and

stone correctly, not

the exact angle to

stone...

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 6

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Lubrication, reassembly and safety checks.

Lubricate as directed on the package with a high

grade trigger lube like Brownells Action Lube Plus,

the moly lube sold by Midway USA from Wheeler

Engineering, Wilson Combats Optima Lube or

Tetragun "G" Grease. I prefer the Brownells lube

and the thicker greases in general. Its not that

easy to access the Handi action and the thicker

greases stay put for a long time. Also, greases

require that you pay extra attention in the field to

avoid dirt and trash entering the top of the hammer

slot and mucking the action up.

Brownells permanent lube, Action Magic II, would

seem ideal for a hard-to-get-to action, but most

shooters like to clean their bores with solvents that

tend to leech out later, and it shouldnt be used. If

petroleum based solvents mix with the dry Action

Magic II, a gummy mess results. Stick with moly

greases and similar products.

Use generous amounts of lube at this point, as the handling

required to reassemble the action parts will tend to remove a

good bit of what you apply.

I keep a couple of cotton swabs and paper towels handy for

removal of excess lubricant.

Use toothpicks to spread the

lube inside holes and evenly

across all surfaces that you

polished. Set pieces aside

after lubing on a piece of

paper towel ready to be

reassembled.

Right before inserting the pins

back into the frame, dip the

ends into your grease. The

extra will be left outside the

frame as it slides into the hole.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 7

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

The arrow at left points to the lobe of the barrel catch lever that must engage

the barrel catch. When reassembling, make sure that the barrel catch lever

correctly engages the barrel catch/lifter assembly before going further or you

will have to diassemble again and it can be frustrating. If correctly

assembled, grasping the barrel catch lever and working it up and down will

cam the catch/lifter assembly back and forth smoothly. If not, try again until

you get the proper alignment of the "teeth" of the lever to the barrel catch.

Assemble the lubricated barel catch, lifter and lifter spring into a unit using

your slave pin. Put some action grease on the slave pin first and it wont fall

while you are trying to fit the catch/lifter assembly into place.

This is not easy to do, so be patient. In

these two views of the catch/lifter

assembly, note the thinner arrows

pointing to where the legs of the lifter

spring must sit in the two parts.

The thicker arrows point to the gear

recess that the lobe on the barrel

catch lever must engage to function

correctly.

This view shows the frame upside down looking into the

triggerguard slot. Insert the unsplined end of a 3/16 pin into

the topmost hole in the LEFT side of the frame.

Once you have aligned the frame holes and the catch/lifter

assembly, insert the 3/16 pin until the splines touch the

frame, pushing the slave pin out the right frame side. Work

the barrel catch lever up and down to see if the barrel catch

cams back and forth. If it does, go on to the next assembly

step. If not, insert the slave pin back in the right frame side

hole and use a punch to push it into the center of the

catch/lifter assembly once again. Fully remove the 3/16

splined pin from the left side and try once again to align the

catch lever lobe and the barrel catch gear recess correctly.

Repeat until successful. Do not fully seat the splined pin!

Slave pin comes out here.

&

back

m

t ca

Mus

Left side of frame.

.

forth

Splines.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 8

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Once the barrel catch pin is partially seated to the splines

and the catch functioning, use your needle-nose pliers or

assembly tweezers to work the hammer back in positon.

Have your splined hammer pin ready to insert (unsplined

end first) from the left side of the frame once you align the

frame and hammer pin holes.

Note the stud the pliers are holding in the photo at left. The

short leg of the hammer spring will be retained by this stud.

As you push the hammer pin in, only insert it a hair past the

hole in the hammer. You must install the hammer spring

before inserting the pin until the splines barely touch the left

side of the frame.

Some of the photos on this page are a little

blurry, but you can get the idea.

Take the hammer spring by the long leg as shown in the

photo to the right and slide the hole created by the coils

between the hammer and the right inside of frame.

Make sure the hammer pin will pass through the holes in

both the hammer and the hammer spring coils and then

seat the pin until the splines of the pin touch the left outside

of the frame.

Its a little hard to see but the white arrows in the photo to

the right are pointing to the short leg of the hammer spring

that must be retained under the hammer stud and the long

leg pointing at you out of the frame bottom.

The two black arrows are pointing to the splined ends of

the hammer and barrel catch pins barely touching the left

frame side.

Dont seat these pins any further yet.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 9

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Triggerguard assembly tips: Put the trigger up through the guard, snap the trigger extension on the trigger as

it was when you disassembled, line up the guard, trigger and extension holes and slide the slave pin in. Use a

punch to align triggerguard, trigger and the extension, then put a dab of grease on the slave pin and push it in

the hole from the opposite side from the punch.

Align with punch and slide the

slave pin in place.

When the slave pin is in place, put a dab

of grease on the ends of the barrel catch

and trigger return springs and insert those

ends into the holes they reside in, and

they are less likely to fall out when hands

are at a premium.

Notice how thin the plastic is around the

slave pin on the triggerguard to the right.

Make sure the frame and triggerguard

holes are aligned before driving the lubed

splined pin in to avoid damage.

With the triggerguard assembled, you ready to add a dab of action

grease onto any area(s) like the sear tip etc. that you may have rubbed

the lube off of while doing this reassembly.

Right before reinserting the triggerguard, snap the long leg of the

hammer spring up on the little ledge inside the frame as shown at the

left.

Read the rest of this page and the next two pages completely and then

get all the tools and parts within easy reach of your right hand before

going on. Getting the triggerguard back in place isnt rocket science,

but having three hands would help...

The first thing to do is to rotate the trigger extension up and around the

back side of the hammer pin, and between the left side of the hammer

on the inside of the frame.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

When you are trying to install the triggerguard

assembly and you can't figure out how to get the barrel

catch spring on the front of the triggerguard to slip into

its position under the catch and allow the front of the

guard to go into place, you can insert the triggerguard

in the frame and use a large punch to wiggle the

spring back under the barrel catch. This is made

possible only if you really make use of all of your

fingers and thumbs. With your left hand, use your left

index finger to raise and hold up the barrel catch

release. Your left thumb must be ready to push the

rear of guard into postion.

Have the large punch and the two triggerguard pins

near your right hand to access easily. You MUST have

the catch lever raised with your left finger to have

(barely!) enough clearance for the barrel catch spring.

Pg. 10

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 11

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Once you have the guard in place you must hold it in

there against all the pressure from the springs with

your left hand and reaching under the frame, insert

the unsplined ends of the lubed pins by hand or

(better) have a helper put the pins in while you hold

the guard in place with BOTH hands. It may help to

align the triggerguard with the frame using your 3/32

punch through the right side front pin hole. Flip the

frame over and tap the pins with a hammer until the

splines just touch the left side of the frame.

Test function before reseating the splined action

pins fully. You don't want extra wear on the frame

and pins by finding out after you seat them that

something is wrong.

Check and see what the pull weight is before

seating pins. If the pull weight is still too high,

disassemble the triggerguard once more and

LIGHTLY stone the top of the trigger that functions

as a sear. KEEP THE FACTORY ANGLES.

Reassemble and check pull weight again.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 12

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

Run these checks BEFORE the final seating of the splined pins, and again AFTER seating them.

Three things to test for before firing - if your weapon fails any of these tests, seek the aid of a professional

gunsmith if you cant troubleshoot the problem yourself:

One: I would clamp the frame with the hammer cocked in a padded vise and hit the frame with a rubber mallet

or slam the frame, cocked, onto a carpeted floor. Do this front and back of frame, about a dozen times without

the hammer falling. Some sort of impact test to see if you can make the cocked hammer slip engagement is

called for. Of course, if your transfer bar is functioning as designed, the gun should only fire if the trigger is

pulled and held to the rear. The hammer falling without the trigger being pulled would defeat a MAJOR safety

feature and leave safety to the secondary system - not a good thing.

Two: I would also make sure that the transfer bar/firing pin functions correctly. Cock hammer, let hammer fall,

keep trigger held to the rear. Until you let go of the trigger the firing pin should stick out of the breechface.

When you let go of the trigger, it should withdraw back into the breechface. Do this several times as well. If

the firing pin doesnt withdraw upon releasing the trigger, then you must find the cause through disassembly

and inspection. Closing the barrel with the firing pin sticking out of the breechface and a round in the chamber

could easily cause your weapon to fire accidently.

Three: Put the barrel on the frame and press down on the front of the barrel and make sure there is good

positive engagement of the barrel catch. You don't want the action to come open when you touch off a round

if it is assembled wrong.

Im sure you have noticed I havent mentioned trimming or replacing springs on this firearm, as I see no need

for inviting the liability and possible lack of reliability of doing so. Trimming or replacing the trigger return spring

could increase the possibility of accidental discharge from an impact. Doing the same thing on the barrel catch

spring increases the likelihood of negative function of the barrel catch - dont do it. A safe lightweight pull can

be achieved without altering any springs.

These instructions apply only to current production firearms of H&R 1871. Ive noted at least two styles of barrel

catches have been made in the past and I have a disassembly book that shows that old style catch on guns

that are new enough to have the transfer bar/lifter instead of the half-cock hammer. The difference is in the

amount of lobes or teeth on the barrel catch that has to engage the ratchet on the bottom of the barrel catch

lever upon reassembly. If your firearm is mechanically different than my photos upon disassembly, I would

carefully reassemble and seek the help of a professional gunsmith.

Using the methods above and not going further into the dangerous area of changing factory geometry of the

parts, just smoothing them and lubricating them, my 30.06 pull went from a 10 pull average of 4 15/16's lbs.

down to a 3.1 lbs. average. The .308 went from 4.75 lbs. to 2.75 and the 25.06 went from 6 lbs. to 2.85.

Do not take the weight of pull below 2.75 lbs., as it is potentially dangerous. A lower than 2.75 lb. trigger and

gloved hands on a hunting rifle could be a BAD combo considering the cramped triggerguard on Handis.

H&R/NEF Handi-Rifle Trigger Work

These instructions can be found at:

www.perkloafm.com

Pg. 13

All contents 2002 perkloafm.com

Email comments to: perklo@perkloafm.com

To do the final pin seating, reverse the wood (or metal) fixture to the left side of the frame and make a flopped

version of the 2 x 4, frame and fixture clamped sandwich from the disassembly instructional. Pad that fixture if

you made a metal one to avoid scratching the frame.

Make double sure all of the pin heads to be seated on the left side of the frame are indeed the splined ends,

and carefully drive them back in place with the appropriate pin punch. Reach under the frame after every few

strikes on a pin and feel for the head to come through the right side. Seat them evenly and if you drive any pin

too far to the right side, flip your 2 x 4, frame and fixture sandwich again and gently tap that pin back a bit.

Remember to check safety function and pull weight once more after seating the pins fully - safety first!

When youre satisfied with your work, reassemble stock and barrel in the reverse order of the disassembly

instructional and enjoy your new trigger.

A couple of additional tips... a minority of people have emailed me and said they didn't find it necessary to

polish the pins and holes. If your Handi doesn't show the rub marks from rough finish I pointed out in the

instructional, then you may not need to. If they are already smooth and loose fitting, polishing would only

add "slop" to your action. This seems to be a rarity though, as most people have written that it helped and

it was required on all three Handi-Rifles that I worked. One person wrote that he lived in a VERY cold climate,

and he was opposed to using a action grease on the internals. If you do live in such a climate, then a lighter

lube that BONDS to the parts like Tetragun oil, Miltech lube or even the lighter Tetragun "G" grease might

be better choices.

Future AFM projects:

Reworking a surplus Browning Hi-Power into an IDPA Custom Defense Pistol, converting a stainless Ruger

Blackhawk .45 Colt into a short-barreled Bisley, Nylon Surgery and a basic gunsmithing supplies essay.

Stay tuned! - perklo

Вам также может понравиться

- Toolpost Attachment For A High Speed Rotary ToolДокумент32 страницыToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- DP Series Build SheetДокумент49 страницDP Series Build SheetJoe Creole100% (1)

- A Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialОт EverandA Treatise on Staff Making and Pivoting: Containing Complete Directions for Making and Fitting New Staffs from the Raw MaterialОценок пока нет

- Grinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogДокумент11 страницGrinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogredneckrepairsОценок пока нет

- Handi Instr OneДокумент9 страницHandi Instr OnenotjustsomeoneОценок пока нет

- Gun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.От EverandGun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.Оценок пока нет

- The M14 Conversion To The M1 Garand: Version OneДокумент13 страницThe M14 Conversion To The M1 Garand: Version Oneleleva13Оценок пока нет

- Brownells-2 5LB1911TriggerPullДокумент4 страницыBrownells-2 5LB1911TriggerPullRyan ShanksОценок пока нет

- Angle Grinder Tube Pipe Sander Polishing AttachmenДокумент14 страницAngle Grinder Tube Pipe Sander Polishing AttachmenEdmar DL100% (1)

- Sear Trigger TuningДокумент4 страницыSear Trigger TuningDustin Gray100% (1)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.От EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Рейтинг: 5 из 5 звезд5/5 (1)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesОт EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesОценок пока нет

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОт EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОценок пока нет

- Cly Mer Catalogue Vol 11Документ36 страницCly Mer Catalogue Vol 11ravenofthenightОценок пока нет

- AKT020 Rivet Jaws InstructionsДокумент12 страницAKT020 Rivet Jaws InstructionsDale WadeОценок пока нет

- Installing An External Bolt Stop/Release On A Remington 700Документ10 страницInstalling An External Bolt Stop/Release On A Remington 700M Poveda0% (1)

- Jewel 2-Stage TriggerДокумент13 страницJewel 2-Stage TriggerAdam BallОценок пока нет

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningОт EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningРейтинг: 2.5 из 5 звезд2.5/5 (2)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Reid 618hr Ins Man Part ListДокумент20 страницReid 618hr Ins Man Part ListzuhzuhzuhОценок пока нет

- Making Your Own Rivets - The AK Files ForumsДокумент7 страницMaking Your Own Rivets - The AK Files Forumsscout50Оценок пока нет

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopОт EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedОценок пока нет

- Us 20060101695Документ11 страницUs 20060101695galak12001100% (1)

- M1 Garand Barrel Replacement  " New BarrelДокумент35 страницM1 Garand Barrel Replacement  " New BarrelToschanoОценок пока нет

- Grinding Lathe Tools On A Belt Sander - For The New Guy - MachinistBlogДокумент13 страницGrinding Lathe Tools On A Belt Sander - For The New Guy - MachinistBlogredneckrepairs100% (1)

- Micro Machine Shop Mods EtcДокумент488 страницMicro Machine Shop Mods Etcsbarnett38@100% (4)

- A Modified Vince Gingery PlasticДокумент13 страницA Modified Vince Gingery PlasticgeppaОценок пока нет

- Single Lip Cutter D-BitДокумент2 страницыSingle Lip Cutter D-Bitsjdarkman1930Оценок пока нет

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationОт EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationОценок пока нет

- Car Maintainer, Group B: Passbooks Study GuideОт EverandCar Maintainer, Group B: Passbooks Study GuideОценок пока нет

- 2010-01-18 191943 CrowningДокумент2 страницы2010-01-18 191943 Crowningbrowar444Оценок пока нет

- Instructions For Making "Home-Made" Ballistic GelatinДокумент3 страницыInstructions For Making "Home-Made" Ballistic Gelatinbrowar444Оценок пока нет

- Blackened and Antiqued Hard..Документ6 страницBlackened and Antiqued Hard..Robin Hughes100% (1)

- How To Formulate Parkerizing SolutionДокумент3 страницыHow To Formulate Parkerizing SolutionOtter1zОценок пока нет

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneОт EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneОценок пока нет

- Gun Trader's Guide, Thirty-Fifth Edition: A Comprehensive, Fully Illustrated Guide to Modern Firearms with Current Market ValuesОт EverandGun Trader's Guide, Thirty-Fifth Edition: A Comprehensive, Fully Illustrated Guide to Modern Firearms with Current Market ValuesОценок пока нет

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsОт EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsОценок пока нет

- Pirate HatДокумент1 страницаPirate HatnotjustsomeoneОценок пока нет

- BB Service Service Manuals A2-Service-Manual 12-752828-000Документ221 страницаBB Service Service Manuals A2-Service-Manual 12-752828-000notjustsomeoneОценок пока нет

- Rockwell JointerДокумент18 страницRockwell Jointernotjustsomeone100% (2)

- Smart Air Dive Computer: Instruction ManualДокумент20 страницSmart Air Dive Computer: Instruction ManualnotjustsomeoneОценок пока нет

- EXA 24X35mm: Back To Main On-Line Manual PageДокумент13 страницEXA 24X35mm: Back To Main On-Line Manual PagenotjustsomeoneОценок пока нет

- Get Your Defensive House in Order PDFДокумент102 страницыGet Your Defensive House in Order PDFnotjustsomeoneОценок пока нет

- Ricohmatic 225Документ37 страницRicohmatic 225notjustsomeoneОценок пока нет

- 1987 B57 Variations of The Model 1885 WinchesterДокумент11 страниц1987 B57 Variations of The Model 1885 Winchesternotjustsomeone67% (3)

- Handi Instr OneДокумент9 страницHandi Instr OnenotjustsomeoneОценок пока нет

- Survival Ammunition ReportДокумент39 страницSurvival Ammunition Reportdesertbutterfly78100% (3)

- Fumble Table: Area Result of RollДокумент1 страницаFumble Table: Area Result of RollLeonartОценок пока нет

- Chapter 6 WeaponsДокумент98 страницChapter 6 WeaponswellsbennettОценок пока нет

- 25mm X 137 FAPDS-TДокумент1 страница25mm X 137 FAPDS-ThotschiОценок пока нет

- Tanza All PDFДокумент3 страницыTanza All PDFEdison de CastroОценок пока нет

- Tau TurretsДокумент2 страницыTau TurretsblahturnipОценок пока нет

- MRP Spec Sheet 1Документ2 страницыMRP Spec Sheet 1raynor16100% (1)

- Rafael TrophyДокумент2 страницыRafael Trophyradamantys4371Оценок пока нет

- World of Firepower 20150304Документ132 страницыWorld of Firepower 20150304Juarez Tome de Almeida100% (4)

- KnivesДокумент22 страницыKnivesroseebagadiongОценок пока нет

- New Equipment For 2300ad: Mitarillette D'assaultДокумент4 страницыNew Equipment For 2300ad: Mitarillette D'assaultnamar13766100% (1)

- Stargrave QRS 2-PagerДокумент2 страницыStargrave QRS 2-PagerKen86% (7)

- Galactic Empire: Quick Build ReferenceДокумент7 страницGalactic Empire: Quick Build ReferenceTravis SkinnerОценок пока нет

- Codex EldarДокумент8 страницCodex EldarCollin McCarterОценок пока нет

- Tuning The Pietta Part OneДокумент19 страницTuning The Pietta Part Oneack67194771100% (2)

- Chapter 7 Forensic ExaminationДокумент7 страницChapter 7 Forensic ExaminationGabriel Sta MariaОценок пока нет

- AC! - Combat Cheat SheetДокумент1 страницаAC! - Combat Cheat Sheetgr1bble83% (6)

- 5e Weapon BreakdownДокумент10 страниц5e Weapon BreakdownGeorgeОценок пока нет

- 9th Edition Crusade Record SheetsДокумент22 страницы9th Edition Crusade Record SheetsMichael N Rebecca CooperОценок пока нет

- Dark Heresy 2e Character Sheet - Desperado CharlatanДокумент2 страницыDark Heresy 2e Character Sheet - Desperado CharlatanAlasdair GoudieОценок пока нет

- Ucjs 10090Документ41 страницаUcjs 10090Tapia10Оценок пока нет

- Safariland Find Your Perfect Holster SAF ProFit GuideДокумент2 страницыSafariland Find Your Perfect Holster SAF ProFit GuidexurxinhooОценок пока нет

- Italian Army 8 September 1943-Regio EserДокумент15 страницItalian Army 8 September 1943-Regio EserBoris Marković100% (1)

- DPS-258 Firearms Tracing Form 09.13.2010Документ2 страницыDPS-258 Firearms Tracing Form 09.13.2010waterfordpoliceОценок пока нет

- Shooting Chrony Users ManualДокумент22 страницыShooting Chrony Users Manualrvpilot100% (1)

- Cr3000 Cyberpunk Red - Jumpstart Ez Reference (Letter) (2019)Документ4 страницыCr3000 Cyberpunk Red - Jumpstart Ez Reference (Letter) (2019)drofsehОценок пока нет

- CardsДокумент35 страницCardsJames RudgeОценок пока нет

- Apache AH-64 30x113mm Target Practice SpotterДокумент17 страницApache AH-64 30x113mm Target Practice SpotterScott_B4UОценок пока нет

- Info Eduard 2013 12ENДокумент44 страницыInfo Eduard 2013 12EN18912170100% (3)

- Magpul 2013 Catalog p01-51Документ27 страницMagpul 2013 Catalog p01-51Brad AlbertsОценок пока нет