Академический Документы

Профессиональный Документы

Культура Документы

Glass Moulding

Загружено:

Udiptya DasИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Glass Moulding

Загружено:

Udiptya DasАвторское право:

Доступные форматы

Raytek Application Note 25

Glass Mold Temperature

Production of Bottles and Glass Containers

How can you control the glass mold temperature

Q

Question

for the production of bottles and glass containers?

Situation Analysis

A

Answer

From the furnace, the molten glass flows into one or more forehearths and is cut by

a shearing blade to form a cylinder of glass called a gob. The gob is dropped into

molds where initial forming is done. The glass first is blown or pressed from below

into the blank molds to create a pre-container. The pre-container is then flipped over

into a final mold, where the final container shaping is done.

• Glass mold temperatures: 400 to 500°C (752 to 932°F)

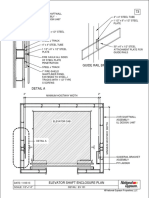

From Furnace Forehearth

Gob

Fiber-Optic Molds

Pyrometer

FA1

Monitoring of the Glass Mold Temperature

Solution and Improvements

A

Answer

Raytek Marathon series FA1 fiber-optic

pyrometer is the perfect match for

temperature measurement at the container

glass molds.

The FA1 fiber-optic pyrometer with its small

optical head and flexible cable is the best choice

for hard-to-reach locations and can be used

without cooling in an ambient environment up to

Fiber-Optic Pyrometer FA1

315°C (600°F).

With the high temperature head and cable, the

electronics enclosure can be mounted away

from the radiated heat in a safe location.

Raytek DataTemp® MultiDrop software is a

great way to capture and record temperature

data for the purpose of mold temperature

control.

Raytek Product Accessories

■ FA1 Fiber-Optic Pyrometer ■ Air Purge

■ Optional: Cooling Platform for

Electronics Housing

■ DataTemp MultiDrop Software

Benefits

■ Viscosity-Control

■ Avoids Glass Breakage

■ High Production Quality

For customized solutions to your process, please contact:

______________________________________________

www.raytek.com

© Raytek 03/2009 Rev. B

Raytek, DataTemp and the Raytek logo are registered

trademarks.

Specifications subject to change without notice.

Вам также может понравиться

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Thermo Scientific Cryogenic Storage BrochureДокумент36 страницThermo Scientific Cryogenic Storage BrochureMarita LouisОценок пока нет

- PF Sensor Selection GuideДокумент19 страницPF Sensor Selection GuideLam quocОценок пока нет

- Marathon MM, MR, FA, FRДокумент4 страницыMarathon MM, MR, FA, FRpenityОценок пока нет

- PEEK - SummaryДокумент3 страницыPEEK - SummaryGregorio PisaneschiОценок пока нет

- Object Detection Food Extreme Temp PhotosДокумент1 страницаObject Detection Food Extreme Temp PhotosBalluff SensorsОценок пока нет

- Cryopreservación AccesoriosДокумент48 страницCryopreservación AccesoriosJimmy Cuevas MonsalveОценок пока нет

- 189 Prod SelectionДокумент1 страница189 Prod Selectionherysyam1980Оценок пока нет

- AMYE Heat Stake Technical Document 03-2016 PDFДокумент10 страницAMYE Heat Stake Technical Document 03-2016 PDFraj_375637980Оценок пока нет

- Cryo Equip Bro - 12-5-17Документ48 страницCryo Equip Bro - 12-5-17John KatabasasaОценок пока нет

- Temperature Sensing Instrumentation For Glass ManufacturingДокумент2 страницыTemperature Sensing Instrumentation For Glass ManufacturingaslamОценок пока нет

- Signet 275X, 276X, 277X Series DryLoc PH and ORP Electrodes (English)Документ8 страницSignet 275X, 276X, 277X Series DryLoc PH and ORP Electrodes (English)129935Оценок пока нет

- Manual: Installation Maintenance Architechural GuideДокумент19 страницManual: Installation Maintenance Architechural GuidenaheedahmedОценок пока нет

- Foamglas Application GuidelinesДокумент36 страницFoamglas Application GuidelinesArgiliathОценок пока нет

- Product Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerДокумент8 страницProduct Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerGỗ MộcОценок пока нет

- PhoenixTM Brochure HTS06 V11 English Email PDFДокумент4 страницыPhoenixTM Brochure HTS06 V11 English Email PDFUtku InanОценок пока нет

- Fiber Optic Hot Spot Temperature Monitoring - Qualitrol CorpДокумент3 страницыFiber Optic Hot Spot Temperature Monitoring - Qualitrol CorpAV REDDYОценок пока нет

- Climaveneta FOCS-N 2022-4822 PDFДокумент42 страницыClimaveneta FOCS-N 2022-4822 PDFCris YañezОценок пока нет

- Fluke Process Thermalert BrochureДокумент4 страницыFluke Process Thermalert BrochureAlireza KhodabandehОценок пока нет

- EasyMax Basic A4Документ2 страницыEasyMax Basic A4Anonymous cgKtuWzОценок пока нет

- EasyMax102 Advanced DS EN 2022Документ2 страницыEasyMax102 Advanced DS EN 2022Leandro colussiОценок пока нет

- Focs2 WДокумент76 страницFocs2 WTECNO AYUDAОценок пока нет

- Sample Preparation - Instructions Use - Smart BlocksДокумент12 страницSample Preparation - Instructions Use - Smart BlocksMea ChristopherОценок пока нет

- 370HR DatasheetДокумент3 страницы370HR DatasheetasdОценок пока нет

- S 21 eДокумент19 страницS 21 eMostafa MohamedОценок пока нет

- Sprinkler 5.6 UprightДокумент5 страницSprinkler 5.6 UprightAli OsmanОценок пока нет

- 720 Pipette Puller ManualДокумент22 страницы720 Pipette Puller ManualPaulo CamargoОценок пока нет

- Ispeed DatasheetДокумент3 страницыIspeed DatasheetasdОценок пока нет

- Wearehouse BroucherДокумент2 страницыWearehouse BroucherSarah FrazierОценок пока нет

- CHEP Datasheet ENДокумент6 страницCHEP Datasheet ENpaduraru_dОценок пока нет

- De Icing SystemДокумент2 страницыDe Icing SystemTateszОценок пока нет

- ND Datasheet C Base v2Документ4 страницыND Datasheet C Base v2Usep LoadОценок пока нет

- TDS LF-360Документ2 страницыTDS LF-360Ofer ShochetОценок пока нет

- Helter: Analyser Shelter PanelДокумент2 страницыHelter: Analyser Shelter PanelpguptaitrОценок пока нет

- Air Cooled Prasad Chiller SpecificationsДокумент6 страницAir Cooled Prasad Chiller Specificationsanusha darvemulaОценок пока нет

- Coolant F TechДокумент1 страницаCoolant F TechDonny Wierya pratamaОценок пока нет

- Technical Data: 1. DescriptionДокумент12 страницTechnical Data: 1. Descriptionwika mepОценок пока нет

- Material Product Data Sheet Zirconia - Polymer Ceramic Abradable PowdersДокумент4 страницыMaterial Product Data Sheet Zirconia - Polymer Ceramic Abradable PowderskerbaubiruОценок пока нет

- Sil Pad Selection GuideДокумент103 страницыSil Pad Selection GuideTheBergquistCompanyОценок пока нет

- Technical Data: Microfast HP Fixed Temperature Release Vk800Документ12 страницTechnical Data: Microfast HP Fixed Temperature Release Vk800fazil yoosufОценок пока нет

- TDS PEEK Filament PDFДокумент2 страницыTDS PEEK Filament PDFRui MatiasОценок пока нет

- TDS PEEK Filament 1Документ2 страницыTDS PEEK Filament 1Krzysztof KardachОценок пока нет

- General Catalogue GFL - EДокумент88 страницGeneral Catalogue GFL - EMadalina CОценок пока нет

- FR408 DatasheetДокумент3 страницыFR408 DatasheetasdОценок пока нет

- TDS LF-371 - Dec22Документ2 страницыTDS LF-371 - Dec22ofershochetОценок пока нет

- Automotive Product Guide V1R1Документ2 страницыAutomotive Product Guide V1R1salvatore702Оценок пока нет

- Article 7-1-2006 RobinsonДокумент18 страницArticle 7-1-2006 RobinsonAnonymous Wu6FDjbОценок пока нет

- TDS LF-350Документ1 страницаTDS LF-350Ofer ShochetОценок пока нет

- Real Time Direct Winding Optical Temperature Monitoring SystemДокумент4 страницыReal Time Direct Winding Optical Temperature Monitoring SystemDelvani Da SilvaОценок пока нет

- Climate Solutions HandbookДокумент44 страницыClimate Solutions HandbookMARIVEL BASAОценок пока нет

- VK102 K5.6 12987 PendentДокумент7 страницVK102 K5.6 12987 PendentPhung BaoОценок пока нет

- Phenix: Low Temperature Cryostat For Powder DiffractionДокумент4 страницыPhenix: Low Temperature Cryostat For Powder DiffractionNikhat JahanОценок пока нет

- TDS LF-371Документ1 страницаTDS LF-371Ofer ShochetОценок пока нет

- Pyrolizer FrontierДокумент68 страницPyrolizer FrontierLuis Ernesto RОценок пока нет

- Loctite TCF 4000 PXF en GLДокумент2 страницыLoctite TCF 4000 PXF en GLxingdrewОценок пока нет

- Slant FinДокумент72 страницыSlant FintooocooolОценок пока нет

- 370 HRДокумент3 страницы370 HRMritunjay SrivastavaОценок пока нет

- Electrical Resin 260: ScotchcastДокумент2 страницыElectrical Resin 260: Scotchcastreddy venkata krishnaОценок пока нет

- Testo 885 Series Thermal Imagers: Sensitivity, Resolution and PerformanceДокумент2 страницыTesto 885 Series Thermal Imagers: Sensitivity, Resolution and PerformancedmsampaОценок пока нет

- Segmentation of Qarshi Industries Private Limited PakistanДокумент6 страницSegmentation of Qarshi Industries Private Limited PakistanReader100% (1)

- Authenticating Digital EvidenceДокумент36 страницAuthenticating Digital Evidenceatty_gie3743Оценок пока нет

- Karamadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestДокумент6 страницKaramadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestQ8123Оценок пока нет

- E10.unit 3 - Getting StartedДокумент2 страницыE10.unit 3 - Getting Started27. Nguyễn Phương LinhОценок пока нет

- Takeover Strategies and DefencesДокумент20 страницTakeover Strategies and DefencesJithu JoseОценок пока нет

- Consumer PresentationДокумент30 страницConsumer PresentationShafiqur Rahman KhanОценок пока нет

- Vedic Town Planning ConceptsДокумент17 страницVedic Town Planning ConceptsyaminiОценок пока нет

- Guide Rail Bracket AssemblyДокумент1 страницаGuide Rail Bracket AssemblyPrasanth VarrierОценок пока нет

- Denso - History PDFДокумент5 страницDenso - History PDFVenkateswaran KrishnamurthyОценок пока нет

- Urban LifestyleДокумент27 страницUrban LifestyleNindy AslindaОценок пока нет

- Sample Database of SQL in Mysql FormatДокумент7 страницSample Database of SQL in Mysql FormatsakonokeОценок пока нет

- Dimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringДокумент22 страницыDimitris Achlioptas Ucsc Bsoe Baskin School of EngineeringUCSC Students100% (1)

- Merchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersДокумент43 страницыMerchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersRohit Kumar Baghel100% (1)

- 11 Stem P - Group 2 - CPT First GradingДокумент7 страниц11 Stem P - Group 2 - CPT First GradingZwen Zyronne Norico LumiwesОценок пока нет

- Data Base Format For Company DetailsДокумент12 страницData Base Format For Company DetailsDexterJacksonОценок пока нет

- Mineral Claim Purchase and Sale Agreement FinalДокумент5 страницMineral Claim Purchase and Sale Agreement Finaldaks4uОценок пока нет

- UTM Firewalls: AR3050S and AR4050SДокумент8 страницUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranОценок пока нет

- BERKLYNInformation SheetДокумент6 страницBERKLYNInformation SheetvillatoreubenОценок пока нет

- Topic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)Документ8 страницTopic 3 Module 2 Simple Annuity (Savings Annuity and Payout Annuity)millerОценок пока нет

- Strategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniДокумент24 страницыStrategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniHilmyTafantoОценок пока нет

- Lite Indicator Admin ManualДокумент16 страницLite Indicator Admin Manualprabakar070Оценок пока нет

- Hung201 PDFДокумент14 страницHung201 PDFMua Dong Tuyet RoiОценок пока нет

- Repro Indo China Conf PDFДокумент16 страницRepro Indo China Conf PDFPavit KaurОценок пока нет

- Trandsend 2Документ3 страницыTrandsend 2dadiОценок пока нет

- Opening The Third EyeДокумент13 страницOpening The Third EyekakamacgregorОценок пока нет

- Problem Solving Questions: Solutions (Including Comments)Документ25 страницProblem Solving Questions: Solutions (Including Comments)Narendrn KanaesonОценок пока нет

- Tutorial 4 QuestionsДокумент3 страницыTutorial 4 QuestionshrfjbjrfrfОценок пока нет

- Hormone Replacement Therapy Real Concerns and FalsДокумент13 страницHormone Replacement Therapy Real Concerns and FalsDxng 1Оценок пока нет

- Granulometry of ClinkerДокумент18 страницGranulometry of ClinkerNael100% (12)

- Analysis of Mozarts k.475Документ2 страницыAnalysis of Mozarts k.475ASPASIA FRAGKOUОценок пока нет