Академический Документы

Профессиональный Документы

Культура Документы

E 2

Загружено:

thirumalaichettiar0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров5 страницMaximum reinforcement for under reinforce section for Limit state design is O.96%bd as b=1000mm for slab and d is in mm. Minimum reinforcement is 0.12%bd. The maximum spacing of MAIN BARS shall not exceed 200mm, preferably to 150 mm and but not less than 100mm.

Исходное описание:

Оригинальное название

e2

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMaximum reinforcement for under reinforce section for Limit state design is O.96%bd as b=1000mm for slab and d is in mm. Minimum reinforcement is 0.12%bd. The maximum spacing of MAIN BARS shall not exceed 200mm, preferably to 150 mm and but not less than 100mm.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров5 страницE 2

Загружено:

thirumalaichettiarMaximum reinforcement for under reinforce section for Limit state design is O.96%bd as b=1000mm for slab and d is in mm. Minimum reinforcement is 0.12%bd. The maximum spacing of MAIN BARS shall not exceed 200mm, preferably to 150 mm and but not less than 100mm.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

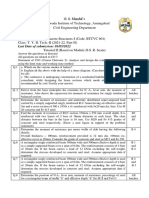

TABLE-l

SI.No. DESCRIPTION OF PANEL I/d(oriX/d) VALUES

IS 456:1964 IS 456:2000 SP:24-1983

For slab panels not supporting brick partition

For slab panels directly supporting brick partition.

1. Simply supported slabs

Spanning in one direction 30 23 25

2. Simply supported slabs

Spanning in two direction 35 25 30

3. Continuous slabs

Spanning in one direction 35 28 30

4. Continuous slabs

Spanning in two direction 40 32 35

5. Cantilever 12 9 10 c. The maximum reinforcement for under reinforce section for Limit state design is O.96%bD as b=1000mm for slab and d is in mm .

d. The minimum reinforcement is·0.12%bd.

e. The Moment of resistance factor Ru=2.76 bd·,,2 for M20 and Fe415.

f. The fever arm z will vary from 0.774 to 0.95 depending on the position of Neutral axis depth. But practical value of 0.87 shall be used to arrive at the steel reinforcement. When the value of

M/bdJ\2 is less than 1.27 the lever arm shall be taken as 0.95d.

g. The value of z/d value can be obtained from the Rg(l) attached for 2

the value of M/bdA •

h. The maximum spacing of MAIN BARS shall not exceed 200mm, preferably to 150 mm and but not less than 100mm. (Ref:

-3-

Illustrated Design of RC building by KaNe, Khanna Handbook &. Torsteel Handbook).

The steel as required at support will be used at mid-sapn also to reduce the deflection and to achieve economy. This is as per 5P24: Explanatory HB of Plain &. RC 15456: 1978.

Please note that too much increase of steel at the mid-span section for the purpose of reducing deflection is not desirable for reason of economy and also for the reason that stell may not remain ductile.

i. The maximum spacing of DISTRIBUTORS shall not be more than 300mm and but not less than 100mm. The table 2 will aid without calculating the amount of reinforcement.

Table 2

Distribution steel per meter width for different depth of slab using Fe415Kn/Sq.mm grade of steel. The value of spacing is given in mm.

Depth Diameter of bar(mm)

Mm 6MM 8mm 10mm 12mm

90 250 - - -

100 225 - - -

110 200 300 - -

120 180 300 - -

130 180 300 - -

140 160 300 300 -

150 150 275 300 -

160 140 250 300 -

180 130 225 300 -

200 110 200 300 300 The maximum spacing is restricted to 300mm where it is more than 300mm.

j. The lap length of bars shall be in tension as the earthquake forces are reversible nature. For various grade of concrete and for Fe41SN/sq.mm the lap length shall be

Grade of concrete Lap lengthx dia. of bar (in mm)

MIS 570

M20 470

M2S 40 0

-4--

k. The dead weight of slab = 25D KN/Sq,m where D is the total thickness in meters.

The dead weight of brick wall =2Oxwidth of wall x height KN/m. The finish weight is taken as 1.5 KN/Sq.m.

DESIGN STEPS(slab) :

1. Determine the loading class for the slab (live load) for which it will be used.

2. Calculate the loading intensity excluding the self weight of the slab w1= LL+Finishes+partition if any. Then w1/lx is calculated.

'-- 3. Find out the end condition of the slab around its perimeter(i.e fixed or

Free) and calculate Iy/lx ratio .

.....

4. For the value of Iy/lx ratio and the boundry condition of the slab find out

the moment coefficient from the table 26 of 15456: 2000 for two way slab

'- if Iy/lx is less than or equal to 2.0. Let this coefficient be ~.

5. Calculate ~Ix value. Using this value and wI/Ix find out the IX/d value

from the Fig 2 or Fig3 or Rg4 attached.

"- 6. Calculate the total load :

D. L: self weight of slab =25D KNjSq.m

Finishes =1.25 KNjSq.m

Partitions if any = 1.0 (say) Kn/sq.m

L.L = 2.0 (say for residential building)

Total load =Ws

Total ultimate load Wd =1.SWs

7. Calculate k1 2

=Wdxlx

8. Calculate the maximum Bending moment over the support by taking the

'- appropriate moment coefficients from the table for the short and long

span. f3x*kl=B.M for short support moment=Mx J3y* kt= B.M for long support moment=My

We will use either the manual calculations to find out the steel area or from the values as given in the SP 16:Design aids for Reinforced concrete to 15456.

-s-

USE OF DESIGN AID:

Ro..: 3 2

9. Calculate := Mx*10 /d where Mx in KNm. Also findout the value of

Ru'y= MY*103/d.2 Referring to Design aid table find out the p the % of steel area. Calculate the steel required for the short as well as for the long

span supports. l.e Ax=px10xd (where d is in mm.) sq.mm.

Ay=px10xd (where d is in mm.) sq.mm.

Referring again the tables the spacing of the bars from the area of steel can be found out. But restrict to a maximum spacing of 200mm to the short span and 300mm for the long span.

MANUAL CALCULATION:

10. Effective depth d =V MxXl03 /2.76 = 19.03 VMx where Mx is in KNm.

11. Find the value of Z the lever ann from the Fig(!).

For short span support.

3 / _ 6 /

12. Ax = Mx*10 0.87 Fy z d -Mx*10 z dxO.87x41S =2769.70 MX/zd

Ax =2769.70 Mx/0.87xd=3183.56 Mx/ d if Kx>1.27

Ax =2769.70 Mx/0.95xd=2915.47 Mx/ d if Kx<1.27

For long support.

13. Ay = My*10 3 /0.S7Fy Z dl=Mx*10 6 / z di xO.S7x415 =2769.70 MJ z di Ay =2769.70 MY/O.87X dl=3183.56 My/ di if Kx>1.27 / z=0.87/ d1=d. 0 Ay =2769.70 MY/O.95X di =2915.47 My/ di if Kx<1.27 / z=0.95/ dl=d. 0

14. Spacing of bars s = 100Oxa/Ax for short support restricting to a maximum value of 200mm.

15. Spacing s= 1000a/Ay for long support restricting to a maximum spacing of 300mm.

Spacing for

80 100 120

50240/ Ax or Ay 78500/ Ax or Ay 113040/ Ax or Ay

160 200960/ Ax or Ay

***************************************************************

70

A MANUAL OF LIMIT STATE DESIGN

Chart 6.9. Minimum effective depth for solid slabs for moment and deflection control in accordance with

IS: 456-2000 Fe 415 Notes:

1. W= WI + W2

2. W2 = Selfwt of slab

3. WI = Slab loading less self wt of slab in kN/m 2

4. 1 = Span in short direction in (rn)

5. For two-way slabs, replace 1 with x

6. 13 = Coefficient of moment (M = 13 wl1 at the midspan section in the short direction.

(Exception: For cantilever slabs 13 = 0.5 )

7. Slab panels are supposed to support brick partitions.

Fe 415

M 15 D/dsl.25

I!l(m)(M~f3wl2)

DEdge conditions in short direction

1·25

--1---4--1-1'2 r---If--t--I--

_-+-_-4-_~--l-1·1 +--+---I--+-+-

--I--+--+--+--+ 1·0 +-+--+--+---11---+-

--l---l--+--+--+--4 0 ·9+--+--+----If--+----+--+-

0'8 r--+---I---f---+-+--l--+--

4'0 3-5 30 2·5 2·0 1-5 1·0 O'S 0

- ~' (k'Njm2)

0·5 "0 ',5 2·0 2·5 3·0 3·5 "0

t(kN/m2)

SLABS-SOLID, R 10

9

t 6 !(m) 5

Chart 6.10. Mini

Two-wa: two-way pan continuous e based on the torsional rigi of the grid ge be closely Sl trapezoidal ( Formulae an spacing ofril ribbed slabs

Flat sla analysed by

Вам также может понравиться

- Deflection1 Bhatt BookДокумент10 страницDeflection1 Bhatt BookthirumalaichettiarОценок пока нет

- Top Down ConstructionДокумент15 страницTop Down ConstructionUkhti EvHaОценок пока нет

- Ponding On The Flat RoofsДокумент4 страницыPonding On The Flat RoofsthirumalaichettiarОценок пока нет

- Getting Started With AutoCAD® Structural Detailing, Steel ModuleДокумент49 страницGetting Started With AutoCAD® Structural Detailing, Steel ModuleAllan David100% (1)

- Deflection1-Bhatt Book PDFДокумент10 страницDeflection1-Bhatt Book PDFthirumalaichettiarОценок пока нет

- Getting Control of Expansive SoilДокумент21 страницаGetting Control of Expansive SoilthirumalaichettiarОценок пока нет

- Components For AutoCADДокумент7 страницComponents For AutoCADthirumalaichettiarОценок пока нет

- 02 WallsДокумент32 страницы02 WallsAmmar AbusalehОценок пока нет

- At FB TD Te TF: Examp/e 4.1Документ1 страницаAt FB TD Te TF: Examp/e 4.1thirumalaichettiarОценок пока нет

- Tab/e Loading End Near Midd/e Penu/ti-Midd/e Other Mate Interior Interior Source Span Support Spans SupportsДокумент1 страницаTab/e Loading End Near Midd/e Penu/ti-Midd/e Other Mate Interior Interior Source Span Support Spans SupportsthirumalaichettiarОценок пока нет

- Notes On Structural DetailingДокумент1 страницаNotes On Structural DetailingthirumalaichettiarОценок пока нет

- Is 14458Документ9 страницIs 14458thirumalaichettiar0% (1)

- Tab/e Loading End Near Midd/e Penu/ti-Midd/e Other Mate Interior Interior Source Span Support Spans SupportsДокумент2 страницыTab/e Loading End Near Midd/e Penu/ti-Midd/e Other Mate Interior Interior Source Span Support Spans SupportsthirumalaichettiarОценок пока нет

- Wood& ArmerДокумент9 страницWood& ArmerthirumalaichettiarОценок пока нет

- Lime MortarДокумент2 страницыLime MortarthirumalaichettiarОценок пока нет

- Isolation of Foundation From Swelling Zone by Using Soil: Cohesive Non Swelling (CNS)Документ16 страницIsolation of Foundation From Swelling Zone by Using Soil: Cohesive Non Swelling (CNS)thirumalaichettiarОценок пока нет

- Typical Values of e For SoilДокумент1 страницаTypical Values of e For SoilthirumalaichettiarОценок пока нет

- Aerocon BlockДокумент5 страницAerocon BlockthirumalaichettiarОценок пока нет

- Aci Crack WidthДокумент6 страницAci Crack WidththirumalaichettiarОценок пока нет

- NotesДокумент1 страницаNotesthirumalaichettiarОценок пока нет

- Quadratic, Cubic, Quartic Equation SolverДокумент6 страницQuadratic, Cubic, Quartic Equation SolverthirumalaichettiarОценок пока нет

- Compound Wall LHardДокумент1 страницаCompound Wall LHardthirumalaichettiarОценок пока нет

- Isolation of Foundation From Swelling Zone by Using Soil: Cohesive Non Swelling (CNS)Документ16 страницIsolation of Foundation From Swelling Zone by Using Soil: Cohesive Non Swelling (CNS)thirumalaichettiarОценок пока нет

- DetailingДокумент3 страницыDetailingthirumalaichettiarОценок пока нет

- SupportsДокумент6 страницSupportsthirumalaichettiarОценок пока нет

- Construction LoadspdfДокумент3 страницыConstruction LoadspdfthirumalaichettiarОценок пока нет

- Scale FactorДокумент2 страницыScale FactorthirumalaichettiarОценок пока нет

- Column Unsupported LengthДокумент1 страницаColumn Unsupported LengththirumalaichettiarОценок пока нет

- T06 Modal Analysis BLDДокумент15 страницT06 Modal Analysis BLDMiguel PalominoОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- 1589314418-09 - Principles of Structural AnalysisДокумент50 страниц1589314418-09 - Principles of Structural AnalysisfranklinОценок пока нет

- Alpha PipesДокумент4 страницыAlpha PipesDanish KhanОценок пока нет

- Appa PDFДокумент7 страницAppa PDFsmwassyОценок пока нет

- An Experimental Study On Kevlar Strengthening of Beam Column ConnectionsДокумент9 страницAn Experimental Study On Kevlar Strengthening of Beam Column ConnectionsMarimuthu KaliyamoorthyОценок пока нет

- 2 2.F2Документ43 страницы2 2.F2Amarjit KulkarniОценок пока нет

- Ground Floor Plan 1:100: Proposed Residen Tial BuildingДокумент4 страницыGround Floor Plan 1:100: Proposed Residen Tial BuildingLubangakene BrianОценок пока нет

- Bogvik Pattern List 19 - KleДокумент19 страницBogvik Pattern List 19 - KleShanghai Bogvik Wear Material Co., LtdОценок пока нет

- Manufacturing Processes Booklet PDFДокумент47 страницManufacturing Processes Booklet PDFmdbedareОценок пока нет

- Equity Trading Fundamentals - Full CourseДокумент26 страницEquity Trading Fundamentals - Full CourseKayerinna PardosiОценок пока нет

- Damp Proof CourseДокумент15 страницDamp Proof CourseKhalida ParveenОценок пока нет

- Methodology - Hydro ProjectДокумент6 страницMethodology - Hydro ProjectsugurpraveenОценок пока нет

- Dead Load 2.0kpa (Due The Purlins, Truss, Roofing, Etc .) Live Load 1.0Kp A P 2Документ2 страницыDead Load 2.0kpa (Due The Purlins, Truss, Roofing, Etc .) Live Load 1.0Kp A P 2Francis Philippe CariñoОценок пока нет

- Orientation On BLGU and MLGU Compliances For RAДокумент33 страницыOrientation On BLGU and MLGU Compliances For RARico TomimbangОценок пока нет

- Benefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Документ4 страницыBenefits of Steel RC Shear Walls in Building Structures - ETN-D-8-21Babrak Khan NoorzoiОценок пока нет

- Deployable Structures - Analysis and Design (C.J.gantes)Документ177 страницDeployable Structures - Analysis and Design (C.J.gantes)Jasper paxtonОценок пока нет

- Technical Proposal - Downtown Views II R.3 - SECUREDДокумент736 страницTechnical Proposal - Downtown Views II R.3 - SECUREDEr Jyotirmaya DalaiОценок пока нет

- Duqm - Quality Induction Abridged VersionДокумент21 страницаDuqm - Quality Induction Abridged VersionibrahimОценок пока нет

- ECBC As A Tool For Energy EfficiencyДокумент10 страницECBC As A Tool For Energy EfficiencyMathimuvanОценок пока нет

- Detailed Estimation of RoadДокумент476 страницDetailed Estimation of RoadJharana KcОценок пока нет

- Case Study Kraljics' MatrixДокумент2 страницыCase Study Kraljics' MatrixMEHDIОценок пока нет

- Tutorial IIДокумент2 страницыTutorial IIBro PatilОценок пока нет

- Construction Management Chapter 5Документ37 страницConstruction Management Chapter 5thapitcherОценок пока нет

- Fire Protection Full Line BRO RevDДокумент32 страницыFire Protection Full Line BRO RevDEduleofОценок пока нет

- Cobiax Abz SlimLine Z151307 11 2018 en FinalДокумент25 страницCobiax Abz SlimLine Z151307 11 2018 en Finalkhalil_82423297Оценок пока нет

- (Basics (Book 154) ) Bert Bielefeld - Basics Construction Scheduling-Birkhäuser Architecture (2013)Документ79 страниц(Basics (Book 154) ) Bert Bielefeld - Basics Construction Scheduling-Birkhäuser Architecture (2013)uci100% (1)

- Design of Column Base Plates Anchor Bolt PDFДокумент34 страницыDesign of Column Base Plates Anchor Bolt PDFAndrei Vlad SimionОценок пока нет

- BMC 4 - Expansion JointsДокумент12 страницBMC 4 - Expansion JointsKreya PatelОценок пока нет

- FW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesДокумент2 страницыFW - 12.5mm Gypsum Board: Description Technical Data Physical PropertiesRaghad GОценок пока нет

- Weld Time ChartДокумент1 страницаWeld Time ChartGeovanny SanjuanОценок пока нет

- TEN 02 Engineered Wood Products and An Introduction To Timber Structural SystemsДокумент7 страницTEN 02 Engineered Wood Products and An Introduction To Timber Structural Systemsdhanya1995Оценок пока нет