Академический Документы

Профессиональный Документы

Культура Документы

Installation Procedure of Heat Exchanger

Загружено:

yayan hИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Installation Procedure of Heat Exchanger

Загружено:

yayan hАвторское право:

Доступные форматы

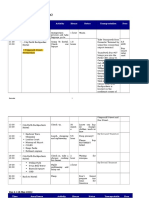

DOC NO.

PIPING CONSTRUCTION AND MECHANICAL EQUIPMENT

INSTALLATION WORK FOR COOLING WATER SYSTEM OF PH-6

PROJECT

CONTRACT NO.1200019097 & 1200012098

INSTALLATION PROCEDURE FOR HEAT EXCHANGER

1|Page of 5

24-Feb-2015

19-Dec-2014

Rev.

Date

Issued for Approval

Description

KEN

MLY

SGN

By

Chkd

Appd

PT SAE

1. GENERAL

This procedure covers minimum requirements for handling and

installation of Heat Exchanger.

2. APPLICABLE ITEMS

This Procedure is applied for item below:

Closed

Cooling

Water

Cooler

Heat

Exchanger

HE-U301

A/B/C/D/E

3. BASIC INFORMATION

DIMENSION (mm)

DESCRIPTION

L

Closed Cooling Water Cooler

Exchanger HE-U301 A/B/C/D/E

Heat

WEIG

HT

(Kg)

-

4. PREPARATION

4.1 Equipment and tool List

Prior to installation, equipment and tools shall be prepared :

a. 45 TON CRANE

b. 25 TON CRANE

c. TRUCK

d. FORKLIFT

e. THEODOLIT / WATER PASS

f. SLING / WEBBING SLING 6 TON

g. SHACKLE

h. TORQUE

i. BODY HARDNESS

4.2 Safety Requirement

2|Page of 5

Prior to install, equipment and tool are used to install shall be

checked to make

sure in safe condition.

a. Check of the crane with load test and document of crane

b. Check validation of operator crane

c. Check validation of rigger

d. Check all safety equipment for personnel

e. Check the truck capacity & Driver lisence

f. Check the forklif capacity & Driver lisence

4.3 Equipment Drawing / Data Sheet / Manual Instruction /

Installation Procedure

Prior to install, all equipment shall be provided with drawing or

data sheet or manual instruction or installation procedure to

make sure that all activities doing by correct manner. If needed,

the supervise by vendor is a must.

5. DESCRIPTION OF WORK PROCEDURE

5.1. Transport Equipment to Installed Foundation

a. All equipment shall be checked on received at site for any

damage and any missing parts from the packing list. If any

discrepancies found shall be reported as described in the

material control procedure. An OSD (Overage, Shortage,

Damage) report shall be prepared for any discrepancies.

b. Care shall be taken to transportation and storage of the

equipment to make sure proper procedures are adopted as per

manufactures recommendations.

c. Packaging shall be removed except the pallet. But if the

equipment is packed to the pallet dan bended with strip plate,

no needed to removed the packaging.

d. Used appropriate crane or forklif to move and lift up the

equipment to truck. E.

e. Make sure the position is steady dan balance.

f. Tightened.

g. Equipment are ready to transport to the installed foundation.

5.2. Pre-installation Checks

a.

b.

The foundation to be checked as per the drawing dimensions

by the surveyor and mark the centerline and co ordinates on

the foundation.

Check the anchor bolt for the correct location and straightness

with respect to the equipment.

3|Page of 5

c.

d.

e.

f.

The surface of the foundation is to be cleaned of all dirt, oil,

and any loose materials and roughened by chipping with

brush hammer before placing the equipment.

The padding plates are to be set-up just beside the anchor

bolts or to suit site condition, except where the bolt is

mounted in a sleeve, then the plates shall be placed as close

to the bolts as possible.

Check the elevation of padding plate by surveyor and correct

if needed, before installation of equipment.

Check the capacity of lifting equipment and rigging plan shall

be prepared and approved before lifting of the equipment.

5.3. Positioning of Equipment / Heat Exchanger Installation

a. The orientation four position ( 0, 90, 180 and 270 ) to be

marked on the equipment for checking orientation as per

drawing.

b. Leveling and verticality shall be done with packing plates and

shims to correct location and elevation and checked with

plumb at least 4 points.

c. If not specified, maximum plumb not more than 25 mm or

1/200 h wherever the smaller to be used.

d. Coordination with Civil Contractor, Once the equipment

has been set in correct location and elevation and approved

the base can be grouted with approved grouting materials

(civil contractor scoop).

The surface to be grouted shall be saturated with water for

at least 24 hours in advance. Any free standing water must be

removed before placing the grout (civil contractor scoop).

e. Recheck the concrete surface to ensure that it is free from

dirt, oil, grease, or any loose materials.

f. Lift down equipment from truck.

g. Removed all stripped bend/plate that it is part of packaging

and also all tightening part to pallet.

h. Using webbing sling, placed on four position (Lifting lugs) and

appropriate crane capacity, standing up the tank.

4|Page of 5

i. Using webbing sling, placed on four position at lifting lugs

j. appropriate crane capacity 45 Ton with weight of HE

appropriate 12 Ton, use of boom 33.85m with radius 10 meter

and move tank to the foundation. Make sure all in safety

manner.

k. Prior tank install to the foundation, make sure foundation has

levelled.

l. Place the tank orientation as per lay out drawing and fit the

anchor bolt holes to the foundation anchor.

m. Set the level, use water pass to make sure the level is correct.

n. Check the settlement.

o. Tightened the anchor bolt.

5.4. Inspection

When equipment has been installed and ready for inspection, the

QC Engineer shall arrange and to invite the Client Representative

to witness and approve the location and orientation check as per

Inspection & Test Plan (ITP).

NO

INSPECTION ITEM

HAP

SAE

ASC

1.

Foundation check

2.

Chipping and padding

3.

Plumbness / levelling

5|Page of 5

4.

Internal Installation,

Cleaning and boxing up

6. DOCUMENTATION

6.4. All Inspection Records shall be filed and documented as per

procedure

6.5. After construction works are finished as contract, all original

required documentations as per contract shall be submitted to

Client and copied for our file.

7. REFERENCE (ATTACHED)

For reference, attached the data sheet or drawing or manual

instruction or installation procedure from the vendor of :

Closed Cooling Water Cooler Heat Exchanger HE-U301

A/B/C/D/E

6|Page of 5

Вам также может понравиться

- MITSUBISHI Engines IdentificationДокумент5 страницMITSUBISHI Engines IdentificationHameed25% (4)

- Tank Method Statement - r0Документ11 страницTank Method Statement - r0AravindanОценок пока нет

- Method Statement For Static Equipment Installation PDFДокумент25 страницMethod Statement For Static Equipment Installation PDFUtku KepcenОценок пока нет

- Method Statement: Al-Khafji FDP Phase-I Onshore FacilitiesДокумент8 страницMethod Statement: Al-Khafji FDP Phase-I Onshore FacilitiesSiddiqui Muhammad AshfaqueОценок пока нет

- Static Equipment ErectionДокумент17 страницStatic Equipment Erectiononur gunes100% (2)

- HYDROTEST - JeevaДокумент68 страницHYDROTEST - JeevaJayaraman KamarajОценок пока нет

- Method Statement For Static Equipment InstallationДокумент25 страницMethod Statement For Static Equipment InstallationJolene Tan82% (11)

- Flushing Procedure Final 11Документ4 страницыFlushing Procedure Final 11Hamada ELaraby50% (2)

- Procedure For Fab, Erec & Testing of Undergroud PipingДокумент12 страницProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86Оценок пока нет

- Tank Procedure by Conventional MethodДокумент8 страницTank Procedure by Conventional Methodsatish04Оценок пока нет

- ITP Heat ExchangerДокумент3 страницыITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Bolted Flanged Joints New Methods Practices ProceedingsДокумент2 страницыBolted Flanged Joints New Methods Practices ProceedingsMladen ČorokaloОценок пока нет

- Work Method Statement For Piping PrefabricationДокумент11 страницWork Method Statement For Piping Prefabricationsoumaya yahyaoui100% (3)

- F-016-Static Equipment Installation ChecklistДокумент3 страницыF-016-Static Equipment Installation Checklisthunghoanglong100% (1)

- Hydrotest ProcedureДокумент12 страницHydrotest Procedurealex_feryando42100% (1)

- Annular Plate RemovalДокумент2 страницыAnnular Plate RemovalVishvjeet Prakash TiwariОценок пока нет

- Pa42 QRH 1 OpsДокумент24 страницыPa42 QRH 1 OpsAnonymous ib89TVОценок пока нет

- WMS JOB Procedure FOR PIPING WORKДокумент9 страницWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923Оценок пока нет

- Replacement of Lip Seal Gasket For Heat ExchangerДокумент10 страницReplacement of Lip Seal Gasket For Heat ExchangerBESTIN67% (3)

- Pressure Vessel Repair ProcedureДокумент7 страницPressure Vessel Repair ProcedureAndy UgohОценок пока нет

- Erection 009 CTP Storage TankДокумент44 страницыErection 009 CTP Storage Tankgst ajah100% (1)

- Desain Kebutuhan Unmanned Aerial Vehicle (Uav) Sebagai Pendukung Kegiatan Operasi Maritim BakamlaДокумент28 страницDesain Kebutuhan Unmanned Aerial Vehicle (Uav) Sebagai Pendukung Kegiatan Operasi Maritim BakamlaDirektorat Penelitian dan Pengembangan Bakamla RIОценок пока нет

- Method Statement For Installation of RO Skids, Pressure Vessels and Connecting Pipes R1Документ7 страницMethod Statement For Installation of RO Skids, Pressure Vessels and Connecting Pipes R1Nauman Zia100% (1)

- MS-M-063 Rev. 1 - Air Fin Cooler InstallationДокумент6 страницMS-M-063 Rev. 1 - Air Fin Cooler InstallationwalitedisonОценок пока нет

- BTE Dome Brochure Jun 10Документ2 страницыBTE Dome Brochure Jun 10م.ذكى فضل ذكىОценок пока нет

- Installation Procedure For Air Heater CoolerДокумент4 страницыInstallation Procedure For Air Heater CoolerRachel FloresОценок пока нет

- Cone Roof Tank Erection ProcedureДокумент8 страницCone Roof Tank Erection ProcedureBoby Thomas100% (1)

- ITP Static EquipmentДокумент12 страницITP Static Equipmentaamirapi100% (3)

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterДокумент2 страницыHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- MS For Tank Installation - R1Документ6 страницMS For Tank Installation - R1alvinchuan100% (1)

- A-1101 B Primary Reformer Catalyst Change Out Work Method StatementДокумент4 страницыA-1101 B Primary Reformer Catalyst Change Out Work Method StatementgururajОценок пока нет

- Air Cooler MaintenanceДокумент13 страницAir Cooler Maintenancemostafa_1000Оценок пока нет

- Installation of Pump ProcedureДокумент7 страницInstallation of Pump Procedureyayan h100% (1)

- Procedure Welding Part 2Документ14 страницProcedure Welding Part 2mohammadОценок пока нет

- Pressure Part Method StatementДокумент49 страницPressure Part Method StatementSerkan Yaşa67% (3)

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Документ15 страницPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenОценок пока нет

- Procedure For Instalattion of VesselДокумент6 страницProcedure For Instalattion of Vesselyayan hОценок пока нет

- Installation Procedure For Pressure Vessel - EnglishДокумент8 страницInstallation Procedure For Pressure Vessel - EnglishApri Dianto92% (13)

- Drum Handling EquДокумент20 страницDrum Handling EquMohd HattaОценок пока нет

- Method Statement For Installation of Diesel Generator SetДокумент7 страницMethod Statement For Installation of Diesel Generator SetAnonymous 8xHUWB100% (5)

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CДокумент2 страницыITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Tubes Expansion ProcedureДокумент3 страницыTubes Expansion Procedurefizanlamin100% (1)

- To Commissioning Manual: Appendix No. 1Документ7 страницTo Commissioning Manual: Appendix No. 1Bassem BalghouthiОценок пока нет

- 静设备英文 Static Equipment Installation ProcedureДокумент6 страниц静设备英文 Static Equipment Installation Procedurejie100% (4)

- Boiler Drum Erection ProcedureДокумент6 страницBoiler Drum Erection Procedureer_sanjaypatel100% (1)

- Method Statement For PipingДокумент13 страницMethod Statement For PipingTauqeer SalimОценок пока нет

- Report No. TA-V-1456Документ2 страницыReport No. TA-V-1456u04ajf3Оценок пока нет

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFДокумент36 страницDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Оценок пока нет

- Itenerary PerthДокумент10 страницItenerary PerthFahmi FedererОценок пока нет

- Method Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaДокумент10 страницMethod Statement For Fabrication and Erection of Piping: Krueng Geukueh, North Aceh, IndonesiaFendik NewbieОценок пока нет

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptДокумент13 страницJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaОценок пока нет

- Pneumatic Test ProcedureДокумент3 страницыPneumatic Test Procedurevijay padale50% (2)

- Specification Erection Static EquipmentДокумент11 страницSpecification Erection Static Equipmentagaricus67% (3)

- Inspection and Test Plan For Water Tube BoilerДокумент13 страницInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- Method Statement - Pressing of Plate To Be Pipe - SignДокумент9 страницMethod Statement - Pressing of Plate To Be Pipe - SignrichadОценок пока нет

- Installation Tray Method StatementДокумент5 страницInstallation Tray Method StatementMohd FadzleОценок пока нет

- 3 Rules For Hip TowingДокумент3 страницы3 Rules For Hip TowingDoug GouldОценок пока нет

- Tanks - Addition of Shell Nozzles by Hot TappingДокумент2 страницыTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzОценок пока нет

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Документ9 страницMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanОценок пока нет

- Steam BoilerДокумент3 страницыSteam BoilerMohammad AzlanОценок пока нет

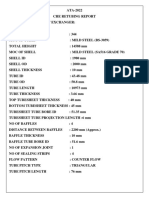

- CHE Retubing ReportДокумент29 страницCHE Retubing ReportRajesh KtrОценок пока нет

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestДокумент4 страницыJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- STS QAC SOP 008 Tube Plugging ProcedureДокумент7 страницSTS QAC SOP 008 Tube Plugging Proceduremohd as shahiddin jafriОценок пока нет

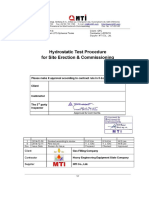

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Документ7 страницHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- QCF301 Hydro Test PackДокумент1 страницаQCF301 Hydro Test Packminhnn0% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Nissan PATROL 2023 - Price List QatarДокумент8 страницNissan PATROL 2023 - Price List QatarghОценок пока нет

- SGBPL Sample DatabaseДокумент2 страницыSGBPL Sample Databaseanon_872569680Оценок пока нет

- Lat Krabang ICD - Final VersionДокумент38 страницLat Krabang ICD - Final VersionTurgenbayar BayarjargalОценок пока нет

- Bench Mark Nova CometДокумент41 страницаBench Mark Nova CometVeeresh T KumbarОценок пока нет

- Times Leader 10-05-2011Документ43 страницыTimes Leader 10-05-2011The Times LeaderОценок пока нет

- Stores Purchase Manual Kerala StateДокумент316 страницStores Purchase Manual Kerala StateArun KrishnanОценок пока нет

- Smart Vehicular Safety SystemДокумент14 страницSmart Vehicular Safety SystemGowsalya GowsОценок пока нет

- TTS Anchor Handling-Towing Winches PDFДокумент5 страницTTS Anchor Handling-Towing Winches PDFbahrulОценок пока нет

- BMW DrivesДокумент7 страницBMW DrivesJay ShahОценок пока нет

- Rig 104 InventoryДокумент16 страницRig 104 InventorypetricamafteiОценок пока нет

- Fundamentals of Automobile EngineeringДокумент18 страницFundamentals of Automobile EngineeringLogeshwari RameshОценок пока нет

- SUMUДокумент12 страницSUMUJean Anderson WilliamsОценок пока нет

- 2022-06-27 FY22 SGR Project ManualДокумент259 страниц2022-06-27 FY22 SGR Project ManualMuhammad SulemanОценок пока нет

- Reply To OppositionДокумент2 страницыReply To Oppositionaaisa1_aОценок пока нет

- Hamptonshire Express Problem #5bДокумент36 страницHamptonshire Express Problem #5bPrashanth CecilОценок пока нет

- EX5 Dream110FI2018.CompressedДокумент106 страницEX5 Dream110FI2018.CompressedZULUx9 SAADОценок пока нет

- Roof Headlining Assy: ComponentsДокумент3 страницыRoof Headlining Assy: Componentsjeremih alhegnОценок пока нет

- Urban Intensities Contemporary Housing Types and Territories - CompressДокумент239 страницUrban Intensities Contemporary Housing Types and Territories - CompressVladimir Elizalde RiosОценок пока нет

- Concrete Polishing & Laser Screed FlooringДокумент7 страницConcrete Polishing & Laser Screed FlooringLamba Techno Flooring SolutionsОценок пока нет

- Photos of TNB Pole Inside Phase A Working Area 22june22Документ7 страницPhotos of TNB Pole Inside Phase A Working Area 22june22MUHAMMAD HAZMI SALLEHUDINОценок пока нет

- GRF PPT05 - by ICAO, Abbas NiknejadДокумент62 страницыGRF PPT05 - by ICAO, Abbas NiknejadAliОценок пока нет

- Ko An 00014719Документ4 страницыKo An 00014719Adrian BorysОценок пока нет

- Civil Engineering Educational TourДокумент9 страницCivil Engineering Educational TourJane BonggoОценок пока нет

- t4 Amali Peka Bab 3 IsotonikДокумент12 страницt4 Amali Peka Bab 3 IsotonikAnita HashimОценок пока нет