Академический Документы

Профессиональный Документы

Культура Документы

DJH USRA 2 8 2 Instructions

Загружено:

wizlish0 оценок0% нашли этот документ полезным (0 голосов)

17 просмотров7 страниц7-page instructions for DJH 'Masterpieces in Miniature' USRA light 2-8-2 kit.

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ7-page instructions for DJH 'Masterpieces in Miniature' USRA light 2-8-2 kit.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

17 просмотров7 страницDJH USRA 2 8 2 Instructions

Загружено:

wizlish7-page instructions for DJH 'Masterpieces in Miniature' USRA light 2-8-2 kit.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

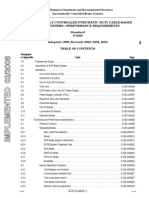

: USRA LIGHT 2-8-2 KITS

in ASSEMBLY INSTRUCTIONS

‘Take your time, read the notes, examine the drawings, and familiarise yourself

with the parts, then follow the simple stages and you will have a loco to rival

‘the best on your layout - built by you.

‘TOOLS REQUIRED: 2 or 3 Swiss files (small) - 10 second glue

i-pair of snips - A pair of pliers

Screwdriver — ‘Tweezers

‘The only other item required is a little effort from you, which will be amply

rewarded at the end by a beautiful running model.

1, ‘THE TENDER

Drawing 1. Take tender body (Part Number 105001) and place onto the tender floor

(P/N 101001) so that the screw holes line up, using seven screws (P/N 108071) and

secure parts together. "Take care not to over-tighten."

Drawing 2. Fit water hatch (P/N 101004) to tender top (P/N 101005) and apply @

Tittle glue to pins on underside of water hatch, now fit tender top to tender

floor (P/N 101001) with 2 screws (P/N 108091) from the underside of the tender.

Make sure you get a good fit here. A few rubs with a file down each side of the

tender top should ensure a snug fit with the sides. Now fit the tender footplate

(P/N 101003) to tender front (P/N 101002) with two screws (P/N 108048) (if you

find these Screws too short use (P/N 108044) x 2 from the extra bag provided).

Take completed part and screw to tender floor with two screws (P/N 108044).

Before tightening screws, make sure the tender footplate fits well around etched

brass tender sides, a little filing my help a better fit.

Drawing 8. Remove coal bunker floor (P/N 105002) from etched fret, lay it flat

Ghi-gently raise (bend) the rear part upward (it's the bit with two holes in).

‘A bend Line has been etched on the bottom of this plate to make sure you obtain

a straight edge. When you think it’s bent enough, try offering up the back part

of the plate to the raised part of the tender top. If it is bent right, the

front of the etching should fit snugly under the back of the tender front, see

diagram. When satisfied screw part to tender top with screw (P/N 108048). Take

The coal pusher (P/N 101006) and with a little glue place over screw head with

pin of coal pusher locating in correct hole, with wire going on top of part.

Tastly, glue the two front pre-bent handrails (P/N 108415) into the holes at the

front corners.

Drawing 4. Assemble trucks first, remove bolster plate (2) (P/N 105003) from

Frets, bend to 90° as per drawing. Screw to truck sideframes (P/N 101007) using

four screws (P/N 108371). Make sure the insulated wheels are fixed to the same

Side of the truck, you identify them as the insulated wheel has a nylon bush

insulating the wheel from the axle. It is best to tighten up one side then put

‘the wheels in, then tighten the other side. Place trucks on a piece of track

and see if they run true, if tight, check that you have the trucks sideframes

square to one another.

-2-

Drawing 5. Tur tender upside down, fit the brake cylinder (P/N 101008) with

a little glue in place, then rear foot boards (2) (P/N 107001 and 107002) with

screws (P/N 108031). Now take 2 screws (P/N 108370) and pass through springs

(P/N 108431) and trucks, then screw up to tender floor. Make sure the insulated

Wheels are all on the same side (it saves wondering way the loco shorts out

later). Fit coupler mounting screws (2) (P/N 108044). (Please note coupling

is not supplied in kit.) Finally, fit coupling pin (P/N 108441).

Drawing 6. Tender rear. Take rear ladder from fret (P/N 105004), fold up

‘along etched lines, to assemble them, glue in place. Next glue rear lamp in

Position (P/N 101009) then fit the 2 rear steps (P/N 101010) in place with a

little glue, to underside of the tender. Lastly, fit the 2 pre-bent rear

corner handrails (P/N 108416) and handrail (P/N 108423).

2, ‘THE LOCOMOTIVE,

‘SUPERSTRUCTURE,

Drawing 1. Unwrap cab from foam packing (P/N 105005). Check to see if all sides

are square. Next, snip the cab floor (P/N 105006) and cab apron (P/N 105007) out

of the etched fret. Bend cab aprom on bend lines as diagram, screw these parts

to the cab, using 4 screws (P/N 108057) and nuts (P/N 108055). (‘The best way to

do this is to turn the cab upside down, drop the cab floor onto bottom of cab,

as shown in illustration one. Make sure the holes line up. Screw the two front

screws in first, then do the same but with the rear making sure the cab apron is

in position, as shown. Hold the nuts inside the cab with a pair of pliers or

tweezers, then screw in from below.) Remove injectors (P/N 107003 and 107004)

from bag, and fit to cab apron with a touch of glue. Next fit small cylinder

casting (P/N 101011) to the cab apron with a touch of glue.

. Take out smokebox front (P/N 101012), bell (P/N 107005), headlight

an 101013) and three medium handrasl knobs (P/N 108407). Fit the headlight

to smkebox front with a touch of glue from the back (this prevents the glue from

showing if too much is applied). Next, fit the bell with a touch of glue and the

‘three handrail knobs, ensuring that the holes are lined up to enable wire to be

threaded through. Take out wire (P/N 108420) and pass it through these holes,

as shown in illustration two, the wire is pre-bent in a half circle.

Drawing 3. Take out boiler (P/N 101014), and file off any small casting lines

with needle file. Fit generator (P/N 101015) to boiler with glue. Fit pop valves

(P/N 107006) to boiler with glue. Assemble power reverse (P/N 101016), cylinder

(P/N 101017) and check valves (P/N 107007) to the boiler with a touch of glue.

heck that the check valve is parallel to the footplate. Next fit the smokebox

front, then fit the cab to the firebox using screw (P/N 108031) which goes

‘through the spectacle plate. Make sure the injector pipes line up with the cast

pipes on the firebox. Adjust with a small pair of pliers if necessary then fit

wire (P/N 108422) from cab to pump as shown. Put the wire in the cab first,

then fit it to the pump. Lastly, fit the builder and trust plates (P/N 105008).

You might find it easier to fit the plate after the model has been painted.

ae

Drawing 4. ‘Take out the cab roof (P/N 101019), back head plate (P/N 101018),

‘drop plate (P/N 105009), window shades (P/N 101020) and back handrails

(P/N 108417). Fit the window stiades above cab side windows and glue from

inside. Next, drop in the back head, fit this in position with screw

(P/N 108044) from below. It's best to turn the cab upside down and pass the

screw through first, before putting the back head in. Fit cab back handrails

into rear of cab, as shown using glue. Next, cut to shape and glue plastic

insulator (P/N 108425) onto bottom of drop plate. Screw this into position

with screws (P/N 108017) as shown. Check this flips up and down freely.

Bend down the seats on the side of the cab as shown in the drawing. Lastly,

fit the cab roof with two screws (P/N 108057), front and rear.

Drawing 5. Assenble turret and starter valves (P/N 107010) onto the firebox,

glue this from the inside, make sure you have this the correct way around.

Glue air tanks (P/N 101021 and 101022) into position as shown, next fit the

air pump (P/N 101023). Glue this from the inside, then (P/N 101025 and 107008)

making sure the check valve is parallel with the footplate. Afix the whistle

(P/N 107009) to side of steam dome as shown. Lastly, fit the builder and trust

plates (P/N 105008) onto the smokebox, choose the one you want. You might

find it easier to fit the plate after the model has been painted.

Drawing 6/7. Fit the seven handrail knobs (P/N 108407) on each side of the

boiler, then the two front handrail knobs (P/N 108406), then run the precut

handrails through the knobs. Glue the knobs in position. Next, fit the cooling

line assenblies (P/N 101026 and 101027), glue these in position as shown in

diagram. Lastly, fit the air pump strainer (P/N 101024) onto the pump on the

left-hand side of the loco as shown in drawing number seven.

GHASSIS

Drawing 1. Take out chassis frames (P/N 105010 and 105011) and bend ends to an

angle of 90° as shown. Take out three brass spacers (P/N 108396), one brass

spacer (P/N 108397), plastic spacer (P/N 108998), 8 screws (P/N 108386) and

2 screws (P/N 108387). Fit spacers to left-hand side of chassis with the screws

in position. Make sure the holes in the spacers are vertical when in position,

screw this to the other side of the chassis frame, as shown in diagram — check

you have the spacers the correct way around, check with the diagram.

Drawing 2. ‘Take out chassis keeper plate (P/N 105012) and bend up the end on

fold Lines at end as shown in diagram. Next, take out the driving wheels

(P/N 108357 x 3 and 108472), balance weights (P/N 101031 x 4, 101029 x 2 and

101030 x 2) glue these to the wheels as shown in diagram. Fit the wheels to

‘the chassis (the best way is to turn it upside down and slot the wheels in one

by one starting at the front). Make sure the bearing blocks slot in position as

shown in diagram. You may have to file the chassis frames with a Swiss file to

remove any burrs and ensure the bearing blocks fit properly. It is very important

at this stage to get the wheels installed correctly, (the insulated wheels go on

‘the left-hand side of the chassis)(the left-hand side is looking from the cab to

the front of the boiler) ~ make sure the gear wheel is in the correct position.

Fit the keeper plate (P/N 105012) with 2 screws (P/N 108387). You may find these

screws are too short, if so replace them with (P/N 108386)in the extra bag

provided. Lastly, spin the wheels to check they revolve freely. You may wish to

blacken the frame before installing the wheels.

Drawii Take out the etched brake shoes (P/N 105016, 105015, 105014 and

'T05013), 8 sleeves (P/N 108857) and 8 screws (P/N 108044), glue the sleeves

into the chassis. Fit the screw through the brake shoe and then screw into

the sleeve as shown in the diagram. It is very important that the brake shoes

do not touch the wheels.

Drawing 4. Take out the coupling rods (P/N 105017, 105018 and 105019) (snip

‘rom the nickel silver fret). Fit these to the chassis with 6 screws (P/N 108872).

Tt is vital that these are installed correctly as shown in diagram. Lastly, run

‘the chassis and ensure that it runs smoothly, make sure you have the rods the

right way up.

Drawing 5. Take out the cylinders (P/N 101032) and the cross head guides

(P/N 105020), 2 screws (P/N 108057), bend the ends of the cross head guides at

90° as shown in diagram. Screw these to the cylinders with screws (P/N 108057),

it is easier to put the cylinders front downwards and put the screws into the

cross head guides and then screw these to the cylinder blocks as shown in the

diagram. Check they are straight when you look from the side.

ing 6. Snip out the valve hanger (P/N 105021) from the nickel silver fret.

@ out valve hanger detail (P/N 101033) and 4 screws (P/N 108057). Screw these

into position as shown, checking that they are the right way round. (You have

to bend the valve hanger up as it is illustrated - make sure you bend these so

the etched line is on the inside of the bend.

Drawing 7. Take out the pilot and deck (P/N 101034) clean any excess casting

(flash) from between the bars at the front, this is easily removed with a knife

blade, then glue the 2 front handrail post holders (P/N 101035) in position.

You can fit the dummy coupler (P/N 101036) at this point if you wish, it fits

into position with the screw (P/N 108031).

Drawing 8. Snip out the motor mounting bracket (P/N 105022), bend this up as

‘Shown. Next screw the motor (P/N 108883) onto the motor mounting plate using

2 screws (P/N 108089), passing one of the screws through the (live +) terminal

washer as shown on diagram.

1 2 screws (P/N 108109) through the cylinders and beam ready to be fitted

onto the chassis. Next slot the cross head guides onto the valve hanger as

shown, when in position secure the two screws (P/N 108109) and the screw

(P/N 108387) to the chassis as shown on diagram.

Drawing 9. Take the cylinders assembled earlier, put these onto the front beam,

‘drop th

Drawing 10. Snip out rods (P/N 105025 and 105026) from the nickel silver fret.

t chéck the cross heads (P/N 107011) slide up and down the guides. Also make

sure the grooves in the cross head guide are free from burrs, this will make sure

the cross head runs freely. When satisfied, take out valve gear (P/N 105023 and

105024), screw (P/N 105023 and 105024) into the valve hanger using steel screw

(P/N 108020), this goes through the white metal part and then through both parts

of the valve gear. This is shown clearly on cut away drawing on the top right-

hand corner of drawing number 10. ‘The screw fixes into position on the back

with a nut (P/N 108030) - don't over-tighten the screw as I found it squeezed

the white metal together - you can fix the nut into position with a touch of glue

if desired, this prevents you looking along your track trying to find the lost

nut!

-5-

It is best to do one side of the valve gear at a time, this way you don't

hhave rods dangling on both sides. Next fit the cross head onto the cross

head guides, push it up to the cylinders as far as it will go, take out

steel screw (P/N 108380), fit this through the hole in (P/N 105023), this

fits through the cross head and then screws into the connecting rod (P/N 105025).

This is a slotted screw, and you can finger tighten, check if your valve gear

moves freely when the crosshead slides up and down. Next screw the return

crank (P/N 105024) onto the crankpin in the wheel (P/N 108472), this is the

wheel with the gear on. The steel screw (P/N 108057) fits through the return

erank, (if a tight fit, check there are no burrs on the inside of the holes,

‘remove Where necessary), and screw into the crank. The return crank has a

slot on the back which will correspond with the one on the crank, this gives

you the slight movement of the valve gear. Lastly, fit the front footplate

step and steam pipe (P/N 101037) onto the cross head using the screw (P/N 108094).

After fitting the valve gear give it a light oil and push the chassis up and

down a piece of track to give it a little run in. Lastly, fit the steam pipes

at the front as shown,

Drawing 11. Now that the chassis is running freely, fit the gear-box in

feaieioa (opm 108886), the top part drops onto the gear and the bottcm plate

screws up from below, turn the chassis upside down to do this. Fit the plastic

flexy sleeve (P/N 108662) onto the gear-box as shown. Next fit the motor shaft

onto the flexy shaft and screw the motor in position using 2 screws (P/N 108371).

lastly, take out the draw bar parts (P/N 108370, 105030, 105029, 108431 and

108105), fit these together as shown making sure (P/N 105030) fits into

(P/N 105029), there is a small hole in the rear for it to slot into. Make sure

when you fit’ this stage together the insulated terminal from the mtor is in

position.

Drawing 12. Fit the lead truck wheel (P/N 108207) into the truck body (P/N 105031),

‘turn it upside down and drop the keeper plate (P/N 105032) on, then screw it into

position using screw (P/N 108031) - do exactly the same for drawing number 13.

Drawing 14. ‘This stage is the final assenbly of the superstructure using 2 rear

fixing Screws (P/N 108031) and the front screw (P/N 108085). Fit the front wire

supports (P/N 108421) into the front beam before you fix the front screw in

position.

15, Fit the front lead and trailing trucks in position using the

shouldered screws (P/N 108371 and 108372), turn the loco upside down and place

it on something soft - in foam or material so as not to damage the paint finish.

A10___ bag _=contents

P c

101011, 101010 102010 Enpty 10103

101013 201025 101007101007 ao1oz 101029

101030 101030

301020 101023 101007 101007 301031101031

101017. 101024 101008 102009 101037 102038

101021.. 101035 101004 101006. 101033 101033

101022... 101016 101002 101003 101036 101039

101025

301026 301018

101027

301012 301019

D E P 6

101014 101002 101032 307032

301005 107010

#

307005 107009

105023

1 107007 1070

(105027 107008 10700

105024 107004 107003

1050:

105028 105030 aoe

105025

3

105026 205005

10500 105001

105020

105020

105006

105021. 105014 x 105013 x 3

105015 105004

105016

108656

108357 x 3

108472 108662

108872 x 6 108883

108920

108207 108912

108212

108229 x 4 a

108442

108419 x 2

108421 x 2 108420

108418 x 2 108417 x 2

108415 x 2

108423

°

108426 x 2

1osoa2,

105010 105022

105029,

20842

I

208366 x s—___99Uv

a080es.

wvey

ere i

on "

cose yp UT

—— serene

108032 x 6. wree

“ ree

aotoxo x 2] J

oscar x

08406

P

108370 x 3

108371 x 7 © 108396 x 3

108397 1083

108380 x 2 108398

Tn

wor

ae 18367 x5

——

BE r00089 2

ve. solos

trrere se

weeny — rrr 2

we xotone x 3

108044 x 2

108386 x 2

Вам также может понравиться

- AAR Spec S-4200Документ58 страницAAR Spec S-4200wizlish100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Cortex Inspection 4-27-16Документ9 страницCortex Inspection 4-27-16wizlishОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Serenics: Anti-Aggression Drugs Throughout HistoryДокумент9 страницSerenics: Anti-Aggression Drugs Throughout HistorywizlishОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Enola Low Grade Master Plan - Low Resolution DraftДокумент42 страницыEnola Low Grade Master Plan - Low Resolution DraftwizlishОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Absolyte Engineering PDFДокумент110 страницAbsolyte Engineering PDFwizlishОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)