Академический Документы

Профессиональный Документы

Культура Документы

Desalination + Cooling

Загружено:

teddy_shashaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Desalination + Cooling

Загружено:

teddy_shashaАвторское право:

Доступные форматы

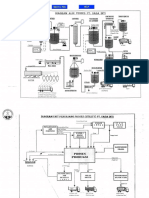

PAUL MUELLER COMPANY – ORE PROCESS ICE SLURRY SYSTEM

Fresh-Water

Supply to

R.O.

Treatment

Ice Float

ORE Separator

Tank

Condensing (IFST)

unit (CU)

Air or Water

Cooled

ICE SLURRY STORAGE

TANK

(ISST)

HX PHE Supply Chilled

Salt Water Supply Water 36˚F

Drain Line

PIPING SCHEMATIC – Desalination + Cooling (Cogen)

GENERAL SYSTEM OPERATION

1. The ORE is the orbital rod evaporator patented to produce ice slurry very efficiently.

2. The CU can be selected as water or air cooled system.

3. The salt water supply is from the sea and passes through a filtration system to remove solid particles. It

is pre-cooled using a HX (heat exchanger) by the cold draining salt water back to the sea. Charging is

controlled via a level control in the IFST.

4. During operation of the ORE system, salt-water solution is circulated to the ORE and IFST and makes

slurry down to -3 deg C.

5. The IFST is a vertical stainless tank use to separate the fresh ice from the salt solution.

6. The scrapper S on the top of the IFST is use to harvests the ice and dumps it into the ISST.

7. The Ice Slurry in the ISST will be thawed by chilled water to be used for air conditioning or cooling

process.

8. Once the Ice Slurry is thaw to about 18 deg C, it will pass through a filtration system or R.O. system to

be used for domestic purposes.

Note:

1. The salt-water solution to be drained can be used as raw material for raw salt manufacturing.

2. Hot water at about 45 deg C can be co-generated is there is a requirement.

Вам также может понравиться

- Indoor Ice-Rink Dehumidification: Application Note 13Документ4 страницыIndoor Ice-Rink Dehumidification: Application Note 13Việt Đặng XuânОценок пока нет

- Design of Sour Water Stripping System: February 2009Документ23 страницыDesign of Sour Water Stripping System: February 2009ririn dwi novitasariОценок пока нет

- DOM9Документ12 страницDOM9Rajesh TipnisОценок пока нет

- A Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForДокумент1 страницаA Look at Hot Gas Defrost: Figure 1 Is A Diagram of An Ammonia Air Unit Designed ForBen MusimaneОценок пока нет

- Jaroslav Vanek, Mark "Moth" Green Steven Vanek: Types of RefrigerationДокумент4 страницыJaroslav Vanek, Mark "Moth" Green Steven Vanek: Types of RefrigerationZerotheoryОценок пока нет

- Unesco - Eolss Sample Chapters: Freezing Desalination ProcessДокумент7 страницUnesco - Eolss Sample Chapters: Freezing Desalination ProcessShyne HikaruОценок пока нет

- Cooling Water TreatmentДокумент115 страницCooling Water TreatmentMuhammad Abdullah100% (1)

- Article 3 Brine Circulated SystemsДокумент46 страницArticle 3 Brine Circulated Systemsmdalt9180Оценок пока нет

- 5.3 Experimental MethodologyДокумент9 страниц5.3 Experimental MethodologySiva Prasad IngetiОценок пока нет

- Performance Test of A: Mini Ice PlantДокумент14 страницPerformance Test of A: Mini Ice PlantBrian TuazonОценок пока нет

- Feed Saturator PaperДокумент21 страницаFeed Saturator PaperaliОценок пока нет

- Structural Design User GuideДокумент23 страницыStructural Design User Guideloie anthony nudaloОценок пока нет

- AppBull Chlo2 08-11Документ2 страницыAppBull Chlo2 08-11Darshan PatelОценок пока нет

- Intersolar Systems Pvt. Ltd. AN ISO 9001: 2000 COДокумент27 страницIntersolar Systems Pvt. Ltd. AN ISO 9001: 2000 COlovleshrubyОценок пока нет

- Experiment 6 Ref SystemДокумент6 страницExperiment 6 Ref SystemRenroseОценок пока нет

- Design of Sour Water Stripping System: February 2009Документ23 страницыDesign of Sour Water Stripping System: February 2009kishna009100% (2)

- Ice Plant RRLДокумент17 страницIce Plant RRLJohn Paul Panganiban SaludaresОценок пока нет

- Design of Sour Water Stripping System: February 2009Документ23 страницыDesign of Sour Water Stripping System: February 2009mohsen ranjbarОценок пока нет

- Hot Gas DefrostДокумент1 страницаHot Gas Defrostarman_1287Оценок пока нет

- Jiunkpe Ns s1 2001 23496065 17005 Turbin - Sasa AppendicesДокумент87 страницJiunkpe Ns s1 2001 23496065 17005 Turbin - Sasa AppendicesLydiaОценок пока нет

- Technical Instructions: Form TI410-5 v3Документ8 страницTechnical Instructions: Form TI410-5 v3薛泽绵Оценок пока нет

- Stator Water System ChemistryДокумент33 страницыStator Water System ChemistrySudhanshu Sekhar Dash100% (1)

- Ice Making Plant Visit ReportДокумент8 страницIce Making Plant Visit ReportAnis Badshah33% (3)

- Mahatma Gandhi Chitrakoot Gramodaya Vishwavidyalaya: Topic:-Ice Manufacturing ProcessesДокумент15 страницMahatma Gandhi Chitrakoot Gramodaya Vishwavidyalaya: Topic:-Ice Manufacturing Processesanimesh100% (1)

- A Solar Ammonia Absorption IcemakerДокумент4 страницыA Solar Ammonia Absorption IcemakeraamesmОценок пока нет

- R. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZДокумент7 страницR. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZLuqmanОценок пока нет

- Ice - Plant - Test - Rig Lab ManualДокумент5 страницIce - Plant - Test - Rig Lab ManualSandeep SainiОценок пока нет

- Myat Noe KhinДокумент42 страницыMyat Noe KhinThaungShanHtet PalatarОценок пока нет

- Yu Ki Ko KoДокумент54 страницыYu Ki Ko KoThaungShanHtet PalatarОценок пока нет

- Solar Thermal EnergyДокумент22 страницыSolar Thermal EnergybhupeshpantОценок пока нет

- Identification gr-051 PDFДокумент1 страницаIdentification gr-051 PDFAvram BakalinaОценок пока нет

- Geothermal EnergyДокумент25 страницGeothermal EnergyMahefuz Khorajiya class 20-bОценок пока нет

- Storage Tanks: CommercialДокумент6 страницStorage Tanks: CommercialNZZZОценок пока нет

- PDF OnlineДокумент9 страницPDF OnlineMilan PitrodaОценок пока нет

- Alfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorДокумент4 страницыAlfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorThái HọcОценок пока нет

- Ice PlantДокумент38 страницIce Planteric labordo100% (1)

- Performance Test of A Mini Ice Plant (Lecture)Документ9 страницPerformance Test of A Mini Ice Plant (Lecture)Alfred100% (1)

- Water ChillerДокумент74 страницыWater ChillerDimitri LyssiОценок пока нет

- Laboratory IceДокумент7 страницLaboratory IceFamero Franz AikenОценок пока нет

- (2.2) D - Melting and BoillingДокумент6 страниц(2.2) D - Melting and BoillingHaniya NadeemОценок пока нет

- Waste Water Treatment System For MMSBДокумент2 страницыWaste Water Treatment System For MMSBarvin4dОценок пока нет

- HES SERIES (High Efficiency) TUBE-ICE MACHINEДокумент2 страницыHES SERIES (High Efficiency) TUBE-ICE MACHINEJosé Ernesto Sánchez VergaraОценок пока нет

- Ice Making PlantДокумент3 страницыIce Making Plantzohaib bilgrami75% (4)

- ESP Design Changes For High GLR and High Sand ProductionДокумент3 страницыESP Design Changes For High GLR and High Sand ProductionKardusОценок пока нет

- Ational Petroleum Conference - Calgary, Alberta (2005-06-07) ) Canadian InternationaДокумент13 страницAtional Petroleum Conference - Calgary, Alberta (2005-06-07) ) Canadian InternationaLuqmanОценок пока нет

- Yu Ki Myat NoeДокумент26 страницYu Ki Myat NoeThaungShanHtet PalatarОценок пока нет

- St-Evaporation 20130628 114721Документ1 страницаSt-Evaporation 20130628 114721teddy_shashaОценок пока нет

- Cross Sectional Elevation ViewДокумент2 страницыCross Sectional Elevation Viewteddy_shashaОценок пока нет

- St-Condensation 20130628 115549Документ1 страницаSt-Condensation 20130628 115549teddy_shashaОценок пока нет

- 0302 Brass Fittings CatalogДокумент69 страниц0302 Brass Fittings Catalogteddy_shashaОценок пока нет

- Erosion Under Drainage CanalДокумент6 страницErosion Under Drainage Canalteddy_shashaОценок пока нет

- Polituku DynastiesДокумент10 страницPolituku Dynastiesteddy_shashaОценок пока нет

- Polituku DynastiesДокумент10 страницPolituku Dynastiesteddy_shashaОценок пока нет

- BPH Zinc GreenTea Papaya LeafДокумент13 страницBPH Zinc GreenTea Papaya Leafteddy_shashaОценок пока нет

- Air Duct Sizer TableДокумент2 страницыAir Duct Sizer Tableteddy_shashaОценок пока нет

- Aqua Turbo IceSlurry GenДокумент6 страницAqua Turbo IceSlurry Genteddy_shashaОценок пока нет

- Dehumidifier ACMVДокумент2 страницыDehumidifier ACMVteddy_shashaОценок пока нет

- Screw Service ManualДокумент71 страницаScrew Service Manualteddy_shasha89% (18)

- Ice Generator ManualДокумент70 страницIce Generator Manualteddy_shashaОценок пока нет

- BOMA - Office Building Standard Methods of Measurement AppendixДокумент41 страницаBOMA - Office Building Standard Methods of Measurement Appendixxavest100% (7)

- Understanding PumpДокумент113 страницUnderstanding Pumpnyr1981_942955963100% (5)

- T HR El 20003 ST PDFДокумент20 страницT HR El 20003 ST PDFAngling Dharma100% (1)

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Документ28 страниц2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteОценок пока нет

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Документ296 страницBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatОценок пока нет

- Liquid Process Piping - Part 1 General Piping Design PDFДокумент33 страницыLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaОценок пока нет

- Final ExamДокумент2 страницыFinal ExamblacmsОценок пока нет

- 1939 - Hammer - Terrain Corrections For Gravimeter StationsДокумент11 страниц1939 - Hammer - Terrain Corrections For Gravimeter Stationslinapgeo09100% (1)

- Śāntarak ItaДокумент8 страницŚāntarak ItaÁtilaОценок пока нет

- Service Marketing - Term End Examination 2021 School of Business Management Narsee Monjee Institute of Management Studies, HyderabadДокумент2 страницыService Marketing - Term End Examination 2021 School of Business Management Narsee Monjee Institute of Management Studies, Hyderabadnatasha bennyОценок пока нет

- High School Physics Rutherford Atom Lesson 27Документ4 страницыHigh School Physics Rutherford Atom Lesson 27John JohnsonОценок пока нет

- Menu Planning in HospitalДокумент4 страницыMenu Planning in HospitalERva Soelkarnaen100% (1)

- Bluesil Ep 150 A3: Insulator Grade Silicone RubberДокумент2 страницыBluesil Ep 150 A3: Insulator Grade Silicone RubberNagendra KumarОценок пока нет

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Документ1 страницаHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesОценок пока нет

- Packing List For GermanyДокумент2 страницыPacking List For GermanyarjungangadharОценок пока нет

- To Tell The TruthДокумент5 страницTo Tell The TruthNabeel Ahmed KhanОценок пока нет

- Compal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentДокумент56 страницCompal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentSuhpreetОценок пока нет

- Cause List 2.1.2023Документ4 страницыCause List 2.1.2023あいうえおかきくけこОценок пока нет

- Ashfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)Документ36 страницAshfaque Ahmed-The SAP Materials Management Handbook-Auerbach Publications, CRC Press (2014)surajnayak77Оценок пока нет

- Data Abstraction and Problem Solving With C Walls and Mirrors 6th Edition Carrano Solutions ManualДокумент36 страницData Abstraction and Problem Solving With C Walls and Mirrors 6th Edition Carrano Solutions Manualallocaturnonylgvtt100% (12)

- Fluid Mechanics HydraulicsДокумент420 страницFluid Mechanics Hydraulicsanonymousdi3noОценок пока нет

- Grade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideДокумент4 страницыGrade 7 Math Lesson 22: Addition and Subtraction of Polynomials Learning GuideKez MaxОценок пока нет

- The Senior High School in The Phillipines: The Way To The WorldДокумент5 страницThe Senior High School in The Phillipines: The Way To The WorldRodel Ramos DaquioagОценок пока нет

- (Official) AVTC5 - Unit 1 - Before ClassДокумент11 страниц(Official) AVTC5 - Unit 1 - Before ClassNhân NguyễnОценок пока нет

- Spies May Be Gathering Encrypted Data To Crack With Future Quantum ComputerДокумент1 страницаSpies May Be Gathering Encrypted Data To Crack With Future Quantum ComputerHÀ ĐỖ VIẾTОценок пока нет

- Lay Planning TypesДокумент1 страницаLay Planning TypesGaurav Shakya100% (1)

- Refrigerant Unit Lab ReportДокумент19 страницRefrigerant Unit Lab Reportakmal100% (2)

- Earthing SystemsДокумент6 страницEarthing SystemsRob PettitОценок пока нет

- Livro Spectrochemical AnalysisДокумент9 страницLivro Spectrochemical AnalysisRicardo PossebonОценок пока нет

- Cover PageДокумент10 страницCover PageAvijit GhoshОценок пока нет