Академический Документы

Профессиональный Документы

Культура Документы

Guidelines On Fabrication of Steel Structure of

Загружено:

samirbendre10 оценок0% нашли этот документ полезным (0 голосов)

201 просмотров3 страницы1. The document provides guidelines for the fabrication of steel structures for a proposed foot-over-bridge and skywalk at Silvassa for Dadra Nagar Haveli Planning and Development Authority.

2. It specifies the use of IS 2062 Grade A steel and outlines requirements for cutting, flattening, straightening, and finishing of steel components. Templates, jigs and fixtures should be used to aid accuracy and reduce errors and manpower.

3. Welding must be done according to approved procedures and specifications by qualified welders, using electrodes that confirm to IS 814, and inspected according to IS 822. Welding should preferably be done in the flat position to avoid excessive heat-affected zones

Исходное описание:

steel fabrication

Оригинальное название

Guidelines on Fabrication of Steel Structure Of

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1. The document provides guidelines for the fabrication of steel structures for a proposed foot-over-bridge and skywalk at Silvassa for Dadra Nagar Haveli Planning and Development Authority.

2. It specifies the use of IS 2062 Grade A steel and outlines requirements for cutting, flattening, straightening, and finishing of steel components. Templates, jigs and fixtures should be used to aid accuracy and reduce errors and manpower.

3. Welding must be done according to approved procedures and specifications by qualified welders, using electrodes that confirm to IS 814, and inspected according to IS 822. Welding should preferably be done in the flat position to avoid excessive heat-affected zones

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

201 просмотров3 страницыGuidelines On Fabrication of Steel Structure of

Загружено:

samirbendre11. The document provides guidelines for the fabrication of steel structures for a proposed foot-over-bridge and skywalk at Silvassa for Dadra Nagar Haveli Planning and Development Authority.

2. It specifies the use of IS 2062 Grade A steel and outlines requirements for cutting, flattening, straightening, and finishing of steel components. Templates, jigs and fixtures should be used to aid accuracy and reduce errors and manpower.

3. Welding must be done according to approved procedures and specifications by qualified welders, using electrodes that confirm to IS 814, and inspected according to IS 822. Welding should preferably be done in the flat position to avoid excessive heat-affected zones

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

PROPOSED FOB AND SKYWALK AT SILVASSA FOR DADRA

NAGAR HAVELI PLANNING AND DEVELOPMENT AUTHORITY

GUIDELINES ON FABRICATION OF STEEL STRUCTURE

1 Specification for steel

IS:2062 Grade A as rolled semi-killed or killed shall be used for

foot-over-bridges

The rolling and cutting tolerances shall be in accordance with

IS:1852

2 Flattening and Straightening of steel

All steel materials plates and structural shall have straight edges,

flat surfaces and be free from twist. If necessary, they shall be cold

straightened or flattened by pressure before being worked or assembled

unless they required to be of curvilinear form. Pressure applied for

straightening or flattening shall be such as it would not injure the material

and adjacent surfaces or edges shall be in close contact or at uniform

distance throughout

Flattening and straightening under hot condition shall not be carried

out unless authorized and approved by the Inspecting Officer

3 Cutting of steel

Flame cutting by mechanically controlled torch/torches shall be

accepted. Provided the edge as given by the torch is reasonable clean

and straight, plates may be cut to shape and beams and other sections

cut to length with a gas cutting torch, preferably oxyacetylene gas should

be used

All flame cut edges shall be ground to obtain reasonably clean

square and true edges. Draglines produced by flame cut should be

removed

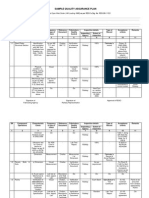

4 Quality Assurance Plan (QAP):

Stagewise manufacturing process from raw material indicating various

steps, test checks and their frequency, sampling plan, authority for grant

of clearance, stage like templating and lay out of foot over bridge,

fixture/jig manufacturing, drilling of component/welding of component initial

assembly, final finishing, final inspection, surface preparation and painting

etc. are clearly shown and signed by contractor

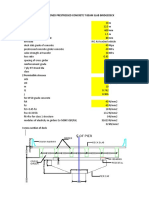

5 Lay out

The layout of structure on template floor is the most important

operation in fabrication. It is essential that the template floor is

perfectly level with adequate lighting arrangement. Steel flooring is

desirable, as it would also minimize variation in dimensions due to

temperature changes. The marking tools and instruments like

square, divider, punches, steel scriber should be of good quality.

Calibrated tape for measurement of lay out must be used

6 Jigs and fixtures

Jig is the device used in the mass production to locate the job and guide

the tool for drilling etc. While a fixture is a simply a device for holding the

work in true shape during processing.

The use of steel templates, jigs and fixtures is preferable to help in

achieving economy, increasing production, reducing man power, reducing

human errors, increasing accuracy and eliminating special match marking

7 Drilling of holes

Quality of fabrication shall be improved if jigs are used during fabrication.

Drilling of the component may be done through jigs. All burrs left by the

drill and sharp edges of the holes shall be removed.

8 Welding Process

Welding shall be carried out in accordance with the approved

welding procedure, specifications by approved welders, processes

and positions. Proforma for welding procedure specification and

welding procedure qualification records are enclosed as Annexure-I

and II.

All welding should be preferably done in flat position (horizontal).

Welding should be done as per drawing ensuring proper size of

weld. Over size welding may lead to excessive heat affected zone

which may lead to failure of material. Welding should be carried-out

in a warm and dry place so that the rainwater or other atmospheric

elements may not come in contact while welding is in progress

Electrodes shall confirm to IS 814 and

welding shall confirm to IS 816

inspection of the welding shall be done as per IS 822

All consumable shall be stored and handled with care and in

accordance with the manufacturers recommendations.

9 Final Cutting and Finishing of component

Final finishing of length, profile and notches etc. it is accomplished by

accurate marking with the help of templates, measurement and gauge

wherever necessitates and than by gas cutting (Chipping, grinding) as the

case may be. Excessive metal is normally chipped off or gas cut (more

than 3 mm) and the exact finishing or profiling is achieved by fine and

accurate grinding.

Вам также может понравиться

- Method Statement For Structural Fabrication & ErectionДокумент11 страницMethod Statement For Structural Fabrication & ErectionBinay94% (16)

- Steel Fabrication Method StatementДокумент12 страницSteel Fabrication Method Statementvolcanox1288% (59)

- Method Statement For PEB WorkДокумент27 страницMethod Statement For PEB WorkVIJAY BAHADUR YADAV100% (3)

- Structural Audit of BridgeДокумент3 страницыStructural Audit of Bridgesamirbendre10% (1)

- QAP of Steel Bridge Girder PDFДокумент6 страницQAP of Steel Bridge Girder PDFVarun JainОценок пока нет

- Method Statement - Structural Steel Erection Methodology For Dome & Connecting Bridge - VR MallДокумент19 страницMethod Statement - Structural Steel Erection Methodology For Dome & Connecting Bridge - VR MallAkash YadavОценок пока нет

- Steel Structure ErectionДокумент33 страницыSteel Structure ErectionAhmed ImranОценок пока нет

- TGN-BC-01 Tack Welding of Reinforcement BarДокумент8 страницTGN-BC-01 Tack Welding of Reinforcement BarFerhat KahveciОценок пока нет

- METHOD Statement of BRIDGE (Major STR)Документ6 страницMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- Methods of Installation For Steel StructureДокумент6 страницMethods of Installation For Steel Structurenanamallow100% (1)

- Anchor Bolt ProcedureДокумент7 страницAnchor Bolt ProcedureAthanasius Kurniawan Prasetyo Adi100% (1)

- Fabrication and Erection of Steel StructureДокумент29 страницFabrication and Erection of Steel Structure978060143692% (48)

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersДокумент15 страницMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhОценок пока нет

- Design of Plate GirderДокумент85 страницDesign of Plate Girdersamirbendre1100% (2)

- Geotech Surat ReportДокумент104 страницыGeotech Surat Reportsamirbendre167% (3)

- Structural Condition Assessment Report of BuildingДокумент18 страницStructural Condition Assessment Report of Buildingsamirbendre1Оценок пока нет

- Fabrication Work For The Construction of Chenab Bridge Part IДокумент2 страницыFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- Guidelines For Fabrication of Steel GirderДокумент17 страницGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- 3.2 Standard1Документ1 страница3.2 Standard1Thi PhamОценок пока нет

- RDSO Norms For Steel Girder FabricationДокумент25 страницRDSO Norms For Steel Girder FabricationSandip DasОценок пока нет

- Checklist For Fabrication of Beam Structure Design & DrawingДокумент4 страницыChecklist For Fabrication of Beam Structure Design & DrawingRupesh KhandekarОценок пока нет

- Erection of Steel Structures PDFДокумент76 страницErection of Steel Structures PDFUmar MohammadОценок пока нет

- Method Statement For Fabrication Works Structural SteelДокумент13 страницMethod Statement For Fabrication Works Structural SteelRohit SharmaОценок пока нет

- Structural Steel ErectionДокумент8 страницStructural Steel Erectionbratishkaity100% (1)

- S-3000-3130-002 - 0-General Specification of Erection of Steel Structure and Miscellanous Materials PDFДокумент17 страницS-3000-3130-002 - 0-General Specification of Erection of Steel Structure and Miscellanous Materials PDFMessaoud Goutas100% (1)

- Chqlist For Fabrication & InspectionДокумент12 страницChqlist For Fabrication & InspectionSuresh ShuklaОценок пока нет

- Spec - WeldingДокумент6 страницSpec - Weldingprasad_kcpОценок пока нет

- Cpc07e-Ms-str-0010 Method of Statement For Installation of BridgeДокумент13 страницCpc07e-Ms-str-0010 Method of Statement For Installation of BridgeMariam MousaОценок пока нет

- Erection ProceduresДокумент7 страницErection ProceduresIbrahim AlsayedОценок пока нет

- Team Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFДокумент3 страницыTeam Leader - Senior Checker For Structural Steel Detailing - Delhi - Delhi - Simsona Technology Pvt. Ltd. - 3 To 6 Years of Experience PDFDeepankar ChoudhuryОценок пока нет

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingДокумент9 страниц7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresОценок пока нет

- Sardar Patel College of Engineering: (An Autonomous Institute Affiliated To The University of Mumbai)Документ57 страницSardar Patel College of Engineering: (An Autonomous Institute Affiliated To The University of Mumbai)Praful7171100% (2)

- Mockingbird Pedestrian Bridge PresentationДокумент53 страницыMockingbird Pedestrian Bridge PresentationThe Dallas Morning News86% (14)

- Fabrication ProcedurДокумент7 страницFabrication ProcedurHarry PangestuОценок пока нет

- MS For Scaffold and Cladding WorkДокумент16 страницMS For Scaffold and Cladding WorkSujan AugustinОценок пока нет

- Erection and Painting of Steel StructureДокумент7 страницErection and Painting of Steel StructureTAHER AMMARОценок пока нет

- Steel ErectДокумент63 страницыSteel ErectEssam Abdelmonem Mohamed Pmp100% (1)

- Basic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BayДокумент7 страницBasic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BaypvmoorthiОценок пока нет

- 1 Method Statement For Barapullah Post Tensioning Rev-CДокумент20 страниц1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhОценок пока нет

- Structure Method StatementДокумент8 страницStructure Method StatementIrfanadi PratomoОценок пока нет

- Anchor Bolt Details & Hole - AISE PDFДокумент1 страницаAnchor Bolt Details & Hole - AISE PDFYash PaulОценок пока нет

- Girder Erection MethodologyДокумент4 страницыGirder Erection MethodologyTanmay Mukherjee100% (1)

- Indian Standard For Steel Erection ToleranceДокумент5 страницIndian Standard For Steel Erection ToleranceMartine BareauОценок пока нет

- Bhanu PEBДокумент27 страницBhanu PEBBhanuprakash KumbarОценок пока нет

- Fabrication Method StatmentДокумент11 страницFabrication Method StatmentAkhilesh KumarОценок пока нет

- Method Statement For General Concrete Work and Cutting Bending of Steel ReinforcementДокумент4 страницыMethod Statement For General Concrete Work and Cutting Bending of Steel ReinforcementSandip PaulОценок пока нет

- Method Statement For Setting Up Anchor Bolts in Steel StructureДокумент3 страницыMethod Statement For Setting Up Anchor Bolts in Steel StructureIbrahim AlrabibОценок пока нет

- Fabrication Inspection of Structural Steel Final 1.28.15Документ12 страницFabrication Inspection of Structural Steel Final 1.28.15Vinod Kumar Verma100% (1)

- MS For PEB Erection R1Документ16 страницMS For PEB Erection R1Gabriel GabeОценок пока нет

- Sample QAP of Steel Bridge GirderДокумент5 страницSample QAP of Steel Bridge Girderuday64668Оценок пока нет

- Methodology For Water Tightness Test For Expansion JointДокумент1 страницаMethodology For Water Tightness Test For Expansion Jointvenkateswara rao PothinaОценок пока нет

- Scope of Works Structural SteelДокумент8 страницScope of Works Structural SteelJonald DagsaОценок пока нет

- Erection SchemeДокумент1 страницаErection SchemeSM ConsultantsОценок пока нет

- Checklist For Post Tensioning 1Документ2 страницыChecklist For Post Tensioning 1Mahendra Babre100% (1)

- Steel Structures Erection Method Statement-DraftДокумент43 страницыSteel Structures Erection Method Statement-DraftMahmoud Fakhereddin100% (1)

- Fabrication of Steel StructureДокумент200 страницFabrication of Steel Structurekesharinaresh100% (1)

- Calculation of Decking Capacity &Документ9 страницCalculation of Decking Capacity &Waqar FaziОценок пока нет

- Guidelines For Fabrication of Steel Girder Procedure in WordДокумент17 страницGuidelines For Fabrication of Steel Girder Procedure in WordManas Rawat100% (1)

- CON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)Документ22 страницыCON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)mnmsingam100% (1)

- Quality Control Procedure Strcture-SSДокумент16 страницQuality Control Procedure Strcture-SSKamran AliОценок пока нет

- DM Water Tank SpecificationДокумент9 страницDM Water Tank SpecificationManish PatelОценок пока нет

- Structural Steel Procedure.Документ9 страницStructural Steel Procedure.Janardhan Surya100% (1)

- Fabrication - Assembly & ErectionДокумент83 страницыFabrication - Assembly & ErectionRengga Andryastama100% (2)

- Ek 33 Çelik Konstrüksiyon Uygulama Planı (Steel Structure Method Statement) ÖrneğiДокумент3 страницыEk 33 Çelik Konstrüksiyon Uygulama Planı (Steel Structure Method Statement) Örneğican akkaleОценок пока нет

- VVVMC Ring Road Rob Structural Quantities NalasoparaДокумент4 страницыVVVMC Ring Road Rob Structural Quantities Nalasoparasamirbendre1Оценок пока нет

- Ornamental Fishery Shed Estimate1Документ1 страницаOrnamental Fishery Shed Estimate1samirbendre1Оценок пока нет

- Electrical Poles Foundation - 3mДокумент1 страницаElectrical Poles Foundation - 3msamirbendre1100% (1)

- PT I Girder Design 20mДокумент18 страницPT I Girder Design 20msamirbendre1Оценок пока нет

- Cost Summary For Strcutures of 90m - ORR - 17.02.2018Документ1 страницаCost Summary For Strcutures of 90m - ORR - 17.02.2018samirbendre1Оценок пока нет

- GAD - 2 - Major Bridge On Tapi RiverДокумент1 страницаGAD - 2 - Major Bridge On Tapi Riversamirbendre1Оценок пока нет

- PT Slab Bridge Deck 20 MДокумент8 страницPT Slab Bridge Deck 20 Msamirbendre1Оценок пока нет

- GAD - 1 - Major Bridge On Tapi RiverДокумент1 страницаGAD - 1 - Major Bridge On Tapi Riversamirbendre1Оценок пока нет

- Tapi River Bridge Cost20022018Документ1 страницаTapi River Bridge Cost20022018samirbendre1Оценок пока нет

- 22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, GbaДокумент4 страницы22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, Gbasamirbendre1Оценок пока нет

- Public Works Department Underpass On Kasara-Mhasa Road For Mumbai Nashik Road Crossing (Ch.1/350) Improvement Roads Under Mrip (Mu26)Документ1 страницаPublic Works Department Underpass On Kasara-Mhasa Road For Mumbai Nashik Road Crossing (Ch.1/350) Improvement Roads Under Mrip (Mu26)samirbendre1Оценок пока нет

- Design of Footing C1: Input DataДокумент24 страницыDesign of Footing C1: Input Datasamirbendre10% (1)

- Water Tank Side Wall 12x6x16Документ2 страницыWater Tank Side Wall 12x6x16samirbendre1Оценок пока нет

- Weir DesignДокумент1 страницаWeir Designsamirbendre1Оценок пока нет

- Ns - Plan, Ele & SecДокумент1 страницаNs - Plan, Ele & Secsamirbendre1Оценок пока нет

- ALCON EstimateДокумент2 страницыALCON Estimatesamirbendre1Оценок пока нет

- Pier Jacketing ReportДокумент5 страницPier Jacketing Reportsamirbendre1100% (1)

- Phytorid STPДокумент4 страницыPhytorid STPsamirbendre1Оценок пока нет

- PCMC-structural Condition Assessment Inception ReportДокумент4 страницыPCMC-structural Condition Assessment Inception Reportsamirbendre1Оценок пока нет

- Estimate of Structures PWD Pali PatnusДокумент3 страницыEstimate of Structures PWD Pali Patnussamirbendre1Оценок пока нет

- Plan LVL A Plan LVL B: Cutout Above Cutout AboveДокумент1 страницаPlan LVL A Plan LVL B: Cutout Above Cutout Abovesamirbendre1Оценок пока нет

- 2008 Experience With Rotor-Stator Interactions in High Head Francis RunnerДокумент10 страниц2008 Experience With Rotor-Stator Interactions in High Head Francis RunnerAlexandre TrudelОценок пока нет

- Screw Jack Welding Machine Operation Manual (English)Документ14 страницScrew Jack Welding Machine Operation Manual (English)hanuarОценок пока нет

- Bridge Cost by RsepsДокумент8 страницBridge Cost by RsepsTahfimul Islam Ruhan100% (1)

- ASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseДокумент10 страницASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseluisОценок пока нет

- Piping System Hydraulic Test Procedure R0Документ6 страницPiping System Hydraulic Test Procedure R0cmc261185Оценок пока нет

- Hal Machine DetailsДокумент2 страницыHal Machine DetailsAmit YadavОценок пока нет

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeДокумент7 страниц22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptОценок пока нет

- Classification and Designation of Welding Filler MaterialsДокумент4 страницыClassification and Designation of Welding Filler MaterialsEka Putri MayaSariОценок пока нет

- Vicwest DiaphragmsДокумент62 страницыVicwest Diaphragmsrmsa17Оценок пока нет

- CMT Spot WeldingДокумент11 страницCMT Spot Weldingkarthick32mechОценок пока нет

- PIM600 ConstructionДокумент54 страницыPIM600 Constructionmika cabelloОценок пока нет

- Welding and Fabrication NotesДокумент47 страницWelding and Fabrication NotesJulius Kiprop100% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFДокумент11 страницEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaОценок пока нет

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-37Документ22 страницыBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-37Mahesh SuranaОценок пока нет

- Vibrating Wire Strain Gage: MODEL EDS-20V SeriesДокумент3 страницыVibrating Wire Strain Gage: MODEL EDS-20V SeriesJosé GomesОценок пока нет

- Industrial Visit To "Tata Motors": By: - SUYASH GUPTA (17250026)Документ2 страницыIndustrial Visit To "Tata Motors": By: - SUYASH GUPTA (17250026)Gupta SuyashОценок пока нет

- 26 - Hot Work Procedure V2Документ18 страниц26 - Hot Work Procedure V2Hussain AhmedОценок пока нет

- Ensuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.EДокумент16 страницEnsuring Weld Quality in Structural Applications: by Duane K. Miller, SC.D., P.Ecentaury2013Оценок пока нет

- ManufProc 6 JoiningAssemblyДокумент118 страницManufProc 6 JoiningAssemblyHannan yusuf KhanОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент8 страницSaudi Aramco Inspection ChecklistAnantha PadmanabhanОценок пока нет

- TroubleshootingДокумент384 страницыTroubleshootinguuganaa ugiОценок пока нет

- c954 Aluminum BronzeДокумент2 страницыc954 Aluminum Bronzeretrospect1000Оценок пока нет

- Metals: Weldability and Lamellar Tearing Susceptibility of High-Strength SN 490C Steel PlatesДокумент16 страницMetals: Weldability and Lamellar Tearing Susceptibility of High-Strength SN 490C Steel PlatesRendra Maha Putra JfОценок пока нет

- KKT Chillers Catalog US Version 072922Документ17 страницKKT Chillers Catalog US Version 072922maicen sipayungОценок пока нет

- Cyclones For Fluidized Bed ProcessesДокумент4 страницыCyclones For Fluidized Bed ProcessesswatkoolОценок пока нет

- Curiticulum "Welder & & Fitter": Application ElectrcДокумент2 страницыCuriticulum "Welder & & Fitter": Application ElectrcanandabelosheОценок пока нет

- Manual Power Wave 350Документ62 страницыManual Power Wave 350oswaldo lopezОценок пока нет

- Gg-12aws-72-Gg-12aws FTДокумент4 страницыGg-12aws-72-Gg-12aws FTLUIS ALFREDO SOLANO NIZAMAОценок пока нет

- Pipe Standash Byp PomДокумент96 страницPipe Standash Byp Pomallouche_abdОценок пока нет

- Mohammad Arif-Updated CV2Документ11 страницMohammad Arif-Updated CV2Instech Premier Sdn BhdОценок пока нет