Академический Документы

Профессиональный Документы

Культура Документы

Cumilag

Загружено:

Ashwini JainОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cumilag

Загружено:

Ashwini JainАвторское право:

Доступные форматы

Insulation Refractories

CUMILAG

USER INDUSTRIES APPLICATION

l Ceramic, Metallurgical, Carbon High temperature kiln hot face / backup lining

black and sponge iron industries

l Ceramic, Metallurgical industries Laboratory kiln hot face lining

l Fertiliser Primary reformer and hydrogen transfer lines

l Steel Blast furnace stoves

l Fertiliser and Power generation High temperature air pre-heaters and

secondary reformer cold face

l Electroceramic Industry Pusher type furnace lining

PROPERTIES UNIT CUMILAG 23 CUMILAG 26 CUMILAG 28 CUMILAG 29 CUMILAG 30 CUMILAG 32 CUMILAG B 201 CUMILAG B 101

o

Maximum Hot Face Temperature C 1260 1400 1540 1550 1650 1750 1800 1850

Bulk Density gm/cc 0.55 0.86 0.88 1.05 1.12 1.28 1.40 1.45

Cold Crushing Strength Kg/cm2 12 18 21 40 50 50 130 75

Reheat Change (For 24 hrs.) % - 0.7at1250oC - 0.2 at 1350oC - 0.2 at 1510oC - 0.4 at 1450oC - 0.6 at 1620oC - 0.3 at 1650oC + 0.15 at 1650oC - 0.2 at 1650oC

Thermal Conductivity

At 400oC Hot Face Temp. 0.14 0.17 0.28 0.31 0.60 0.59 1.37 1.48

At 600oC Hot Face Temp. W/moK 0.17 0.23 0.30 0.33 0.60 0.59 1.38 1.43

At 800oC Hot Face Temp. 0.24 0.31 0.32 0.37 0.55 0.47 1.32 1.12

At 1000oC Hot Face Temp. 0.26 0.35 0.36 0.42 0.60 0.55 1.17 1.11

At 1200oC Hot Face Temp. 0.30 0.38 0.39 0.46 0.60 0.58 1.14 1.05

Chemical Analysis

Al2O3 37.20 57.34 67.21 57.51 73.60 74.16 91.06 98.50

SiO2 % 45.1 39.15 31.35 38.42 25.45 23.21 8.29 0.70

Fe2O3 0.80 0.80 0.62 0.72 0.54 0.36 0.14 0.12

Recommended Laying Mortars CUMIBOND CUMIBOND CUMIBOND CUMIBOND CUMIBOND CUMIBOND CUMIBOND LA 282/ CUMIBOND

LK FX LK FX LK 65 LK FX LM 36 LM 36 CUMIBOND LA 102 LA 102

Note : The above typical values shown are based on average test result on standard samples. Properties are subjected to reasonable variation based on product shape etc. and hence should be considered for general guidence only.

CUMILAG insulation refractories are manufactured from pure and synthetic raw materials ensuing consistently high quality. They are intended for

applications demanding unique combination of chemical, mechanical stability and insulating properties. They are suitable for applications at service

temperatures ranging from 1250 oC to 1850 oC. Most of the clay-based conventional refractories are not recommended for temperature beyond

1550 o C. The bubble alumina range of insulating refractories is light weight, has good load bearing capacity, and low heat capacity. They can be

directly exposed to flame, and combustion products.

OUTSTANDING FEATURES

lVery high refractoriness l Low shrinkage and creep l High structural strength l High resistance to reducing atmosphere

lLow thermal conductivity l Uniform pore size and distribution

CUMILAG 23, 26, 28, 29 : Calcined clay and high alumina based inulating refractory.

CUMILAG 30, 32 : Electro-fused mullite based insulating refractory with a secondary mullite bond.

CUMILAG B201 : Electro-fused high-alumina bubbles with a secondary mullite bond.

CUMILAG B101 : Electro-fused high-alumina bubbles with a glass free alumina bond.

Feasibility of special shapes require case-by-case study by CUMI manufacturing and Technical team. We would request all our

customers to kindly ask CUMI Sales Representatives for detail Product Data, Quality Assurance Plans etc. as and when applicable.

CARBORUNDUM UNIVERSAL LIMITED

CERAMICS DIVISION

September - 2007

l Works: l Works: l Regd Office:

Plot No. 102 & 103, Sipcot Industrial Complex, Plot No. 35,36 48-51, Adhartal Industrial Estate, “Parry House”, 6th Floor, 43, Moore Street,

Phase II, Ranipet 632 403, TN, India. Jabalpur 482 004, MP, India. Chennai 600 001, TN, India

ISO 9001 : 2000

Certificate:44 100 970103-E3 Tel.: 04172 244582, 244197 Fax: 04172 244982. Tel.: 0761 2680398, 2680759, 2680725 Tel.: 044 42216789, Fax : 044 2535176

U NORD e-mail: cumicsranipet@cumi.murugappa.com Fax: 0761 2680678. www.cumi.murugappa.com

Вам также может понравиться

- MURUGAPPA GROUP 100 years US $3 billion 29 companies +30,000 peopleДокумент6 страницMURUGAPPA GROUP 100 years US $3 billion 29 companies +30,000 peopleKARTHIGEYAN.RОценок пока нет

- Introduction To Fused Cast RefractoryДокумент7 страницIntroduction To Fused Cast RefractorypetemberОценок пока нет

- N.R. Engineering: Chemical AnalysisДокумент4 страницыN.R. Engineering: Chemical Analysisrajesh reddyОценок пока нет

- Stainless Steel Data PDFДокумент4 страницыStainless Steel Data PDFRobert SumińskiОценок пока нет

- Avesta Broschyr 4-Sid LowresДокумент4 страницыAvesta Broschyr 4-Sid LowresKamal ShahОценок пока нет

- PROTECTIVE COATING FOR CONCRETE & STEELДокумент2 страницыPROTECTIVE COATING FOR CONCRETE & STEELkhrisna.dipa.utamaОценок пока нет

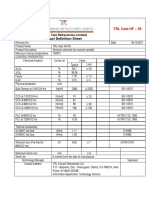

- Data Sheet TRL Cast HF-50Документ1 страницаData Sheet TRL Cast HF-50TEODOROОценок пока нет

- DR Fixit Pidipoxy MI EP Jan 2020Документ3 страницыDR Fixit Pidipoxy MI EP Jan 2020rakeshОценок пока нет

- Report CUMI - Correct.Документ28 страницReport CUMI - Correct.Dinesh guhan50% (2)

- ListofApprovedVendors03.01.2022Документ68 страницListofApprovedVendors03.01.2022Shivansh KushwahОценок пока нет

- MPCB NonFerrousREPROCESSORSДокумент6 страницMPCB NonFerrousREPROCESSORSpatilgargiОценок пока нет

- 8376 Electronic Component CleanerДокумент3 страницы8376 Electronic Component CleanerPrakash Kumar100% (1)

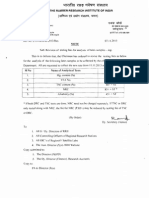

- Rubber Research Institute Testing FeeДокумент15 страницRubber Research Institute Testing FeemoumonaОценок пока нет

- Sterling Agro PresentationДокумент25 страницSterling Agro PresentationViteysatya SengОценок пока нет

- Fly Ash BrickДокумент8 страницFly Ash BrickYashraj PatidarОценок пока нет

- Ahmedabad Cluster: FoundryДокумент24 страницыAhmedabad Cluster: FoundrySonal PatelОценок пока нет

- List of Captive Generation Plants in Tamil NaduДокумент1 страницаList of Captive Generation Plants in Tamil NaduMadhavan RamОценок пока нет

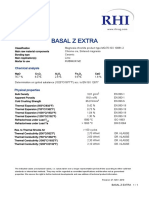

- Basal Z Extra: Chemical AnalysisДокумент1 страницаBasal Z Extra: Chemical Analysismahreza189Оценок пока нет

- Specification HGRM-30 GRADEДокумент1 страницаSpecification HGRM-30 GRADESanjayОценок пока нет

- PDS Insulyte 11Документ1 страницаPDS Insulyte 11Mohammed AhteshamОценок пока нет

- Accgun Ins 11Документ1 страницаAccgun Ins 11pulakjaiswal85Оценок пока нет

- Regional HSE Manager - Pune - FOSECO India Limited - 8 To 13 Years of ExperienceДокумент3 страницыRegional HSE Manager - Pune - FOSECO India Limited - 8 To 13 Years of ExperienceMuruganОценок пока нет

- Zinc Coatings PDFДокумент12 страницZinc Coatings PDFMuhammadImaduddienSalamОценок пока нет

- SUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFДокумент1 страницаSUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFgiuseppe.timpone1Оценок пока нет

- Test Ce Tificate: C EMI AL OM OS On PercentДокумент2 страницыTest Ce Tificate: C EMI AL OM OS On PercentPravin HonmuteОценок пока нет

- 01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)Документ268 страниц01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)ManojОценок пока нет

- NameДокумент18 страницNameDharamОценок пока нет

- 20-2572-MTC - 2 PDFДокумент1 страница20-2572-MTC - 2 PDFQualityОценок пока нет

- Presentatie John Van Der Zeeuw, AtotechДокумент24 страницыPresentatie John Van Der Zeeuw, AtotechDinh TuОценок пока нет

- Forging Process, Types, Equipment & Heat TreatmentsДокумент12 страницForging Process, Types, Equipment & Heat TreatmentsDheeraj KashyapОценок пока нет

- Christian Pfeiffer Foreign Matter TrapДокумент1 страницаChristian Pfeiffer Foreign Matter TrapMohamedОценок пока нет

- Dokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerДокумент8 страницDokumen - Tips - Castables and Refractories For Cement Dri Sponge Iron Kiln CoolerjulianoducaОценок пока нет

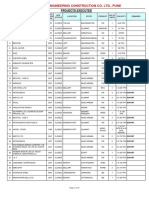

- TECC List of Projects CompletedДокумент15 страницTECC List of Projects Completedpatitay036817Оценок пока нет

- Belzona - Cold Curing WrapsДокумент4 страницыBelzona - Cold Curing WrapsNay ThihaОценок пока нет

- 4620D Test Report (For Thickness AA15)Документ2 страницы4620D Test Report (For Thickness AA15)weiiiiiОценок пока нет

- Dioxido de Titanio R-2196+ - TDSДокумент1 страницаDioxido de Titanio R-2196+ - TDSBenito JuárezОценок пока нет

- Hitachi's Moving Electrode ESP and FGD SystemsДокумент9 страницHitachi's Moving Electrode ESP and FGD SystemsSudi ArtoОценок пока нет

- Hi-Tea Menu PackageДокумент32 страницыHi-Tea Menu PackageRupesh GuravОценок пока нет

- Icf VD 2017-18 PDFДокумент102 страницыIcf VD 2017-18 PDFsonipuruОценок пока нет

- Glass 4 - 5 11 - 2015Документ70 страницGlass 4 - 5 11 - 2015Laxman KumarОценок пока нет

- Phasing Plan for FGD Implementation in Bihar, Jharkhand, Odisha and West BengalДокумент16 страницPhasing Plan for FGD Implementation in Bihar, Jharkhand, Odisha and West BengalVibhas KumarОценок пока нет

- Corrosion in Cement Plants Caused by Acid GasesДокумент5 страницCorrosion in Cement Plants Caused by Acid GasesAnonymous NxpnI6jCОценок пока нет

- Fused and Sintered AluminaДокумент7 страницFused and Sintered AluminaSaragadam DilsriОценок пока нет

- Inconel 601 Alloy 601 Uns n06601 Din 2.4851Документ3 страницыInconel 601 Alloy 601 Uns n06601 Din 2.4851SamkitОценок пока нет

- Hastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600Документ3 страницыHastelloy B3 / Alloy B3 / UNS N10675 / DIN 2.4600SamkitОценок пока нет

- TSL Bhushan - Colour CoatedДокумент21 страницаTSL Bhushan - Colour Coatedabdul jawad100% (1)

- Hot Dip Galvanizing Process ExplainedДокумент13 страницHot Dip Galvanizing Process ExplainedaselabollegalaОценок пока нет

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Документ1 страницаRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityОценок пока нет

- Stainless Steel Grade Composition ChartДокумент8 страницStainless Steel Grade Composition ChartZaveri SagarОценок пока нет

- En 8Документ3 страницыEn 8ajaykrishnaaОценок пока нет

- Anantapur Industry ListДокумент4 страницыAnantapur Industry ListM.Venkata Siva ReddyОценок пока нет

- 2017 GST - Sant Retail Price List Dated 27.07.17 PDFДокумент60 страниц2017 GST - Sant Retail Price List Dated 27.07.17 PDFkoto group100% (1)

- Mill TC en 19 6.00MMДокумент1 страницаMill TC en 19 6.00MMKamal BhandariОценок пока нет

- Hazardous Waste Recyclers ListДокумент16 страницHazardous Waste Recyclers ListUnitedWork ServiceОценок пока нет

- 718 Stangard Egf (NV)Документ5 страниц718 Stangard Egf (NV)Sandeep gangulyОценок пока нет

- Companywise Plant ListДокумент9 страницCompanywise Plant ListSabyasachi BangalОценок пока нет

- Refractory in IndiaДокумент5 страницRefractory in IndiaEM EZОценок пока нет

- Application of DCS in Cement Manufacturing ProcessДокумент48 страницApplication of DCS in Cement Manufacturing ProcessShashwat OmarОценок пока нет

- Ceramic Fiber Blanket Insulation Properties and ApplicationsДокумент1 страницаCeramic Fiber Blanket Insulation Properties and ApplicationsfrankieОценок пока нет

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryОт EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryОценок пока нет

- Unit 4 Multiple Linear RegressionДокумент3 страницыUnit 4 Multiple Linear RegressionManchilot TilahunОценок пока нет

- Extrusion Course MaterialДокумент43 страницыExtrusion Course MaterialIncharge Training and Placement CellОценок пока нет

- Noise, Nonlinear Distortion and System ParametersДокумент200 страницNoise, Nonlinear Distortion and System ParametersKhang Nguyen0% (1)

- S50MC-C8 - 2 Man B&WДокумент381 страницаS50MC-C8 - 2 Man B&WhaizriОценок пока нет

- Cryptography Using Chaotic Neural Network Based On Image ProcessingДокумент6 страницCryptography Using Chaotic Neural Network Based On Image Processingwaqas tahirОценок пока нет

- GE8152 EG Model - II MCQ (Part-A) - Print - QuizizzДокумент6 страницGE8152 EG Model - II MCQ (Part-A) - Print - QuizizzsivashanmugamОценок пока нет

- Civil Engineering 7000 MCQs - Civil Engineering QuizДокумент26 страницCivil Engineering 7000 MCQs - Civil Engineering QuizvishalОценок пока нет

- Ggeo 5 ManualДокумент524 страницыGgeo 5 ManualIancu-Bogdan TeodoruОценок пока нет

- CShearers-Geometry ProblemsДокумент13 страницCShearers-Geometry ProblemsSreenath CharyОценок пока нет

- 19-02 RIP The Routing Information ProtocolДокумент12 страниц19-02 RIP The Routing Information Protocolrichard akpagniОценок пока нет

- Methods of Separating & Purifying Substances 1 QPДокумент11 страницMethods of Separating & Purifying Substances 1 QPShahzaib AhmadОценок пока нет

- The Plant and Animal CellsДокумент2 страницыThe Plant and Animal CellsLeny MacraОценок пока нет

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsДокумент44 страницыOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Оценок пока нет

- SQL Injection: Understanding and Mitigation TechniquesДокумент37 страницSQL Injection: Understanding and Mitigation TechniquesShimelis AberaОценок пока нет

- Bomin Paek and Alan Morse, Minjung Kim, & Hoyoon Jung, 2020. Sport Consumer Flow and Shopping Well-Being in Online ShoppingДокумент16 страницBomin Paek and Alan Morse, Minjung Kim, & Hoyoon Jung, 2020. Sport Consumer Flow and Shopping Well-Being in Online ShoppingRen SuzakuОценок пока нет

- Fourth Quarter Long Test in Math 9 DIRECTIONS: Choose The Letter of The Correct Answer and Write It On Your Answer SheetДокумент2 страницыFourth Quarter Long Test in Math 9 DIRECTIONS: Choose The Letter of The Correct Answer and Write It On Your Answer SheetAnonymous L4KwQcDq100% (22)

- Implementing The I C Bus: New Instructions For MCS-51 BASICДокумент2 страницыImplementing The I C Bus: New Instructions For MCS-51 BASICRadunОценок пока нет

- 145 - Cafco MANDOLITE CP2 - Cellular BeamsДокумент0 страниц145 - Cafco MANDOLITE CP2 - Cellular Beamswidayat81Оценок пока нет

- Measure Front & Back Pants PatternДокумент8 страницMeasure Front & Back Pants PatternAlicia MyersОценок пока нет

- Vendors ListДокумент59 страницVendors ListGoliBharggav100% (1)

- Department of Education: Weekly Home Learning PlanДокумент56 страницDepartment of Education: Weekly Home Learning PlanJaneth Miguel SatrainОценок пока нет

- Finding the Force and Center of Pressure on a Submerged Plane SurfaceДокумент12 страницFinding the Force and Center of Pressure on a Submerged Plane SurfaceSudheer Kumar JnvОценок пока нет

- Diagrama Elétrico F-250Документ153 страницыDiagrama Elétrico F-250Bruno Ayres de AbreuОценок пока нет

- Java EE Enterprise Application DevelopmentДокумент17 страницJava EE Enterprise Application DevelopmentQaisar ShehzadОценок пока нет

- The Trouble With Physics Smolin PDFДокумент24 страницыThe Trouble With Physics Smolin PDFshubhram2014Оценок пока нет

- Giovanni Boccaccio Boccaccio, Giovanni 1313-75, Italian Poet and Storyteller, Author of The DecameronДокумент3 страницыGiovanni Boccaccio Boccaccio, Giovanni 1313-75, Italian Poet and Storyteller, Author of The Decameronmay ann dimaanoОценок пока нет

- Chapter 1 MATLAB Basics 2015 An Introduction To MATLAB Programming and Numerical Methods For EngineersДокумент13 страницChapter 1 MATLAB Basics 2015 An Introduction To MATLAB Programming and Numerical Methods For EngineersSneeakyAsianОценок пока нет

- GDM Ch-17 Abuts Ret WallsДокумент136 страницGDM Ch-17 Abuts Ret WallsNguyen Ngoc DuyenОценок пока нет

- Muh Eng 50hzДокумент8 страницMuh Eng 50hzaleks canjugaОценок пока нет

- 01-03 GPON Basic ConceptsДокумент5 страниц01-03 GPON Basic ConceptsFabioAlmeidaОценок пока нет