Академический Документы

Профессиональный Документы

Культура Документы

Ethanol Manufacture

Загружено:

chemical78Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ethanol Manufacture

Загружено:

chemical78Авторское право:

Доступные форматы

ETHANOL MANUFACTURE

Process Description

CSR Distilleries Operations Pty Limited produces ethanol by the fermentation of sugars in molasses,

which is a by-product of the sugar milling process. The sugars are converted to alcohol using yeast. The

alcohol is then separated from the fermented wash and is processed and purified through a series of

distillation columns to produce ethanol with a strength of approximately 96% by volume (95SG).

The information below describes this process.

Molasses Production:

Ethanol Production:

FERMENTATION

CSR Ethanol is produced by the fermentation of the sugars in molasses.

Sucrose (disaccharide) is first converted to glucose or fructose (monosaccharides) through the following

hydrolysis reaction:

C112H24O11 + H2O 2C6H12O6

Sucrose Water Glucose

The Ethanol is then produced by the fermentation of these monosaccharide sugars according to the

following reaction:

C6H12O6 2C2H5OH + 2CO2

Glucose Ethanol Carbon Dioxide

The reaction is exothermic and liberates 1200 kJ/kg of ethanol.

ETHANOL MANUFACTURE

Process Description

Fermentation

ETHANOL MANUFACTURE

Process Description

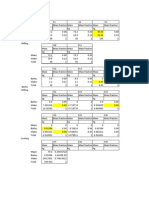

DUNDER

The concentrated effluent removed from the base of the wash column is called Dunder. This is

transferred to storage at Onooie for use as a fertilizer. At Onooie the Dunder is loaded into trucks for

irrigation of sugar cane crops. It may be nutrient enriched by the addition or urea and sulphuric acid to

produce Liquid One Shot.

PRE-DISTILLATION COLUMN

The dilute ethanol condensed from the wash column is then introduced to a pre-distillation column. Here

the ethanol is further diluted to ~ 15% v/v and many of the volatile impurities are removed (eg aldehydes

and ketones). The vapour from the top of this column is then fed into the purification column and the

dilute ethanol from the base of the column is fed to the rectifying column.

PURIFICATION COLUMN

The purification column concentrates the ethanol and impurities to ~ 95 - 96% v/v Ethanol. This product is

referred to as ‘heads’. Any excess ethanol from this column is fed back into the pre-distillation column for

reprocessing to minimise production of low grade heads.

RECTIFYING COLUMN

The rectifying column concentrates the ethanol to ~96% v/v Ethanol. Lower volatile impurities such as

propanol and fusel oils are removed from this column. For the purpose of this exercise, this product is

referred to as 95SG.

Вам также может понравиться

- Brief Refinery Write Up GRДокумент11 страницBrief Refinery Write Up GRShiv KumarОценок пока нет

- Supply ChainДокумент19 страницSupply Chainmarkkishan100% (2)

- Technical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanyДокумент26 страницTechnical and Economic Feasibility Study of Establishing Ethanol Fuel Plant in Kenana Sugar CompanyAymen babourОценок пока нет

- Material BalanceДокумент27 страницMaterial BalanceJohn Bryan AldovinoОценок пока нет

- 2.2 Manual Calculation of Materials and Energy Balances 2.2.1 Mass Balance Plant Complete If The Amount That Targeted Is AchievedДокумент34 страницы2.2 Manual Calculation of Materials and Energy Balances 2.2.1 Mass Balance Plant Complete If The Amount That Targeted Is AchievedmmbmnbmnbОценок пока нет

- Ammonium Sulphate ModifiedДокумент13 страницAmmonium Sulphate ModifiedNitin MohandasОценок пока нет

- Biomass Steam Power Plant LayoutДокумент4 страницыBiomass Steam Power Plant LayoutAli Raza RavianОценок пока нет

- Mass Balance Draft CHE 514N FORM-1-4-Calculation Sheets TemplateДокумент8 страницMass Balance Draft CHE 514N FORM-1-4-Calculation Sheets TemplateLouie G NavaltaОценок пока нет

- Ferrovanadium PDFДокумент199 страницFerrovanadium PDFMuhammad Rizki Ash-Shidiq0% (1)

- Sugarcane IntroductionДокумент2 страницыSugarcane IntroductionMahadevaiah KanchiОценок пока нет

- Liquid ChemicalДокумент5 страницLiquid ChemicalHenil DudhiaОценок пока нет

- WTE Project Finance PresentationДокумент22 страницыWTE Project Finance PresentationAugust Restiawan Soetisnjo100% (3)

- Class NoteДокумент58 страницClass NoteEmebu SamuelОценок пока нет

- Riskman SectionD Group3 Case2Документ8 страницRiskman SectionD Group3 Case2subhrajyoti_mandal100% (1)

- DR Seema ParohaДокумент21 страницаDR Seema ParohaTEERATH RAJОценок пока нет

- Paradeep DFRДокумент22 страницыParadeep DFRioeuserОценок пока нет

- Market Pulp Outlook: London Pulp Week November 2018Документ17 страницMarket Pulp Outlook: London Pulp Week November 2018Wagner V. Veríssimo (wvverissimo)100% (1)

- Mass Balance Grain Whisky Version 1.0Документ6 страницMass Balance Grain Whisky Version 1.0angry_granОценок пока нет

- Industrial Production of Ethanol From Sugar CaneДокумент4 страницыIndustrial Production of Ethanol From Sugar CanequixoticepiphanyОценок пока нет

- Stock Valuation 6 04112020 033540pmДокумент24 страницыStock Valuation 6 04112020 033540pmabcОценок пока нет

- LNG PDFДокумент16 страницLNG PDFFauzi badrikaraОценок пока нет

- Sugar Production ProcessДокумент2 страницыSugar Production ProcessedmarkОценок пока нет

- Ethanol From Molasses PDFДокумент20 страницEthanol From Molasses PDFmebrahtomОценок пока нет

- Water, Wastewater and Waste Management in Brewing IndustriesДокумент10 страницWater, Wastewater and Waste Management in Brewing Industriesuh6VGEvdLtgItjlSОценок пока нет

- Advanced Primary Treatment For Municipal WastewaterДокумент4 страницыAdvanced Primary Treatment For Municipal WastewaterSrđan MaletićОценок пока нет

- Flujo de Caja - Costos de ProducciónДокумент11 страницFlujo de Caja - Costos de ProducciónDanielIgnacioLuengoCordovaОценок пока нет

- BTU CalculatorДокумент1 страницаBTU CalculatorBenny W PriyonoОценок пока нет

- PolarimetryДокумент12 страницPolarimetryglasswavesОценок пока нет

- Production: Santosh Kr. Paswan Roll No 138510 ME3 YearДокумент21 страницаProduction: Santosh Kr. Paswan Roll No 138510 ME3 YearEricMargateОценок пока нет

- Technicalreport Alcoholtechnology PDFДокумент0 страницTechnicalreport Alcoholtechnology PDFAmol DeshmukhОценок пока нет

- Successful Trial of FRSДокумент4 страницыSuccessful Trial of FRSIfzal Mir100% (1)

- Virtual Sugarcane Biorefinery Report 2011Документ127 страницVirtual Sugarcane Biorefinery Report 2011Brazilian Bioethanol Science and Tech. LaboratoryОценок пока нет

- Vanillin From BagasseДокумент10 страницVanillin From BagasseUday Wagh0% (1)

- 2001 - Davis - The Chemistry of Colour RemovalДокумент9 страниц2001 - Davis - The Chemistry of Colour RemovalguigaldianoОценок пока нет

- Tequila VinassesДокумент9 страницTequila VinassesdomgarciОценок пока нет

- Distillery Spent Wash TreatmentДокумент21 страницаDistillery Spent Wash TreatmentTravis Morris0% (1)

- Ankush Agarwal New 12345Документ100 страницAnkush Agarwal New 12345Sharjeel AhmadОценок пока нет

- Fresh Refined Suger-Meghna Group of IndustriesДокумент16 страницFresh Refined Suger-Meghna Group of Industriesiphone nokiaОценок пока нет

- Diffusion Vs MillingДокумент4 страницыDiffusion Vs MillingcbqucbquОценок пока нет

- Tutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFДокумент38 страницTutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFBuyuОценок пока нет

- Sugarcane ProcessingДокумент17 страницSugarcane Processingdmttapia-1Оценок пока нет

- FACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFДокумент2 страницыFACTORY PERFORMANCE (KPI) JULY 2021 TO MAY 2022 (Version 1) .XLSB Rev1 PDFGeorge oburaОценок пока нет

- Description of Process - Nbsm-1Документ10 страницDescription of Process - Nbsm-1avisheklochunОценок пока нет

- Energy Balance On ReactorДокумент6 страницEnergy Balance On ReactorShahid IsmailОценок пока нет

- Issct 2013 Juice Extraction Systems PDFДокумент19 страницIssct 2013 Juice Extraction Systems PDFJeffersonPalacios100% (2)

- Distillery Wastwater Treatment-CDM Project-2012Документ60 страницDistillery Wastwater Treatment-CDM Project-2012tsrinivasan5083Оценок пока нет

- KemiraДокумент4 страницыKemiraMuhammad UmairОценок пока нет

- Nanofiltration and Reverse Osmosis in WinemakingДокумент5 страницNanofiltration and Reverse Osmosis in WinemakingfasihaОценок пока нет

- DMRДокумент4 страницыDMRkyamanywa richardОценок пока нет

- Material BalanceДокумент26 страницMaterial BalanceSai Krishna Lakkavajjala0% (1)

- Presentation by Dewan Mushtaq GroupДокумент21 страницаPresentation by Dewan Mushtaq Groupmms_mzОценок пока нет

- Part 3 Operation Standards For Ethanol Production Process EdДокумент12 страницPart 3 Operation Standards For Ethanol Production Process EdabrhshОценок пока нет

- BottlingДокумент14 страницBottlingWasiYamanChoudhuryОценок пока нет

- Calculos Formulacion AbonoДокумент23 страницыCalculos Formulacion AbonoJohan Vargas ArteagaОценок пока нет

- Sugarcane Processing Technologies: by Md. Akram HossainДокумент16 страницSugarcane Processing Technologies: by Md. Akram HossainDeva Mk100% (1)

- ADL 14 - Production and Operation Management MaterialДокумент90 страницADL 14 - Production and Operation Management Materialapandey_43Оценок пока нет

- Projected Cash Flow Keffi Flour Mills LimitedДокумент3 страницыProjected Cash Flow Keffi Flour Mills LimitedHrh SaddiquahОценок пока нет

- Fermentation of EthanolДокумент7 страницFermentation of EthanolGlenn GidoОценок пока нет

- Industrial Training 1Документ32 страницыIndustrial Training 1KumarShiveshОценок пока нет

- HW0021 Manufacture of EthanolДокумент5 страницHW0021 Manufacture of Ethanollily augustОценок пока нет

- Report (Surface Plasmon Resonance)Документ8 страницReport (Surface Plasmon Resonance)waseemwaseem33Оценок пока нет

- Hardness Conversion Chart: Rockwell Rockwell Superficial Brinell Vickers ShoreДокумент4 страницыHardness Conversion Chart: Rockwell Rockwell Superficial Brinell Vickers ShoreedwardpranantaОценок пока нет

- Upgrad Course Plan - FinalДокумент2 страницыUpgrad Course Plan - Finalmk_valiantОценок пока нет

- Inquiries, Investigations and Immersion: Quarter 3 - Module 1Документ8 страницInquiries, Investigations and Immersion: Quarter 3 - Module 1Kenneth BautistaОценок пока нет

- Activity 0 Blinking Led: Logic Circuit and Switching Laboratory Manual Msu-IitДокумент4 страницыActivity 0 Blinking Led: Logic Circuit and Switching Laboratory Manual Msu-IitMark EricОценок пока нет

- Manual IDEC FC5A AdvancedДокумент343 страницыManual IDEC FC5A AdvancedJoako FilipovichОценок пока нет

- Froebelian Eglantyne Jebb, Save The ChildrenДокумент3 страницыFroebelian Eglantyne Jebb, Save The ChildrenLifeinthemix_FroebelОценок пока нет

- Schumann Piano Concerto in A Minor Op 54 SM PDFДокумент101 страницаSchumann Piano Concerto in A Minor Op 54 SM PDFMKGUОценок пока нет

- Sheroune 2 1 1.aflДокумент11 страницSheroune 2 1 1.afludhaya kumarОценок пока нет

- HO4 EstimationДокумент9 страницHO4 EstimationMirza Naveed BaigОценок пока нет

- How To Get Google Maps API Key For Android. Issues and Errors SolvedДокумент11 страницHow To Get Google Maps API Key For Android. Issues and Errors SolvedFrancisco FeitosaОценок пока нет

- Lesson 7 Identifying and Analyzing ClaimsДокумент11 страницLesson 7 Identifying and Analyzing ClaimsConnieRoseRamosОценок пока нет

- P1 2012 Dec QДокумент6 страницP1 2012 Dec QBilal AliОценок пока нет

- Template CVДокумент2 страницыTemplate CVadera32Оценок пока нет

- EBOOK IDEO - HCD - ToolKit PDFДокумент200 страницEBOOK IDEO - HCD - ToolKit PDFangy_brooksОценок пока нет

- Six Levels of Linguistic AnalysisДокумент12 страницSix Levels of Linguistic AnalysisRoshio Tsuyu Tejido67% (3)

- Importance of Communication in SocietyДокумент16 страницImportance of Communication in SocietyPh843 King's Kids StudentCenterОценок пока нет

- Operational Categorization STДокумент3 страницыOperational Categorization STFalcon Peregrine100% (1)

- Grade 8 Term 3 Project 2021Документ2 страницыGrade 8 Term 3 Project 2021Londiwe PrincessОценок пока нет

- TcbrasterДокумент1 страницаTcbrasterjimusosОценок пока нет

- Nan-36creating Bluetooth® Low Energy Applications Using nRF51822Документ35 страницNan-36creating Bluetooth® Low Energy Applications Using nRF51822rm65457Оценок пока нет

- Slac Eval MayДокумент36 страницSlac Eval MayJMAR ALMAZANОценок пока нет

- SAP Query IntroductionДокумент7 страницSAP Query Introductionkashram2001Оценок пока нет

- xr602t Receiver ManualДокумент7 страницxr602t Receiver Manualrizky tantyoОценок пока нет

- Solman PDFДокумент71 страницаSolman PDFdav00034Оценок пока нет

- 9 tribologyofGO-UHWMPEДокумент10 страниц9 tribologyofGO-UHWMPEA P BОценок пока нет

- Visual ModelingДокумент6 страницVisual ModelingAlinordinОценок пока нет

- Dispute CaseДокумент4 страницыDispute CasedilansОценок пока нет

- MASTERY TEST IN SCIENCE 10 Module 3 Week 4Документ3 страницыMASTERY TEST IN SCIENCE 10 Module 3 Week 4christine ann sta. mariaОценок пока нет

- Pitch Lesson PlanДокумент6 страницPitch Lesson Planapi-318222702Оценок пока нет

- Sugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthОт EverandSugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthРейтинг: 4 из 5 звезд4/5 (6)

- The Obesity Code: Unlocking the Secrets of Weight LossОт EverandThe Obesity Code: Unlocking the Secrets of Weight LossРейтинг: 4 из 5 звезд4/5 (6)

- The Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyОт EverandThe Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Love Yourself, Heal Your Life Workbook (Insight Guide)От EverandLove Yourself, Heal Your Life Workbook (Insight Guide)Рейтинг: 5 из 5 звезд5/5 (40)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomОт EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomРейтинг: 4 из 5 звезд4/5 (1)

- The Noom Kitchen: 100 Healthy, Delicious, Flexible Recipes for Every DayОт EverandThe Noom Kitchen: 100 Healthy, Delicious, Flexible Recipes for Every DayОценок пока нет

- Summary of Mary Claire Haver's The Galveston DietОт EverandSummary of Mary Claire Haver's The Galveston DietРейтинг: 5 из 5 звезд5/5 (2)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsОт EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsРейтинг: 4 из 5 звезд4/5 (49)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincОт EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincРейтинг: 3.5 из 5 звезд3.5/5 (137)

- Secrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainОт EverandSecrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainРейтинг: 3.5 из 5 звезд3.5/5 (38)

- The End of Craving: Recovering the Lost Wisdom of Eating WellОт EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellРейтинг: 4.5 из 5 звезд4.5/5 (82)

- Find Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeОт EverandFind Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeРейтинг: 4 из 5 звезд4/5 (3)

- Glucose Revolution: The Life-Changing Power of Balancing Your Blood SugarОт EverandGlucose Revolution: The Life-Changing Power of Balancing Your Blood SugarРейтинг: 5 из 5 звезд5/5 (352)

- The Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthОт EverandThe Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthОценок пока нет

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookОт EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Eat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouОт EverandEat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouОценок пока нет

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОт EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОценок пока нет

- Metabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeОт EverandMetabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeОценок пока нет

- Grit & Grace: Train the Mind, Train the Body, Own Your LifeОт EverandGrit & Grace: Train the Mind, Train the Body, Own Your LifeРейтинг: 4 из 5 звезд4/5 (3)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingОт EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingРейтинг: 4 из 5 звезд4/5 (3)

- The Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodОт EverandThe Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodОценок пока нет

- The Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyОт EverandThe Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyОценок пока нет

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthОт EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthРейтинг: 2 из 5 звезд2/5 (1)