Академический Документы

Профессиональный Документы

Культура Документы

2851 - MS Electrical Works

Загружено:

leoconsolacionИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2851 - MS Electrical Works

Загружено:

leoconsolacionАвторское право:

Доступные форматы

P. O.

Box 70 Doha

State of Qatar

J~fi-:JJJ 69 Qatar Petroleum

Fax No +974-4291084 Tel No: +974-4240444

r---

I

! ;

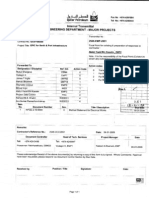

Internal Transmittal

ENGINEERING DEPARTMENT· MAJOR PROJECTS

Project No. 2546 Contract No.: GC07100300

Project Title: EPIC for Berth & Port Infrastructure

Transmittal No :

! 2546-EMP-2851 !

, Focal Point for collating & preparation of responses to

Contractor :

Abdul Yazid Bin Kassim ! EMP2

Note: It is the responsibility of the Focal Point (Collator) to obtain any outstanding responses.

1--_···

I Remarks:

i Contractor's Reference No.:

2546-CCC/2851

Date: 04-01-2009

Project Manager

~: _ --D~te - --l

i I

I I.

06-01-2009

Document Controller

Head of Tech. Services

Nabeel AI-Buenain, EMP

Tel: +974424 0498

Tel: +974-4240447

Prasannan Patinharekkara, EBM33

Vedagiri K, EMP1

Please acknowledge Receipt of the above document(s) by retuming a copy of this form duly signed. Where Comments / Approval have been requested, please respond via Document Control Section by Due Date,

Received by

Position I Title

Signature:

Date:

Page 1 of 1

PROJECT I CONTRACT REF.: 2546 I GC071 00300

ENGINEERING, PROCUREMENT, INSTALLATION AND COMMISSIONING (EPIC) FOR BERTHS AND PORT INFRASTRUCTURE FOR RAS LAFFAN PORT EXPANSION PROJECT

DOCUMENT TITLE:

METHOD STATEMENT FOR ELECTRICAL WORKS

JOiNT VENTURE

CONSOLIDATED CONTRACTORS GROUP S.AL rccc:

TEYSEER CONTRACTING COMPANY (TCC) www.ccc.qr

cccrrcc

REV

ClA/ClC Review

Reason For Revision

Checked

Date

Review

1

DOCUMENT NUMBER:

o

Method Statement for Electrical Works

Table of Contents

1.

Work

2.. Purpose

Definitions

4. References

5. Responsibilities

6. Procedure

7. Equipment Required for Execution of Job

8. Attachments

Page:2 of Ii

for

Electrical Works

1,0 SCOPE OF

& responsibilities

out

inside

2.0 PURPOSE

Is detail the

that

to be carried in order to have all

tools

to ensure that the work is being

in

manner.

DEFINITIONS

the purpose of this

the following definitions / abbreviation shall apply.

PROJECT COMPANY CONTRACTOR

Ras Laffan Port Expansion Project Qatar Petroleum (QP)

Consolidated Contractors International Company (CCIC)

Engineering, Procurement, Installation and Commissioning

Ras Laffan Industrial City Ras Laffan Power Company

Permit To Document

RLlC, RAS GAS & QATAR Location.

Method Statement

Quality Control Procedure

Inspection & Plan

Issued by QP, depending on

EPIC

RLiC RLPC PTW

Hazard Analysis

Health

REV. 0

Page :3

Method Statement for Electrical Works

REFERENCES

Philosophy

RPTY262.0001

Installation Standards-Power

RPGE,2.66.0001

Typical Installation Details - Electrical Building

RPGE.2.68.0001

Installation Details - Electrical Building Lighting Fixtures

RPTY.2.65.0001

Electrical Installation Standards Earthing

5.0 RESPONSIBILITIES

5.1 The Engineer/Foreman is responsible for all the activities that are being carried inside the building and at site. He shall ensure that all works are carried out according to applicable safety procedures and project specification.

Engineer/Foreman shall be responsible for carrying out work according to approved project construction drawing & specification.

5.3

Engineer! Foreman shall be responsible for material handling, loading

equiprnents, materials tools

unloading of

The engineer! foreman at site is also responsible for complete safety force.

to his

5.5 The Authorized work permit holder/signatory shall obtain work permits from

authorities,

shall fully

measures are implemented

1

to

on

out

in

PPE

RPGE-2-19-0004

Page 4 of 9

Method Statement for Works

-----_._------_.

Permits Work permit

be

from

HousekeeRing

Work site has to be Housekeeping shall be done on

(d) §ecurity

from environmental hazards.

Materials, equipments damages.

(e) In§Rection, Testing and Commissioning

in

around the worksite to be

thefts and

All installations shall be inspected by OP appointed supervisor approved inspection and test plan (ITP).

as per OP

62 Earthing and Lightning Protection

(a) Drilling Bore Holes for Earth Rod installation:

Certified auger machine to be mobilised to site.

Location of drilling to be marked up by surveyor as per project approved drawings. Verify underground facilities and ensure that drilling point is free from any underground utility like cable, pipeline etc.

Area shall be barricaded.

Only job assigned persons to be Competent person to operate the (b) Jnstaliation of Earth Rods and Earth Pits~

within

barricaded area.

Rods in

borehole,

pre cast concrete earth

it

connector as

REV, 0

Page 50f9

Method Statement for Electrical Works

Install

connect

to

bus

from the

Apply anti-corrosion flexible (d) Lightning Protection

Install tinned copper tape on roof parapet the approved lightning protection layouts.

to

and

and downwards as

Connect the tape to the connectors.

earth grid using yellow

earth

and

Typical installation details to be followed during installation and OP approval after installation is mandatory.

Raise RFI for activities inspection as per

ITP sequence of inspection.

6.3 Cable Tray and Ladders Installation

Offload cable tray and ladders from truck manually and with extreme care.

Stack the trays on wooden battens inside building or in a secured place with warning signs and barricade.

install supports for cable trays and ladder. Modify supports if required using drill machine, grinder and welding machine. Apply touch-up paint wherever required.

Raise RFi for cable tray installation prior to cable pulling.

Drums Meggering

When cable drums are received they shall be visually inspected to ensure that they are not damaged.

Inspection shall

raised for cable drums testing. tested (meggering and

electrician to out

shall be recorded as per to

as

on

Page 6 9

Method Statement for Elcctrkal'Vorks

Competent the cable as

to operate the

schedule and

Perform ladders.

Install identification tags as per standard

and

Proceed with

activity removing outer insulation jacket the

Dress the cable inside the equipment; crimp the conductors

terminate the ends on pre-assigned locations as OP approved drawings.

Perform meggering and continuity test after glanding and termination. Torque test to be performed on terminations using certified torque wrench.

6.6 DC High Voltage Test (For 33KV Cables and Below)

After completion of jointing, glanding and end terminations the cables will be remeggered.

Prior to commencing the high voltage test, the area should be effectively roped off to exclude unauthorized entry.

The tests will be conducted witnessed and recorded by the Site Electrical OC Inspector.

test will be applied to each conductor with

armour shields earth.

other conductors shorted to

The initial test voltage will be applied to the stabilize.

and the voltage allowed to

The applied voltage will be increased gradually until final test voltage is reached and the voltage and leakage current recorded each step after stabilization.

The final test voltage will be applied as per ITP's, the leakage current

no of insulation should occur.

When each test is complete and rubber insulated shall be

(Above

to

to

Doc. No. RPGE-2·19·00()4

REV. 0

Page 7 of 9

Method Statement for Electrical Works

on trench, followed.

procedure

Testing prior to installed shall be done

pre-commissioning vendor/specialist in accordance to project

All tests performed shall to approved

signed by CCIC and OP inspectors.

standard

& duly

6 .. 8 Small Power and Lighting Installations

Small power and lighting installation installation of GI conduits, trunking,

junction boxes, sockets switches, lighting fixtures, wiring etc.

All the above has to be carried and typical installation details.

International installation practice has to be followed through out the work execution.

in accordance with project approved drawings

Wherever necessary 'A' type ladders, scaffolding with safety harness has to be used for 100% fall protection.

Safety of personnel and property is the first priority.

Care has to be taken during wire insulation stripping by knife to avoid finger injuries.

Trained electricians to perform the task.

All circuits to be tested prior energising as per approved ITP.

Necessary tests to

performed and recorded for OP

6.9 Equipment Installation inside building (MCC, Power Distribution Boards, UPS, HVAC Panel)

All equipment to packing

transported from stores to worksite using a hiab truck/trailer. when equipments are

the equiprnents on

in upright position. certified crane.

Shift

or

tests

to

plan.

No. RPGE·2 .. 19·0004

REV. o

Page 8 of 9

Method Statement for Works

EQUIPMENT REQUIRED

EXECUTION

JOB

1

2 Hydraulic crane

3 Hiab truck

4 Dyna truck

5 Pick

Trailer

8.0 ATTACHMENT

8.1 Job Hazard Analysis

REV.1.l

<0 LL o

W 01

«I

0..,

o w (f)

:>

w a:::

I

I I

I 1

~-+'-+--+--+--1

1 en

, '-

~ CD CD E

..Q ._

E .g CO

CD CD 0 ,/',

~ 0..1 I'

0« CO I

~!QI L

I I i I

1 I I

I

o: !Z W ~ w 0::

::> a w rr:

COW 00.. Jo..

_lz 0«0 ffi~

z~ wo 00

,---,-------,----

c

(!)

E

0. '3 0'" w

tI= o

..c

,8 '~

(j)

(!) z « I o

iri o z

....

e

(j) l.0

E 0

(j) 0

..... 0

ns ~

....

W M

"C I

0 II) W

.r:::.x: CD

..... b. n,

(I) 0 a:::

:!::;: 0

z

E C\'l C

l.- f.) 00

o "i: 0::

u.t) UJ

.~~ (J)

II)W I

~L.. tl

«i 0 III

eLL "0

'-

< Q.

>. c

- "0

.! c;

::;

C\'l .8

U)

III

.D

C

ro

o ..- N c0 <i

0

:>

ur

0::

>. i

(/) I

- t I

(j) c: <D

c: (!) Q.

C E 0 I

0 0.. "-

f/l "5 0.. -I

.... o,

(!) 0-

o, W a

I

I

I

I :r::

c

0 '<t

:;:; 0

o 0

:::l 0

'-

_, ,

f/l CI)

C ..-

,

0 N

U ,

'+- W

0 Ci

-' Q.

c 0::

(!)

E ci

e Z

:>

0 ()

""- 0

2. 0

N (I)

'-

:::l

C -0

0 (!)

s: o

00 e

w CL

0 :=:

E

Q,

CL <5

c c o

~

(p

CL

i~

I>

I~

L

I !

I

I

, ,

I 'V i

110,

',91i

[0'1

, 'F

IN i ',' , I 'I.!.!

! C) I In.

ll:k:: I ! ci I Iz I

10 !

I 0 I r o I L __ ~,,_J

l<-

c

~

'-

(l) (D (l)

(D Cl·

:c c III

If) Cl) c,

c c

0 ui

a. 0 0

If)

QI 0 U

0::

0 U N rt:i ","l0 tci r--.:

-

s:

en 0)

l:i "C 0)

ro

-o E

m E u:i

.:c::. ... (IJ _,

3:«1 '(i5 U c

Il::::t: c ~ (D

0 c E

0 (D o,

0 e: c, ·S

0

s: (D ,_ 0-

;: 0.. 0.. W

(D

If) 0)

'0 ro

,_ E

ro

N ro

It! u

:::r:: I.f) ...-

c (D

E a. ·S 0- W

Q) 0) ro E ro -o

.::t:. U o ,I:: (I)

~

0

0

0

m

.....

,

N

ill

C)

a.

IX:

ci

z

Q

0

C

l.f:; -,

I ~I

WI

0::1

(0

....

I.)

,_ ifl

0 "- (II

If) (J)

"2: o til

fE II!

(J) !l.

c, 0

::! >.

(j) -

0 O~

U -00

U 0 O(f)

U 0 '0

..

....

e

0

U

- II)

t: "0

...

0) C'I:!

E N

flJ

Q) :x:

-

~

-

en

"0

0 fIl

J: ~

- ....

0) 0

::E3:

IE ~

r... 0

0 !.-

I.!..-

0

.!2 ~

fIlW

~ ....

m 0

t:1J..

0:(

>-

-

Q)

-

m

en II)

.tJ "0

,_

0 m

., N

II!

::J:

'ii

':;:;

c:

III

....

0

e, (J) E

I ill (J)

C '- 0- u x

(J)

jg£; 00 .~ ..c u If) C

OlCO c>' '6= CO CO o ::! _ C

tI= CO o E

o

--

u

c.

m

t!J

c C

~

m "oJ

E "Q

C

:J :;

I co :2

E ~

:J

..c 0

0

00 0

,

.. ~ m

0 ....

. C .

N

1.- .

III W

U C}

C C o,

0 ::J !l::

] ci

III :z

::n co u

_.

ro f,f')

U c 0

0

(0 I/)

"a

...

m

N \D

I'll

J: 0)

itl i- ro

E

:;:; ::; (\)

c: ·E~ 'U

(II

....

0 c

n, crl

E

::;

I

I/)

Q,

<I>

....

€I)

>.

-

':;

:;:;

g

« <0

:>

w e::::

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bee Ter Approval Dos DontsДокумент2 страницыBee Ter Approval Dos DontsleoconsolacionОценок пока нет

- UPCAT Reviewer Practice Test 2Документ36 страницUPCAT Reviewer Practice Test 2Eleder MaraОценок пока нет

- HV Cable SizingДокумент11 страницHV Cable Sizingvikasmit2k2100% (3)

- Islamic Centers, PhilippinesДокумент3 страницыIslamic Centers, Philippinesleoconsolacion100% (1)

- 2851 - MS Electrical WorksДокумент16 страниц2851 - MS Electrical Worksleoconsolacion100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)