Академический Документы

Профессиональный Документы

Культура Документы

ETL Pressure Relief Valves Datasheet PDF

Загружено:

Nanasaheb PatilИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ETL Pressure Relief Valves Datasheet PDF

Загружено:

Nanasaheb PatilАвторское право:

Доступные форматы

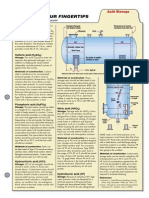

Pressure & Vacuum Relief Valves

(Breather Valves, Conservation Vents)

Protecting People, Property and Our Planet

TECHNICAL DATA

Storage Tank Equipment

Pressure/Vacuum Relief Valves

Application

Direct acting pressure/vacuum relief valves are low pressure

devices specifically designed to protect tanks, process systems

and equipment from excessive pressure and vacuum.

As well as providing the primary layer of protection for tanks

and process systems, pressure/vacuum valves also minimise

emission losses of gases or vapours , thus protecting the

environment and providing significant financial savings.

Pressure and vacuum relief valves are also commonly known

as breather valves or conservation vents.

Principle of Operation

Elmac pressure/vacuum relief valves have weight-loaded or

spring-loaded pallets. Flow through the valve is controlled

by the weight of the pallet or the spring force acting on the

pallet to keep the device closed.

Once the pressure or vacuum in the tank reaches the pallet

closing force, the pallet will start to lift off the seat and allow

flow through the valve.

Due to its air-cushioned sealing technology, Elmac valves

prevent emission losses until very close to the set pressure,

and prevents air intake until very close to the set vacuum.

The geometry of the valves has been developed in order to

optimise overall performance in terms of high flow capacity,

set pressure, sealing and re-sealing.

The modular nature of Elmacs valves means they can be

tailored to meet specific customers requirements: whether

this is pressure or vacuum-protection only; or vapours and

gases either piped-away or vented to atmosphere.

A weatherhood protects the pressure vent port and a mesh

screen is fitted to prevent intrusion of foreign matter into the

valve.

Features & Benefits

Pressure / vacuum relief valves provide

high flow capacity from a compact valve size

Wide range of pressure and vacuum settings to provide

maximum tank protection whilst ensuring minimum gas loss

Designed and manufactured to

API Std 2000:2009 / ISO28300:2008

Superior sealing meets the stringent demands

of emission control regulations

Exceeds seat leakage requirements of

API Std 2000:2009 or ISO28300:2008

No measurable leakage below 90% of the set pressure,

less than 1 SCFH at 90% of the set pressure

Low leakage minimises evaporation loss

Economic savings due to reduced product loss

Alternative connection types available on request

Stem/pallet proximity switches available

Valve sizing service assists optimum

valve performance / cost specification

Elmac technical support

Customer Support

Elmac Technologies Limited

Greenfield, Flintshire, United Kingdom CH8 9DP

T +44 (0) 1352 717600 F +44 (0) 1352 717642 E sales@elmactechnologies.com

Issue No

All specifications are correct at time of print, are for guidance

05 (05/14) purposes only and subject to change without prior notice.

Protecting People, Property and Our Planet

TECHNICAL DATA

Storage Tank Equipment

Protecting People, Property and Our Planet

Pressure & Vacuum to Atmosphere

General Arrangements

Series RV1 valves which are vented to atmosphere, are designed to protect your tank from damage created by over-pressure or

excessive vacuum. Costly product evaporation losses due to normal tank breathing are greatly reduced.

RV1

RV10S

RV1SS

RV1S0

Weight Loaded

Vacuum Spring Loaded

Pressure & Vacuum Spring Loaded

Pressure Spring Loaded

Product Features

Designed and tested according to API2000

Sizes available from 2 to 12 nominal bore

Standard materials include carbon steel and stainless steel. Others on request

Vented to atmosphere

Modular construction

The inlet and outlet flanges are in accordance with ASME B16.5 150LB RF. Others on request

FEP diaphragms effectively prevent the seat and pallet from sticking.

Valves can be specially supplied with a flame arrester, inlet pipe or lining

Setting Pressures

Set Pressure

Set Vacuum

Units

RV1

RV10S

RV1SS

RV1S0

mbar

psi

mbar

psi

2 ~ 69

0.03 ~ 1.0

-2 ~ -43

-0.03 ~ -0.62

2 ~ 69

0.03 ~ 1.0

-43 ~ -480

-0.62 ~ -6.96

69 ~ 1034

1.0 ~ 15.0

-43 ~ -480

-0.62 ~ -6.96

69 ~ 1034

1.0 ~ 15.0

-2 ~ -43

-0.03 ~ -0.62

Dimensions

Nominal Bore

Inch

mm

L

mm

W*

mm

336

215

2

50

429

270

3

80

487

296

4

100

651

395

6

150

803

496

8

200

935

596

10

250

1112

676

12

300

W* indicates width, which is not marked in figures

M: Weight is approximate for a Series RV1 valve. Does not include pallet weights.

HRV1, RV10S

mm

HRV1SS, RV1S0

mm

M

Approx. kg

340

376

435

545

628

732

842

530

563

601

755

859

980

1130

15

28

55

108

174

241

340

www.elmactechnologies.com

TECHNICAL DATA

Storage Tank Equipment

Protecting People, Property and Our Planet

Pressure & Vacuum Piped Away

General Arrangements

H

B

Series RV2 valves are used for pressure and vacuum relief where vapours must be piped away. Special pallets in this series virtually

eliminate the intake of air and the escape of vapours except during normal breathing, thus reducing the loss of product.

RV2

RV20S

RV2SS

RV2S0

Weight Loaded

Vacuum Spring Loaded

Pressure & Vacuum Spring Loaded

Pressure Spring Loaded

Product Features

Designed and tested according to API2000

Sizes available from 2 to 12 nominal bore

Standard materials include carbon steel and stainless steel. Others on request

Pressure vents to pipeline, vacuum vents from atmosphere

Modular construction

The inlet and outlet flanges are in accordance with ASME B16.5 150LB RF. Others on request

FEP diaphragms effectively prevent the seat and pallet from sticking.

Valves can be specially supplied with a flame arrester, inlet pipe or lining

Setting Pressures

Set Pressure

Set Vacuum

Units

RV2

RV20S

RV2SS

RV2S0

mbar

psi

mbar

psi

2 ~ 69

0.03 ~ 1.0

-2 ~ -43

-0.03 ~ -0.62

2 ~ 69

0.03 ~ 1.0

-43 ~ -480

-0.62 ~ -6.96

69 ~ 1034

1.0 ~ 15.0

-43 ~ -480

-0.62 ~ -6.96

69 ~ 1034

1.0 ~ 15.0

-2 ~ -43

-0.03 ~ -0.62

Dimensions

Inlet x Outlet Bore

Inch

mm

L

mm

W*

mm

HRV2, RV20S

mm

371

190

344

2 x 3

50 x 80

461

229

404

3 x 4

80 x 100

507

279

504

4 x 6

100 x 150

671

343

643

6 x 8

150 x 200

826

406

750

8 x 10

200 x 250

955

483

881

10 x 12

250 x 300

1141

533

986

12 x 14

300 x 350

W* indicates width, which is not marked in figures

M: Weight is approximate for a Series RV2 valve. Does not include pallet weights.

HRV2SS, RV2S0

mm

A

mm

B

mm

M

Approx. kg

517

564

639

829

940

1088

1237

140

156

168

216

273

320

381

227

264

326

414

472

544

619

34

58

85

160

249

344

493

www.elmactechnologies.com

TECHNICAL DATA

Storage Tank Equipment

Protecting People, Property and Our Planet

Pressure-Only Relief Valves

General Arrangements

Series PR1 and PR2 valves are for use where pressure relief is required. The vapours relieved can be either vented to atmosphere

or piped away. In order to avoid tank damage, spring or weight-loaded pallets can be selected for different set pressures.

PR1

PR1S

PR2

PR2S

Weight Loaded

Spring Loaded

Weight Loaded

Spring Loaded

Product Features

Designed and tested according to API2000

Sizes available from 2 to 12 nominal bore

Standard materials include carbon steel and stainless steel. Others on request

Vented to atmosphere or piped away

Modular construction

The inlet and outlet flanges are in accordance with ASME B16.5 150LB RF. Others on request

FEP diaphragms effectively prevent the seat and pallet from sticking.

Valves can be specially supplied with a flame arrester, inlet pipe or lining

Setting Pressures

Set Pressure

Units

PR1

PR1S

PR2

PR2S

mbar

psi

2 ~ 69

0.03 ~ 1.0

69 ~ 1034

1.0 ~ 15.0

2 ~ 69

0.03 ~ 1.0

69 ~ 1034

1.0 ~ 15.0

Dimensions

Inlet (x Outlet) Bore

Inch

mm

LPR1

LPR2

HPR1

HPR1S

HPR2

HPR2S

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

140

156

168

216

273

320

381

125

151

192

238

264

306

334

215

270

296

395

496

596

676

190

229

279

343

406

483

553

215

220

240

430

242

415

2 (x 3)

50 (x 80)

270

258

267

453

291

452

3 (x 4)

80 (x 100)

296

282

304

470

369

504

4 (x 6)

100 (x 150)

395

368

370

580

467

653

6 (x 8)

150 (x 200)

500

458

421

652

542

732

8 (x 10)

200 (x 250)

600

529

495

743

643

851

10 (x 12) 250 (x 300)

685

629

557

835

701

952

12 (x 14) 300 (x 350)

W* indicates width, which is not marked in figures

M: Weight is approximate for Series PR1 and PR2 valves. Does not include pallet weights.

www.elmactechnologies.com

W*PR1 W*PR2

MPR1

MPR2

Approx. Approx.

kg

kg

10

17

26

45

74

106

149

30

34

50

90

147

204

292

TECHNICAL DATA

Storage Tank Equipment

Protecting People, Property and Our Planet

Vacuum-Only Relief Valves

General Arrangements

Series VR1 and VR2 valves are for use where vacuum relief is required. Intake relief is from the atmosphere and achieved by using

a spring or weight-loaded pallet to achieve the required set pressure. These valves can be installed vertically or horizontally.

A

L

VR1

VR1S

VR2

VR2S

Weight Loaded

Spring Loaded

Weight Loaded

Spring Loaded

Product Features

Designed and tested according to API2000

Sizes available from 2 to 12 nominal bore for the VR1 Series, or 3 to 14 for the VR2 Series

Standard materials include carbon steel and stainless steel. Others on request

Vertical or horizontal installation

Modular construction

The inlet and outlet flanges are in accordance with ASME B16.5 150LB RF. Others on request

FEP diaphragms effectively prevent the seat and pallet from sticking.

Valves can be specially supplied with a flame arrester, inlet pipe or lining

Setting Pressures

Set Vacuum

Units

VR1

VR1S

VR2

VR2S

mbar

psi

-2 ~ -43

-0.03 ~ -0.62

-43 ~ -480

-0.62 ~ -6.96

-2 ~ -43

-0.03 ~ -0.62

-43 ~ -480

-0.62 ~ -6.96

Dimensions

Nominal Bore

LVR1

LVR2

HVR1

HVR1S

HVR2

HVR2S

W*VR1

W*VR2

mm

mm

mm

mm

mm

mm

mm

mm

mm

307

210

383

2

50

400

220

237

397

212

385

3

80

454

258

259

394

255

415

4

100

599

282

329

515

317

453

6

150

729

368

385

575

400

586

8

200

838

456

468

675

481

671

10

250

1002

529

519

770

579

786

12

300

629

634

885

14

350

W* indicates width, which is not marked in figures

M: Weight is approximate for Series VR1 and VR2 valves. Does not include pallet weights.

140

156

168

216

273

320

381

158

204

228

304

368

418

496

-

190

229

279

343

406

483

533

Inch

mm

www.elmactechnologies.com

MVR1

MVR2

Approx. Approx.

kg

kg

18

32

46

87

137

191

285

-

12

20

35

68

105

150

210

Вам также может понравиться

- Types of Ball Valves (Floating, Trunnion)Документ11 страницTypes of Ball Valves (Floating, Trunnion)swapnil PATILОценок пока нет

- Installation, Operation and Maintenance Manual For Emergency Relief ValveДокумент18 страницInstallation, Operation and Maintenance Manual For Emergency Relief ValveVaeco Đoàn Tncs Hcm100% (1)

- Design Code SummaryДокумент12 страницDesign Code SummaryShane HancockОценок пока нет

- 7.2.24 - Breather ValvesДокумент28 страниц7.2.24 - Breather Valvessav33Оценок пока нет

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- Mistakes and Misconceptions in Valve Leak TestingДокумент5 страницMistakes and Misconceptions in Valve Leak TestingNadi Jothidan KLОценок пока нет

- Isolation Valves - Linear MovementДокумент9 страницIsolation Valves - Linear MovementEmad A.AhmadОценок пока нет

- STD 111Документ25 страницSTD 111Sanjay Patel0% (1)

- FRP PresentationДокумент21 страницаFRP PresentationKhairul AnwarОценок пока нет

- VALVES - NotesДокумент17 страницVALVES - NotesPortifer Harrison Ray Mubanga100% (1)

- Powell API602 Forged Steel ValveДокумент50 страницPowell API602 Forged Steel Valvedragon2065Оценок пока нет

- Hydraulics CurriculumДокумент8 страницHydraulics CurriculumChris ChrisОценок пока нет

- 03 Metal Packing Support PlatesДокумент3 страницы03 Metal Packing Support PlatesypatelsОценок пока нет

- Introduction To Pressure VesselsДокумент17 страницIntroduction To Pressure Vesselsvenky2hema100% (1)

- IHS PetroChem Collection Listing Aug13Документ48 страницIHS PetroChem Collection Listing Aug13OumorsyОценок пока нет

- The A To Z of Valve MaterialsДокумент4 страницыThe A To Z of Valve Materialscool47guy09Оценок пока нет

- Alvaer DNV2.7-3 PDFДокумент23 страницыAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- 650-680 Rev 4 - Hydrostatic Test ExemptionsДокумент3 страницы650-680 Rev 4 - Hydrostatic Test ExemptionspediОценок пока нет

- M y Units of Gasket Seating StressДокумент11 страницM y Units of Gasket Seating StressLcm TnlОценок пока нет

- Nord Lock Washers InfoДокумент8 страницNord Lock Washers InfoMaclean ArthurОценок пока нет

- BREECH LOCK Presentation Dec2004 Tcm24 226146Документ24 страницыBREECH LOCK Presentation Dec2004 Tcm24 226146Harinarayanan Samsari Kizhake VeetilОценок пока нет

- Designing A CGMP BioprocessДокумент5 страницDesigning A CGMP Bioprocesshareesh13hОценок пока нет

- Development of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateДокумент23 страницыDevelopment of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateratnakarpatilОценок пока нет

- TorquingДокумент7 страницTorquingVicky KumarОценок пока нет

- Acid StorageДокумент1 страницаAcid StorageChelsea SkinnerОценок пока нет

- Spiral Wound GasketsДокумент3 страницыSpiral Wound GasketsHarish GundaОценок пока нет

- BEL - 6D Through Conduit GateДокумент2 страницыBEL - 6D Through Conduit Gateasoka.pwОценок пока нет

- Brittle Fracture of Carbon Steel Piping During Hydrostatic TestingДокумент4 страницыBrittle Fracture of Carbon Steel Piping During Hydrostatic TestingSH1961Оценок пока нет

- 1 Process VesselsДокумент4 страницы1 Process VesselsARIANA NICOLE RELIGIOSOОценок пока нет

- Composite Clamp Design, TestingДокумент15 страницComposite Clamp Design, TestingDaniel Inemugha100% (1)

- 1113 Maintenance of PRVДокумент63 страницы1113 Maintenance of PRVhardito sussatrioОценок пока нет

- Cast - Basket Strainers - 2nd EditionДокумент27 страницCast - Basket Strainers - 2nd EditionmartinnovelОценок пока нет

- Water SoftenersДокумент11 страницWater Softenersadel rihanaОценок пока нет

- Valves Reference PDFДокумент35 страницValves Reference PDFJulio RodriguezОценок пока нет

- BR 170 1Документ7 страницBR 170 1Himanshu ChaturvediОценок пока нет

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesДокумент4 страницыDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoОценок пока нет

- Trunnion Mounted Ball ValveДокумент20 страницTrunnion Mounted Ball ValveJignesh PandyaОценок пока нет

- Nabakem Metal Surface Coating AgentДокумент6 страницNabakem Metal Surface Coating Agentsutrisno00Оценок пока нет

- FOAMGLAS Cellular Glass InsulationДокумент18 страницFOAMGLAS Cellular Glass InsulationermizeОценок пока нет

- Basics On Piping LayoutДокумент11 страницBasics On Piping Layoutpuru55980Оценок пока нет

- Safety Maintenance-Cleaning For Oxygen ServiceДокумент2 страницыSafety Maintenance-Cleaning For Oxygen ServiceleapswitchОценок пока нет

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Документ23 страницыES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsОценок пока нет

- Heat ExchangerДокумент36 страницHeat ExchangerUsman MansuriОценок пока нет

- Pipeline Pigs What Is A Pipeline Pig?Документ11 страницPipeline Pigs What Is A Pipeline Pig?Vicente GLОценок пока нет

- Cryogenic Service Ball ValveДокумент2 страницыCryogenic Service Ball ValvesaminasritnОценок пока нет

- Pressure Vessel HandoutДокумент14 страницPressure Vessel HandoutEng Mohammed100% (1)

- Why InsulationДокумент13 страницWhy InsulationnguyenОценок пока нет

- Low Temperature and Cryogenic Ball ValvesДокумент4 страницыLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- Piping Fundamentals:: M.N.RaghuДокумент26 страницPiping Fundamentals:: M.N.RaghuAlex Salvin100% (2)

- Ball Valve Seat Seal Injection SystemДокумент28 страницBall Valve Seat Seal Injection SystemmudrijasmОценок пока нет

- MSA Ball Valves PDFДокумент24 страницыMSA Ball Valves PDFLuka Borna100% (1)

- 1 PipelineДокумент69 страниц1 PipelineEhab MohammedОценок пока нет

- Tstexhs: Exhaust Gas Heat ExchangersДокумент4 страницыTstexhs: Exhaust Gas Heat ExchangersTempcoОценок пока нет

- Requirement in EN ISO 1442 2017Документ6 страницRequirement in EN ISO 1442 2017Sơn Nguyễn TháiОценок пока нет

- Needle ValveДокумент8 страницNeedle ValveMuhammad Chilmi100% (1)

- BS 4504 Slip On Flanges PDFДокумент7 страницBS 4504 Slip On Flanges PDFMaclean ArthurОценок пока нет

- Intro To Process Engg and Design Thakore & BhattДокумент597 страницIntro To Process Engg and Design Thakore & BhattVikas Kamath76% (46)

- Molecular Sieve CalculationДокумент11 страницMolecular Sieve CalculationNanasaheb Patil100% (1)

- Chiller McQuay WSC (200-1250ton) WDC (400-2500ton) Chiller Centrifugo - Enfriado - Por - Agua PDFДокумент100 страницChiller McQuay WSC (200-1250ton) WDC (400-2500ton) Chiller Centrifugo - Enfriado - Por - Agua PDFNanasaheb Patil100% (2)

- Grinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and SwitchgrassДокумент14 страницGrinding Performance and Physical Properties of Wheat and Barley Straws, Corn Stover and SwitchgrassNanasaheb Patil0% (1)

- 0042 207x 2861 2990206 8Документ6 страниц0042 207x 2861 2990206 8Nanasaheb Patil100% (1)

- The Eomposition of Cashew Nut-Shell Liquid (CNSL) and The Detection of A - Copy (30165921)Документ2 страницыThe Eomposition of Cashew Nut-Shell Liquid (CNSL) and The Detection of A - Copy (30165921)Nanasaheb PatilОценок пока нет

- The Phenolic Acids of Pzsz"achia F'eraДокумент4 страницыThe Phenolic Acids of Pzsz"achia F'eraNanasaheb PatilОценок пока нет

- Studies On Cyclohexanone FormaldehydeДокумент5 страницStudies On Cyclohexanone FormaldehydeNanasaheb PatilОценок пока нет

- The Composition 01 The Unsaturated PhenolicДокумент8 страницThe Composition 01 The Unsaturated PhenolicNanasaheb PatilОценок пока нет

- High Production Volume (HPV) Chemical Challenge ProgramДокумент10 страницHigh Production Volume (HPV) Chemical Challenge ProgramNanasaheb PatilОценок пока нет

- Synthesis of A Novel Cardanol-Based Benzoxazine Monomer and Environmentally Sustainable Production of Polymers and Bio-CompositesДокумент6 страницSynthesis of A Novel Cardanol-Based Benzoxazine Monomer and Environmentally Sustainable Production of Polymers and Bio-CompositesNanasaheb PatilОценок пока нет

- Journal Chromatography, 213 (1981) 287-300: C15"n-. CI %I - N 8 n-2 11 R e - N 4 OH OH 0 11 74Документ14 страницJournal Chromatography, 213 (1981) 287-300: C15"n-. CI %I - N 8 n-2 11 R e - N 4 OH OH 0 11 74Nanasaheb PatilОценок пока нет

- The Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronДокумент23 страницыThe Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronNanasaheb PatilОценок пока нет

- Excavation Trench Permit Ex 1 F0206Документ5 страницExcavation Trench Permit Ex 1 F0206emeka2012Оценок пока нет

- CFM Tutorial 5Документ26 страницCFM Tutorial 5Nithin Yadav0% (1)

- Daily Lesson Log Personal Dev TДокумент34 страницыDaily Lesson Log Personal Dev TRicky Canico ArotОценок пока нет

- Geostats Pty LTD: Base Metal AnalysesДокумент1 страницаGeostats Pty LTD: Base Metal AnalysesJhony Enrique Morales LauraОценок пока нет

- Antibacterial Effects of Essential OilsДокумент5 страницAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- CBLMДокумент37 страницCBLMDTVS Inc.Оценок пока нет

- The Prosecution of Kim Jong Il - Accountability in A Post 9-11 WorldДокумент21 страницаThe Prosecution of Kim Jong Il - Accountability in A Post 9-11 WorldimpunitywatchОценок пока нет

- To Be or Not To Be Healthy 4144Документ3 страницыTo Be or Not To Be Healthy 4144Vesna Milosavljevic100% (1)

- Bakery Business PlanДокумент15 страницBakery Business PlanGayu AishuОценок пока нет

- Standard DetailsДокумент168 страницStandard DetailsMurathan Paksoy100% (1)

- TruEarth Case SolutionДокумент6 страницTruEarth Case SolutionUtkristSrivastavaОценок пока нет

- 2016 Liberal Policy ResolutionsДокумент86 страниц2016 Liberal Policy ResolutionsCPAC TVОценок пока нет

- Competency Competency Multiple Choice Multiple Choice ComputationДокумент4 страницыCompetency Competency Multiple Choice Multiple Choice ComputationAaron James LicoОценок пока нет

- This Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsДокумент2 страницыThis Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsKim TanОценок пока нет

- Ch09 Layout Strategy - StudentДокумент28 страницCh09 Layout Strategy - StudentMarineth MonsantoОценок пока нет

- Assignment 1 Front SheetДокумент9 страницAssignment 1 Front SheetBách PhạmОценок пока нет

- French Pharmacopoeia PDFДокумент15 страницFrench Pharmacopoeia PDFHasan Abu AlhabОценок пока нет

- HSE TBT Schedule - Apr 2022Документ1 страницаHSE TBT Schedule - Apr 2022deepak bhagatОценок пока нет

- Me22 M1a1Документ2 страницыMe22 M1a1Jihoo JungОценок пока нет

- Drug StudyДокумент4 страницыDrug Studysnowyfingers100% (1)

- Specification and Maintenance Manual: Sequence Flashing Lights (SFL)Документ13 страницSpecification and Maintenance Manual: Sequence Flashing Lights (SFL)Javier Eduardo Alzate BogotaОценок пока нет

- Materials Today: Proceedings: Ashish Malik, Shivam KohliДокумент7 страницMaterials Today: Proceedings: Ashish Malik, Shivam KohliSenthil KumarОценок пока нет

- Measurement and Correlates of Family Caregiver Self-Efficacy For Managing DementiaДокумент9 страницMeasurement and Correlates of Family Caregiver Self-Efficacy For Managing DementiariskhawatiОценок пока нет

- Endothermic ReactionДокумент8 страницEndothermic ReactionMibvase IkhuruvoseОценок пока нет

- Cytomegalovirus Infection and Disease in The New Era of Immunosuppression Following Solid Organ TransplantationДокумент9 страницCytomegalovirus Infection and Disease in The New Era of Immunosuppression Following Solid Organ TransplantationReza Firmansyah IIОценок пока нет

- Wel-Come: Heat Treatment Process (TTT, CCT & CCR)Документ14 страницWel-Come: Heat Treatment Process (TTT, CCT & CCR)atulkumargaur26Оценок пока нет

- Bituminous MixesДокумент13 страницBituminous MixesRanjit SinghОценок пока нет

- Quick Guide To Cardiopulmonary Care 4th EditionДокумент185 страницQuick Guide To Cardiopulmonary Care 4th EditionLorenzo Romero AlbarranОценок пока нет

- BETP - Exp Clientele Dir 2012 - 03may2012Документ187 страницBETP - Exp Clientele Dir 2012 - 03may2012Fernando EndayaОценок пока нет

- Respirator LangmanДокумент10 страницRespirator LangmanSavu MalinaОценок пока нет