Академический Документы

Профессиональный Документы

Культура Документы

Injection Moulding Trouble Shooting PDF

Загружено:

web312_tw100%(1)100% нашли этот документ полезным (1 голос)

17 просмотров3 страницыShort shot, record groove effect Adjust feed to minimum consistent cushion Increase injection pressure Increase injection speed Increase back pressure Increase barrel temperatures Increase mould temperature.

Исходное описание:

Оригинальное название

injection-moulding-trouble-shooting.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документShort shot, record groove effect Adjust feed to minimum consistent cushion Increase injection pressure Increase injection speed Increase back pressure Increase barrel temperatures Increase mould temperature.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

17 просмотров3 страницыInjection Moulding Trouble Shooting PDF

Загружено:

web312_twShort shot, record groove effect Adjust feed to minimum consistent cushion Increase injection pressure Increase injection speed Increase back pressure Increase barrel temperatures Increase mould temperature.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

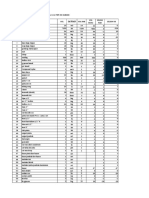

Performance Plastics Injection Moulding Trouble Shooting Guide

Fault

Recommendation

1. Short shot, record

groove effect

1.

2.

3.

4.

5.

6.

Adjust feed to minimum consistent cushion

Increase injection pressure

Increase injection speed

Increase back pressure

Increase barrel temperatures

Increase mould temperature, particularly for very

thin large area parts

7. Check non-return valve

8. Improve venting

9. Enlarge gates, sprue diameters and runners.

2. Weld line

1.

2.

3.

4.

5.

6.

Increase mould temperature

Increase injection speed

Increase melt temperature

Increase hold on pressure

Check venting

Relocate gate to change flow pattern

3. Sink marks

1.

2.

3.

4.

5.

6.

7.

8.

Increase injection pressure

Optimise holding pressure time

Reduce screw speed

Reduce nozzle and metering zone temperatures

Increase feed zone temperature

Adjust back pressure

Increase mould temperature

Enlarge gates and runners

4. Burnt streaks

(brown)

1.

2.

3.

4.

Increase back pressure

Decrease screw speed

Increase cylinder temperature

Use machine with larger barrel shot size

5. Moisture streaks

1. Sufficiently pre-dry material, check manufacturers

guidelines

2. Check packaging

3. Check storage of material

4. If possible, feed directly from the dryer in a closed

system

5. Increase back pressure

Performance Plastics Ltd

Tel.

0844 3351134

Fax

01425 403325

Website www.performance-plastics.co.uk

E-mail info@performance-plastics.co.uk

Performance Plastics Injection Moulding Trouble Shooting Guide

Fault

Recommendation

6. Cold slug

1. Increase nozzle temperature

2. Reduce injection speed

3. Create cold slug well in the mould opposite sprue

bush

7. Tails & Hooks

especially near raised

engraving etc.

1.

2.

3.

4.

5.

Reduce injection speed

Increase injection pressure

Increase mould temperature

Avoid sharp transitions, reduce engraving depth

Relocate gate

8. Glass fibre streaks

1.

2.

3.

4.

5.

Increase injection time

Increase mould wall temperature

Increase melt temperature

Optimise hold pressure time

Increase hold pressure

9. Jetting

1. Reduce injection speed or injection profile (slow

fast)

2. Increase melt temperature

3. Impinge gate onto mould wall/surface

4. Smooth transition gate to moulded part

5. Increase gate diameter

6. Relocate gate

10. Diesel effect

1.

2.

3.

4.

5.

Check vents are clear of dirt / debris

Reduce clamping force of the machine

Reduce injection speed

Ensure vents are deep enough

Avoid entrapped air by changing flow profile

11. Flash

1.

2.

3.

4.

5.

6.

Increase clamp force

Optimise change-over point

Reduce holding pressure

Reduce melt temperature

Reduce mould temperature

Stiffen mould

12. Delaminating

1.

2.

3.

4.

Eliminate contamination

Check compatibility of dye / masterbatch

Check moisture content

Check melt homogeneity and plasticising

performance

5. Reduce injection speed

6. Reduce melt temperature

7. Increase mould temperature

Performance Plastics Ltd

Tel.

0844 3351134

Fax

01425 403325

Website www.performance-plastics.co.uk

E-mail info@performance-plastics.co.uk

Performance Plastics Injection Moulding Trouble Shooting Guide

Fault

Recommendation

13. Blister

1.

2.

3.

4.

Slow down or reduce decompression

Check granule feed

Increase back pressure and adjust screw speed

Reduce metering stroke

14. Dark spots

1.

2.

3.

4.

5.

6.

7.

Check granule for impurities

Clean plasticising unit

Reduce barrel temperature

Reduce screw speed

Reduce back pressure

Check hot runner temperature

Reduce regrind dose

15. Cloudy / milky

transparent parts

1. Check for cross contamination with other polymers

in every area of operation.

16. Unusually low

maximum service

temperature

1.

2.

3.

4.

5.

6.

Increase melt temperature

Increase injection speed

Optimise injection hold position and time

Reduce injection pressure

Increase mould temperature

Maintain equal mould temperatures on both halves

of mould tool

7. Anneal parts at as high a temperature as possible

Performance Plastics Ltd

Tel.

0844 3351134

Fax

01425 403325

Website www.performance-plastics.co.uk

E-mail info@performance-plastics.co.uk

Вам также может понравиться

- EASE151855 Folder-QMC-Engels LRДокумент68 страницEASE151855 Folder-QMC-Engels LRweb312_twОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Heating and Cooling in Plastic Processing 07032014 Mr. Sanjiv ParikhДокумент40 страницHeating and Cooling in Plastic Processing 07032014 Mr. Sanjiv Parikhweb312_tw100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- COMP Polymer Applications Compendium 0130201Документ157 страницCOMP Polymer Applications Compendium 0130201web312_twОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Ge Valox PBT Pet PC E45329Документ40 страницGe Valox PBT Pet PC E45329web312_twОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Regloplas P100S LoResДокумент2 страницыRegloplas P100S LoResweb312_twОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Topic 3 - Cellular Materials-Foams (Part 2)Документ67 страницTopic 3 - Cellular Materials-Foams (Part 2)web312_tw100% (2)

- From Rotation To Swiveling: Injection MoldingДокумент4 страницыFrom Rotation To Swiveling: Injection Moldingweb312_twОценок пока нет

- Moldex3D ApprovedДокумент61 страницаMoldex3D Approvedweb312_twОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- SPE - Micro Injection MoldingДокумент60 страницSPE - Micro Injection Moldingweb312_twОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Arburg-Micro Injection MouldingДокумент12 страницArburg-Micro Injection Mouldingweb312_twОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Anton PaarДокумент16 страницAnton Paarweb312_twОценок пока нет

- Nisse I Injection Moulding Machines OpДокумент2 страницыNisse I Injection Moulding Machines Opweb312_twОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Introduction To VEL - Profile Die - 20120426Документ25 страницIntroduction To VEL - Profile Die - 20120426web312_twОценок пока нет

- Flange Leakage Check by DNV method-PASSДокумент9 страницFlange Leakage Check by DNV method-PASSJafer SayedОценок пока нет

- Mark Scheme (Results) Summer 2019: Pearson Edexcel International GCSE in Chemistry (4CH1) Paper 1CRДокумент27 страницMark Scheme (Results) Summer 2019: Pearson Edexcel International GCSE in Chemistry (4CH1) Paper 1CREZ25% (4)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- JEE - MODULE 4 - CHEM - Organic ChemistryДокумент214 страницJEE - MODULE 4 - CHEM - Organic ChemistryHrittik Das100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Matriculation Chemistry (Hydroxy Compound)Документ71 страницаMatriculation Chemistry (Hydroxy Compound)ridwan100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Food AdditivesДокумент78 страницFood AdditivesNaveenОценок пока нет

- 02 - Failure Analysis of Oscillating Hammer Mill Used in The Sugarcane Industry (2022)Документ16 страниц02 - Failure Analysis of Oscillating Hammer Mill Used in The Sugarcane Industry (2022)Jose Martin ChaconОценок пока нет

- Effect of Priming Treatment and Storage Containers To Enhance The Seed Quality of Tomato SeedsДокумент8 страницEffect of Priming Treatment and Storage Containers To Enhance The Seed Quality of Tomato SeedsMamta AgarwalОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 24 Organic Review 2023Документ37 страниц24 Organic Review 2023Elyssa En YingОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- A Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaДокумент8 страницA Novel and Rapid LC-MS:MS Assay For The Determination of Mycophenolate and Mycophenolic Acid in Human PlasmaFKUPN 2002Оценок пока нет

- 71 - Sterility TestsДокумент9 страниц71 - Sterility TestsPrincess DolphinОценок пока нет

- Sika Viscocrete - 5201nsДокумент2 страницыSika Viscocrete - 5201nssidath thiranjayaОценок пока нет

- M256 MSDSДокумент26 страницM256 MSDSBrian PonderОценок пока нет

- Rekapmaterial 9Документ1 страницаRekapmaterial 9harimurtieОценок пока нет

- Chemistry o Level NotesДокумент11 страницChemistry o Level NotesThaboooОценок пока нет

- US7503964Документ11 страницUS7503964leagallo00Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Inorganic Chemistry MCQ On Atomic StructureДокумент13 страницInorganic Chemistry MCQ On Atomic StructureHemant SadangiОценок пока нет

- RAB BLK - CirebonДокумент181 страницаRAB BLK - CirebonFebruar Suryadi MОценок пока нет

- 74-014 Duplex-Superduplex Ss Pipe To Astm A790 2020Документ13 страниц74-014 Duplex-Superduplex Ss Pipe To Astm A790 2020kuttub28Оценок пока нет

- Chemical Cross-Linking Methods For Cell Encapsulation in HydrogelsДокумент24 страницыChemical Cross-Linking Methods For Cell Encapsulation in HydrogelsBogdan CoșmanОценок пока нет

- WESER Stop Valve, With Plugged Drain Port, Union Thread, Figure 173 2GДокумент2 страницыWESER Stop Valve, With Plugged Drain Port, Union Thread, Figure 173 2GMihai Tudor DeacОценок пока нет

- Ullmann's Enc. of Industrial ChemistryДокумент72 страницыUllmann's Enc. of Industrial ChemistrySlim Toumi50% (2)

- Ch8651 Mass Transfer-Ii Unit IДокумент22 страницыCh8651 Mass Transfer-Ii Unit ISherly ThomasОценок пока нет

- A Thermodynamic Analysis of Methanation Reactions of Carbon Oxides For The Production of Synthetic Natural GasДокумент12 страницA Thermodynamic Analysis of Methanation Reactions of Carbon Oxides For The Production of Synthetic Natural GasJam imtiazОценок пока нет

- Mil STD 1246CДокумент36 страницMil STD 1246COmОценок пока нет

- Full Download General Organic and Biochemistry An Applied Approach 2nd Edition James Armstrong Solutions ManualДокумент36 страницFull Download General Organic and Biochemistry An Applied Approach 2nd Edition James Armstrong Solutions Manualwaylayfilsaxaq100% (26)

- ENSC 3520 - Chemical-Induced Carcinogenesis - Students PDFДокумент123 страницыENSC 3520 - Chemical-Induced Carcinogenesis - Students PDFSamuel WongОценок пока нет

- Fuels, Furnaces & Refractories 4Документ6 страницFuels, Furnaces & Refractories 4PRAKHAR SINGHОценок пока нет

- 1 - Volumetric Analysis v2Документ14 страниц1 - Volumetric Analysis v2skyeandoОценок пока нет

- Performance Task 2Документ8 страницPerformance Task 2sdasadsaОценок пока нет

- 12th Chemistry Loyola Guide New Edition 2022-2023 English Medium Download PDFДокумент25 страниц12th Chemistry Loyola Guide New Edition 2022-2023 English Medium Download PDFThamizh Murasu100% (1)