Академический Документы

Профессиональный Документы

Культура Документы

Design of Machine Elements Par

Загружено:

boyo999100%(7)100% нашли этот документ полезным (7 голосов)

3K просмотров197 страницThe maximum tensile force from the sail during trimming operations is 15kN and acts at a distance of 100mm from the deck plate. Determine the required size of fillet weld for the support stem to deck plate connection if the allowable shear stress in the weld is 85MPa.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe maximum tensile force from the sail during trimming operations is 15kN and acts at a distance of 100mm from the deck plate. Determine the required size of fillet weld for the support stem to deck plate connection if the allowable shear stress in the weld is 85MPa.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(7)100% нашли этот документ полезным (7 голосов)

3K просмотров197 страницDesign of Machine Elements Par

Загружено:

boyo999The maximum tensile force from the sail during trimming operations is 15kN and acts at a distance of 100mm from the deck plate. Determine the required size of fillet weld for the support stem to deck plate connection if the allowable shear stress in the weld is 85MPa.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 197

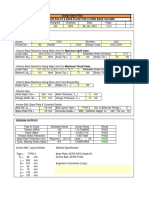

394 Design of Machine Elements Design of Welded Sons oe

15x10° _ 1337, 1 Na? © Solution:

Bending aes, Oo" TT" Tigv7 Th h This problem canbe solved by the following two methods:

Resultant ses, cording o mame shear srs theory Method 1

: : rows PSG 113, he ses induced in this type of welding

Leafy ,,,(2

toa beer = 2 (BP 66M,

oe HE) ool E) goats

aD

enss .

ar 2285 vin? 566.5410

ot 170 = ee! a=)

f hx Rx50? i )

‘Alowable shear ses inthe veld material oe om

smokin tress 125 7

j= BBL ste 125 125

actorof fey 16 Method 2:

Equating this Teac with the allowable shear stress of 78.125Nhun*

mans 2

572.85

7125

=8.6mm Say Sum Ans,

Result:

‘The weld siza, = 9mm

A manual winch for a sailing ship is

shown in fig. 3.5%. The maximum tensile

force from the sail during trimming

‘operations is ISKN and ate at a distance

of 100mm from the deck plate. A deck

plate is welded to the pivot support tem of

50mm diameter as indicated. Determine

the required size of filet weld for the

support stem to deck plate connection if

the allowable shear stress in the weld is

85MPa.

Fig. 3.57

‘The welded joint given ithe problem is subjced to direct shear stress and bending

sts

Area of weld, A = x Dt= x x 50 x 0.707 x h= 111A mm?

P_ 15000 135.5

atin 7 Nm

Bonding moment, M, = Px ¢ = 15000 x 100 = 1.5 x 10°N-mm

Frow able 32.6 oc PSGDB 11.6

Direct shear stross, t=

I weld thickness is considered

: (22 orm = PS orth 1388498 Ane

My _ 1sx1o _ 1080.54

7,7 Teak

Resultant stress, accocding to maximum shear stress theory

Bending stress, =

1 2 1 /f10s0.s4 135) _ 356.8

tae tye, eae Eff M8054) 4 (185) 556.8 vie

aoa = SEY oY = Sr

tis uequetooe sen me

5568

:

-SSmum Say Tun Ans.

Result:

‘The weld size, h= Tmt

3.96. Design of Machine Elemer

Bei ees

A plate bracket used to support a machine,

support plate and a central loading plate, as shown in fig. 3.58. Calculate the necessary size of

the fillet weld if the allowable shear stress in the weld is $0MPa. The arrangement should

provide a factor of safety of 1.6.

assembled using steel angle sections welded to a

| orate on

supe pate ee

ij ston ‘calor

Fig. 358

Given data:

WY SON

MPa

FOS = 1.6

To find:

Weld size,

© Soluion:

‘Tho weld structure given in the problem is subjected to direct shear and bending stresses

‘Area of weld, A= 600 +900 + 50 50-4 50 + 50) x 0.707h

A= 1414 om?

B_ S0xl0” _ 3536

Direct shear stress, e= Ze ST = SS

Bending moment, Ms = P xe

0 x 10 x 1800 = 90 x 10°N-mm

L

Section modulus, Zp —%

»

Design of Welded Joins

oreo

3.2.7 or PSGDB 11.6 i

bed a oon eee

wold is considered a fine of unit thickness. Since the structure is oy) 00

ee eee ee

weld portion (1, 28.3). Kea | Ret

Then the value is multiplied by 2to pot x offal portion

Tar" Te hat by= lo, PAUP) + (log * Aah) + (lo, +Aghs)

A,= 1x 900 9000? to

0 1 = Snot

mm)

bd? 1x900°

Toy = SL 200 50.75 x 1h

vr

Bd 50x?

Jam fg, = 2S = 4.167 mnt

By AIS

hy = F—y, =450~450=0

450-0 450m

+ d= (60.75 x 1084900 C+ (4.187 +50 450%) 4+ (4.167 +80» 450°) 81 x 108

For fill orton ofthe wld stwture

Fox =2 = 81 «10° = 162 x 10%mm*

1

Section modulus, Z, © 200 )

y= P8450

thickness of the weld is considered

Z = 360004) « 0.707 = 2545208 mn?

4G _ 90x10" 3536.

Bendingstes, o9= = og pwn!

Resultant stress,

3.98 Design of Machine Elements

(

blo shear sires, 1= 2 = 3D 4 Sonim”

‘lowable shear stress, ¢= “ESE = FE

quating the value of taf the allowable shear stress,

1803

i

cf 3s6mm Say donme

50

Result:

Weld sizo, h= 4mm

1A fabricated sel bracket frms th suppor fora machine hosting system as shown in fig 3:0

snd const of two boted connections and a welded pate connection. Calculate the required

filet weld sie forthe 30mm thick plate o baseplate connection i the allowable shear tet in

the weld is 20M

15}

(2st)

To find:

Weld size, h

Design of Welded Joints 3.99

© Solution:

From table 3.2.4 ar PSGDB 11.3, for this typeof weld

424PL _ 424x250? «280

ae Pol T*

Bending stress, =

= 28914 vp?

OT01P _ O707H25«10"

Diret shear stress, r= S77 pets

According to maximum shear stress theory, resultant shear stress

= 6.8mm say 6.5mm Au.

Result:

The weld size, b = 6.57

ae aes

Apts Stn lng ard 3mm hick is welded aright ane

te enor plata by mm fll wld ae shown in fg 46

Catala the manson torque that can be exerted by the plate

if the permissible shear stress in weld material is 45N/mu’.

Given data:

Length of weld, /= 500mm

Size of weld, h= 12mm

Permissible shear stress, t= 43N/inum?

To find:

Maximum torque exerted, Mr

Вам также может понравиться

- Machine Design ProblemsДокумент1 269 страницMachine Design ProblemsChristopher Petys90% (10)

- Solution Manual For Design of Machine Elements, 8 E 8th EditionДокумент57 страницSolution Manual For Design of Machine Elements, 8 E 8th Editionrubendoctora100% (1)

- Machine Design Solution ManualДокумент1 269 страницMachine Design Solution ManualDiana Barchuk0% (1)

- Machine DesignДокумент45 страницMachine DesignSean Ackerman78% (9)

- 1472636232Документ48 страниц1472636232Mushini Nagabhushan33% (3)

- Design of Machine ElementsДокумент150 страницDesign of Machine Elementsguru prasad100% (2)

- Design of Mechanisms Problem Set 9 With SolutionsДокумент31 страницаDesign of Mechanisms Problem Set 9 With SolutionsAshley Moreira67% (3)

- Shaft, Keys and CouplingДокумент29 страницShaft, Keys and CouplingDarshanОценок пока нет

- Machine Design Ebook1Документ184 страницыMachine Design Ebook1Hew LetОценок пока нет

- Theory of Machine and Mechanism (4th Sem)Документ336 страницTheory of Machine and Mechanism (4th Sem)Kishor Kunal80% (10)

- Design of Gantry GirderДокумент28 страницDesign of Gantry Girders_bharathkumar75% (12)

- Shaft DesignДокумент18 страницShaft DesignWest100% (1)

- Machine DesignДокумент520 страницMachine DesignMohan Varkey100% (2)

- 50998335YG1M - Design of Machine Elements - II - Solution ManualДокумент80 страниц50998335YG1M - Design of Machine Elements - II - Solution ManualKetan V. JoshiОценок пока нет

- Machine DesignДокумент170 страницMachine DesignkokoОценок пока нет

- Belt DesignДокумент56 страницBelt DesignJade Jazzrel Maglente Aclaro0% (1)

- Design of Helical SpringsДокумент32 страницыDesign of Helical SpringsAHMAD FIRDAUS ILIAS100% (1)

- Design of Machine ElementsДокумент508 страницDesign of Machine ElementsPrashanth Kumar93% (15)

- Machine DesignДокумент463 страницыMachine DesignReymart Ebora100% (4)

- Machine Design Shaft DesignДокумент8 страницMachine Design Shaft DesignJer LaguitanОценок пока нет

- Machine DesignДокумент376 страницMachine Designssierro100% (5)

- 5.2 Flanged Bolt CouplingДокумент11 страниц5.2 Flanged Bolt CouplingShayneBumatay0% (1)

- Design of Machine ElementsДокумент92 страницыDesign of Machine ElementsDida Khaling100% (2)

- 77-3 Bevel GearДокумент7 страниц77-3 Bevel Gearrip1111760% (1)

- Machine Elements in Mechanical Design Solution PDFДокумент309 страницMachine Elements in Mechanical Design Solution PDFazkonaОценок пока нет

- Machine DesignДокумент412 страницMachine Designrajmarathi100% (1)

- NPTEL - Design of Machine Elements 1Документ464 страницыNPTEL - Design of Machine Elements 1Hardik Gupta75% (8)

- Engg Sol ManualДокумент133 страницыEngg Sol Manualmiddieman147100% (6)

- Machine Design Final ReportДокумент23 страницыMachine Design Final ReportAvk Sanjeevan100% (2)

- Machine Design - Design of ClutchesДокумент12 страницMachine Design - Design of ClutchesSachin Chaturvedi90% (21)

- 4363 111 Machine Design IДокумент6 страниц4363 111 Machine Design Iyogesh_b_k100% (2)

- Notes On Lesson: Faculty Name Code Subject Name CodeДокумент108 страницNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoОценок пока нет

- ASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeДокумент3 страницыASME Shaft Design Allowable Stress and Diameter Equations and Calculators - Engineers Edge - WWW - EngineersedgeGautam Tyagi100% (1)

- Mech-V-Design of Machine Elements I U6Документ27 страницMech-V-Design of Machine Elements I U6Haniya FathimaОценок пока нет

- Mechanical Design PART - 01: Buet Buet Buet BuetДокумент71 страницаMechanical Design PART - 01: Buet Buet Buet BuetShadmanSakiefHridoy100% (1)

- 2 Chain DrivesДокумент35 страниц2 Chain DrivesMohammad UmairОценок пока нет

- Machine DesignДокумент495 страницMachine DesignWalter Zert100% (2)

- Structural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesДокумент122 страницыStructural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesPascasio PascasioОценок пока нет

- Indrumator Metal - EGДокумент37 страницIndrumator Metal - EGhooky1100% (1)

- Chapter 6 SolnДокумент7 страницChapter 6 SolnJayesh BankotiОценок пока нет

- Plate Girder DesignДокумент8 страницPlate Girder Designkalpanaadhi100% (1)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDДокумент4 страницыDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghОценок пока нет

- DSS AssignmentДокумент29 страницDSS AssignmentRahul SharmaОценок пока нет

- Base Plate DesignДокумент32 страницыBase Plate DesignGautam Sharma50% (2)

- Vinyl Acetate MonomerДокумент21 страницаVinyl Acetate Monomermardhiatul.asmaОценок пока нет

- At Very Low Cutting SpeedsДокумент40 страницAt Very Low Cutting SpeedsThulasi Ram100% (1)

- Concrete CalculationДокумент10 страницConcrete CalculationKaye Ibañez CastilloОценок пока нет

- Design of Base Plate As Per IS800Документ180 страницDesign of Base Plate As Per IS800buildcon62% (13)

- Unit 5Документ31 страницаUnit 5Nirina ArimananaОценок пока нет

- Case Study ppt11Документ25 страницCase Study ppt11WHATS APP STATUSОценок пока нет

- DmeДокумент13 страницDmebaskarkmlОценок пока нет

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsДокумент26 страницWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraОценок пока нет

- Sebuah Poros Berputar 200 RPMДокумент5 страницSebuah Poros Berputar 200 RPMaming amongОценок пока нет

- 77-9 Design of CranesДокумент10 страниц77-9 Design of Cranesrip111176Оценок пока нет

- Weld Design CalculationsДокумент7 страницWeld Design CalculationsanwarОценок пока нет

- Design of Retaining WallДокумент6 страницDesign of Retaining WallSasidhar KatariОценок пока нет

- Toaz - Info Merge PRДокумент81 страницаToaz - Info Merge PRMildred CanopinОценок пока нет

- Pile Cap Design 1Документ19 страницPile Cap Design 1katheranОценок пока нет